Flame-retardant and antibacterial PLA (polylactic acid) biodegradable composite for 3D (three dimensional) printing

A technology of biodegradable and composite materials, which is applied in the field of flame-retardant and antibacterial PLA biodegradable composite materials, can solve the problems of dust and waste liquid pollution, high corrosion of equipment, and generation of dioxin, etc., and achieves strong bactericidal power, low cost, Long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A flame-retardant and antibacterial PLA biodegradable composite material for 3D printing, prepared from the following raw materials by weight:

[0046] The weight average molecular weight is 5×10 5g / molPLA 100 parts

[0047] 5 parts sodium bicarbonate

[0048] Chitosan biguanide hydrochloride 10 parts

[0049] Carboxylic liquid nitrile rubber 3 parts

[0050] The mass ratio of antioxidant 1010 and diphenyloctyl phosphite is 0.5 part of antioxidant composed of 4:1

[0051] Ethylene-methacrylate-glycidyl ester 0.5 parts

[0052] 1 part pentaerythritol stearate

[0053] DOPO derivative flame retardant 5-10 parts

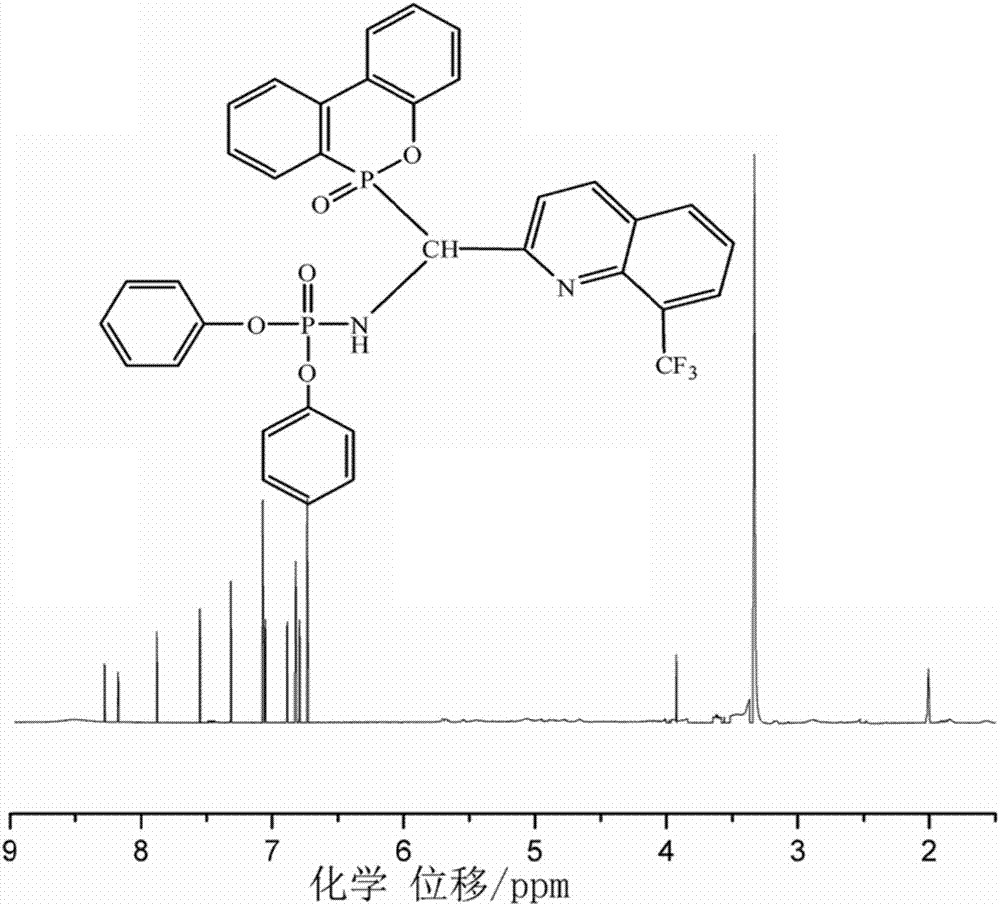

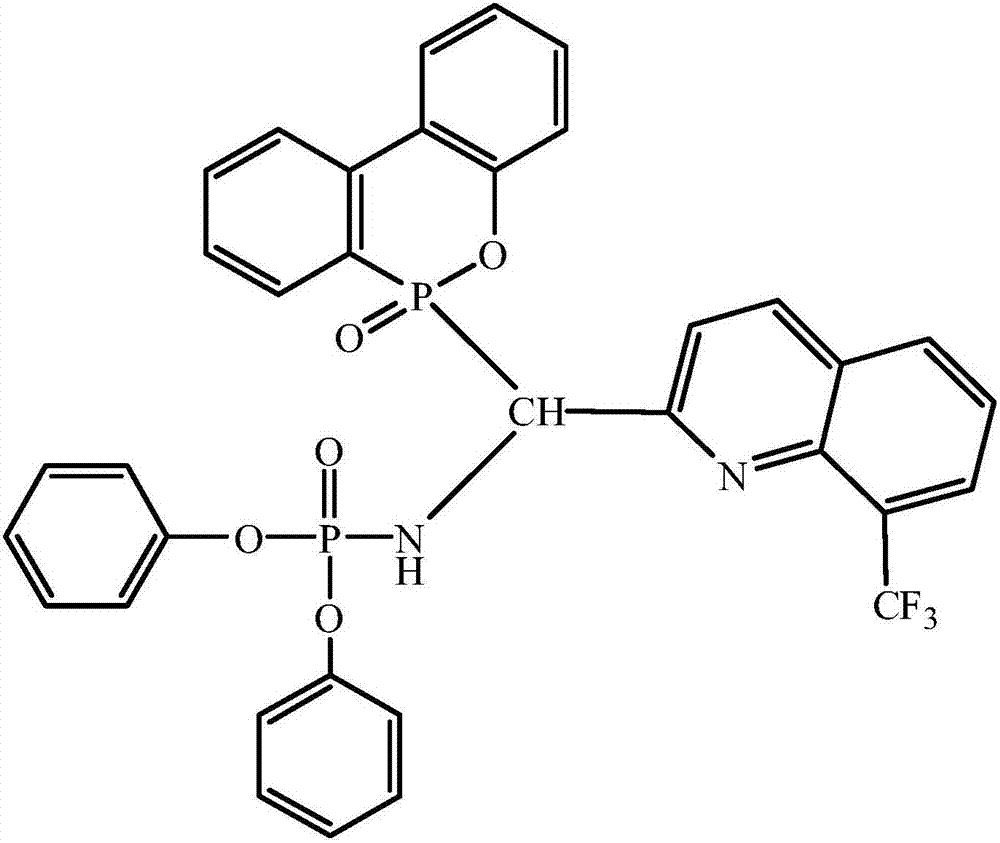

[0054] Among them, the structural formula of DOPO derivative flame retardant is:

[0055]

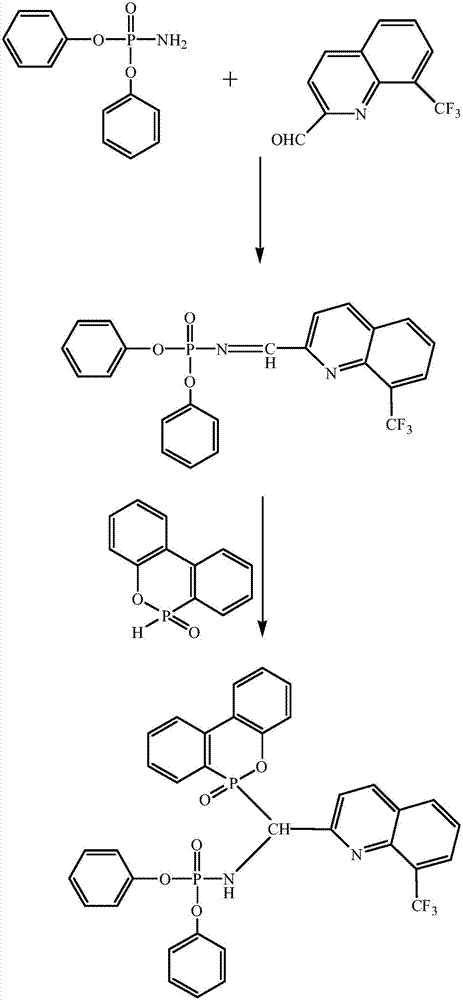

[0056] The synthetic steps of described DOPO derivative flame retardant are:

[0057] (1) 7.5g of biphenylphosphoramidate and 6.8g of 8-trifluoromethylquinoline-2-carbaldehyde were heated in 85.5g of ethanol at 70°C for 6h. After the reaction was over, the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com