Polylactic acid/vegetable sponge fiber composite material and method for making same

A technology of loofah fiber and composite material, which is applied in the field of polylactic acid/loofah fiber composite material and its preparation, can solve the problems of inapplicable biodegradable thermoplastics, etc., and achieve the effect of improving heat distortion temperature and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

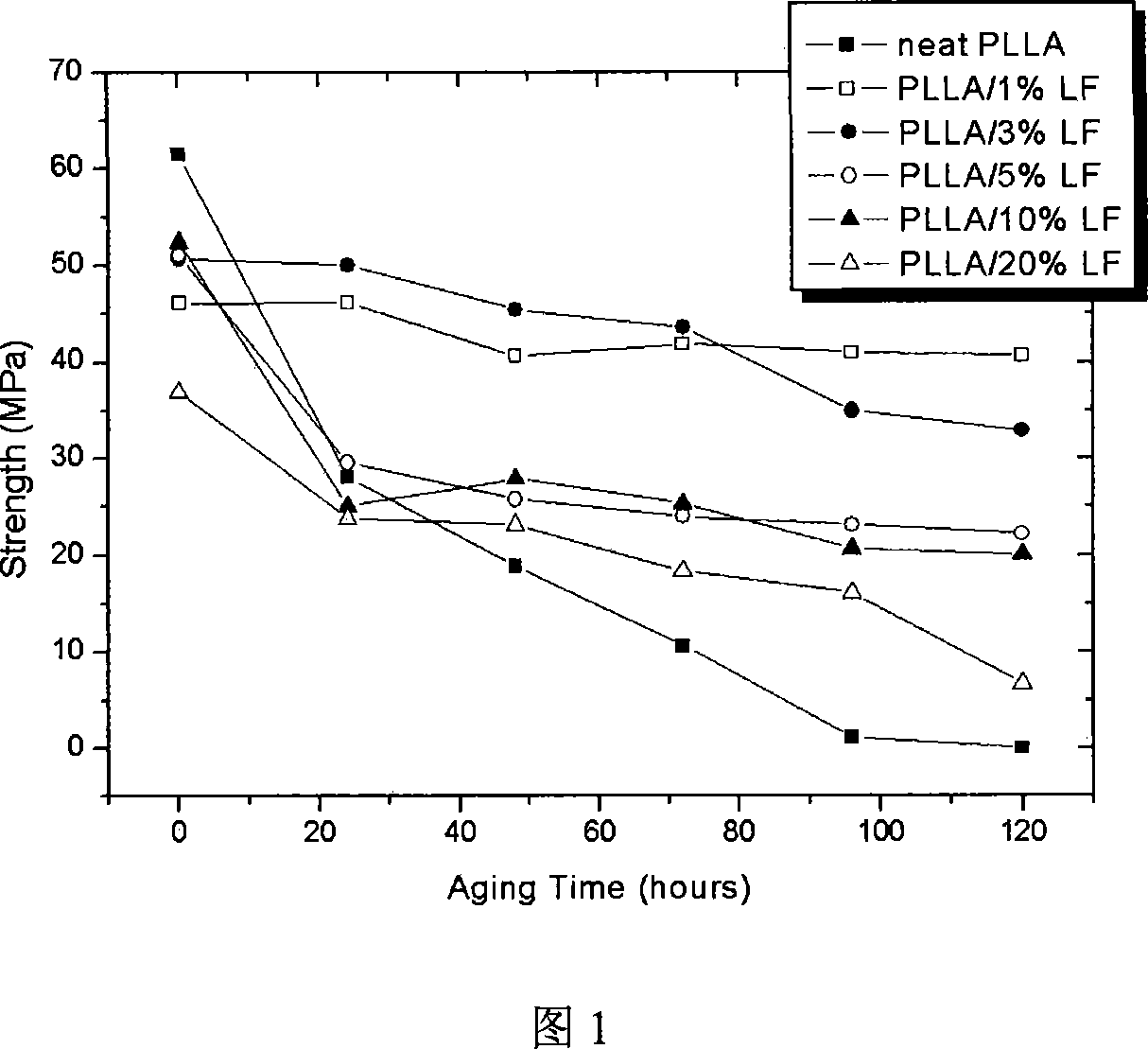

[0026] Example 1: 100 parts of vacuum-dried pure polylactic acid PLLA was melt-processed in a torque rheometer at 190°C and 32 rpm for 8 minutes, and then hot-pressed at 190°C for 5 minutes in a thermocompression molding machine to form a thin plate. Its performance is shown in Table 1.

Embodiment 2

[0027] Embodiment 2: the loofah fiber is cut into pieces, cleaned with clear water, pulverized after vacuum drying for 8 hours, and sieved with a 50-mesh sieve; by mass percentage, 10 parts of loofah fiber, 70 parts of concentration of NaOH solution and 20 parts of absolute ethanol solution were mixed together and azeotroped for 2 hours, during which NaOH and absolute ethanol were continuously added to keep the ratio between the loofah fibers, NaOH solution and absolute ethanol; then deionized water washing until the pH value is 7, filter with suction, and dry the obtained loofah fiber in an oven at 80°C for 8 hours; by mass percentage, 5 parts of the above-mentioned alkali-treated loofah fiber, 1 part of silane coupling agent γ-glycidol Ether propyltrimethoxysilane, 85 parts of absolute ethanol, 1 part of 0.1mol / L hydrochloric acid solution and 8 parts of deionized water were refluxed and stirred for 2 to 4 hours. Dry in oven for 12 hours. The organically modified loofah fib...

Embodiment 3

[0029] Embodiment 3: Loofah modification method is the same as embodiment 2, wherein the silane coupling agent is gamma-aminopropyl triethylsiloxane. After mixing 97 parts of vacuum-dried PLLA, 3 parts of modified loofah fiber, 0.1 part of lubricant calcium stearate and 0.1 part of heat stabilizer epoxy soybean oil, put them in a torque rheometer at 190 °C with a rotation speed of Melt blending was performed at 32 rpm for 8 minutes, and then hot pressed at 190° C. for 5 minutes in a thermocompression molding machine to form a thin plate. Its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com