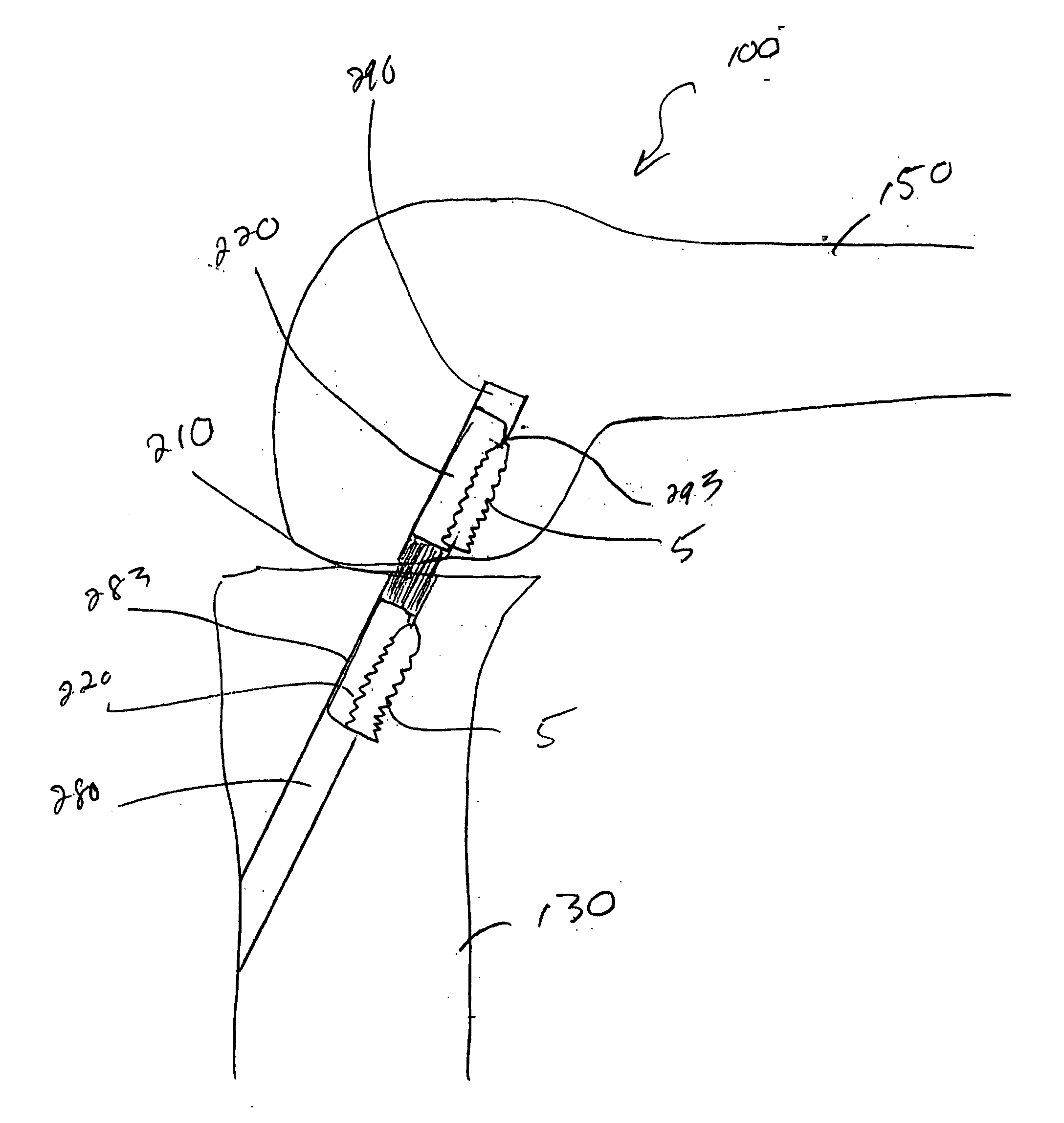

Method of performing anterior cruciate ligament reconstruction using biodegradable interference screw

a technology of biodegradable interference screws and anterior cruciate ligaments, which is applied in the field of surgical procedures for the repair of anterior cruciate ligaments, can solve the problems of meniscal damage and articular cartilage damage, one of the most frequently injured joints, and the inability to perform high-level or recreational sports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Biodegradable composite bone pins 1 were prepared in a conventional manner and into the femurs of mammalian laboratory animals. The pins were of the following three compositions: A) composites of 15 / 85% by volume β-tricalcium phosphate and (85 / 15)poly (lactide co-glycolide); B) poly(lactide); and C) composite of 15% / 85% by volume β-tricalcium phosphate and poly(lactide). About 24 months after implantation, the animals were euthanized and histological sections were obtained. As seen in FIG. 11A, a bone pin 500 having a Composition (A) demonstrated a significant degree of absorption when compared with the original diameter indicated by arrows 505, and significant tissue (bone) in-growth. In addition, minimal tissue reaction was observed. As seen if FIGS. 11B and 11C, bone pins 510 and 520 having Composition (B) exhibited minimal absorption compared with the original diameters indicated by arrows 515 and 525, respectively. As seen in FIG. 11D, a bone pin 530 having Composition C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar ratio | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com