Sprue bush and bush part therof

A technology for sleeves and parts, applied in the field of sleeve parts, can solve the problems of deterioration of the quality of formed parts and changes in the shape of the mold, and achieve the effects of high heat dissipation, wire drawing inhibition, and high cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the embodiment examples mentioned above do not limit the technical scope of the present invention.

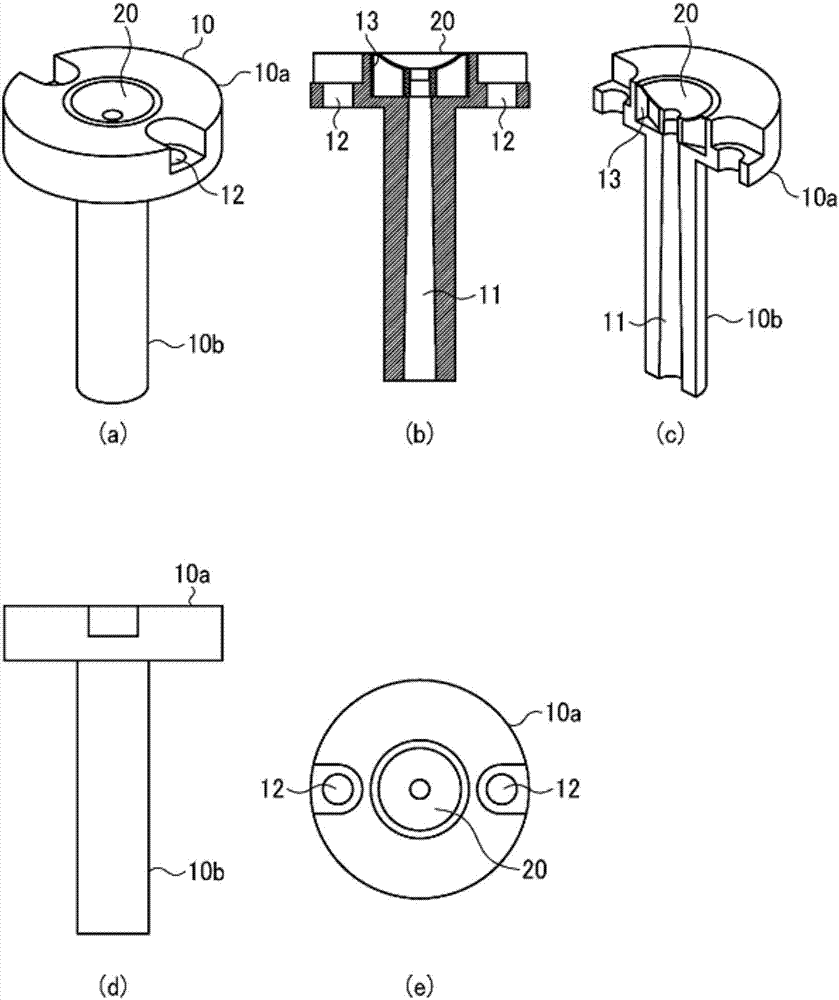

[0038] figure 1 It is a figure which shows the structure of the sprue bushing in 1st Embodiment of this invention, figure 1 (a) is a perspective view of the appearance, figure 1 (b) is a sectional view, figure 1 (c) is a sectional perspective view, figure 1 (d) is a side view, figure 1 (e) is a plan view. The sprue bushing in the first embodiment includes a sprue bushing main body 10 and a bushing member 20 attached to the sprue bushing main body 10 .

[0039] The sprue bushing main body 10 is formed of a steel material having hardness required for properties such as wear resistance and durability, and the sprue bushing main body 10 is a disc-shaped head 10a and a cylindrical shaft having a smaller diameter than that. The portion 10b is integrally formed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com