Remade cheese with long shelf life and preparation method thereof

A shelf-life and processed cheese technology, which is applied to the field of long-shelf-life processed cheese and its preparation, can solve the problems of short refrigerated shelf life and poor stringiness, and achieves a simple preparation method, easy operation and excellent stringability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

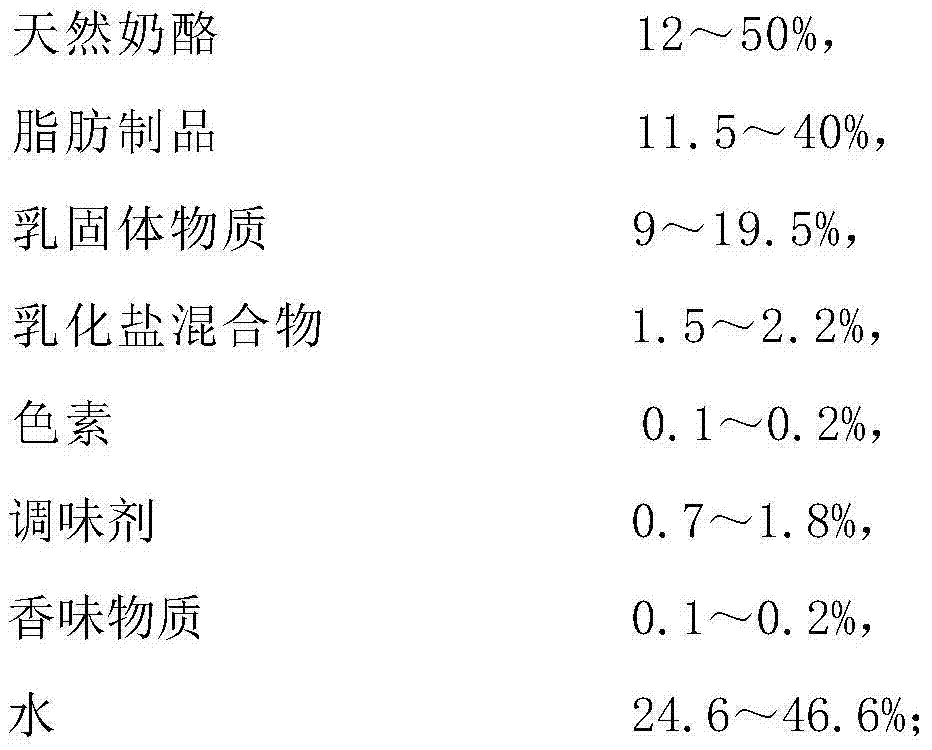

[0048] Raw material formula:

[0049]

[0050] Preparation:

[0051] 1. According to the above recipe, put all the raw materials except fat products and natural cheese into the melting pot, and the number of blades is 5 pieces. The temperature was controlled at 30°C, and the premixed slurry was obtained by shearing and stirring at 1400 rpm for 3 minutes;

[0052] 2. Add fat products and natural cheese to the premixed slurry, stir at 600rpm, steam directly to a temperature of 70°C, and then keep warm for 13 minutes to obtain an emulsified mixed slurry;

[0053] 3. Rapidly cool the emulsified mixed slurry to below 20°C, and then refrigerate at 6°C for 2 days to obtain processed cheese;

[0054] 4. Use a cutting machine to cut the processed cheese into 2×2×4mm 3 Strips, packaged and sterilized by ultra-high pressure at 700Mpa for 25 minutes, refrigerated at 5°C after sterilization to obtain processed cheese products with a long shelf life.

Embodiment 2

[0056] Raw material formula:

[0057]

[0058] Preparation:

[0059] 1. According to the above formula, put all the raw materials except fat products and natural cheese into the melting pot, the number of blades is 3 pieces, the temperature is controlled at 25°C, and the mixture is sheared and stirred at 1000rpm for 7 minutes to obtain a premixed slurry;

[0060]2. Add fat products and natural cheese to the premixed slurry, stir at 700rpm, steam directly to a temperature of 60°C, and then keep warm for 12 minutes to obtain an emulsified mixed slurry;

[0061] 3. Rapidly cool the emulsified mixed slurry to below 20°C, and then refrigerate at 4°C for 1 day to obtain processed cheese;

[0062] 4. Use a cutting machine to cut the processed cheese into 2×2×4mm 3 Strips, packaged and sterilized by ultra-high pressure at 600Mpa for 20 minutes, refrigerated at 6°C after sterilization to obtain processed cheese products with a long shelf life.

Embodiment 3

[0064] Raw material formula:

[0065]

[0066]

[0067] Preparation:

[0068] 1. According to the above recipe, put all the raw materials except fat products and natural cheese into the melting pot, and the number of blades is 4 pieces. The temperature was controlled at 35 ° C, and the premixed slurry was obtained by shearing and stirring at 1300 rpm for 9 minutes;

[0069] 2. Add fat products and natural cheese to the premixed slurry, stir at 800rpm, steam directly to a temperature of 65°C, and keep warm for 11 minutes to obtain an emulsified mixed slurry;

[0070] 3. Rapidly cool the emulsified mixed slurry to below 20°C, and then refrigerate at 8°C for 1 day to obtain processed cheese;

[0071] 4. Use a cutting machine to cut processed cheese into 4×4×20mm 3 Granular, packaged and sterilized by ultra-high pressure, the pressure is 1000Mpa, the time is 10min, refrigerated at 8°C after sterilization, and processed cheese products with long shelf life are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com