Molding material for welding

A molding material, acrylic technology, applied in the field of molding materials for welding, can solve the problems of luminance reduction and inability to obtain luminance, achieve excellent glossy surface, and improve the effect of poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

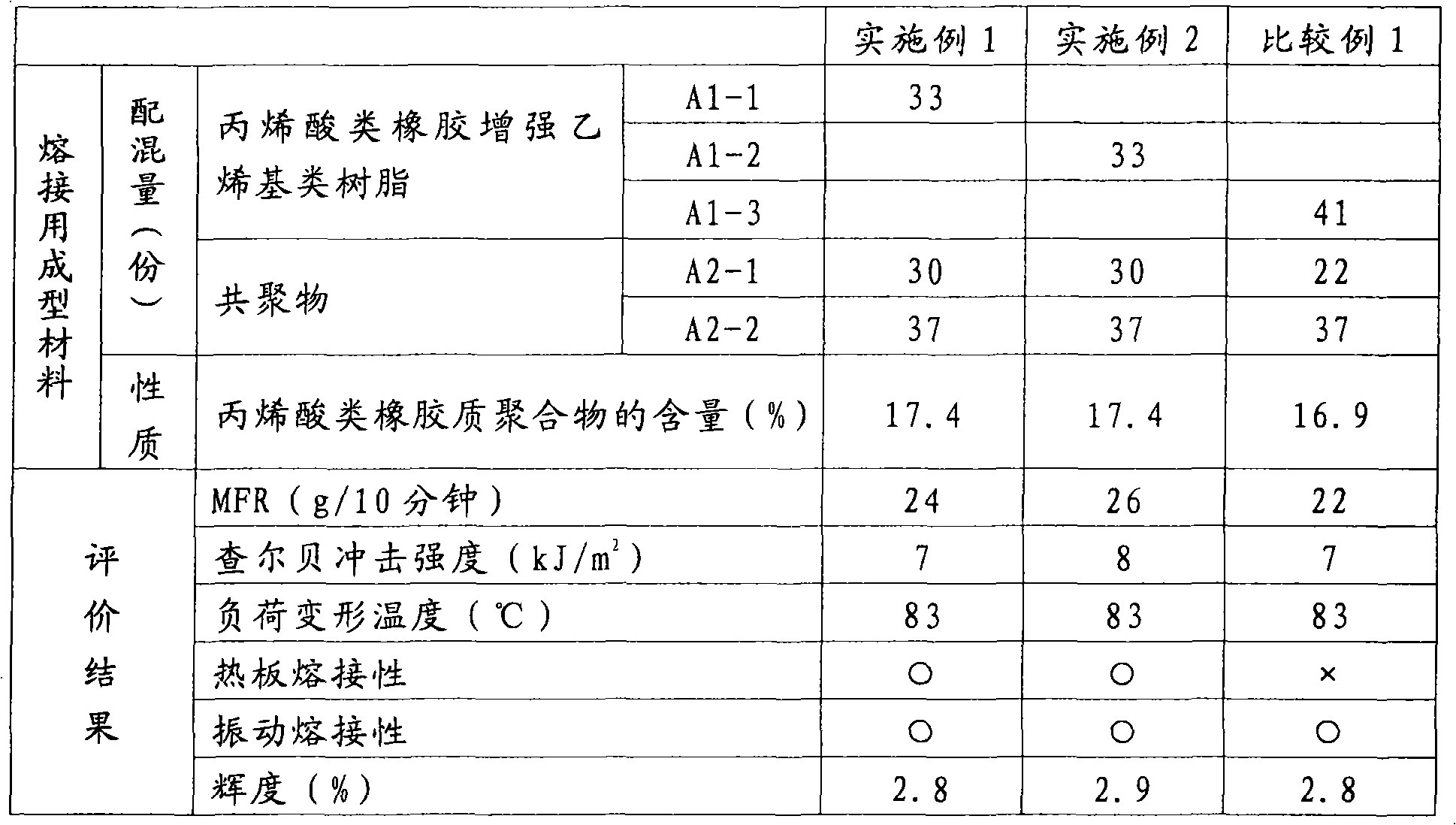

[0157] Hereinafter, the present invention will be specifically described with examples, but the present invention is by no means limited to these examples. It should be noted that, unless otherwise specified, the parts and % in the examples are based on mass.

[0158] 1. Evaluation method

[0159] Various evaluation methods used in this example are as follows.

[0160] (1) Melt flow rate

[0161] Measurement was performed based on ASTM-D1238 (240° C., 10 kg). The unit is g / 10 minutes.

[0162] (2) Charpy impact strength

[0163] Measured based on ISO179 (normal temperature). The unit is kJ / m 2 .

[0164] (3) Load deflection temperature

[0165] The measurement is based on ISO75 (under load), and the unit is °C.

[0166] (4) hot plate weldability

[0167] The pellets composed of molding materials are put into a molding machine (model "IS-25EP", manufactured by Toshiba Machine Co., Ltd.), melted at a temperature of 220-250°C, and molded into a hot plate welding with a ...

manufacture example 1

[0208] Production example 1 (manufacture of acrylic rubber reinforced vinyl resin [A1-1])

[0209] The latex was prepared by two-step polymerization.

[0210] The first process is to add 10.0 parts of n-butyl acrylate, 0.02 parts of allyl methacrylate, 1.0 parts of sodium dodecylbenzenesulfonate to the reactor equipped with reflux cooler, stirring blade, thermometer and temperature regulating device. 0.003 parts of cumene hydroperoxide, 0.004 parts of sodium edetate, 0.003 parts of ferrous sulfate, 0.05 parts of sodium formaldehyde sulfoxylate, and 180 parts of ion-exchanged water. While stirring, the mixture was heated. Then, the temperature of the reaction system was set at 60° C. to perform polymerization for 80 minutes. Next, keeping the temperature of the reaction system at 60°C, a mixture consisting of 25.0 parts of n-butyl acrylate, 0.05 parts of allyl methacrylate and 0.006 parts of cumene hydroperoxide was continuously added within 90 minutes to carry out polymerizat...

manufacture example 2

[0215] Production example 2 (manufacture of acrylic rubber reinforced vinyl resin [A1-2])

[0216] The latex was prepared by two-step polymerization.

[0217] The first process is to add 10.0 parts of n-butyl acrylate, 0.005 parts of allyl methacrylate, 1.0 parts of sodium dodecylbenzenesulfonate into the reactor equipped with reflux cooler, stirring blade, thermometer and temperature adjustment device. 0.003 parts of cumene hydroperoxide, 0.004 parts of sodium edetate, 0.003 parts of ferrous sulfate, 0.05 parts of sodium formaldehyde sulfoxylate, and 180 parts of ion-exchanged water. While stirring, the mixture was heated. Then, the temperature of the reaction system was set at 60° C. to perform polymerization for 80 minutes. Next, keeping the temperature of the reaction system at 60°C, a mixture consisting of 25.0 parts of n-butyl acrylate, 0.013 parts of allyl methacrylate and 0.006 parts of cumene hydroperoxide was continuously added within 90 minutes to perform polymeriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com