Starch-based biodegradable composite material and preparation method thereof

A technology of biodegradation and composite materials, applied in the field of starch-based biodegradable composite materials and their preparation, can solve the problems of low mechanical strength, easy moisture absorption, loss of mechanical properties, etc., and achieve good hydrophobicity, good water resistance, enhanced The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of modified bacterial cellulose fiber is as follows:

[0042] Add acetic anhydride and ethylene glycol into the mixer at a molar ratio of 1:1, heat and stir at 100°C for 100 minutes. After the two substances are compatible, add a catalyst (p-toluenesulfonic acid) accounting for 5% of the total mass of acetic anhydride and ethylene glycol, and then heat to a reaction temperature of 100°C for reaction. The reaction time is 100 minutes, and finally a Carboxylic pale yellow clear liquid product. Cut the bacterial cellulose fiber into small pieces, add a sodium hydroxide solution with a mass percentage concentration of 10%, swell at a temperature of 50°C for 60 minutes, then wash it repeatedly with water and then dry it, and then mix with the aforementioned light yellow clear liquid product Mixing, adding a small amount of concentrated sulfuric acid, and reacting with mechanical stirring for 100 minutes under the conditions of pH value of 4 and temper...

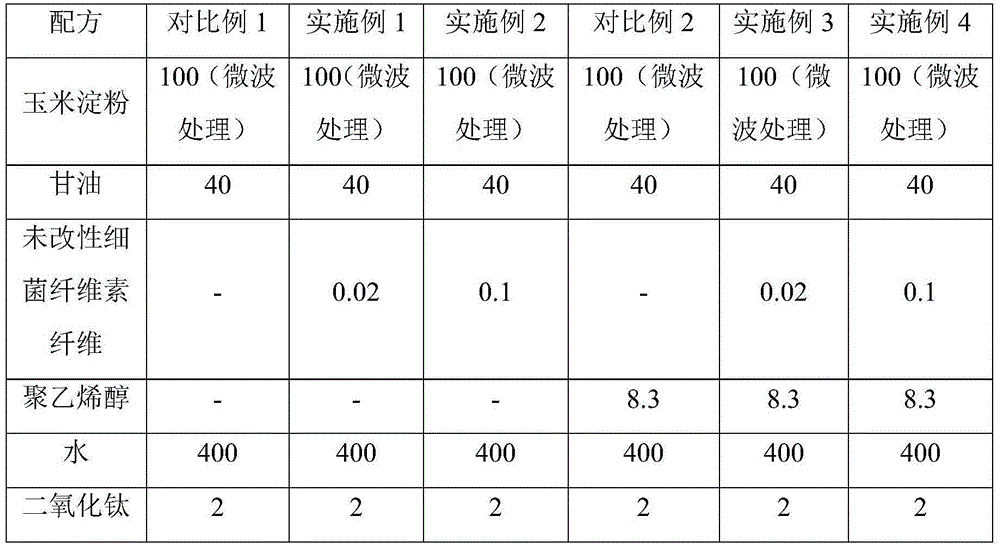

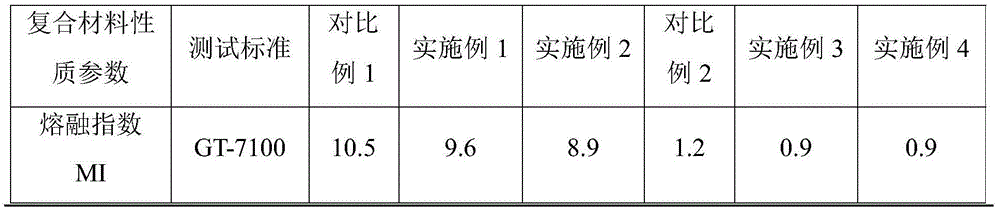

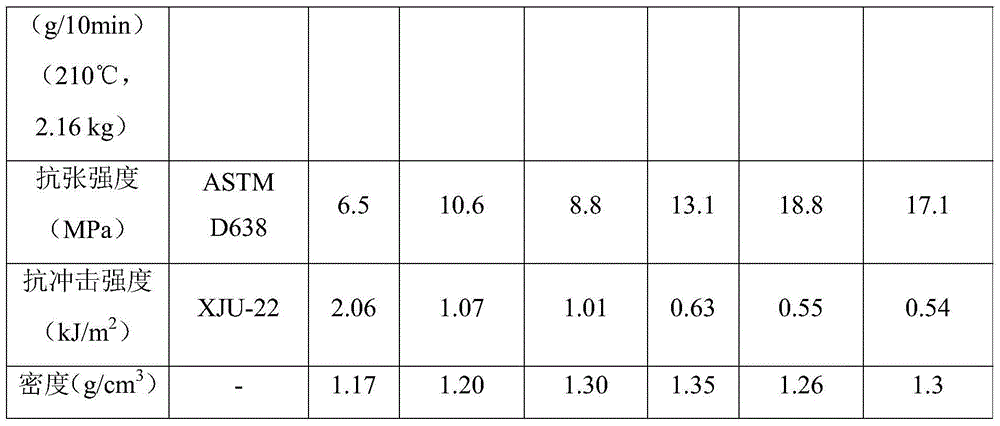

Embodiment 1

[0046] The formulation ratios described in Table 1 below were used to prepare starch-based biodegradable composite materials. First, the cornstarch was treated with 900W high-power microwave for 30 seconds, then the microwave-modified cornstarch, glycerin and water were mixed to form a starch suspension, and then the starch suspension was placed in a mechanical mixer for dispersing for 1 hour. Add the water-dispersed unmodified bacterial cellulose fiber into the starch suspension, then place it in a mechanical mixer and stir for 30 minutes at a temperature of 80°C, take it out and put it into a blast drying oven to dehydrate at a temperature of 80°C for 24 hours, then add Titanium dioxide is extruded, granulated, and injected into a finished product. After testing, the tensile strength of the injection molding sample can reach 10.6MPa.

Embodiment 2

[0048] Except the addition amount of unmodified bacterial cellulose fiber is different, other conditions are all the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com