A high-performance environment-friendly water-based ship interior paint

An environmentally friendly, high-performance technology, applied in epoxy resin coatings, antifouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of low surface energy performance and poor anti-corrosion performance, and achieve stable performance and excellent surface migration non-toxic, easy to recoat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The first step: preparation of epoxy resin with fluoroalkyl segment in side chain

[0069] Add 6.40 parts of isophorone diisocyanate, 15.18 parts of perfluorodecyl ethyl alcohol, and 7.83 parts of butyl acetate into the reaction kettle in sequence, fill it with nitrogen or argon, stir at a constant speed, heat to 95°C, and wait until the materials are completely After dissolving, the reaction was incubated for 2 hours. 0.01 part of dibutyltin dilaurate was added, and the reaction was continued for 7 hours while stirring at 95°C. After cooling to 50°C, add 42.35 parts of epoxy resin E20 and 28.22 parts of butyl acetate to form a 60% epoxy resin E20 solution, add 0.01 part of dibutyltin dilaurate, heat up to 70°C, and continue the heat preservation reaction for 7 hours. The synthesized isocyanate-terminated fluorine-containing compound was grafted onto the side chain of bisphenol A epoxy resin E20. After the reaction, vacuumize for 3 hours, remove excess solvent under r...

Embodiment 2

[0104] The first step: preparation of epoxy resin with fluoroalkyl segment in side chain

[0105] Add 5.35 parts of isophorone diisocyanate, 12.75 parts of perfluorodecyl ethyl alcohol, and 10.41 parts of butyl acetate into the reaction kettle in sequence, fill it with nitrogen or argon, stir at a constant speed, heat to 95°C, and wait until the materials are completely After dissolving, the reaction was incubated for 2 hours. 0.015 parts of dibutyltin dilaurate was added, and the reaction was continued for 7 hours while stirring at 95°C. After cooling to 50°C, add 42.88 parts of epoxy resin E20 and 28.58 parts of butyl acetate to form a 60% epoxy resin E20 solution, add 0.015 parts of dibutyltin dilaurate, heat up to 70°C, and continue the heat preservation reaction for 7 hours. The synthesized isocyanate-terminated fluorine-containing compound was grafted onto the side chain of bisphenol A epoxy resin E20. After the reaction, vacuumize for 3 hours, remove excess solvent un...

Embodiment 3

[0145] The first step: preparation of epoxy resin with fluoroalkyl segment in side chain

[0146] Add 6.36 parts of isophorone diisocyanate, 15.12 parts of perfluorodecyl ethyl alcohol, and 7.66 parts of butyl acetate into the reaction kettle in sequence, fill it with nitrogen or argon, stir at a constant speed, heat to 95°C, and wait until the materials are completely After dissolving, the reaction was incubated for 2 hours. 0.01 part of dibutyltin dilaurate was added, and the reaction was continued for 7 hours while stirring at 95°C. After cooling to 50°C, add 42.50 parts of epoxy resin E20 and 28.34 parts of butyl acetate to form a 60% epoxy resin E20 solution, add 0.01 part of dibutyltin dilaurate, heat up to 70°C, and continue the heat preservation reaction for 7 hours. The synthesized isocyanate-terminated fluorine-containing compound was grafted onto the side chain of bisphenol A epoxy resin E20. After the reaction, vacuumize for 3 hours, remove excess solvent under r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

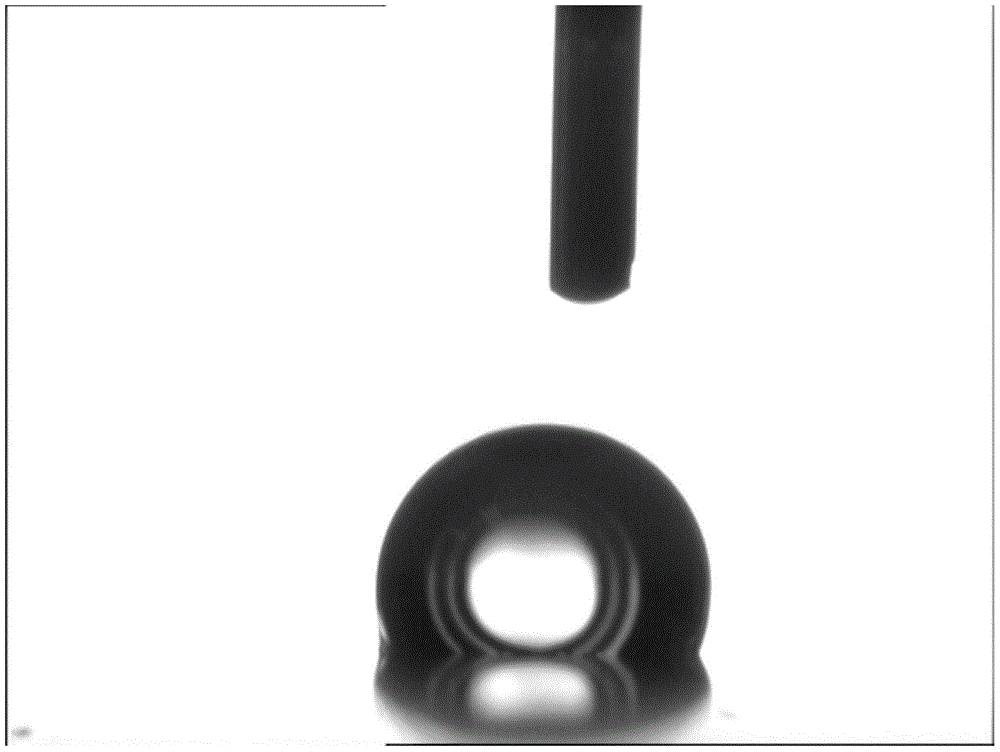

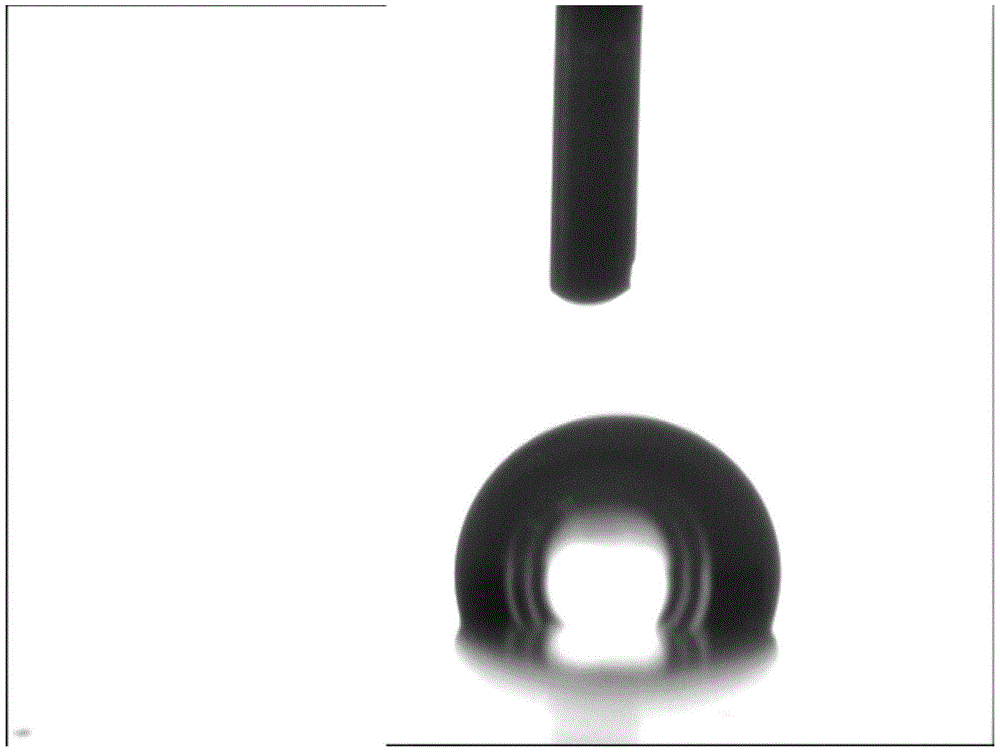

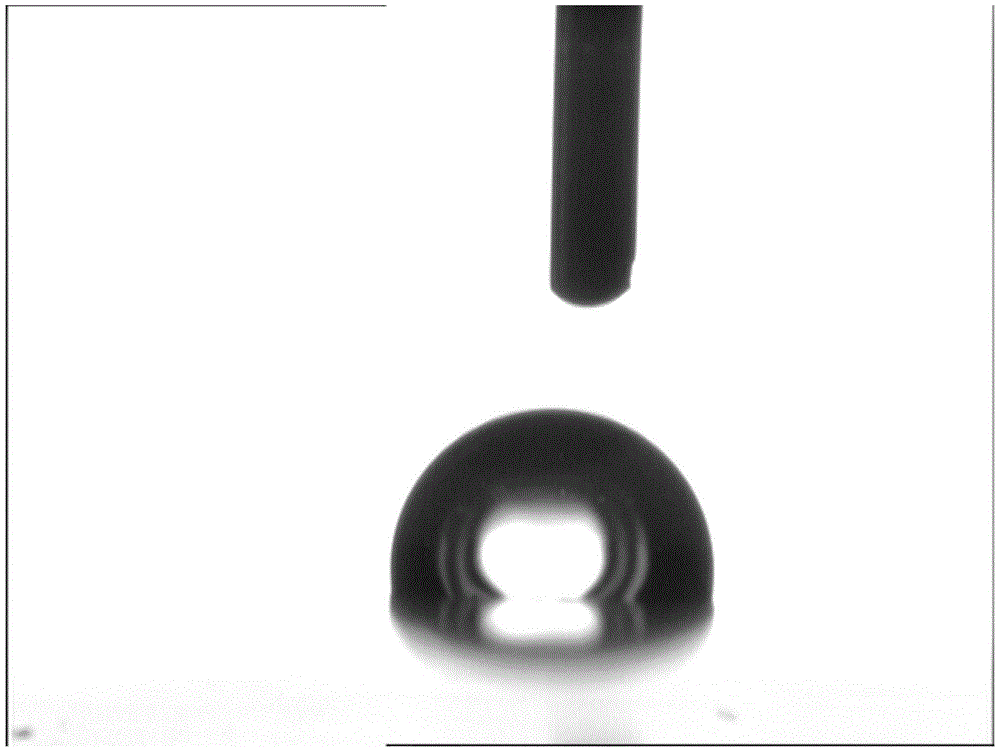

| water contact angle | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com