Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Stringiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A palpable tissue texture abnormality characterized by fine or string-like myofascial structures.

Dental bleaching compositions having long-term rheological stability and devices, kits and methods that utilize such compositions

ActiveUS20080025925A1Improve adhesionReduce stringinessCosmetic preparationsToilet preparationsHigh concentrationPolyethylene oxide

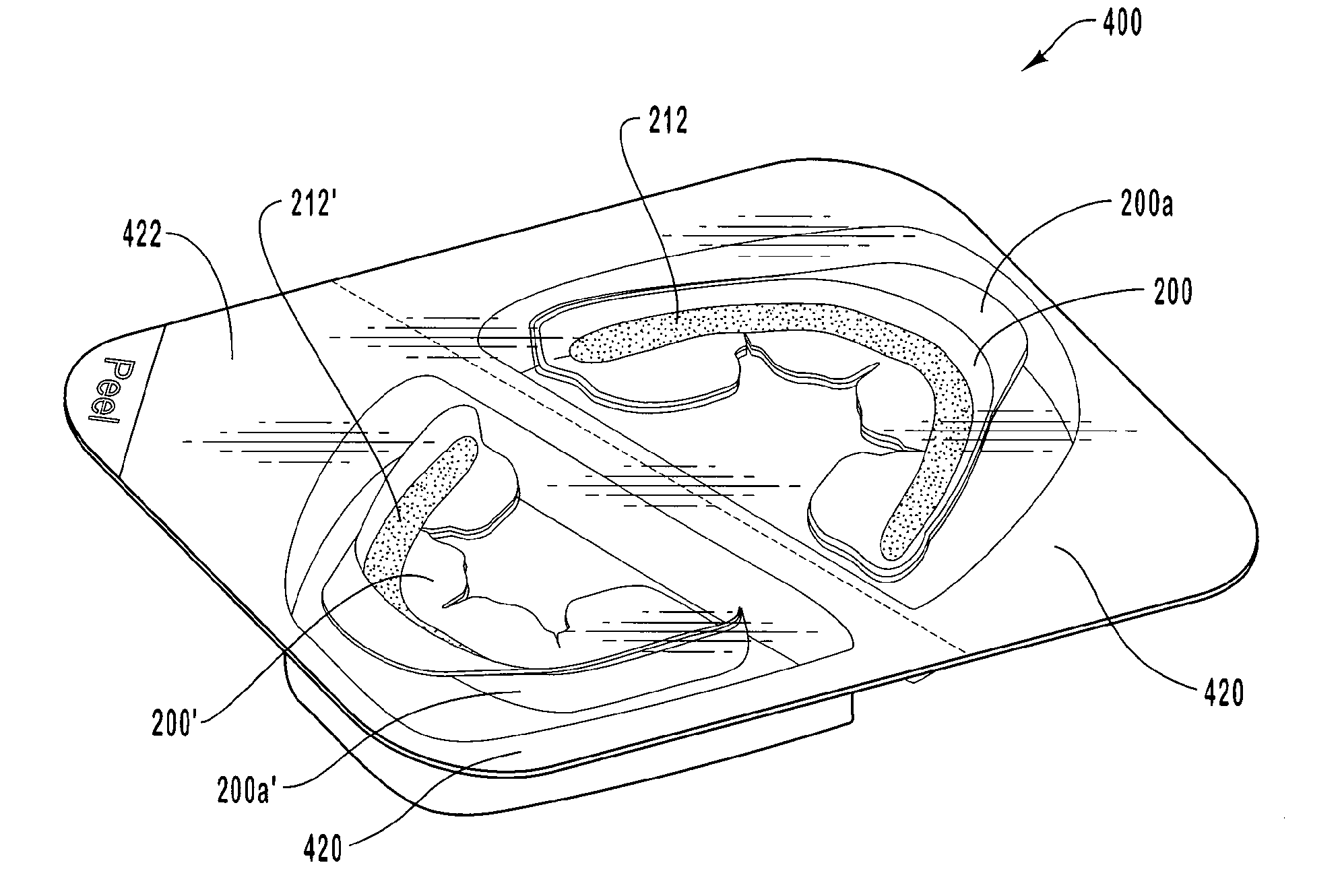

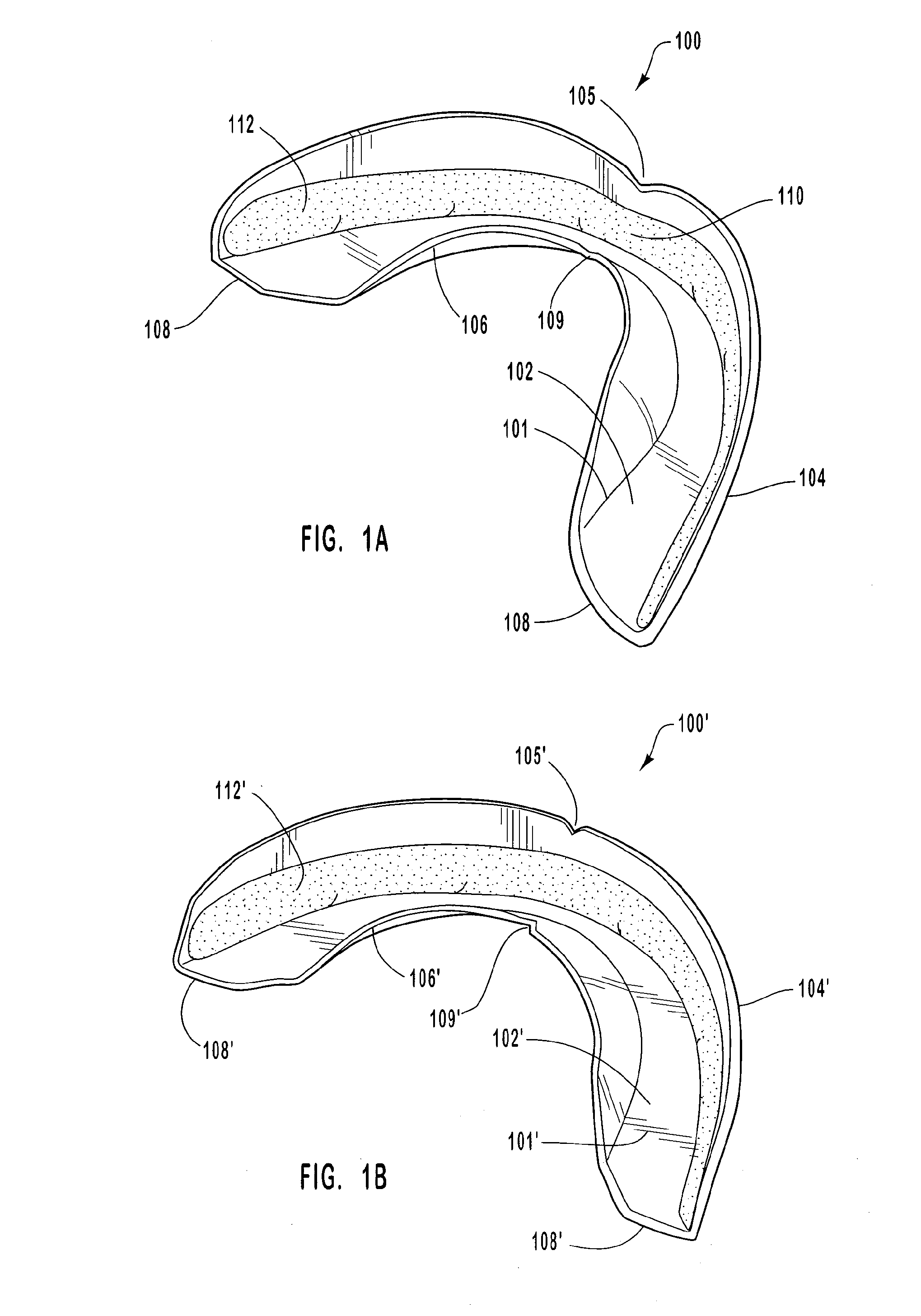

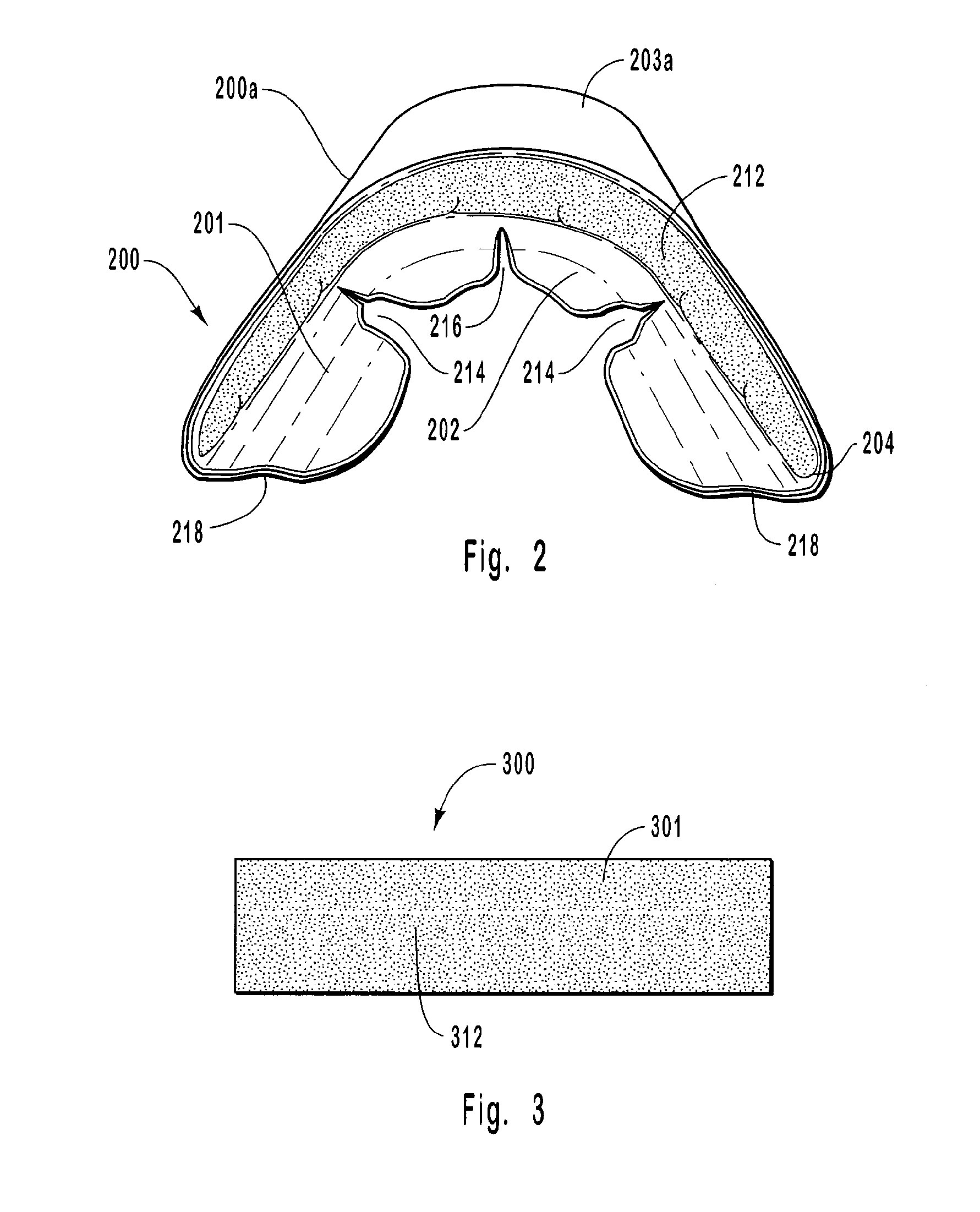

Dental bleaching compositions include a dental bleaching agent, a generally linear high molecular weight (i.e., greater than about 500,000) polyvinyl pyrrolidone (PVP) and / or polyethylene oxide (PEO) tissue adhesion agent included in amount that imparts a high level of adhesiveness, a rheology-modifying agent such as fumed silica or fumed alumina that reduces or eliminates stringiness otherwise caused by the high molecular weight PVP and / or PEO, and a solvent or carrier. Dental bleaching compositions may include carboxypolymethylene instead of or in addition to PVP and / or PEO, wherein the fumed silica or fumed alumina increases long-term rheological stability even in the presence of a high concentration of dental bleaching agent. Dental treatment devices including a barrier layer and a quantity of the dental bleaching composition positioned adjacent to the barrier layer.

Owner:ULTRADENT PROD INC

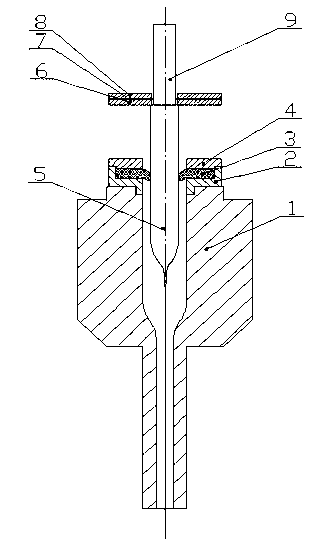

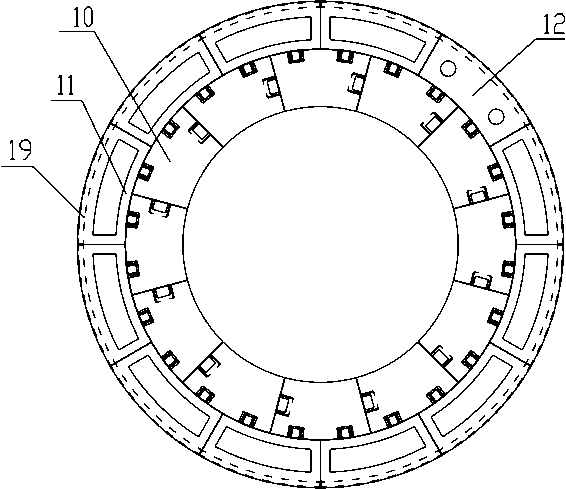

Wiredrawing method and wiredrawing device for outer diameter fluctuation optical fiber perform

ActiveCN102838275AStable airflowIncrease the drawing lengthGlass fibre drawing apparatusGlass productionEngineeringLarge size

The invention relates to a wiredrawing method and a wiredrawing device for an outer diameter fluctuation optical fiber perform, particularly a large-size outer diameter fluctuation optical fiber perform. Compared with an existing wiredrawing method, the wiredrawing method has the different points that a radial seal adjustable device is arranged at a furnace mouth at the upper end of a heating cavity of a wiredrawing furnace; and in the wiredrawing process, the optical fiber perform is clung to the radial seal adjustable device, so that a radial gap between the optical fiber perform and the radial seal adjustable device, i.e. the difference between the outer diameter of the optical fiber perform and the seal aperture of the radial seal adjustable device, is kept in the range of 0 to 0.2mm. According to the invention, the radial gap between the large-size perform with nonuniform outer diameter variation and the radial seal adjustable device is always kept in a small allowable gap range or tends to zero in the wiredrawing feeding process, so that the wiredrawing quality is ensured and the technical difficult problem that the large-size outer diameter fluctuation optical fiber perform cannot be directly subjected to wiredrawing processing is solved; and the yield and the processing efficiency of optical fibers are further improved and the stringiness of the single perform is also improved, so that the optical fiber manufacturing cost is further reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Method for preparing platy or lump processed cheese and cheese obtained

ActiveCN101564062AMaintain drawabilityLow heating temperatureCheese manufactureEngineeringBrowning reaction

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improves the prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD

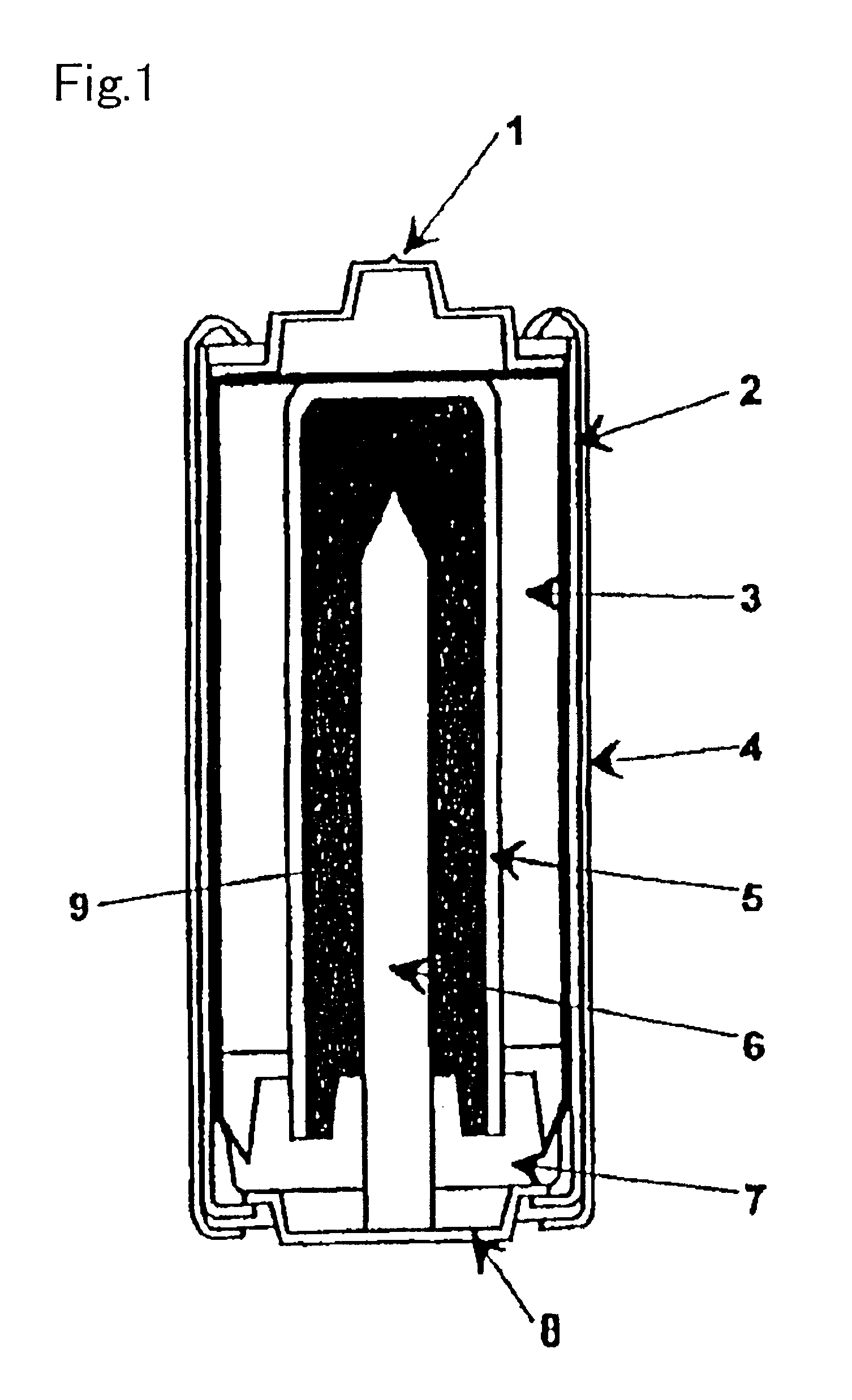

Gelating agent for alkaline cell and alkaline cell

InactiveUS6667133B1Excellent in stringiness of solutionIncrease speedActive material electrodesAlkaline accumulator electrodesCross-linkMeth-

A gelating agent for an alkaline cell is a cross-linked polymer (A) comprising (meth)acrylic acid and / or its alkali metal salt as a main constituent monomer unit and obtained by an aqueous solution polymerization or a reversed phase suspension polymerization and satisfies the following required conditions (1), (2). The gelating agent has good draining property, satisfactorily high speed charging property of the alkaline electrolytic solution and is therefore effective to produce cells with little unevenness of the charging amount of the electrolytic solution and having uniform quality by mass production and an alkaline cell using the gelating agent is provided with durable discharge time and remarkably excellent impact resistance for a long duration. The said required conditions are required condition (1); that the gelating agent contains 50% by weight or more of a particle whose swollen particle size becomes 300 to 4,000 mum when the gelating agent is swollen in an aqueous potassium hydroxide solution of 40% by weight concentration and required condition (2); that the aqueous potassium hydroxide solution of 40% by weight concentration containing 3% by weight of the gelating agent has 0 to 20 mm stringiness.

Owner:SANYO CHEM IND LTD

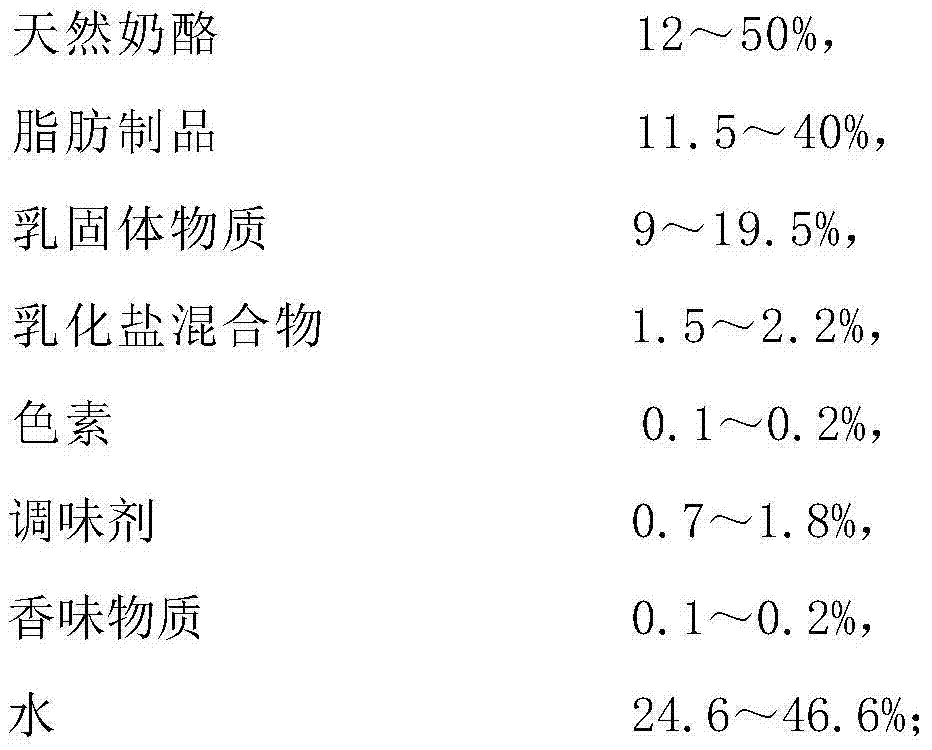

Remade cheese with long shelf life and preparation method thereof

The invention discloses a remade cheese with a long shelf life and a preparation method thereof. The remade cheese comprises the following components and respective content: 12-50 percent of natural cheese, 11.5-40 percent of fat product, 9-19.5 percent of milk solid substance, 1.5-2.2 percent of emulsifying salt mixture, 0-0.2 percent of pigment, 0-1.8 percent of flavoring agent, 0-0.2 percent of flavor component and 24.6-46.6 percent of water. The preparation method of the remade cheese comprises the following steps: (1) shearing all of the raw materials except the fat product and the natural cheese, and premixing the sheared product; (2) adding the fat product and the natural cheese into the premixed slurry, and heating and stirring the mixture for emulsification; (3) quickly cooling the emulsified product and subjecting the cooled product to cold storage; and (4) subjecting the product obtained in the step (3) to cutting, package, sterilization under ultrahigh pressure and cold storage. In order to overcome the defects of poor wire-drawing property, short shelf life during cold storage and the like of the traditional remade cheese, the invention provides the remade cheese with excellent wire-drawing property and long shelf life.

Owner:SHANGHAI JIAO TONG UNIV

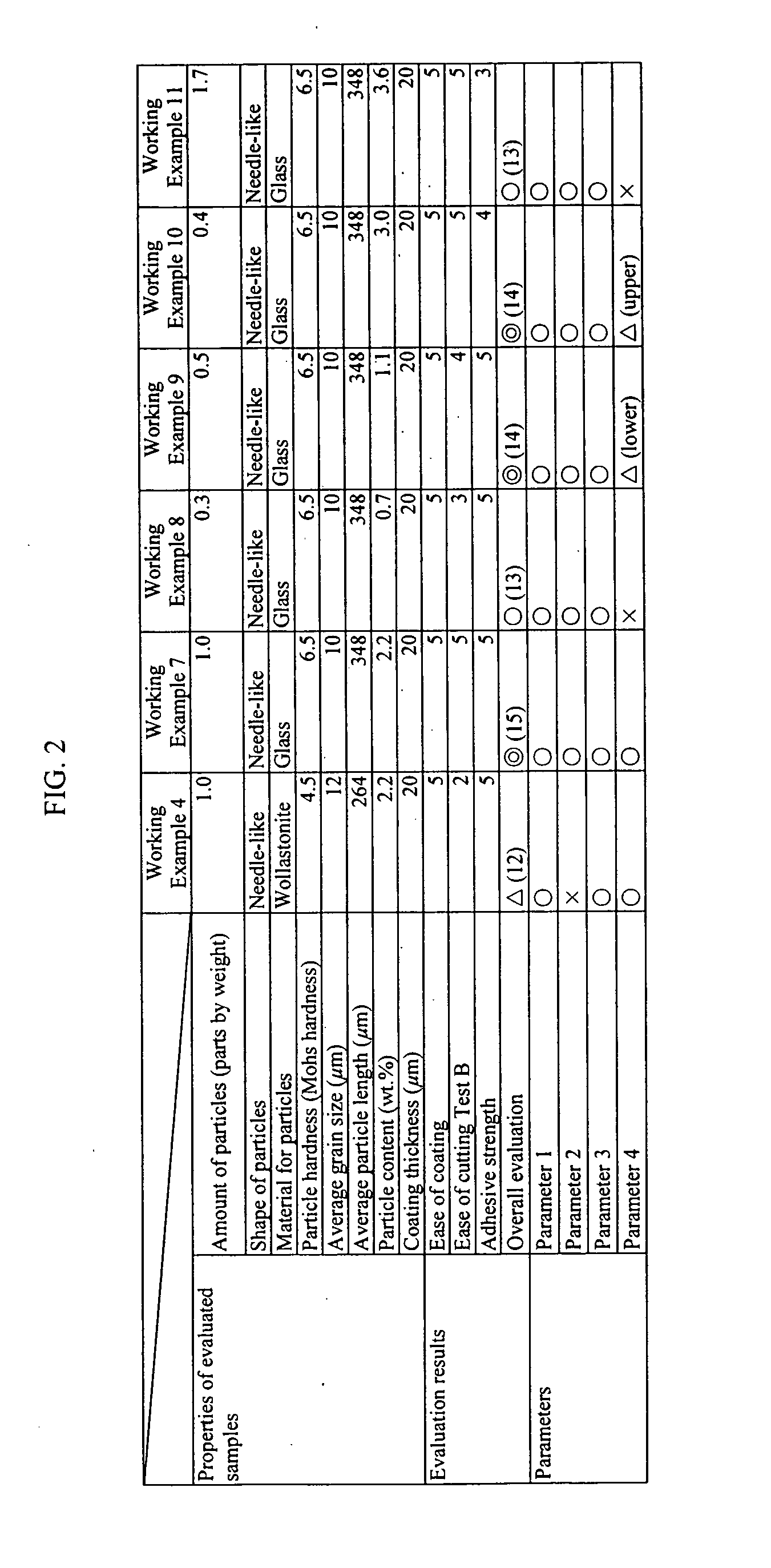

Transfer tape

InactiveUS20040180196A1Non-macromolecular adhesive additivesFilm/foil adhesives without carriersBand shapeEngineering

[An object of the present invention is] to provide transfer tape that maintains strong adhesive strength but can be reliably cut at a stipulated position. The adhesive film contains needle-shaped particles. If the adhesive strength is made high, then the adhesion between the adhesive ingredients is increased, thus forming a film that is difficult to cut. If a force is applied to the band-shaped ribbon in a direction outside the plane in which the adhesive coating is applied, then the film of the adhesive coating becomes thin and the needle-shaped particles rupture the film and cut the adhesive film. Moreover, the cut adhesive film draws the cut end to the needle-shaped particles, and as a result it is cut completely without stringiness.

Owner:GENERAL CO LTD

Cheese-like food for baking

Disclosed are a heat-tolerant cheese-like food, which shows a characteristic stringiness, similar to the texture of a stringy natural cheese in a heat-melted state, even after cooling down, and shows no change in appearance or shape after baking; and a method for producing the same. The heat-tolerant cheese-like food, which shows a characteristic stringiness, similar to the texture of a stringy natural cheese in a melted state, even in the case of substantially containing no such a natural cheese, and shows no change in appearance or shape after baking, can be obtained by preparing a cheese-like food comprising, each in a specific amount, of three components, i.e., a heat-set protein, milk protein and etherified tapioca starch. A cheese-like food having a favorable fermented flavor and characteristic stringiness can be obtained by preparing a cheese-like food which comprises a lactic acid fermentation broth containing a heat-set protein.

Owner:FUJI OIL CO LTD

Oral composition containing crystalline cellulose surface-treated with water-soluble substance

InactiveCN101563064ADisperse fastGood shape retentionCosmetic preparationsToilet preparationsCelluloseAdditive ingredient

The invention relates to an oral composition, particularly a dentifrice composition, which contains crystalline cellulose surface-treated with a water-soluble substance and is excellent in shape retention and dispersibility in the oral cavity. The oral composition of the invention can be favorably placed on a brush such as a toothbrush because it has low spinnability, and also enables blended components to immediately disperse throughout the oral cavity when it is used in the oral cavity, therefore, an active ingredient can be dispersed throughout the oral cavity for longer time, and a favorable feeling of use can be provided.

Owner:SUNSTAR KK

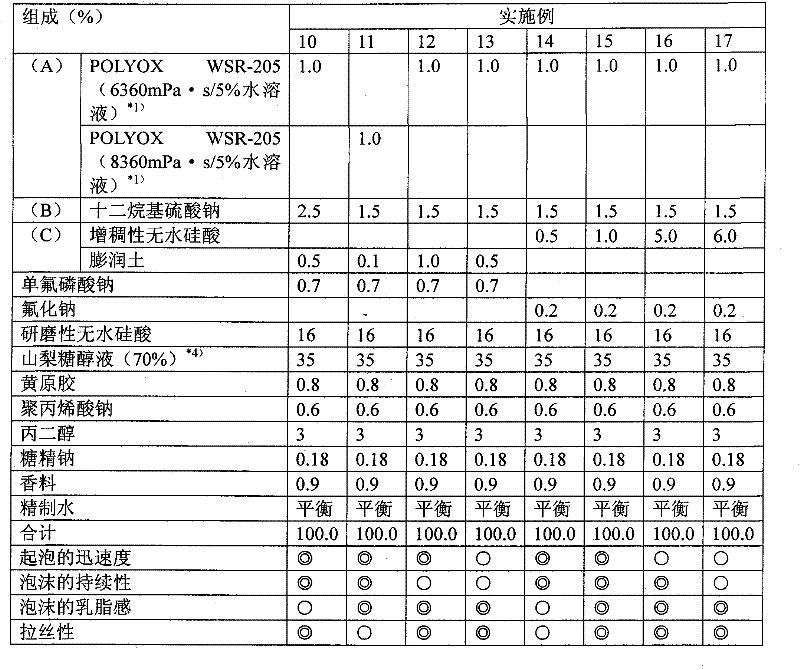

toothpaste composition

ActiveCN102264343AImprove fastnessExcellent foaming speedCosmetic preparationsToilet preparationsToothpastePolymer chemistry

Provided is a toothpaste composition that foams quickly with brushing, that has excellent foam stability and creaminess, and that has excellent ease of application to the toothbrush (no stringiness).

Owner:LION CORP

Gelating agent for alkaline cell and alkaline cell

Owner:SANYO CHEM IND LTD

Formula and preparation method of water seepage emulsion

InactiveCN104825377AStrong drawingGood drawing effectCosmetic preparationsToilet preparationsBetaineAdditive ingredient

The invention discloses a formula of a water seepage emulsion. The water seepage emulsion is composed of the following raw materials by weight: 1-15% of glycerin, 1-10% of butylene glycol, 1-10% of betaine, 1-5% of olive oil, 1-5% of jojoba oil, 1-5% of polydimethylsiloxane, 1-5% of caprylic / capric triglyceride, 0.01-1% silk protein glue, 0.5-5% of a snail extracted liquid, 0.01-0.5% of hyaluronic acid, and the balance water. The water seepage emulsion provided by the invention has the advantages that: 1. the product has very strong stringiness, can have obvious drawing effect and generating a lot of water drops simultaneously by taking a small amount of the emulsion to flap on hands or on the face; and 2. the product contains multiple moisturizing ingredients, and can achieve excellent moisturizing effect by release of the water drops produced by flapping.

Owner:上海彤颜实业有限公司

Antistatic polyester and nylon composite superfine fiber and production method thereof

ActiveCN103320896AHigh tensile strengthGood drawingElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsTextile fiberPolyester

The invention discloses an antistatic polyester and nylon composite superfine fiber and a production method thereof. The antistatic polyester and nylon composite superfine fiber is composed of a superfine polyester fiber as a core wire and a denatured nylon 6 fiber layer coating outside the core wire, and an antistatic nanopowder material is arranged in the externally-coated denatured nylon 6 fiber layer; and the denatured nylon 6 is obtained through adding a silica nanopowder material under the active catalysis of a cerium oxide nanopowder material. The result of experimental tests on the antistatic polyester and nylon composite superfine fiber obtained through the production method shows that the surface resistivity of the antistatic polyester and nylon composite superfine fiber is in a range of 10<7>-10<9>, and the provided denatured nylon 6 increases the tensile strength of nylon 6, so the stringiness of nylon 6 is good, thereby the coating wire drawing of nylon 6 and the superfine polyester fiber is realized, and textile fibers obtained through the coating wire drawing have the characteristic advantages of polyester, has the characteristic advantages of nylon and also has a good antistatic effect.

Owner:宁波三邦日用品有限公司

Method for reducing stringiness of a resinous composition during hot plate welding

InactiveUS20080283189A1Good lookingImprove adhesionLamination ancillary operationsLaminationPhysical chemistryStringiness

Disclosed is a method for reducing stringiness during hot plate welding of an article comprising a resinous composition which comprises at least one step of contacting with water a surface of the article to be welded. The method also results in improved cycle time for preparation of the final article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Emulsifier blend and process for making rapidly soluble instant beverage products

A novel dissolution agent, and its use in the manufacture of instant (flavored and unflavored) beverage products, (coffee, hot chocolate, teas, creamy juice drinks, milk shakes, nutritional drinks, and the like, especially instant coffee products), that have improved mouthfeel ('creaminess', 'richness', 'body', 'complexity', 'body-richness', 'substantial') and thickness, without 'sliminess' or 'stringiness'. This novel dissolution agent may also be used to make a binder solution that will be used during manufacturing in the agglomeration process. The instant beverage products made according to the present invention, (especially preferred are instant coffee products), can deliver a creamy, rich, preferably foamy, beverage with a clean, improved mouthfeel and thickness without 'sliminess' or 'stringiness', as well as a higher flavor impact, at a lower dosage of solids (5-10%, preferably 6.5-8.5%, and more preferably 7.5%).

Owner:THE PROCTER & GAMBLE COMPANY

Low-Stringiness Thickener and Cosmetic Material Admixed with Said Thickner

InactiveUS20160250131A1Reduce stringinessGood spreadabilityCosmetic preparationsToilet preparationsALLYL SUCROSEStringiness

The present invention was aimed to provide a low-stringiness thickener consisting of a compound in high demand as a thickener for cosmetics, i.e., polyacrylic acid or a salt thereof, or PAMPS or a salt thereof, where a stringiness property of the compound was reduced.A low-stringiness thickener consisting of a compound selected from polyacrylic acid. a salt of polyacrylic acid, PAMPS, and a salt of PAMPS, wherein the weight-average molecular weight of the compound is 500 thousand to 8 million, and wherein the content of the compound having the molecular weight of 10 million or higher is 10 mass % or less.

Owner:SHISEIDO CO LTD

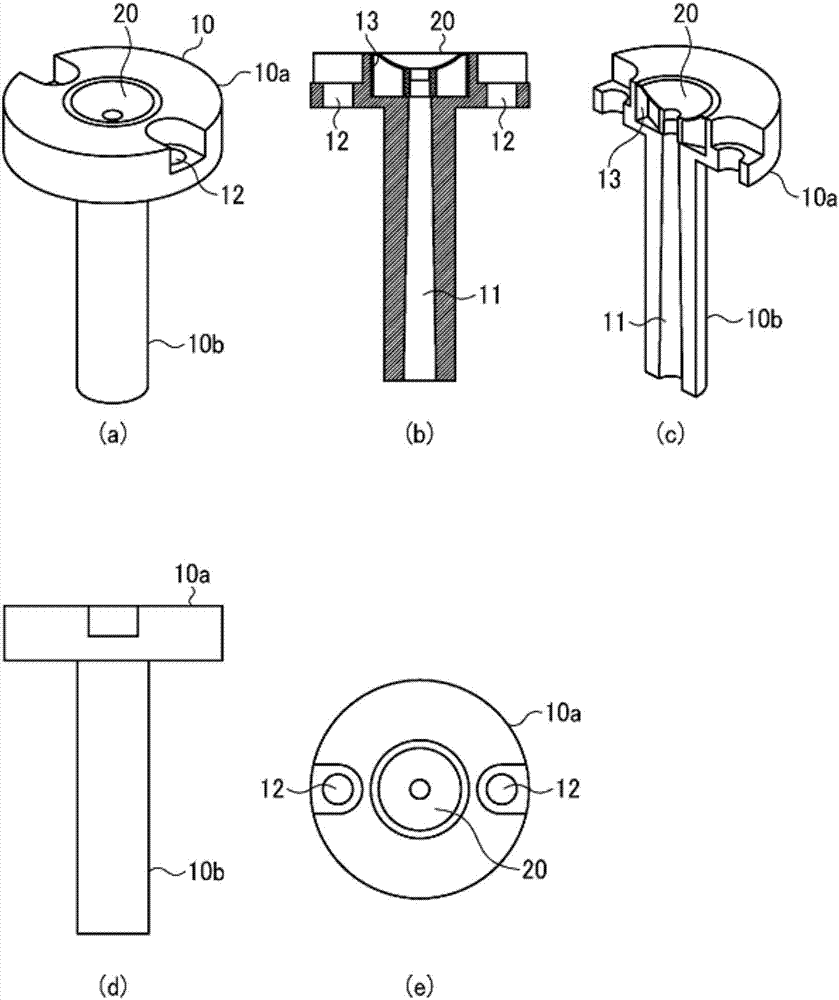

Sprue bush and bush part therof

Provided is a new sprue bush capable of preventing stringiness. The sprue bush attached to a mold for molding synthetic resin is provided with: a sprue bush body (10) having a flow path for the synthetic resin injected from an injection molding nozzle and having a concave part (13) on a surface thereof on a side where the synthetic resin is to be poured; and a bush part (20) embedded in the concave part (13). The bush part (20) has a nozzle contact surface (21) where the injection molding nozzle contacts, a through-hole (22) extending from an opening of the nozzle contact surface (21) and communicating with a flow path of the spur bush body to form the flow path for the synthetic resin, and a plurality of ribs (23) extending radially from an inner peripheral surface of the through-hole toan outside.

Owner:PLA MOUL SEIKO

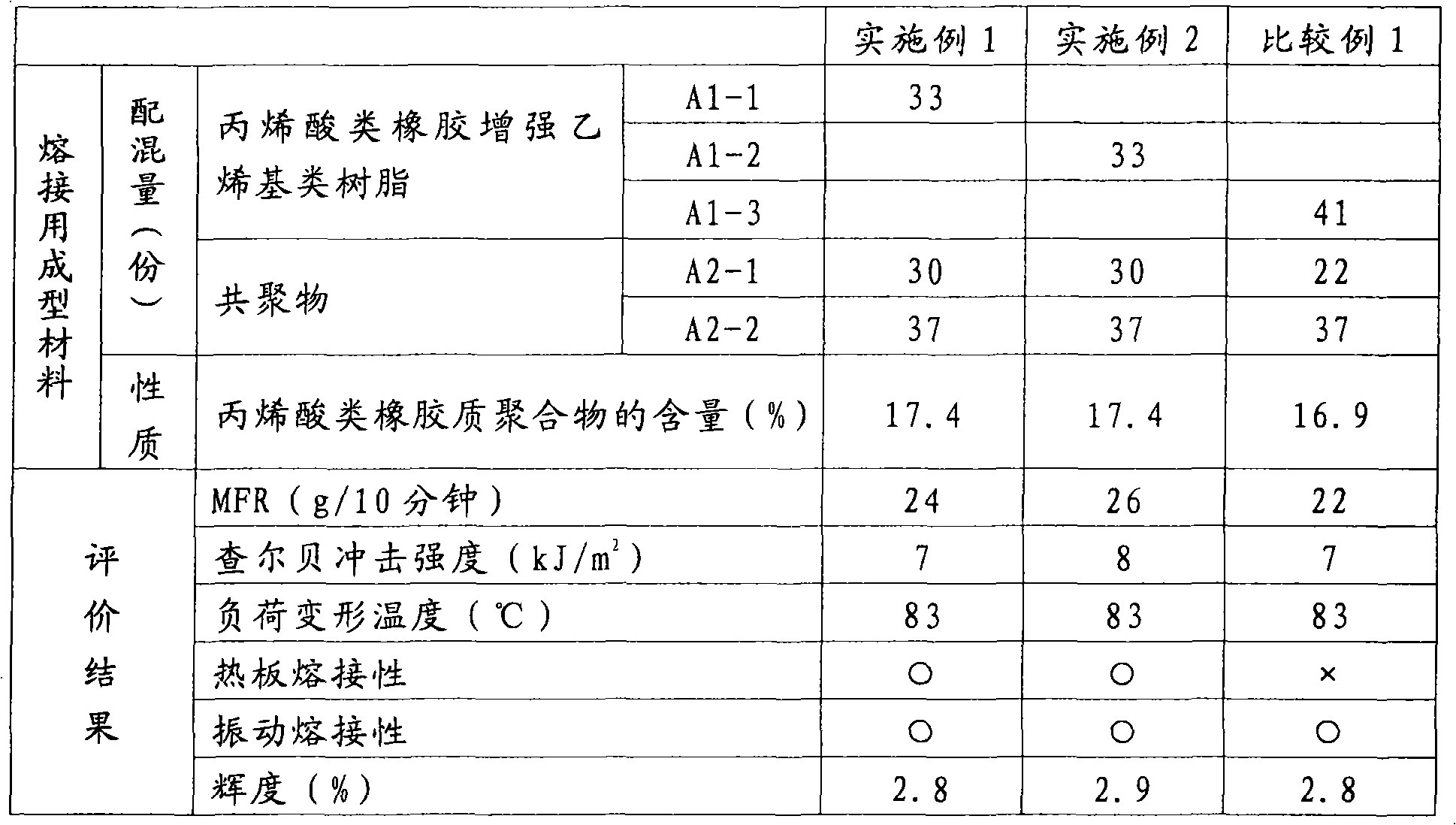

Molding material for welding

A molding material for welding which, when used for bonding resin parts to each other by a welding method such as vibration welding or hot plate welding, can be prevented from developing a (string) burr or from showing stringiness or the like between the welding part of a hot die, e.g., a hot plate, and a housing-constituting material. The molding material can hence diminish appearance failures. The molding material comprises either a rubber-reinforced resin obtained by polymerizing vinyl monomers comprising an aromatic vinyl compound and a vinyl cyanide compound in the presence of an acrylicrubbery polymer having a gel content less than 70% or a mixture of the rubber-reinforced resin and a (co)polymer of a vinyl monomer. The content of the acrylic rubbery polymer in the molding materialis 5-40 mass% based on the whole molding material.

Owner:大科能宇菱通株式会社

Cheese-containing food and method for producing same

InactiveCN102781247AGood dispersionIncrease consumptionCheese manufactureFood preparationAdditive ingredientFood material

Provided are a production method, whereby a cheese-containing food allowing consumers to easily enjoy the texture of natural cheese and so on can be produced, and the cheese-containing food produced by said method. The production method comprises crushing a cheese, mixing the same with a powdery soup stock and ingredients (food materials to be used as ingredients in soup), and pressurizing and reshaping the resulting mixture. A soup, which allows consumers to enjoy the texture and stringiness of natural cheese, can be prepared by putting the cheese-containing food obtained by the aforesaid production method in a cup, etc., pouring an appropriate amount of hot water and thus dissolving the food. Thus, an instant soup product, which allows consumers to easily enjoy the texture of natural cheese and so on, can be obtained and the scope of cheese intake at home can be broadened.

Owner:MEIJI CO LTD

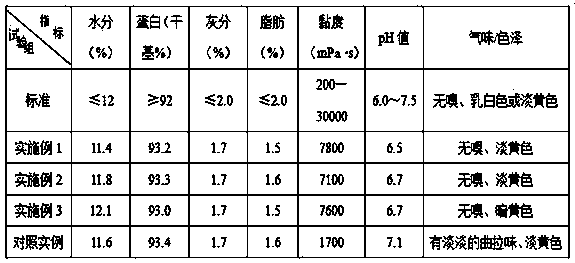

Production method for modified casein

The invention discloses a production method for modified casein. Qula casein is directly used as a raw material and is puffed through an extruder to produce the modified casein, so that the wire drawing property of the qula casein is effectively improved and is doubled, so that the standard of fresh milk casein is basically met. The emulsibility, the dissolving property and the viscosity of the qula casein are enhanced, and the casein production technology and the quality of a product are improved; the problems of low dissolving property, odor of the product and the like of conventional qula casein are solved; meanwhile, the obtained modified casein product is high in viscosity and high in flowability; the product has a bright color, smells normally, is crystalline, has a good dissolving characteristic, and can meet a high product quality standard; all physical and chemical indexes such as proteins, fat and ash meet the standard.

Owner:GANSU PULUO BIOTECH

Nozzle for use in hot runner mold

A nozzle (26) for a hot runner mold (10) having a cavity (29) and a runner (27) formed in a body (24) thereof and communicating with the cavity. The nozzle leads to the runner and has a heating means (36), a heat-insulating groove (37), and a heat transmitting ring (38) provided on an outer peripheral surface (35) thereof. The nozzle has a f low passageway (33) formed therein. The heating means, the groove, and the ring are arranged in order along a direction of flow of resin (51) within the passageway. The groove serves to prevent heat generated by the heating means from being transferred to a distal end portion (43a) of the nozzle. The ring serves to release the heat of the distal end portion to the body. With this arrangement, the resulting molded product (11) can be removed from the mold without causing any stringiness between the runner and the distal end portion.

Owner:HONDA MOTOR CO LTD

Branched polycarbonate resin and process for production thereof

A branched polycarbonate resin prepared from a divalent phenol, a carbonate precursor, a branching agent, and a chain terminating agent is provided, in which the branching agent is composed of a trisphenol compound represented by the general formula (I). The use of the branching agent brings about excellent washability and permits molding which barely suffers from sagging (blow down) of the melt or stringiness thereof and is accompanied with high melt tension and excellent moldability, thus enabling efficient production of good molded products at high productivity.

Owner:IDEMITSU KOSAN CO LTD

Oxide precursor, oxide layer, semiconductor element, and electronic device, and method of producing oxide layer and method of producing semiconductor element

ActiveUS20170335461A1Exquisite patternTransistorSemiconductor/solid-state device manufacturingImpurityMetal

An aliphatic polycarbonate, an oxide precursor, and an oxide layer are provided, which are capable of controlling stringiness, when a thin film that can be employed for an electronic device or a semiconductor element is formed by a printing method. In an oxide precursor of the present invention, a compound of metal to be oxidized into a metal oxide is dispersed in a solution containing a binder (possibly including inevitable impurities) made of aliphatic polycarbonates, and an aliphatic polycarbonate having a molecular weight of 6000 or more and 400000 or less constitutes 80% by mass or more of all the aliphatic polycarbonates.

Owner:JAPAN ADVANCED INST OF SCI & TECH +1

Feed for replacement gilt of black pig and preparation method of feed

InactiveCN104757308AKeep healthyImprove reproductive performanceFood processingAnimal feeding stuffBiotechnologyBran

The invention discloses a feed for a replacement gilt of a black pig and a preparation method of the feed. The feed is prepared from the raw materials in parts by weight: 190-200 parts of rice meal, 170-180 parts of maize meal, 100-120 parts of barley albumen powder, 120-140 parts of puffing bran, 80-90 parts of puffing rice bran, 20-30 parts of pork tongues, 10-20 parts of meat stringiness, 3-4 parts of soybean oil, 70-90 parts of lucerne, 50-60 parts of okra, 30-40 parts of mungbean sprouts, 20-30 parts of bamboo leaves, 20-35 parts of cucumbers, 15-20 parts of snake butter, 10-15 parts of commelina communis, 20-30 parts of buckwheat kernels, 10-20 parts of cashew nuts, 40-50 parts of goat milk, 8-10 parts of dextrin, 0.5-1 parts of garlic paste, 12-13 parts of molasses, 0.5-0.6 parts of flavoring agent and 0.5-1 part of black pig nutrient. The feed is nutritive, healthy, delicious, tasty, safe and nonhazardous, can guarantee the physical health of the replacement gilt and maintain favorable production reproductive performance of the replacement gilt, and favorable material bases are laid for a high conception rate and a high farrowing rate in the future.

Owner:铜陵绿生牧业有限责任公司

Transfer tape

InactiveUS7208226B2Low overall adhesive strengthEasy to cutNon-macromolecular adhesive additivesOther accessoriesBand shapeEngineering

[An object of the present invention is] to provide transfer tape that maintains strong adhesive strength but can be reliably cut at a stipulated position. The adhesive film contains needle-shaped particles. If the adhesive strength is made high, then the adhesion between the adhesive ingredients is increased, thus forming a film that is difficult to cut. If a force is applied to the band-shaped ribbon in a direction outside the plane in which the adhesive coating is applied, then the film of the adhesive coating becomes thin and the needle-shaped particles rupture the film and cut the adhesive film. Moreover, the cut adhesive film draws the cut end to the needle-shaped particles, and as a result it is cut completely without stringiness.

Owner:GENERAL CO LTD

Method for preparing platy or lump processed cheese and cheese obtained

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improvesthe prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD CO LTD

Molding material for welding

A molding material for welding which, when used for bonding resin parts to each other by a welding method such as vibration welding or hot plate welding, can be prevented from developing a (string) burr or from showing stringiness or the like between the welding part of a hot die, e.g., a hot plate, and a housing-constituting material. The molding material can hence diminish appearance failures. The molding material comprises either a rubber-reinforced resin obtained by polymerizing vinyl monomers comprising an aromatic vinyl compound and a vinyl cyanide compound in the presence of an acrylic rubbery polymer having a gel content less than 70% or a mixture of the rubber-reinforced resin and a (co)polymer of a vinyl monomer. The content of the acrylic rubbery polymer in the molding material is 5-40 mass% based on the whole molding material.

Owner:大科能宇菱通株式会社

Nozzle for use in hot runner mold

A nozzle (26) for a hot runner mold (10) having a cavity (29) and a runner (27) formed in a body (24) thereof and communicating with the cavity. The nozzle leads to the runner and has a heating means (36), a heat-insulating groove (37), and a heat transmitting ring (38) provided on an outer peripheral surface (35) thereof. The nozzle has a f low passageway (33) formed therein. The heating means, the groove, and the ring are arranged in order along a direction of flow of resin (51) within the passageway. The groove serves to prevent heat generated by the heating means from being transferred to a distal end portion (43a) of the nozzle. The ring serves to release the heat of the distal end portion to the body. With this arrangement, the resulting molded product (11) can be removed from the mold without causing any stringiness between the runner and the distal end portion.

Owner:HONDA MOTOR CO LTD

Cheese-like food for baking

Disclosed are a heat-tolerant cheese-like food, which shows a characteristic stringiness, similar to the texture of a stringy natural cheese in a heat-melted state, even after cooling down, and shows no change in appearance or shape after baking; and a method for producing the same. The heat-tolerant cheese-like food, which shows a characteristic stringiness, similar to the texture of a stringy natural cheese in a melted state, even in the case of substantially containing no such a natural cheese, and shows no change in appearance or shape after baking, can be obtained by preparing a cheese-like food comprising, each in a specific amount, of three components, i.e., a heat-set protein, milk protein and etherified tapioca starch. A cheese-like food having a favorable fermented flavor and characteristic stringiness can be obtained by preparing a cheese-like food which comprises a lactic acid fermentation broth containing a heat-set protein.

Owner:FUJI OIL CO LTD

Internal-fixation bone cement diaphysis prosthesis, prefabricated part and production method of internal-fixation bone cement diaphysis prosthesis

The invention discloses internal-fixation bone cement diaphysis prosthesis, a prefabricated part and a production method of the internal-fixation bone cement diaphysis prosthesis. The internal-fixation bone cement diaphysis prosthesis is characterized by comprising a thin layer of bone cement attached to the inner wall of a marrow cavity at the broken end of fractured bone, the thickness of the thin layer is 0.1-0.3 cm, the cover range is 6-8 cm in the left and right sides of the broken end of fractured bone, and the bone cement curing degree is between the later state of stringiness and the earlier state of dough.

Owner:WUXI NO 2 PEOPLES HOSPITAL

Gelating agent for alkaline cell and alkaline cell

The present invention is formed by utilizing the cross-linked polymer of acrylic acid and / or methacrylic acid and / or alkali metal salts obtained by aqueous solution polymerization method or reverse phase suspension polymer as the main constituent unit, and has the following (1 ), (2) The gelling agent for alkaline batteries and the batteries using it, the discharge continuity and impact resistance of alkaline batteries are excellent, the rolling liquid of alkaline electrolyte is good, corresponding to The high-speed filling of the liquid and the small deviation of the electrolyte filling amount can effectively mass-produce batteries with uniform quality. (1) In the concentration of 40% by weight potassium hydroxide aqueous solution, the swellable gelled particles with a particle diameter of 300 to 4000 μm contain 50% or more; The stringiness of the aqueous solution is 0-20mm.

Owner:SANYO CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com