Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Extensional viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

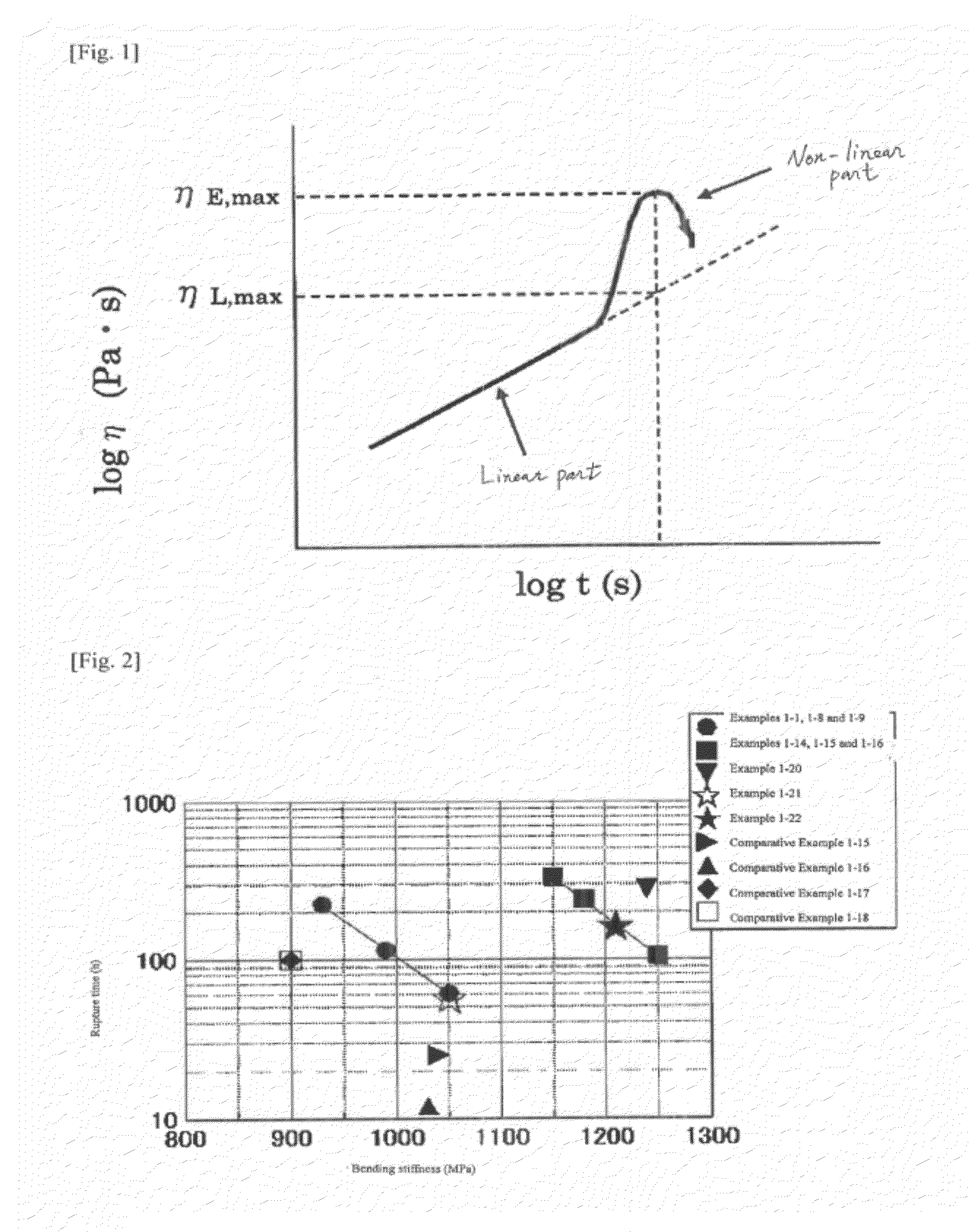

Inventor

Extensional viscosity (also known as elongational viscosity) is a viscosity coefficient when applied stress is extensional stress. This parameter is often used for characterizing polymer solutions. Extensional viscosity can be measured using rheometers that apply extensional stress. Acoustic rheometer is one example of such devices. ηₑ=σₙ/ɛ where ηₑ is the extensional viscosity or elongational viscosity σₙ is the normal stress: σₙ=F/A ɛ is the rate of strain: ɛ=1/LdL/dt For a Newtonian Fluid, the uniaxial elongational viscosity is three times the shear viscosity which can be derived using the continuity equation for incompressible fluids.

Melt processable starch composition

The present invention relates to starch compositions which contain starch and additives. The starch has a weight average molecular weight ranging from about 1,000 to about 2,000,000. The additives can be plasticizers or diluents. The composition containing the starch and the additive is formed by means of passing the composition through a die to produce fibers, foams or films. These compositions have an extensional viscosity in the range from about 50 to about 20,000 pascal seconds. The starch compositions preferably contain a polymer that is substantially compatible with starch and has a weight-average molecular weight of at least 500,000.

Owner:THE PROCTER & GAMBLE COMPANY

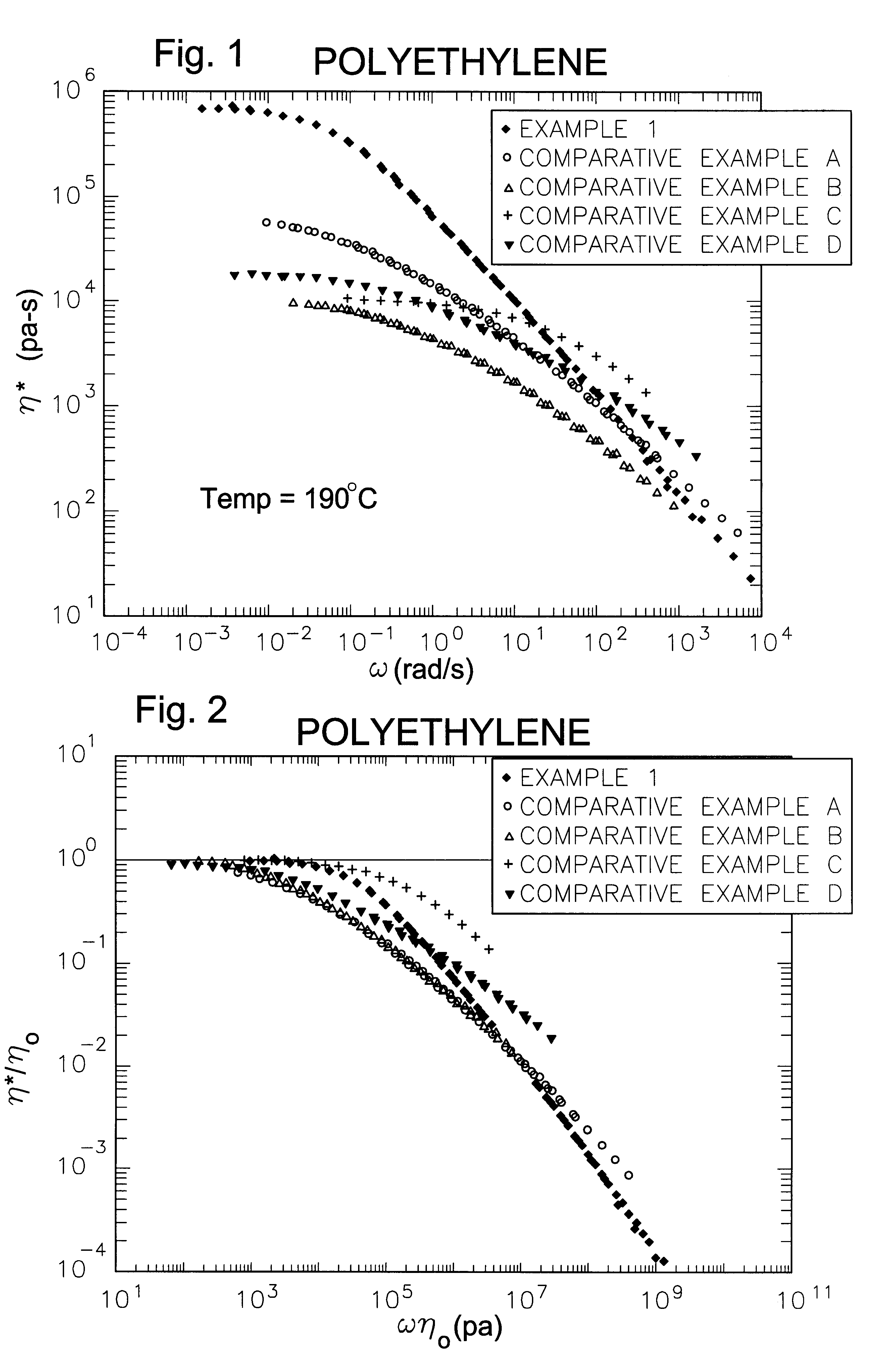

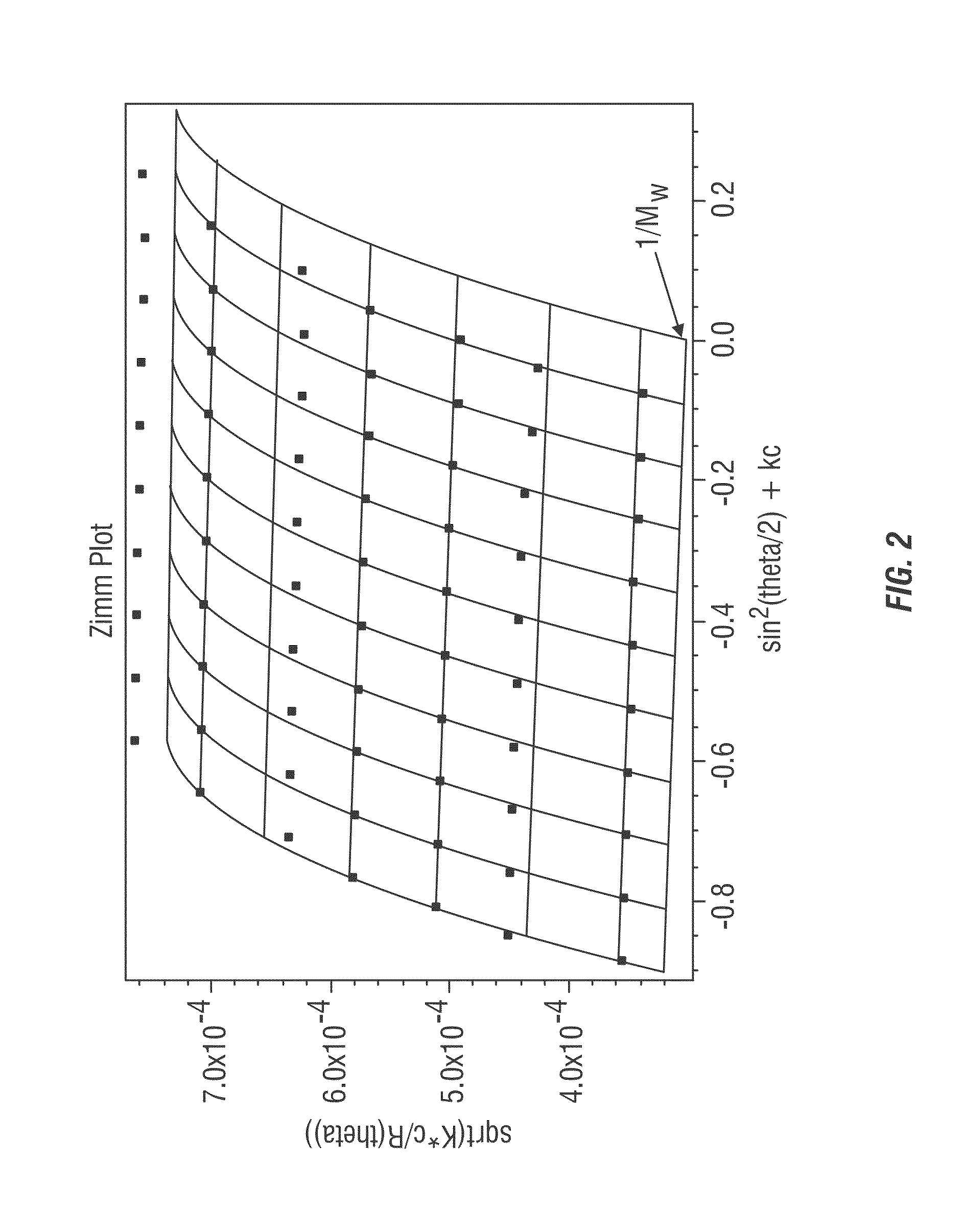

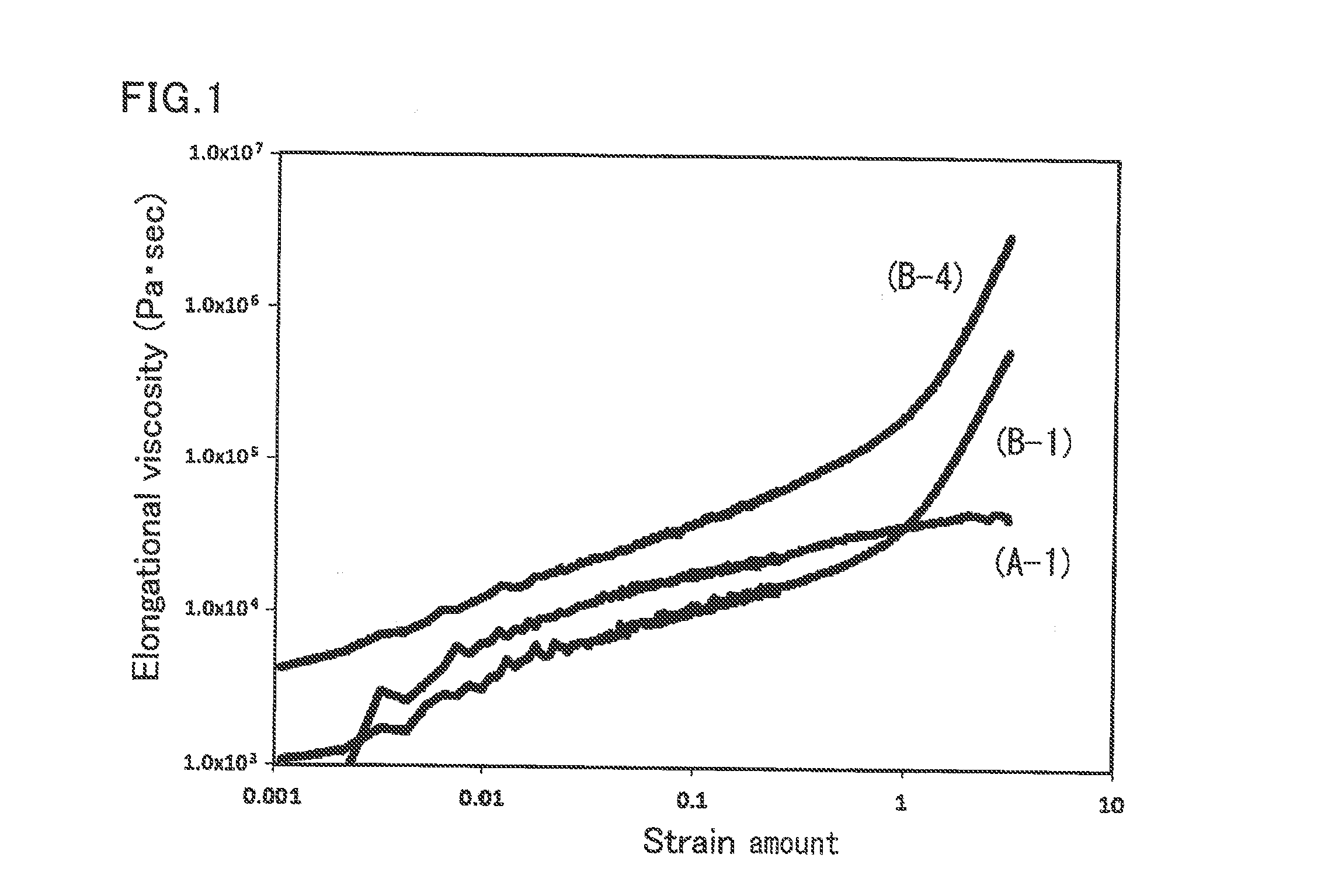

Processing olefin copolymers

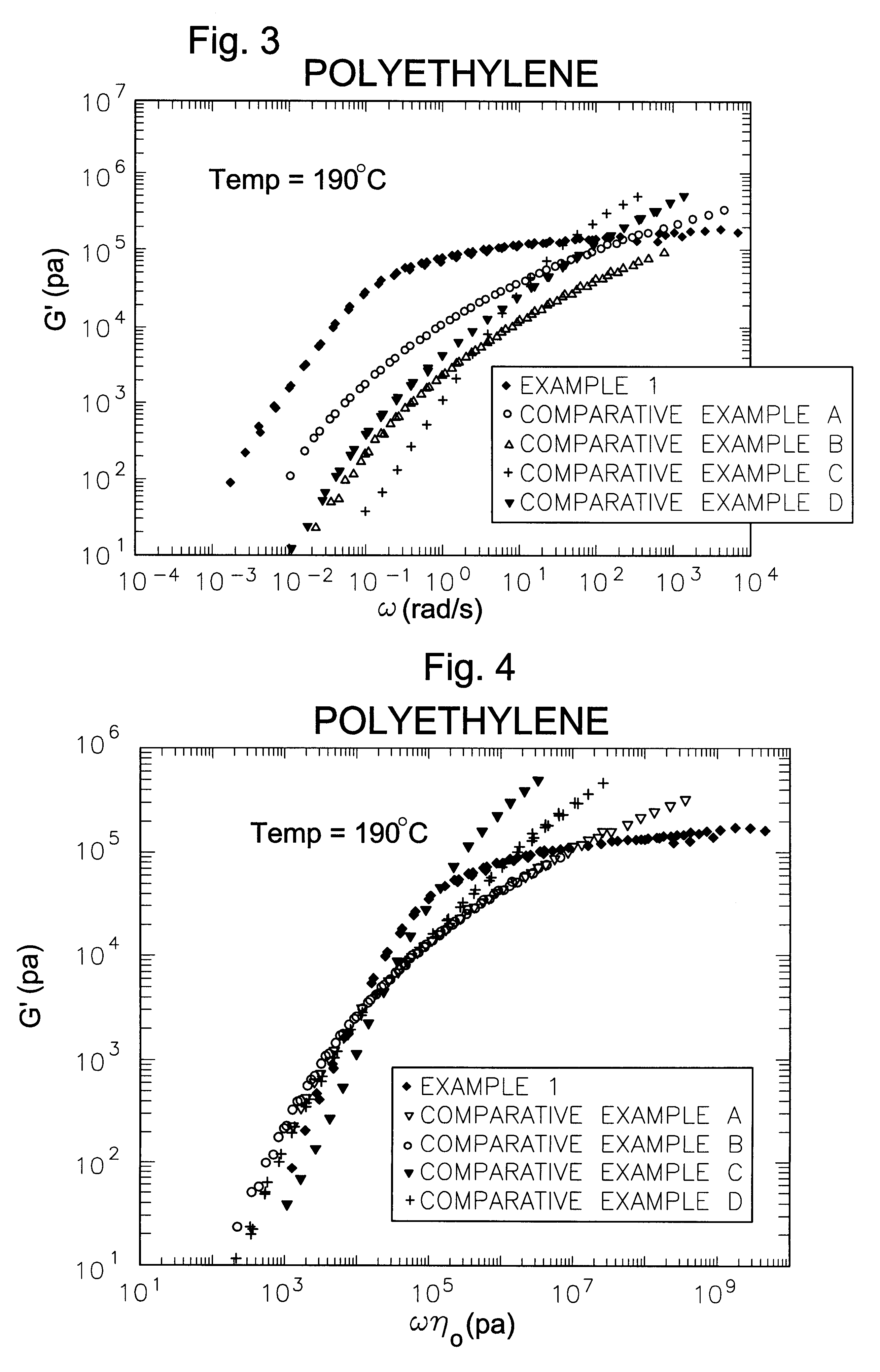

The invention is directed to essentially saturated hydrocarbon polymer composition comprising essentially saturated hydrocarbon polymers having A) a backbone chain, B) a plurality of essentially hydrocarbyl sidechains connected to A), said sidechains each having a number-average molecular weight of from 2500 Daltons to 125,000 Daltons and a MWD by SEC of 1.0-3.5; and having A) a Newtonian limiting viscosity (eta0) at 190° C. at least 50% greater than that of a linear olefinic polymer of the same chemical composition and weight average molecular weight, preferably at least twice as great as that of said linear polymer, B) a ratio of the rubbery plateau modulus at 190° C. to that of a linear polymer of the same chemical composition less than 0.5, preferably <0.3, C) a ratio of the Newtonian limiting viscosity (eta0) to the absolute value of the complex viscosity in oscillatory shear (eta*)at 100 rad / sec at 190° C. of at least 5, and D) a ratio of the extensional viscosity measured at a strain rate of 1 sec-1, 190° C., and time=3 sec (i.e., a strain of 3) to that predicted by linear viscoelasticity at the same temperature and time of 2 or greater. Ethylene-butene prepared by anionic polymerization and hydrogenation illustrate and ethylene-hexene copolymers prepared by coordination polymerization illustrate the invention. The invention polymers exhibit improved processing characteristics in that the shear thinning behavior closely approaches that of ideal polymers and exhibit improved strain thickening.

Owner:EXXONMOBIL CHEM PAT INC

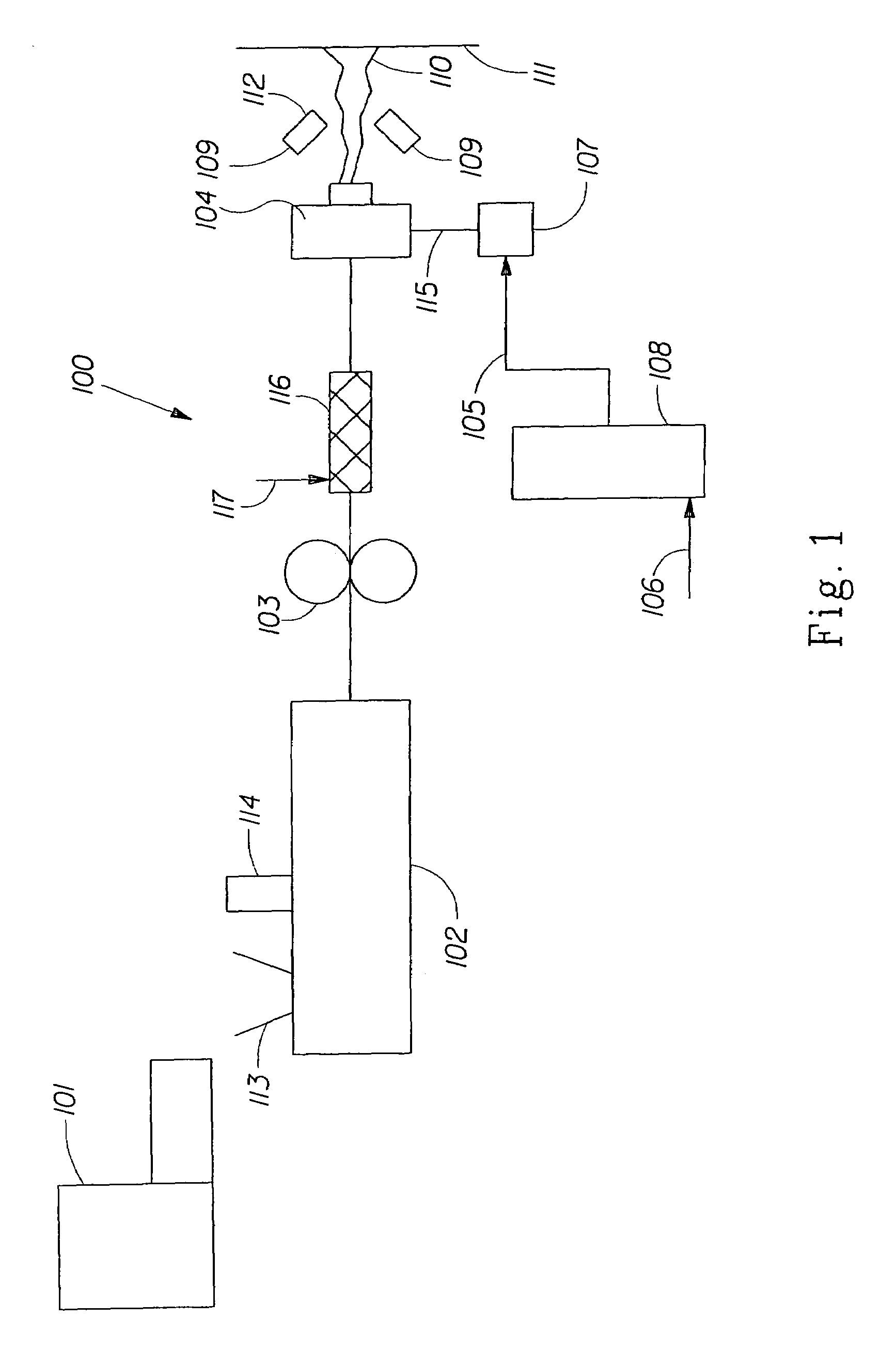

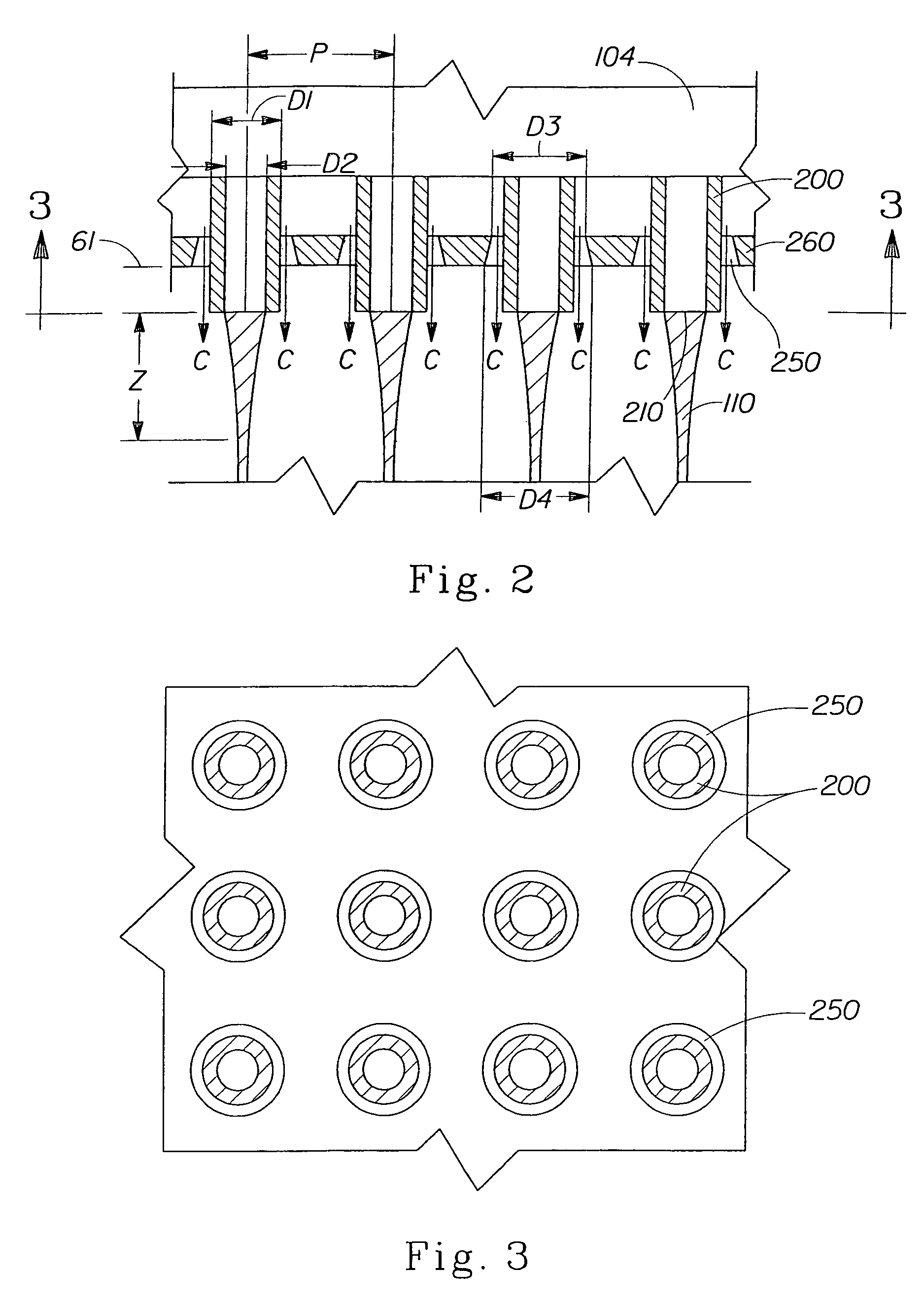

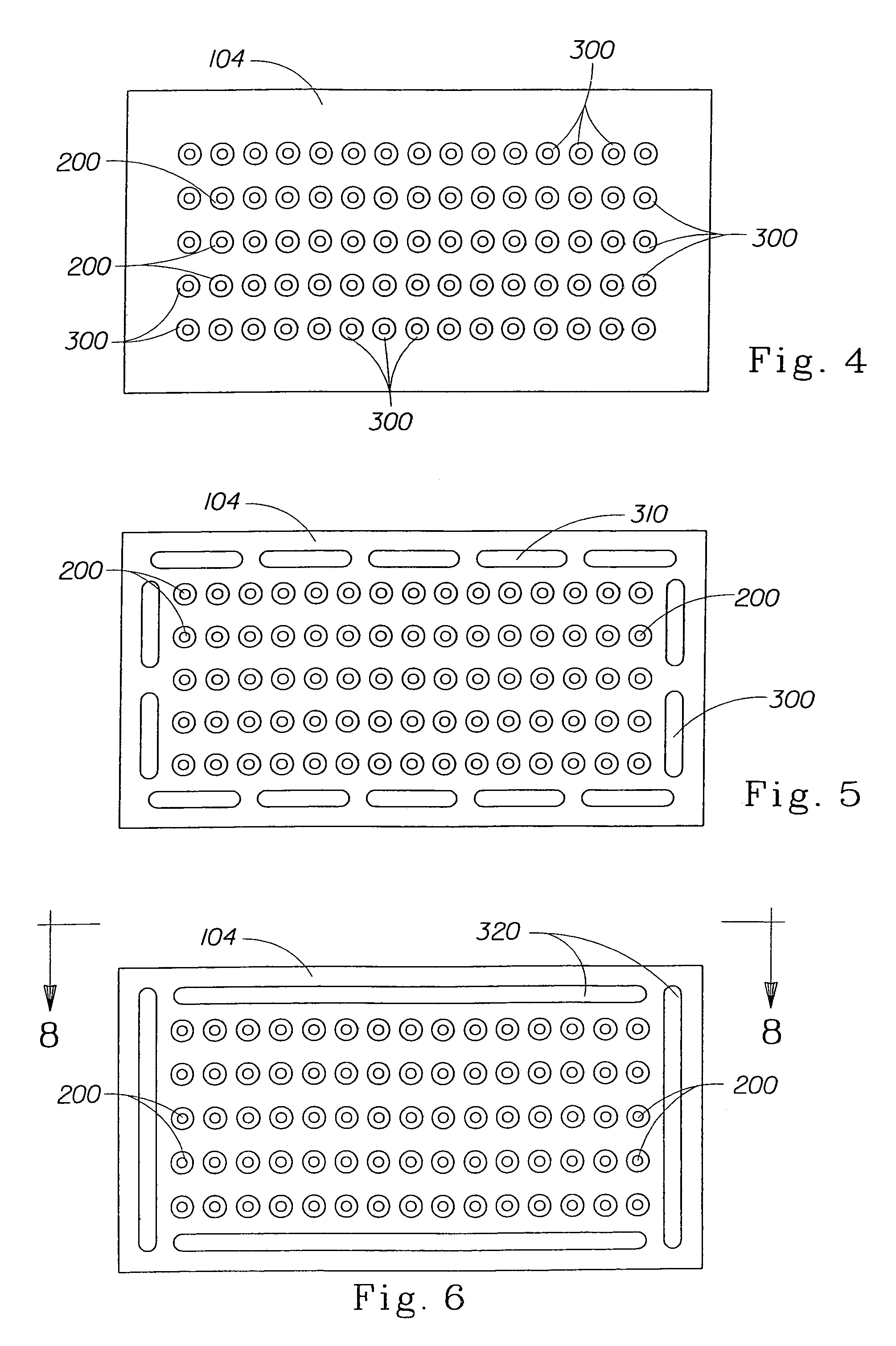

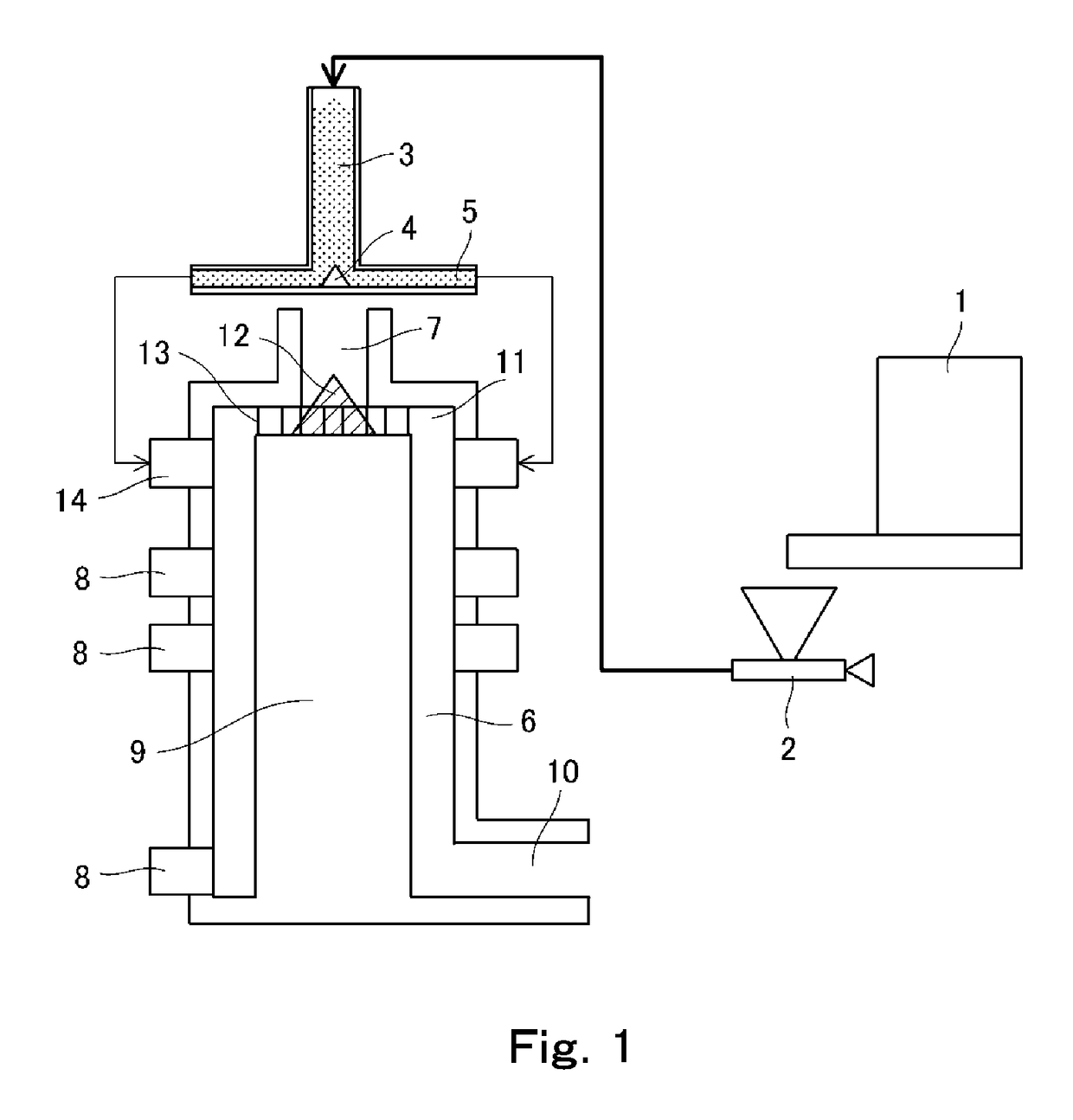

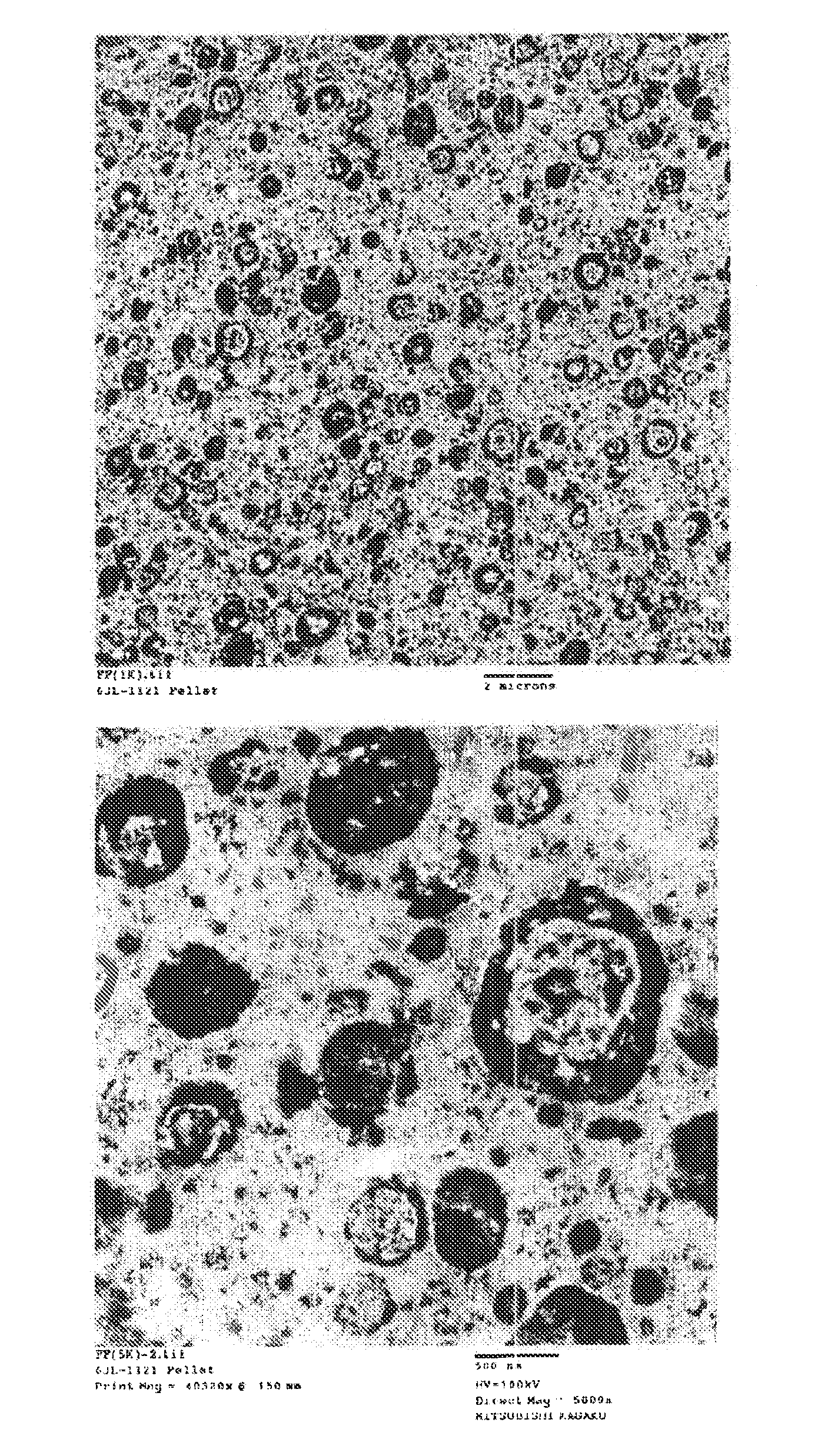

Micro rheometer for measuring flow viscosity and elasticity for micron sample volumes

InactiveUS20080134765A1Small sample sizeCost-effectiveMaterial analysis by optical meansMaterial thermal analysisMeasurement precisionMechanics

A micro-rheometer for measuring flow characteristics such as viscosity, elasticity, and flow rate of a sample liquid combines well defined micro-fabricated flow channels having geometry changes forming a constriction region therein to a monolithically fabricated pressure sensor arrays. The pressure sensor array positions pressure sensors to measure the viscosity of the sample liquid while flowing in a uniform length of the flow passage and to measure the extensional viscosity while flowing through the constriction region of the passage. The invention can improve the measurement accuracy of the flow rate, viscosities, or elasticities over a wide range of shear rate. The accuracy of the viscosity over a broader range of shear rate or flow rate measurement over broader range of flow rates can be accomplished by employing monolithically integrated pressure sensors fabricated with different sensitivities disposed in a known manner. The invention further includes necessary components such as a display, a pumping system, valve manifolds, and software for a portable or laboratory measurement instrument, process control, and high throughput measurements.

Owner:RHEOSENSE

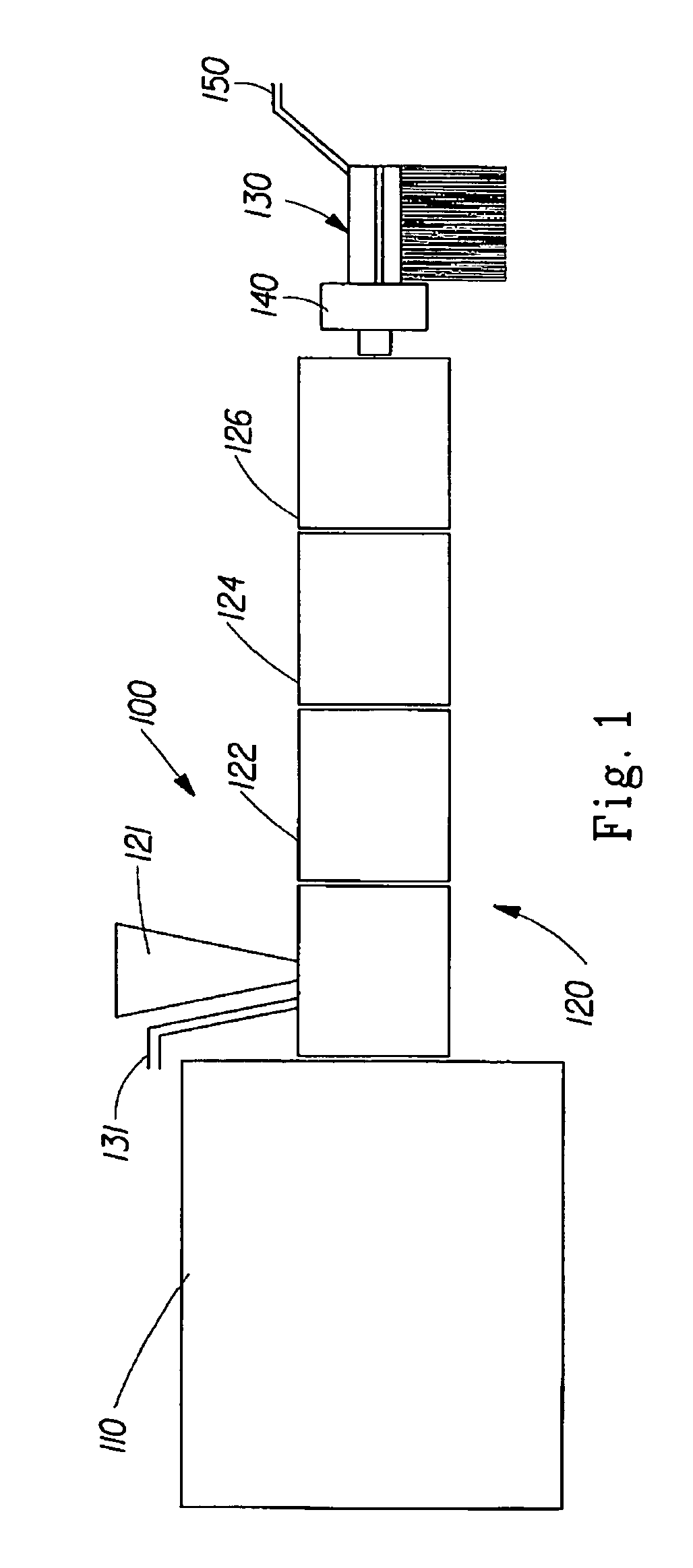

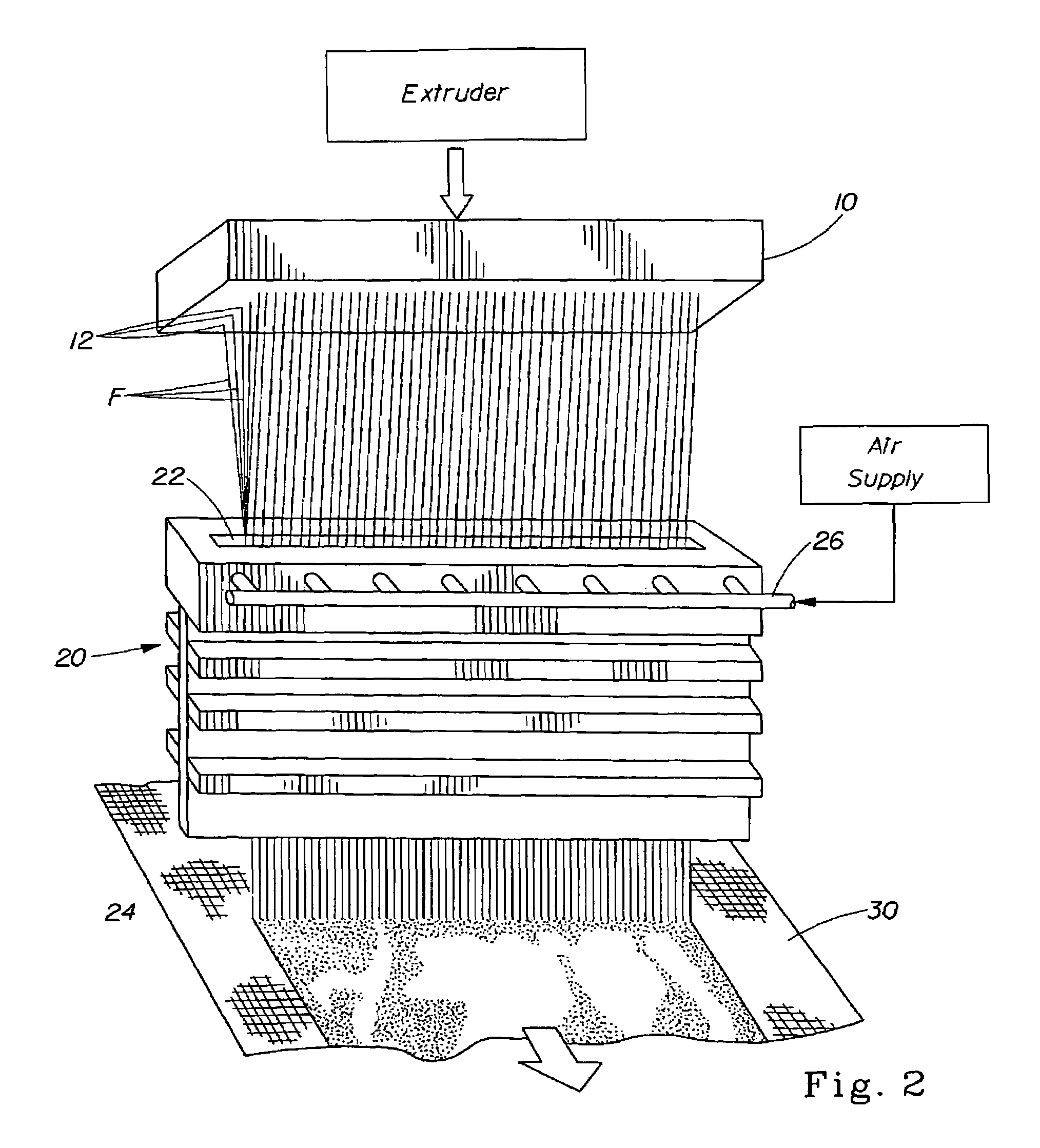

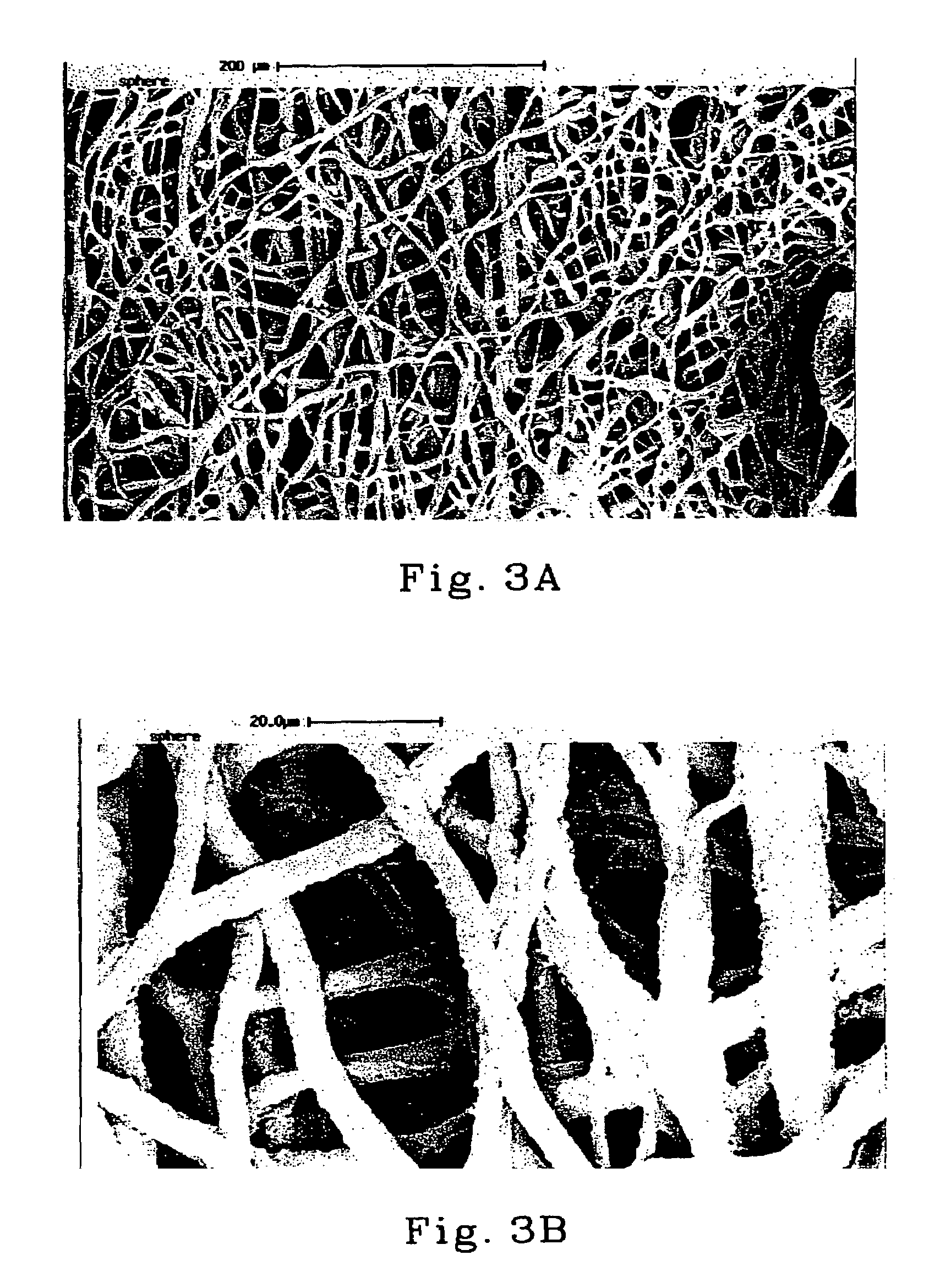

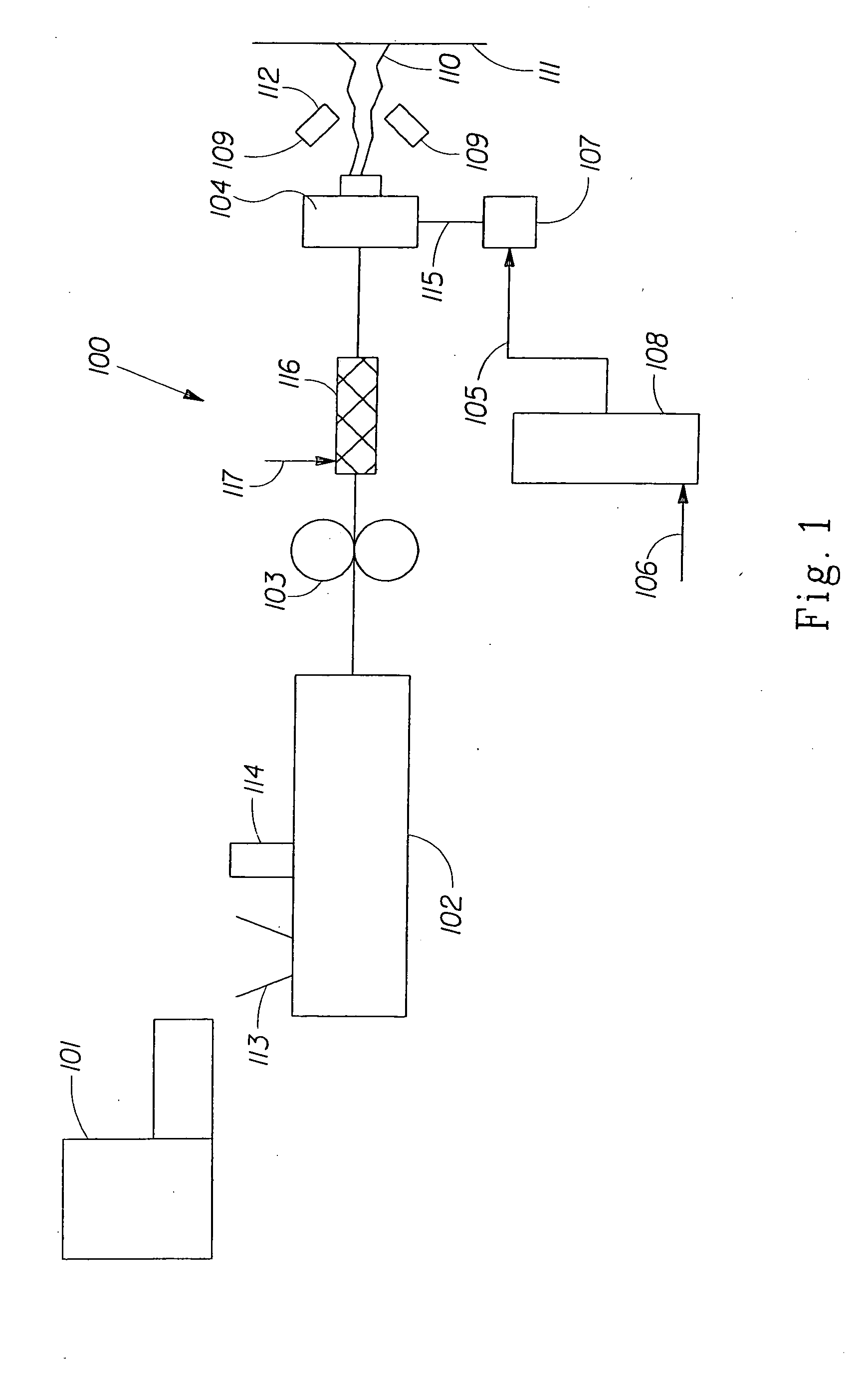

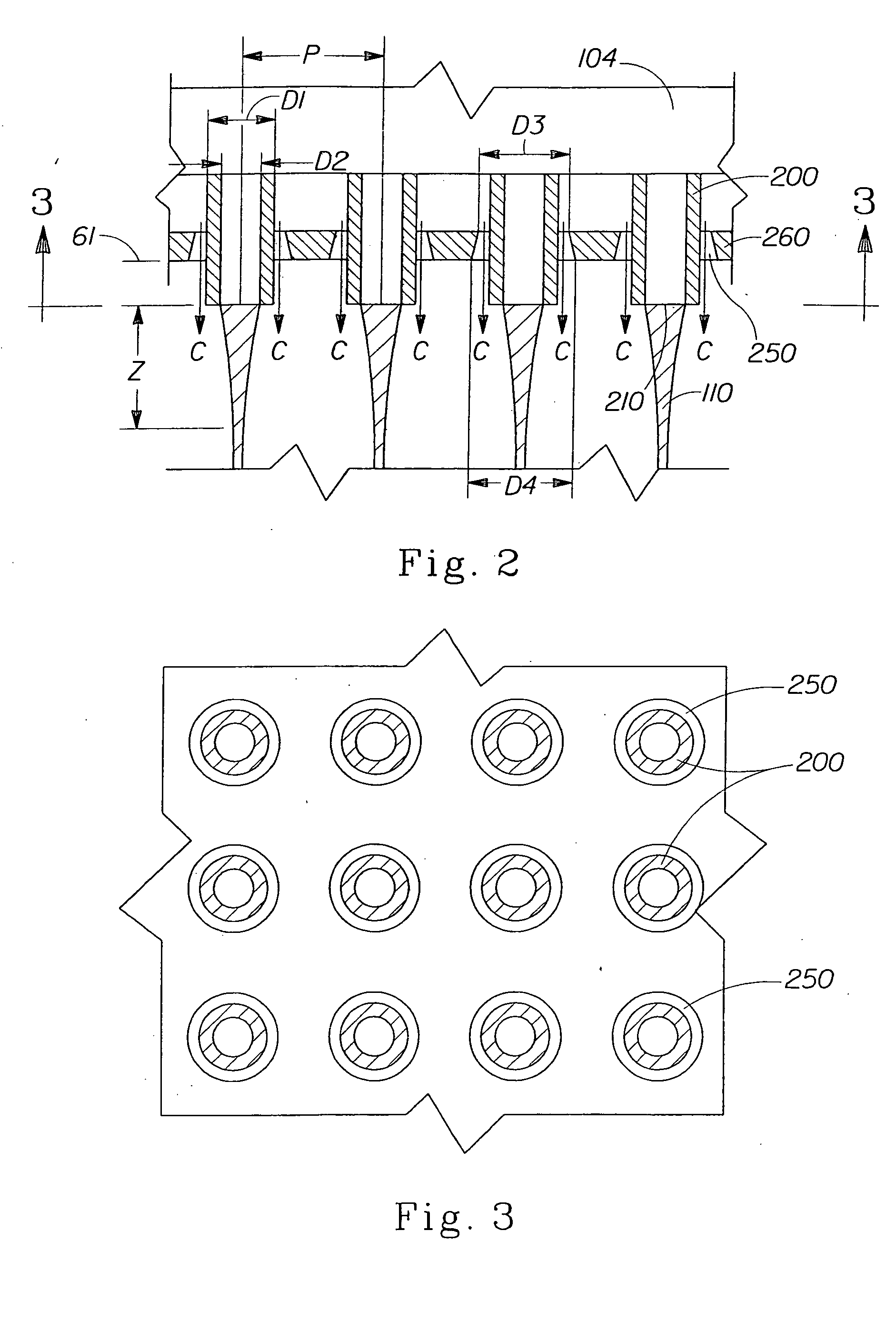

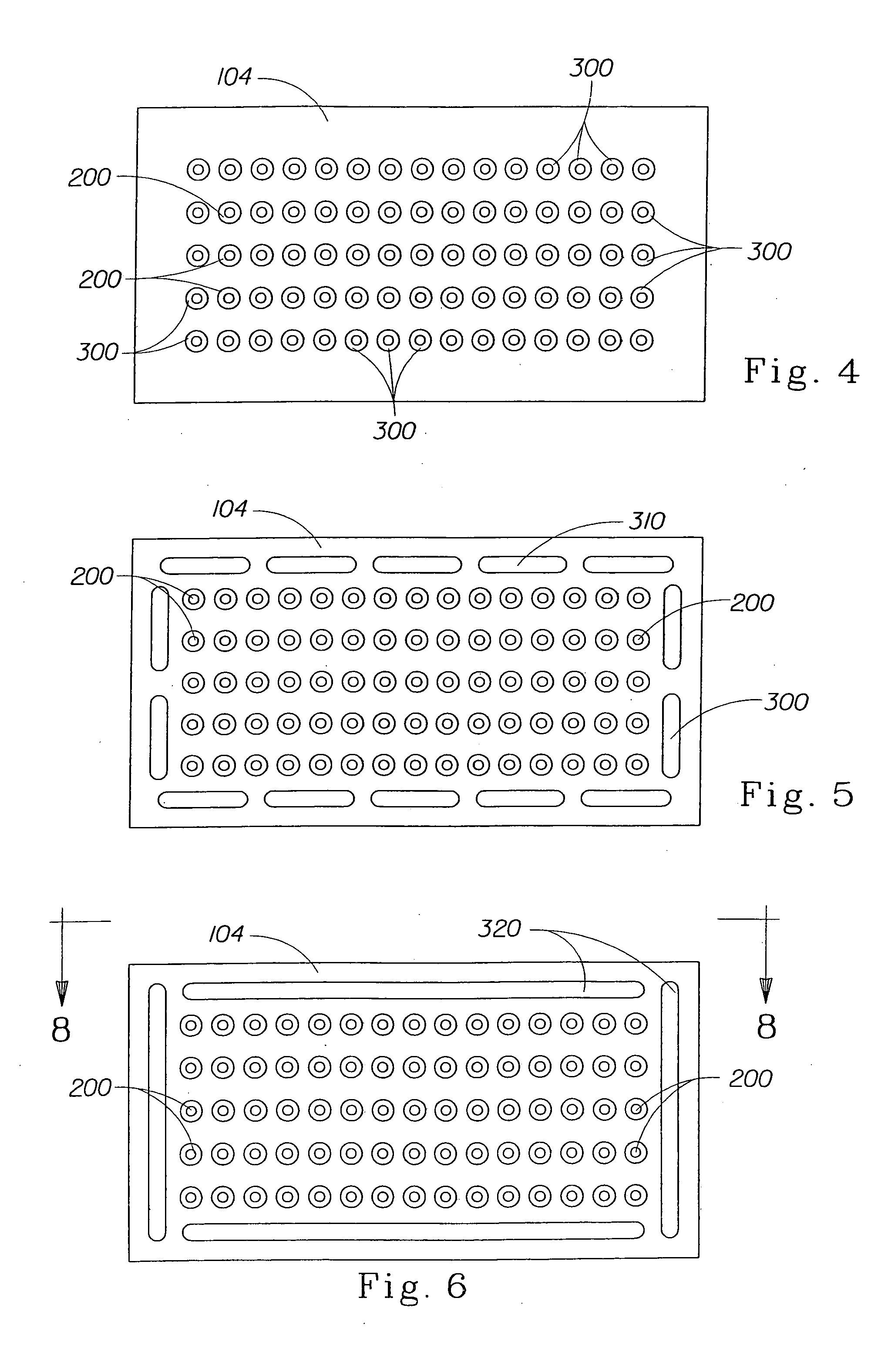

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS7025821B2Starch dervative coatingsAmylose/amylopectin derivative coatingsFiberThermoplastic

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal·Seconds to about 80 Pascal·Seconds and an apparent extensional viscosity in the range of from about 150 Pascal·Seconds to about 13,000 Pascal·Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:PROCTER & GAMBLE CO

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS20050076809A1Starch dervative coatingsAmylose/amylopectin derivative coatingsThermoplasticFiber

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal.Seconds to about 80 Pascal.Seconds and an apparent extensional viscosity in the range of from about 150 Pascal.Seconds to about 13,000 Pascal.Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:THE PROCTER & GAMBLE COMPANY

In situ moisture generation and use of polyfunctional alcohols for crosslinking of silane-functionalized resins

InactiveUS8460770B2Improve propertiesReduce rateSynthetic resin layered productsSpecial surfacesSilanesStrong acids

Polymer compositions comprise a (i) silane-functionalized polymer, e.g., a polyethylene grafted with vinyl triethoxy silane, (H) polyfunctional alcohol e.g., α,α,α′,α′˜tetramethyl-I,3-benzenediethanol and, optionally, (iii) acid, e.g., an alkylated aryl disulfonic acid. The use of polyfunctional alcohols in the absence of a strong acid yields a light-crosslinking of the silane-functionalized polymer and this, in turn, provides a polymer melt with improved extensional properties such as elongational viscosity and melt strength. The use of a polyfunctional alcohol in combination with a blocked strong acid provides a slow rate of crosslinking during melt processing and a high degree of ultimate crosslinking after the polymer composition has been shaped or molded.

Owner:DOW GLOBAL TECH LLC

Composition for polyolefin resin foam, foam of the same, and process for producing foam

InactiveUS20050049322A1Good flexibilityGood cushioning propertiesOther chemical processesMixingExtensional viscosityPolymer science

A composition for polyolefin resin foam, which comprises a polymer component comprising a polyolefin resin and a rubber and / or thermoplastic elastomer, and a powder particle, wherein the composition has an extensional viscosity as measured with a capillary rheometer (temperature, 200° C.; shear rate, 5,000 [1 / s]) of from 20 to 100 kPa·s.

Owner:NITTO DENKO CORP

Foamable polymeric composition

Owner:TEKNOR APEX

Toner

Provided is a toner including a toner particle containing an amorphous resin, a colorant, a release agent, and a crystalline resin, wherein, when η0.01 represents the extensional viscosity of the toner at a Hencky strain at 90° C. of 0.01 and η0.69 represents the extensional viscosity of the toner at a Hencky strain at 90° C. of 0.69, η0.01 and η0.69 satisfy the relationships of the following formulas (1) and (2):3.0×104 Pa≤η0.01≤2.0×105 Pa formula (1)2.0≤[η0.69 / η0.01]. formula (2)

Owner:CANON KK

Cutting resistant ultrahigh molecular weight polyethylene fiber, preparation method and application thereof

ActiveCN106555244AHigh elongation at breakImprove extensional viscosityMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberExtensional viscosity

The invention provides a cutting resistant ultrahigh molecular weight polyethylene fiber, a preparation method and application thereof. The cutting resistant ultrahigh molecular weight polyethylene fiber includes: ultrahigh molecular weight polyethylene fiber; and hard fiber dispersed in the ultrahigh molecular weight polyethylene fiber. Specifically, the ultrahigh molecular weight polyethylene fiber and the hard fiber are in a mass ratio of 100:(2-8). Compared with the prior art, according to the cutting resistant ultrahigh molecular weight polyethylene fiber provided by the invention, on the basis of meeting the cutting resistant performance EN388 five-grade standard, through control of the content of the hard fiber, the extension viscosity of a spinning solution in the preparation process is improved, thus further improving the mechanical properties of the finished fiber product, the obtained finished fiber product has high strength, and also has small end breakage number. Experimental results show that the cutting resistant ultrahigh molecular weight polyethylene fiber provided by the invention has strength up to 26.9cN / dtex, elongation at break up to 5%, and an end breakage number of less than or equal to 1 per million meters.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

Shampoo Compositions Containing Cationic Polymer and an Anionic Surfactant Mixture

The invention provides an aqueous shampoo composition comprising, in admixture: (i) a first anionic surfactant in which the ratio between the molecular weights of the polar (hydrophilic) and non-polar (hydrophobic) parts of the molecule is less than 1.5; (ii) a second anionic surfactant in which the ratio between the molecular weights of the polar (hydrophilic) and non-polar (hydrophobic) parts of the molecule is greater than 1.5, and (iii) a cationic polymer having a molecular weight of at least 100,000 Dalton and a cationic charge density of at least 0.5 meq / g; in which the weight ratio of (i):(ii) ranges from 3:1 to 1:3. Shampoo compositions according to the invention demonstrate reduced extensional viscosity (i.e. are less “stringy”). They also provide for the delivery of a significantly increased level of conditioning without any significant increase in product stringiness.

Owner:CONOPCO INC D B A UNILEVER

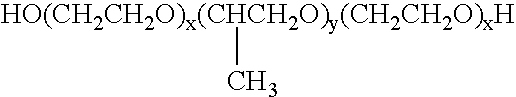

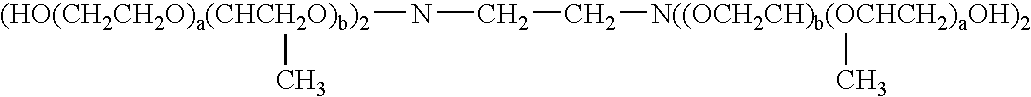

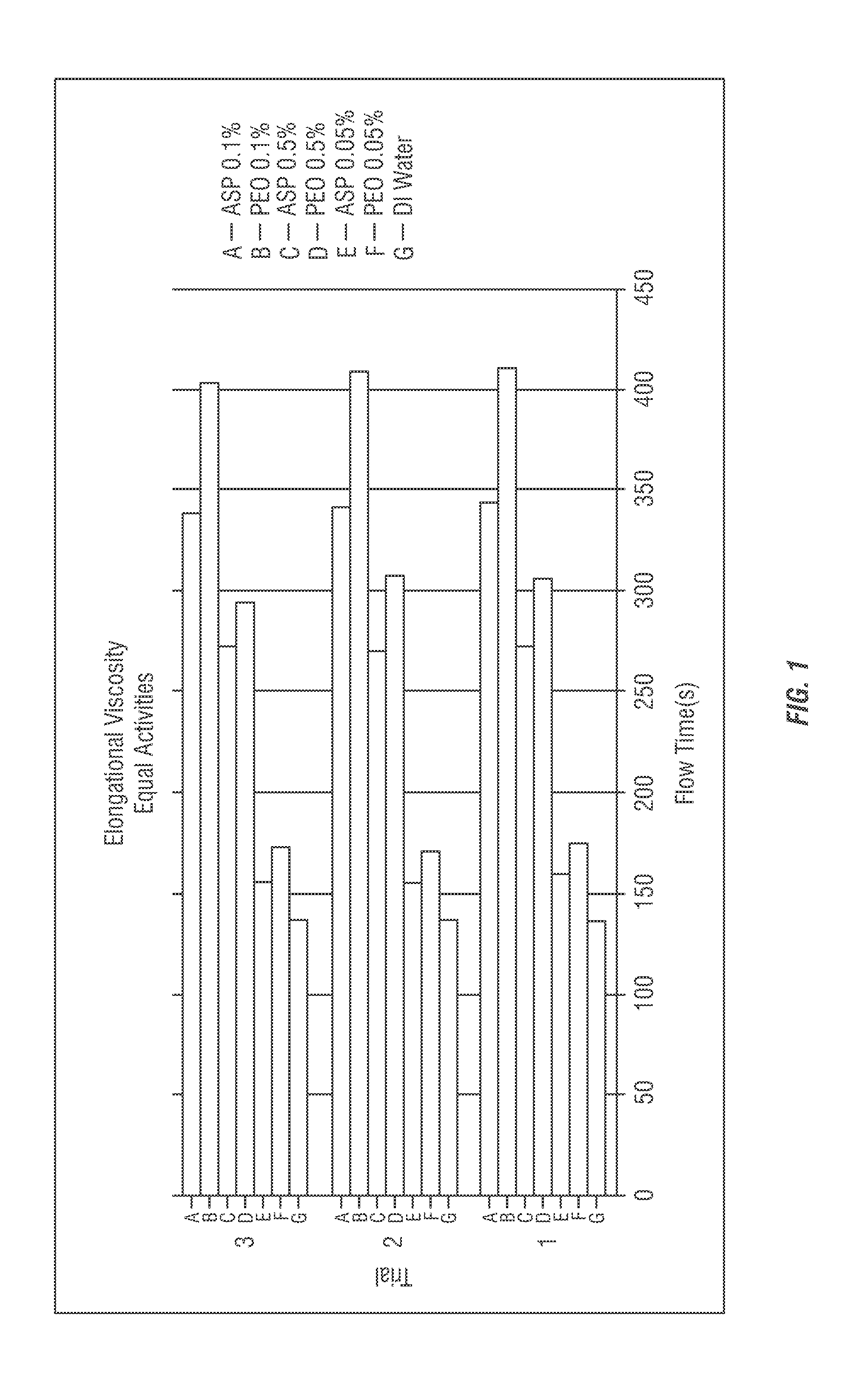

Reduced misting alkaline cleaners using elongational viscosity modifiers

ActiveUS20130284205A1Easy to removeOrganic detergent compounding agentsAnionic surface-active compoundsAlkalinitySulfonate

Alkaline spray-on cleaners that can be delivered by pump or pressurized gas aerosol spray have been made with reduced choking mists are disclosed. The cleaning composition comprises the use of anti-mist components consisting of large anionic copolymer comprised of acrylamide and AMPS (acrylamide-sodium 2-acrylamido-2-methylpropane sulfonate), and polyethylene oxide polymers that create non-Newtonian solutions. The composition also includes a surfactant, and a source of alkalinity.

Owner:ECOLAB USA INC

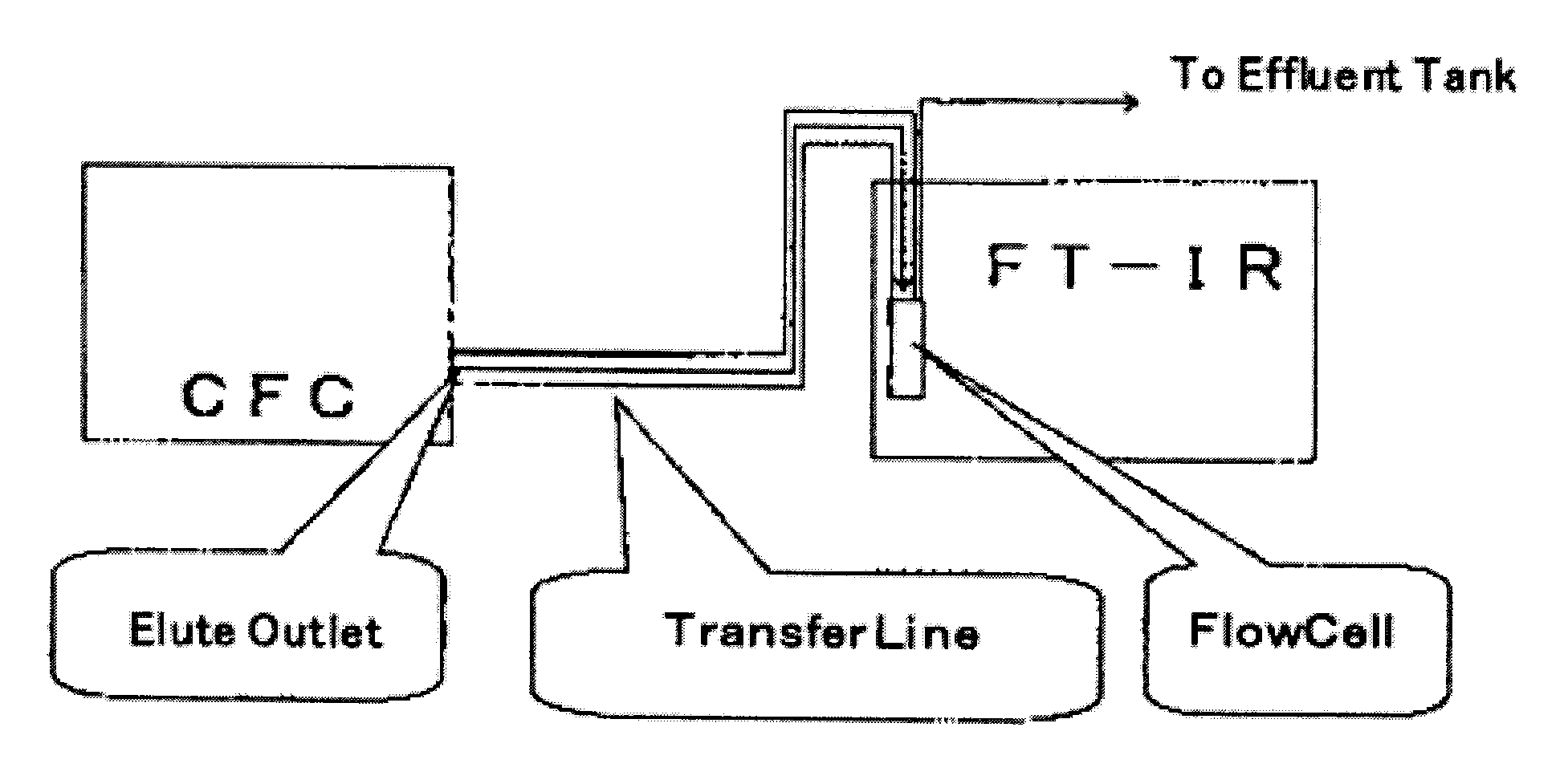

Propylene-based polymer and method for producing the same, and propylene-based resin composition

A propylene-based polymer comprising the following component (A) insoluble in p-xylene at 25° C. and component (B) soluble in p-xylene at 25° C., wherein (i) the weight average molecular weight (Mw) measured with GPC is 100,000 to 1,000,000, (ii) the content of the component insoluble in hot p-xylene is 0.3% by weight or lower, and (iii) the degree of strain hardening (λ max) in measurement of elongational viscosity is 2.0 or higher; and a method for producing the same, along with a resin composition comprising a propylene-ethylene copolymer (Z) in an amount of 50.0 to 99.9% by weight and a propylene-based polymer (M) in an amount of 0.1 to 50.0% by weight.Component (A): a component (CXIS) insoluble in p-xylene at 25° C., having requirements specified by (A1) to (A5). Component (B): a component (CXS) is soluble in p-xylene at 25° C., having requirements specified by (B1) to (B4).

Owner:JAPAN POLYPROPYLENE CORP

Reduced misting alkaline cleaners using elongational viscosity modifiers

ActiveUS9206381B2Easy to removeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsExtensional viscosityAlkalinity

Alkaline spray-on cleaners that can be delivered by pump or pressurized gas aerosol spray have been made with reduced choking mists are disclosed. The cleaning composition comprises the use of anti-mist components consisting of large anionic copolymer comprised of acrylamide and AMPS (acrylamide-sodium 2-acrylamido-2-methylpropane sulfonate), and polyethylene oxide polymers that create non-Newtonian solutions. The composition also includes a surfactant, and a source of alkalinity.

Owner:ECOLAB USA INC

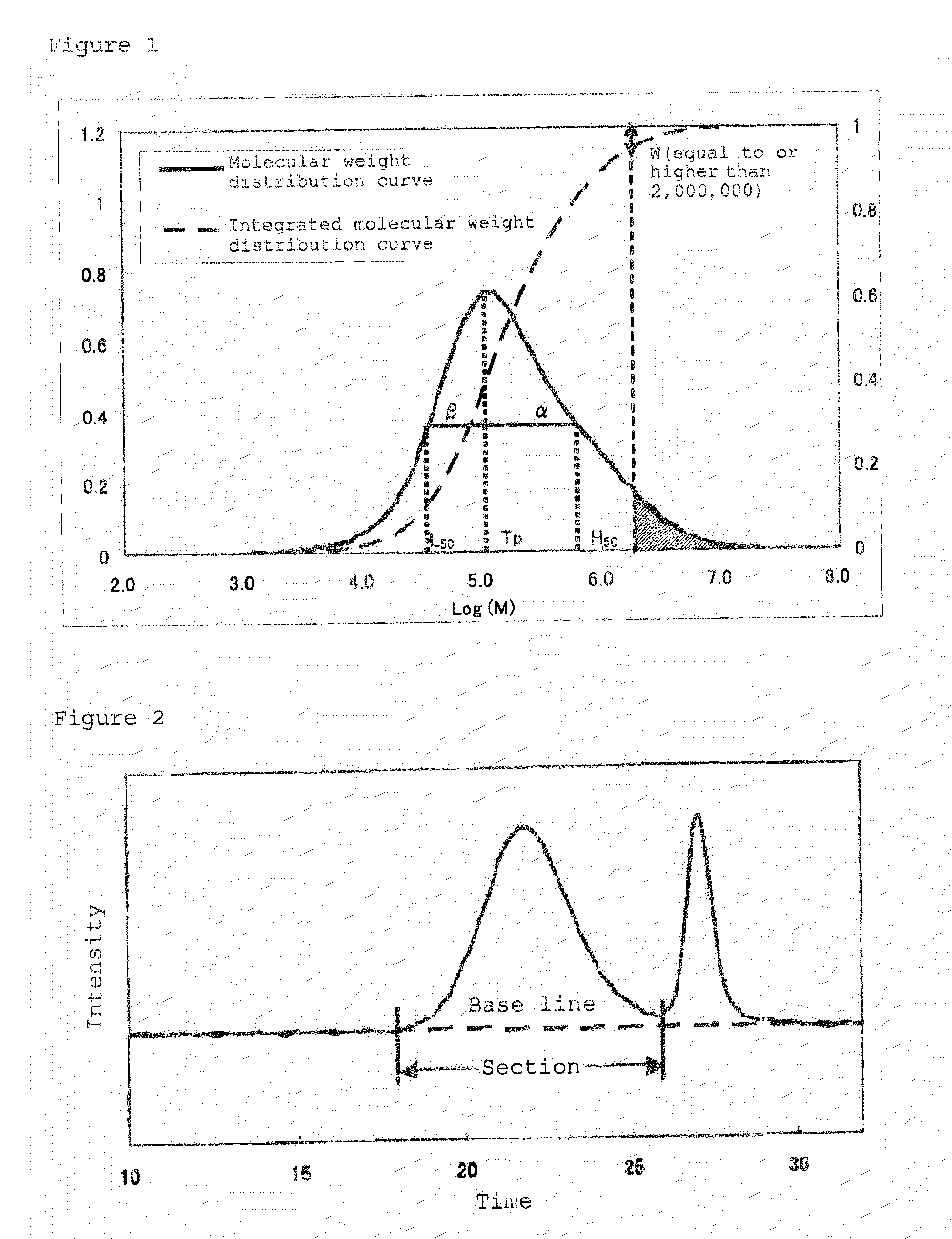

Propylene-based polymer, production method therefor, composition using the same, and application thereof

ActiveUS20100227987A1High melt tensionImprove liquidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationBlow moldingExtensional viscosity

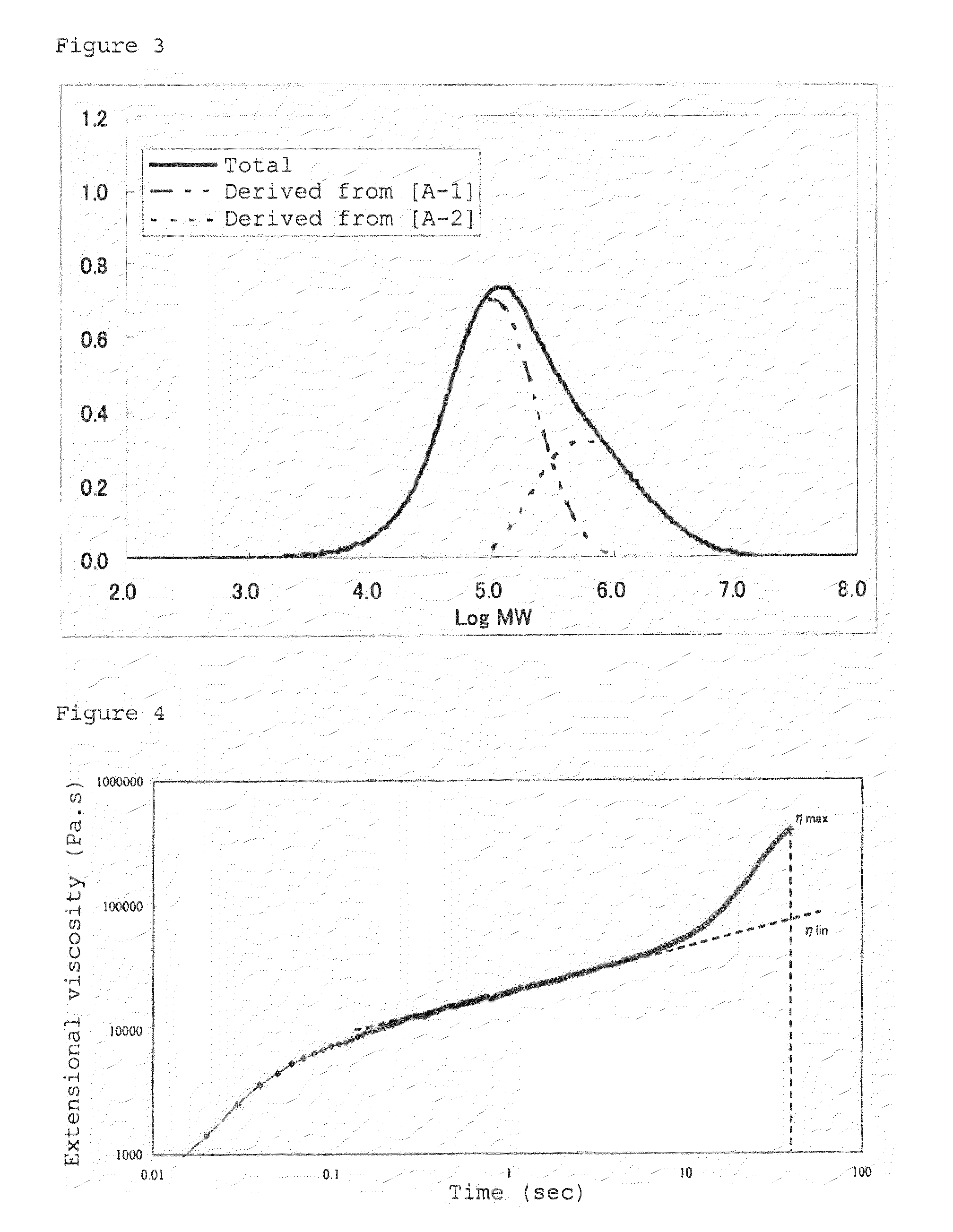

A propylene-based polymer which is suitably applicable to foam molding, sheet molding, blow molding or the like, because of having good flow characteristics, high melt tension, high swell ratio and thus good molding workability.It is attained by a propylene-based polymer or the like characterized by satisfying the following requirements (i) to (vi).Requirement (i): MFR is 0.1 g / 10 minutes to 100 g / 10 minutes.Requirement (ii): Q value by GPC is 3.5 to 10.5.Requirement (iii): ratio of components with a molecular weight of equal to or higher than 2,000,000, in a molecular weight distribution curve obtained by GPC, is equal to or larger than 0.4% by weight and less than 10% by weight.Requirement (iv): components, which elute at a temperature of equal to or lower than 40° C., are equal to or less than 3.0% by weight, in temperature rising elution fractionation by ODCB.Requirement (v): isotactic triad fraction (mm) measured with 13C-NMR is equal to or higher than 95%.Requirement (vi): strain hardening degree (λmax), in measurement of extensional viscosity, is equal to or higher than 6.0.

Owner:JAPAN POLYPROPYLENE CORP

Polypropylene resin composition and expanded molding

ActiveUS9522984B2Excellent characteristicsLight weightThin material handlingExtensional viscosityPolymer science

A polypropylene-based resin composition is provided that can provide a foam molding that exhibits an excellent closed cell characteristic and excellent extrusion characteristics, that is light weight and has a rigid feel, and that has an excellent recyclability.This polypropylene-based resin composition contains 100 weight % or is less than 100 weight % but at least 70 weight % of component (A) below and contains 0 weight % or is greater than 0 weight % but not more than 30 weight % of component (B) below,component (A):a propylene-based resin composition that comprises at least the following two components: a propylene-α-olefin copolymer (A1) satisfying conditions (A-1) to (A-3) and a propylene homopolymer (A2), (A1) and (A2) being obtained by polymerization by a multistage polymerization method, and this propylene-based resin composition having a content of (A1) of 1 to 20 weight % and a content of (A2) of 99 to 80 weight %, having a melt flow rate in the range from 5 to 20 g / 10 minutes and exhibiting strain hardening in a measurement of extensional viscosity at a temperature of 180° C. and a strain rate of 10 s−1,(A-1) an α-olefin content of 15 to 85 weight %,(A-2) an intrinsic viscosity η of 5 to 20 dL / g,(A-3) a Mw / Mn of 5 to 15;component (B):a propylene-based resin composition comprising at least the following two components: a propylene homopolymer or a propylene-α-olefin copolymer having a content of non-propylene α-olefin of less than 1 weight % (B1), which has an MFR of 10 to 1000 g / 10 minutes, and a propylene-α-olefin copolymer (B2) that has a weight-average molecular weight of 500,000 to 10,000,000 and a content of non-propylene α-olefin of 1 to 15 weight %, (B1) and (B2) being obtained by polymerization by a multistage polymerization method, and this propylene-based resin composition having a content of (B1) of 50 to 90 weight % and a content of (B2) of 50 to 10 weight %, and satisfying prescribed conditions (B-1) to (B-3).

Owner:JAPAN POLYPROPYLENE CORP

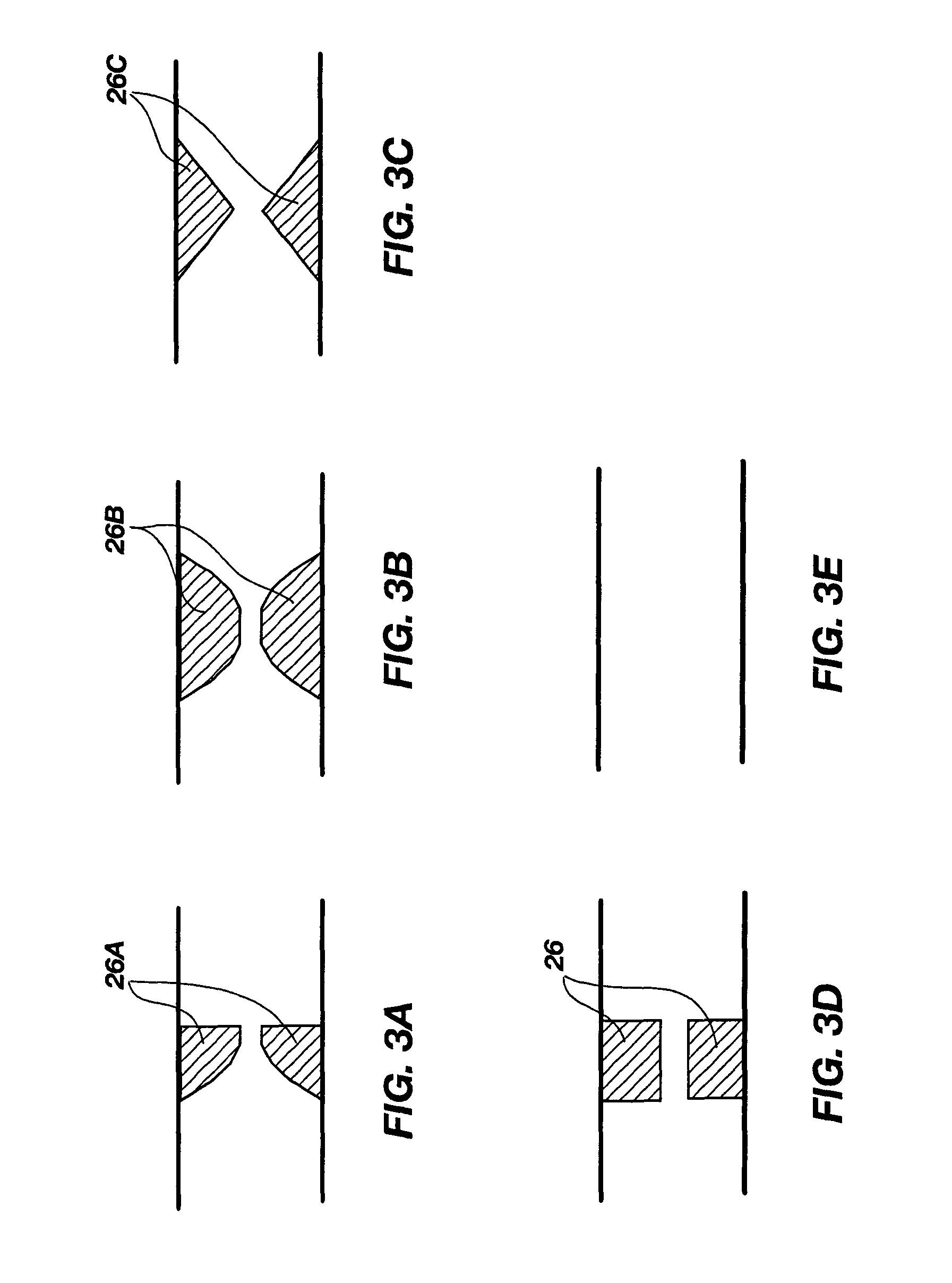

Polyethylene based resin, producing catalyst for the same, method for producing the same, hollow plastic molded article containing polyethylene based resin, and use of the same

ActiveUS20120058288A1Increased durabilityGood moldabilityLayered productsOrganic-compounds/hydrides/coordination-complexes catalystsExtensional viscosityHigh load

A polyethylene based resin exhibiting excellent moldability and durability and having an excellent balance between impact resistance and stiffness; and a hollow plastic molded article using the foregoing resin, which exhibits excellent moldability, durability and barrier properties and has an excellent balance between impact resistance and stiffness, are provided. The polyethylene based resin satisfies the following requirements (1) to (4): (1) a high-load melt flow rate (HLMFR) is from 1 to 100 g / 10 min; (2) a density is from 0.940 to 0.960 g / cm3; (3) a strain hardening parameter λmax of elongational viscosity is from 1.05 to 1.50; and (4) a rupture time in a full notch tensile creep test and a density satisfy the following relational expression (A): log (rupture time)≧−355×(density)+337.6 (A).

Owner:JAPAN POLYETHYLENE CORP

Micro rheometer for measuring flow viscosity and elasticity for micron sample volumes

InactiveUS7770436B2Small sample sizeExtremely cost-effectiveMaterial analysis by optical meansMaterial thermal analysisMeasurement precisionMechanics

A micro-rheometer for measuring flow characteristics such as viscosity, elasticity, and flow rate of a sample liquid combines well defined micro-fabricated flow channels having geometry changes forming a constriction region therein to a monolithically fabricated pressure sensor arrays. The pressure sensor array positions pressure sensors to measure the viscosity of the sample liquid while flowing in a uniform length of the flow passage and to measure the extensional viscosity while flowing through the constriction region of the passage. The invention can improve the measurement accuracy of the flow rate, viscosities, or elasticities over a wide range of shear rate. The accuracy of the viscosity over a broader range of shear rate or flow rate measurement over broader range of flow rates can be accomplished by employing monolithically integrated pressure sensors fabricated with different sensitivities disposed in a known manner. The invention further includes necessary components such as a display, a pumping system, valve manifolds, and software for a portable or laboratory measurement instrument, process control, and high throughput measurements.

Owner:RHEOSENSE

Propylene-based polymer, production method therefor, composition using the same, and application thereof

ActiveUS8080624B2High melt tensionImprove liquidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationBlow moldingExtensional viscosity

A propylene-based polymer which is suitably applicable to foam molding, sheet molding, blow molding or the like, because of having good flow characteristics, high melt tension, high swell ratio and thus good molding workability.It is attained by a propylene-based polymer or the like characterized by satisfying the following requirements (i) to (vi).Requirement (i): MFR is 0.1 g / 10 minutes to 100 g / 10 minutes.Requirement (ii): Q value by GPC is 3.5 to 10.5.Requirement (iii): ratio of components with a molecular weight of equal to or higher than 2,000,000, in a molecular weight distribution curve obtained by GPC, is equal to or larger than 0.4% by weight and less than 10% by weight.Requirement (iv): components, which elute at a temperature of equal to or lower than 40° C., are equal to or less than 3.0% by weight, in temperature rising elution fractionation by ODCB.Requirement (v): isotactic triad fraction (mm) measured with 13C-NMR is equal to or higher than 95%.Requirement (vi): strain hardening degree (λmax), in measurement of extensional viscosity, is equal to or higher than 6.0.

Owner:JAPAN POLYPROPYLENE CORP

Propylene-based polymer and method for producing the same, and propylene-based resin composition

A propylene-based polymer comprising the following component (A) insoluble in p-xylene at 25° C. and component (B) soluble in p-xylene at 25° C., wherein (i) the weight average molecular weight (Mw) measured with GPC is 100,000 to 1,000,000, (ii) the content of the component insoluble in hot p-xylene is 0.3% by weight or lower, and (iii) the degree of strain hardening (λ max) in measurement of elongational viscosity is 2.0 or higher; and a method for producing the same, along with a resin composition comprising a propylene-ethylene copolymer (Z) in an amount of 50.0 to 99.9% by weight and a propylene-based polymer (M) in an amount of 0.1 to 50.0% by weight.Component (A): a component (CXIS) insoluble in p-xylene at 25° C., having requirements specified by (A1) to (A5). Component (B): a component (CXS) is soluble in p-xylene at 25° C., having requirements specified by (B1) to (B4).

Owner:JAPAN POLYPROPYLENE CORP

Cohesive thin liquids to promote safe swallowing in dysphagic patients

PendingCN108902914APromote safe swallowingFood ingredient as antioxidantOrganic active ingredientsExtensional viscosityFood bolus

Nutritional products having improved cohesiveness for promoting safer swallowing of food boluses for patients having swallowing conditions are provided as well as methods of making and using such products. The nutritional products may include nutritional compositions and high molecular weight, water-soluble polymers such that the nutritional products have extensional viscosities that provide improved cohesiveness to the nutritional products. Methods of administering such nutritional products to patients having impaired swallowing ability and / or dysphagia are also provided.

Owner:SOC DES PROD NESTLE SA

Method for the Production of Single-and/or Multiple-Coated Substrates

InactiveUS20080248321A1Expand the scope of useEasy to buildLiquid surface applicatorsPaper coatingCardboardFree falling

A process for the production of singly and / or multiply coated paper and / or board, except for photographic papers and self-adhesive labeling papers, which are particularly suitable for printing, packaging and inscription, is described. The substrate, for example base paper or board, is coated once or several times with a free-falling liquid curtain, the coating liquid having in particular an extensional viscosity of from 1 to 1000 Pa·s at a Hencky strain of from 1 to 15.

Owner:VOITH PATENT GMBH

Stabilized emulsions with acidic agents

ActiveUS20190374444A1Improve stabilityImprove efficiencyCosmetic preparationsMake-upExtensional viscosityPolyol

The combination of polyols with certain active ingredients has been found to mitigate the potential irritating nature of some active ingredients (e.g., hydroxy acids, etc.). When applied to lips, this combination may provide for therapeutic and / or cosmetic benefits including smoother lips, increased moisturization, reduced water loss and combinations thereof. However, formulating stable emulsions with certain active ingredients has proved problematic. The present application also provides new stabilization mechanisms for the emulsions involving alteration of the extensional viscosity of the internal phase.

Owner:AVON PROD INC

Binary surfactant systems for developing extensional viscosity in cleaning compositions

InactiveUS20050272630A1High viscosityIncrease elasticityOrganic detergent compounding agentsSurface-active detergent compositionsExtensional viscositySURFACTANT BLEND

The present invention relates to cleaning compositions having a viscoelastic rheology and, in particular, to hypochlorite compositions having a viscoelastic rheology, which compositions are formulated to have optimized viscosity together with optimized elasticity. The present invention affords a range of rheologies for simultaneously achieving optimal viscosity and optimal elasticity. The inventive composition also provides, when formulated as a drain opener, the advantage of ready penetration through standing water, as well as adherence to partial clogs.

Owner:THE CLOROX CO

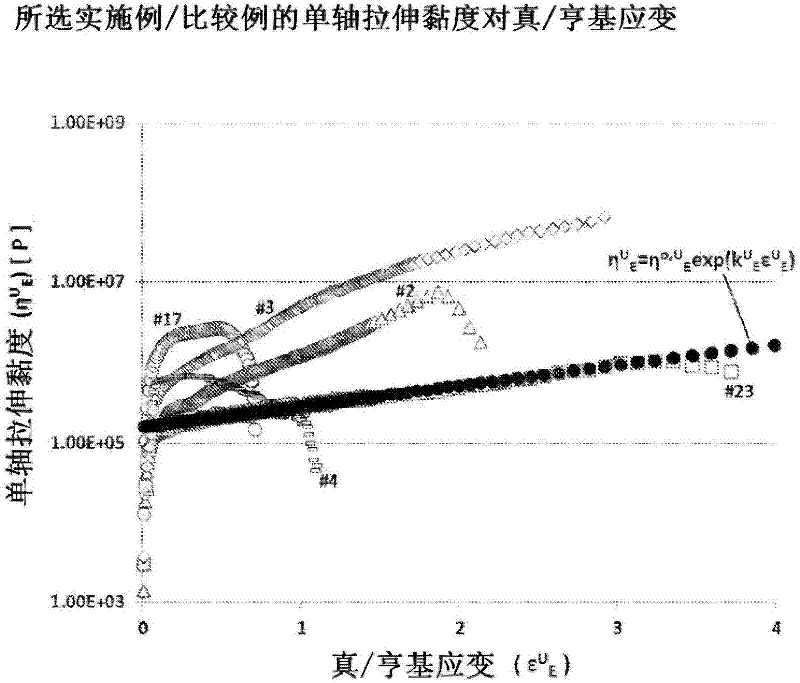

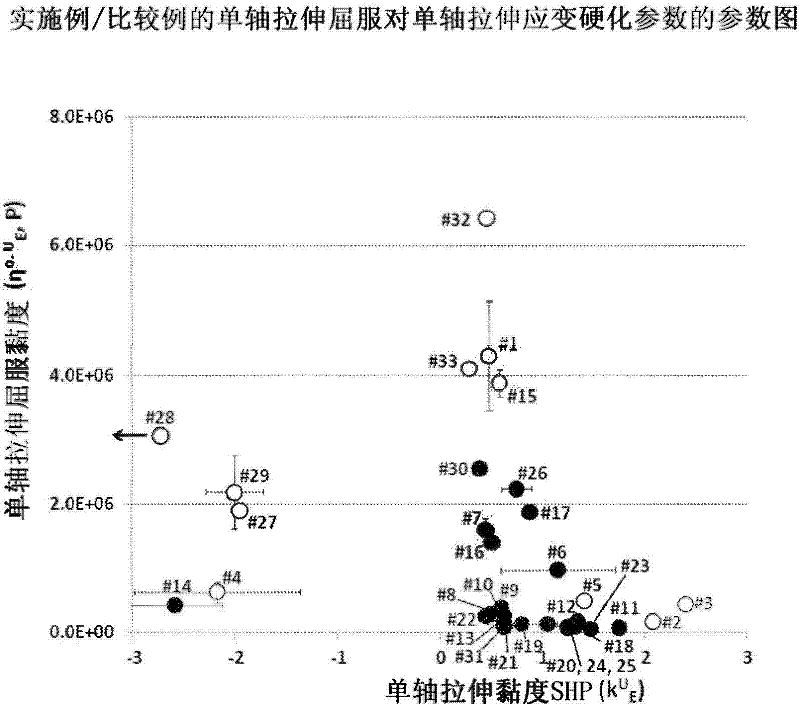

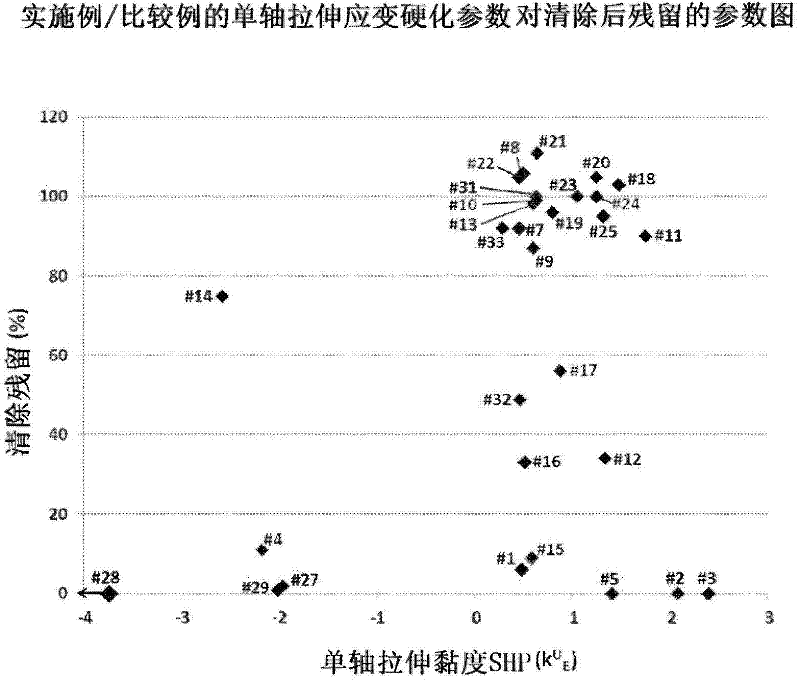

Chewing gums having improved removability based on extensional flow properties

InactiveCN102595922AThe extensional flow properties haveImprove cleanabilityChewing gumExtensional viscosityChewing gum

A chewing gum, when chewed, produces a cud having improved removability from environmental surfaces by virtue of its extensional viscosity strain hardening parameter. Specifically, the cud has a extensional strain hardening parameter of less than zero or greater than 2.0.

Owner:WM WRIGLEY JR CO

Preparation of graft modified high melt elasticity and high extensional viscosity foamed polypropylene material (PP-g-GMA/ST)

The invention relates to a method for preparing a graft modified high melt elasticity and high extensional viscosity foamed polypropylene material (PP-g-GMA / ST). Dicumyl peroxide is adopted as an initiator for hydrogen elimination reaction to form a PP macro-radical bond; the radical bond may generate graft or chain scission reaction; the reaction activity of ST serving as a co-initiator is higher than that of GMA; the ST is grafted to the PP in priority; after a more stable styryl macro-radical is formed, the styryl macro-radical is reacted with glycidyl methacrylate to realize the branching of polypropylene in a double screw extruder serving as a reactor; and the grafting rate of the PP can be improved. The method can prepare the graft modified high melt elasticity and high extensional viscosity foaming polypropylene material (PP-g-GMA / ST). The PP with high grafting rate can improve the melt strength and the extensional viscosity of a PP system and the strain hardening. The high melt strength and high extensional viscosity can promote the stable increase of air bubbles, block the rapid diffusion of air, reduce the combination of the air bubbles, limit the breakage of bubble pores, and improve the foaming molding of the PP material. The added inorganic nano nucleating agent refines crystal grains of a polypropylene structure, destroys polypropylene crystallinity to strengthen the viscosity of a fusant when the polypropylene is heated and melted, and enlarges a temperature range suitable for foaming molding.

Owner:林世平

Polypropylene-based resin sheet and formed object

ActiveUS20170029611A1High forming temperatureLow of base materialExtensional viscosityHeat resistance

A polypropylene resin sheet which shows sufficiently reduced drawdown with excellent melt elongation and further has good heat resistance and good appearance. The polypropylene resin sheet may be formed from a polypropylene resin composition, the polypropylene resin composition containing: 60% to 97% by weight of a first polypropylene resin having a melt flow rate range of 0.1 to 10 g / 10 min, and 3% to 40% by weight of a modified polypropylene resin having a elongational viscosity ratio to the first polypropylene resin of at least 1.5, at a strain of 3, obtained by melt kneading a second polypropylene resin, a conjugated diene compound, and a radical polymerization initiator.

Owner:KANEKA CORP

toner

Provided is a toner including a toner particle containing an amorphous resin, a colorant, a release agent, and a crystalline resin, wherein, when η0.01 represents the extensional viscosity of the toner at a Hencky strain at 90° C. of 0.01 and η0.69 represents the extensional viscosity of the toner at a Hencky strain at 90° C. of 0.69, η0.01 and η0.69 satisfy the relationships of the following formulas (1) and (2):3.0×104 Pa≦η0.01≦2.0×105 Pa formula (1)2.0≦[η0.69 / η0.01]. formula (2)

Owner:CANON KK

Inner liner for pneumatic tires, method for producing same, and pneumatic tire

ActiveCN103648798AExcellent melt formabilityExcellent gas barrier performanceWithout separate inflatable insertsSpecial tyresExtensional viscosityElastomer

A purpose of the present invention is to provide an inner liner for pneumatic tires, which has excellent melt moldability and thus has high gas barrier properties and is capable of maintaining the characteristics such as the gas barrier properties even in cases where the inner liner experiences deformation such as stretching or bending when in use. Another purpose of the present invention is to provide a method for producing an inner liner having the above-mentioned characteristics, while suppressing increase of the production cost. The present invention is an inner liner for pneumatic tires, which comprises eight or more resin layers, and which is characterized in that: the inner liner comprises, as the resin layers, a layer (A) that is formed of a resin composition containing a gas barrier resin and a layer (B) that is arranged adjacent to the layer (A) and formed of a resin composition containing an elastomer; both of the elongational viscosity (EtaA) of the resin composition of the layer (A) and the elongational viscosity (EtaB) of the resin composition of the layer (B) at a predetermined temperature are 1,000 Pas or more; and the elongational viscosity ratio EtaA / EtaB is 0.2-10 (inclusive).

Owner:KURARAY CO LTD +1

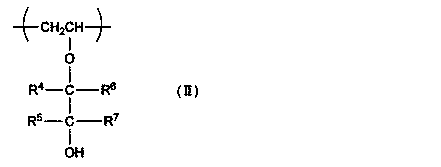

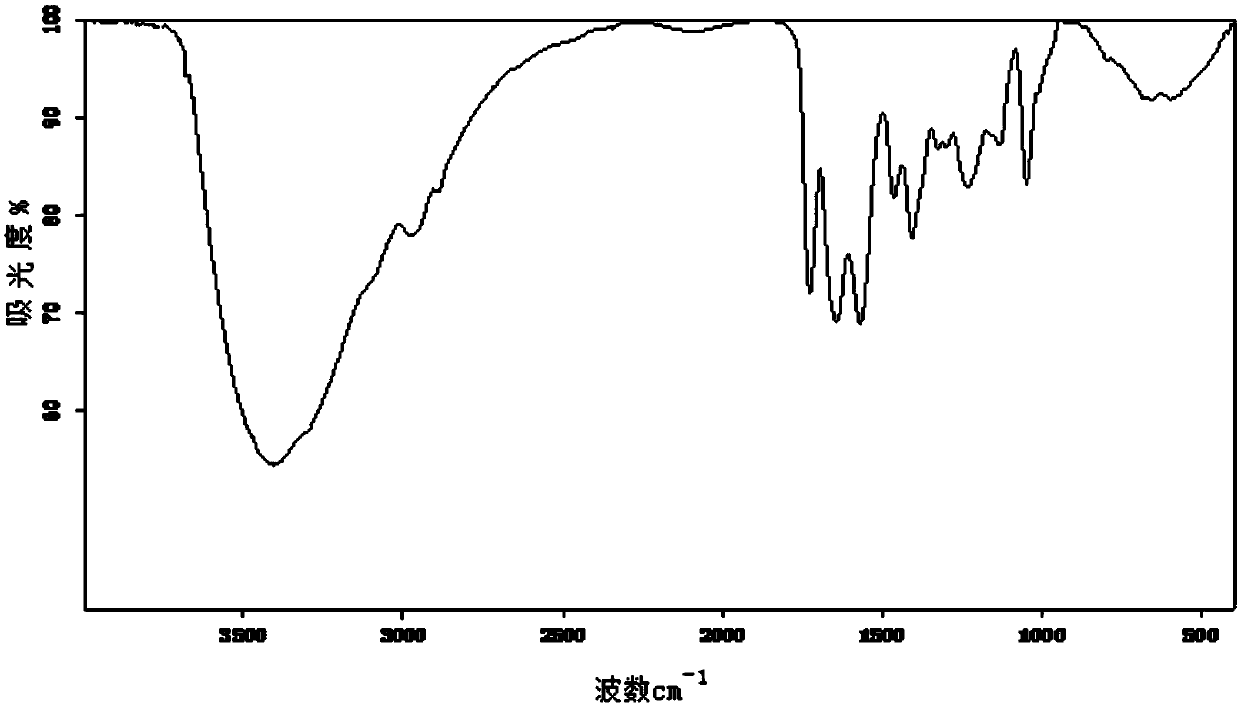

Preparation method of amino-terminated hyperbranched aliphatic polyester and application thereof

The invention relates to a method for amino-terminated hyperbranched polyester, in particular relates to a method for preparing amino-terminated hyperbranched aliphatic polyester and application thereof, and belongs to the technical field of hyperbranched polymer synthesis. The method for preparing the amino-terminated hyperbranched aliphatic polyester comprises the following steps: adding a certain amount of hydroxyl-terminated hyperbranched aliphatic polyester and high melting point amino carboxylic acid into a reaction container, heating and melting at a heating temperature of 80-180 DEG C,adding a certain metering ratio of catalyst into a reaction system, continuing the reaction for 3-10 hours under the conditions of stirring and vacuumizing, and cooling to obtain a target product. The method has the beneficial effects that the hardness of conventional epoxy resin sold on the market is improved, the reactivity of the terminal amino group and the epoxy group of the epoxy resin is better, and the obtained epoxy resin has good tensile strength, elongation at break and tensile viscosity strength under the same test conditions.

Owner:WEIHAI CY DENDRIMER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com