A kind of flame retardant with surface mobility and preparation method thereof

A technology of surface migration and flame retardants, applied in the field of flame retardants, can solve problems such as impact and unfavorable material properties, and achieve the effects of simple process, low cost, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

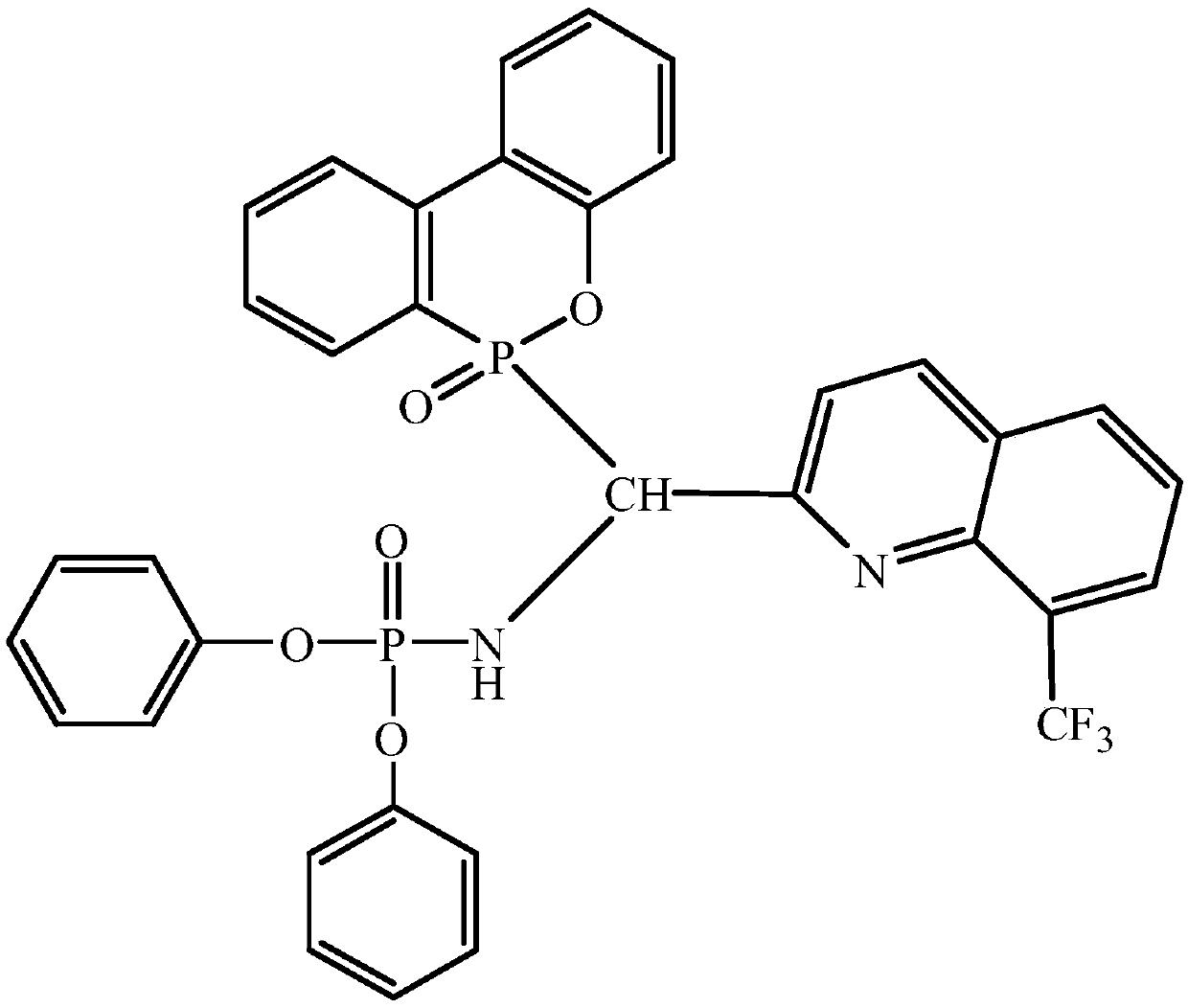

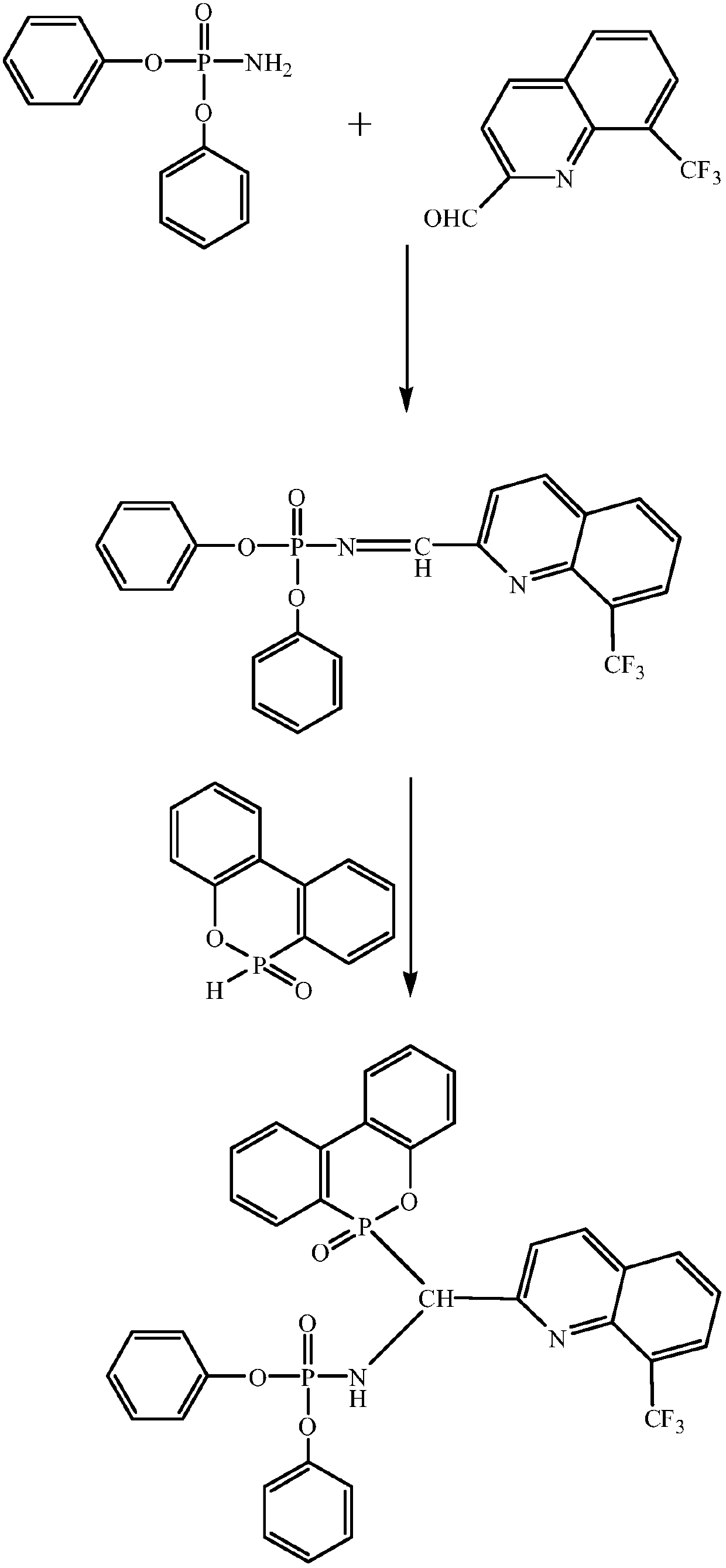

[0031] A kind of synthetic steps of flame retardant with surface mobility is:

[0032] (1) 7.5g of biphenylphosphoramidate and 6.8g of 8-trifluoromethylquinoline-2-carbaldehyde were heated in 85.5g of ethanol at 70°C for 6h. After the reaction was over, the intermediate product I was obtained. reaction system;

[0033] (2) Add 6.5g of DOPO to the reaction system containing the intermediate product I obtained in step (1) and heat at 70°C for 5h. After the reaction, wash and dry to obtain a flame retardant with surface mobility. Yield 84.5%.

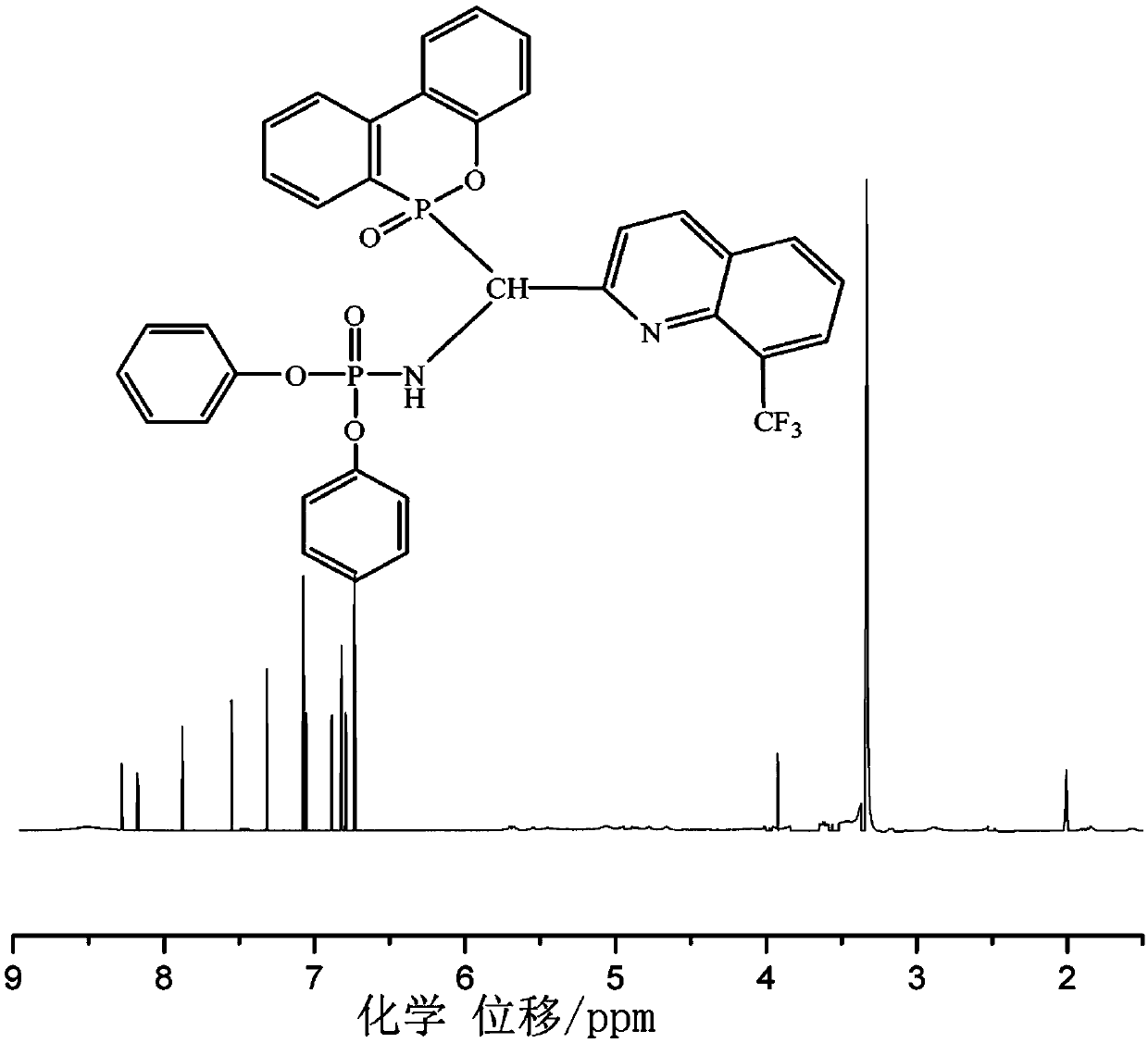

[0034] The infrared test results are as follows:

[0035] FTIR (KBr): N-H stretching vibration peak 3410cm -1 , C-H stretching vibration peak 3070cm -1 , C-N characteristic peak 1288cm -1 , C-F characteristic peak 1100cm -1 , P-O-C characteristic peak 1032cm -1 , P-O-Ph characteristic peak 1231cm -1 , P-Ph characteristic peak 1595cm -1 , P=O characteristic peak 1212cm -1 , the out-of-plane bending vibration peak of the aromatic h...

Embodiment 2

[0039] A kind of synthetic steps of flame retardant with surface mobility is:

[0040] (1) 12.5g of biphenylphosphoramidate and 11.3g of 8-trifluoromethylquinoline-2-carbaldehyde were heated in 214.2g DMF at 70°C for 8h. After the reaction, intermediate product I was obtained. reaction system;

[0041] (2) Add 10.8g of DOPO to the reaction system containing the intermediate product I obtained in step (1) and heat at 70°C for 6.5h. After the reaction, wash and dry to obtain a flame retardant with surface mobility , yield 85.8%.

[0042] The infrared test results are as follows:

[0043] FTIR (KBr): N-H stretching vibration peak 3440cm -1 , C-H stretching vibration peak 3080cm -1 , C-N characteristic peak 1288cm -1 , C-F characteristic peak 1100cm -1 , P-O-C characteristic peak 1035cm -1 , P-O-Ph characteristic peak 1235cm -1 , P-Ph characteristic peak 1595cm -1 , P=O characteristic peak 1212cm -1 , the out-of-plane bending vibration peak of aromatic hydrogen is 850cm ...

Embodiment 3

[0045] A kind of synthetic steps of flame retardant with surface mobility is:

[0046] (1) 24.9g of biphenylphosphoramidate and 22.5g of 8-trifluoromethylquinoline-2-carbaldehyde were heated in 568.8g DMF at 70°C for 10h. After the reaction, intermediate product I was obtained. reaction system;

[0047] (2) Add 21.6g of DOPO to the reaction system containing the intermediate product I obtained in step (1) and heat at 70°C for 8h. After the reaction, wash and dry to obtain a flame retardant with surface mobility. Yield 87.1%.

[0048] The infrared test results are as follows:

[0049] FTIR (KBr): N-H stretching vibration peak 3430cm -1 , C-H stretching vibration peak 3065cm -1 , C-N characteristic peak 1288cm -1 , C-F characteristic peak 1105cm -1 , P-O-C characteristic peak 1035cm -1 , P-O-Ph characteristic peak 1235cm -1 , P-Ph characteristic peak 1595cm -1 , P=O characteristic peak 1213cm-1 , the out-of-plane bending vibration peak of aromatic hydrogen is 800cm -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com