Illumination aging-resistant ABS plastic and preparation method thereof

A technology of ABS plastic and light resistance, which is applied in the field of light aging resistant ABS plastic and its preparation, can solve the problem of excessive raw materials, etc., and achieve the effects of low product cost, excellent comprehensive performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

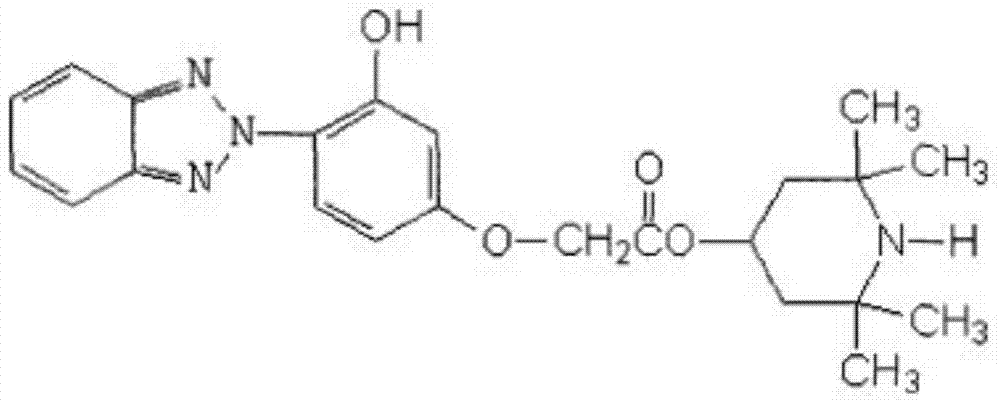

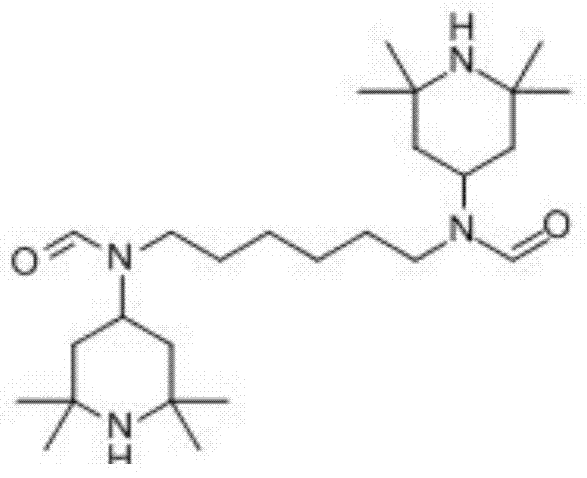

Image

Examples

Embodiment 1

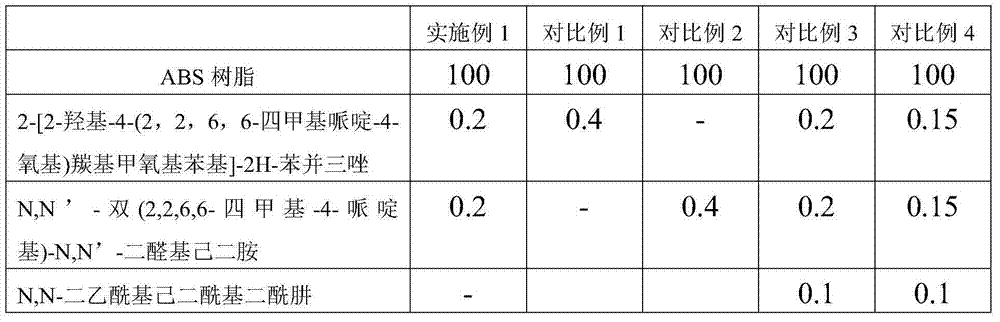

[0029] Each raw material was weighed according to the data corresponding to Example 1 in Table 1.

[0030] Add each component into a high-speed mixer, control the rotation speed at 350 rpm at room temperature, mix for 8 minutes, take it out, transfer it to a screw extruder, and extrude and granulate at a temperature of 175°C to obtain the resistant Light aged ABS plastic.

[0031] Table 1: Light aging resistance ABS plastic formula table Unit: kg

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com