Biodegradable composite and preparation method thereof

A composite material and biodegradable technology, applied in the field of biodegradable composite materials and their preparation, can solve the problems of increased production cost, difficult preparation, and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

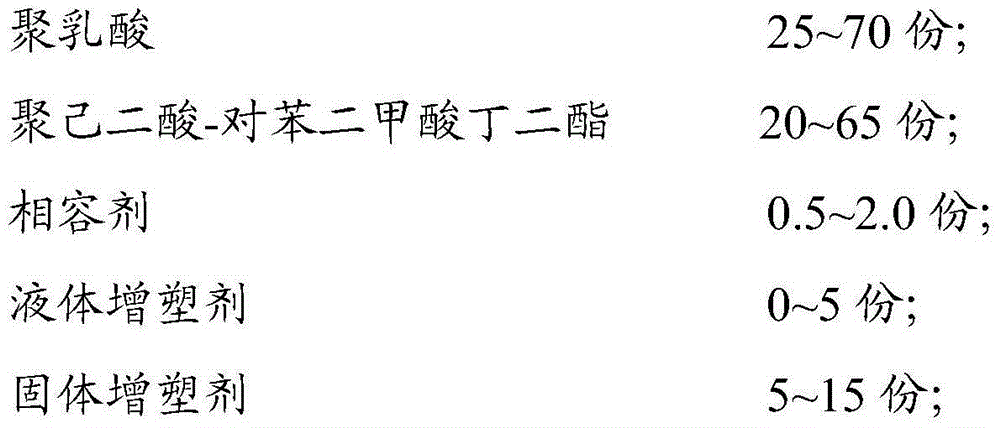

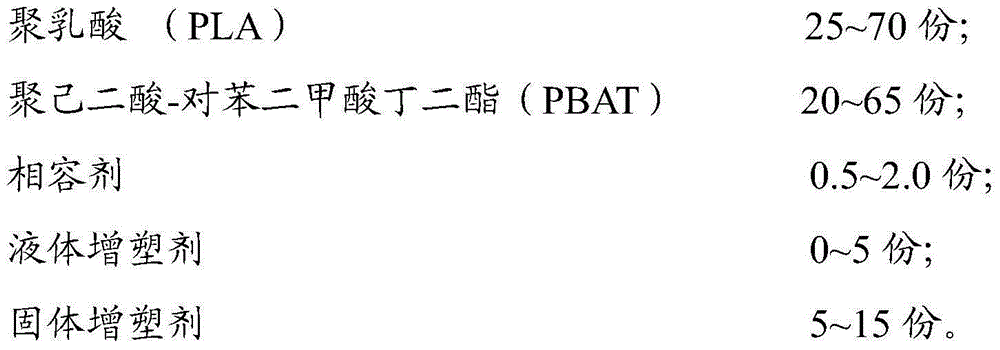

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned biodegradable composite material comprises the following steps:

[0027] Step S110, drying the polylactic acid and polybutylene adipate-terephthalate.

[0028] In this step, polylactic acid and polybutylene adipate-terephthalate are dried at 60° C. to 100° C. for 2 to 10 hours.

[0029] Preferably, the drying treatment adopts a vacuum oven or a blast drying oven.

[0030] Step S120, mix polylactic acid, polybutylene adipate-terephthalate, compatibilizer, liquid plasticizer and solid plasticizer evenly, then add them into an extruder, extrude and granulate to obtain a biodegradable composite material .

[0031] Preferably, polylactic acid, polybutylene adipate-terephthalate, compatibilizer, liquid plasticizer and solid plasticizer are added into a mixer and stirred at high speed for mixing.

[0032] Preferably, a twin-screw extruder is used for extrusion granulation, the temperature of the twin-screw extruder is 120°C-190°...

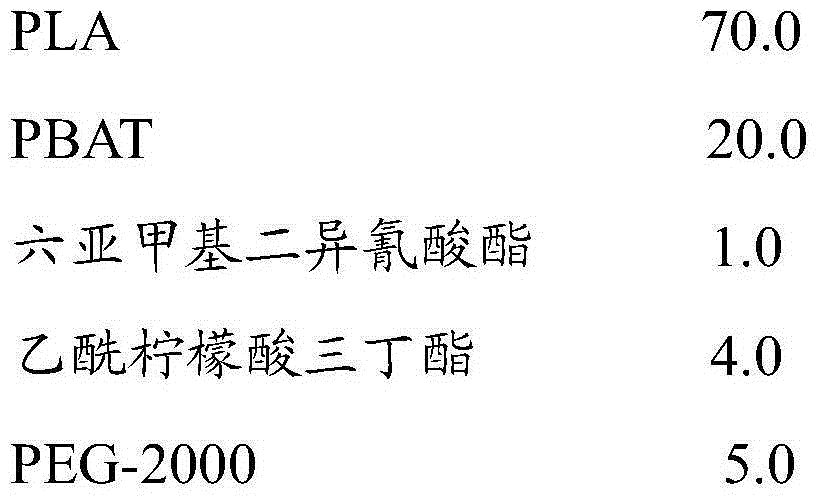

Embodiment 1

[0045] Place PLA and PBAT in an air-blast drying oven at 80°C for 4 hours, and then weigh the raw materials of each component according to the following parts by mass:

[0046]

[0047]Stir the above-mentioned raw materials uniformly at room temperature in a high-speed mixer, and then add the obtained mixture into twin-screws to extrude and granulate. The temperature of the twin-screw extruder is: zone 1 135°C, zone 2 165°C, zone 3 175°C, zone 4 185°C, zone 5 185°C, zone 6 185°C, zone 7 175°C, head temperature 165°C, screw The speed is 200rpm, and the aspect ratio is 40:1. Dry the pellets granulated by the extruder in an air-blast drying oven at 80°C for 4 hours, and then extrude and blow the film through a single-screw extruder. The temperatures of the three temperature zones of the blown film machine are: 150°C, 160°C ℃, 170℃, inflation ratio 2.5:1.

Embodiment 2

[0049] PLA and PBAT were dried in an air-dried oven at 80°C for 5 hours, and then the raw materials of each component were weighed according to the following parts by mass:

[0050]

[0051] Stir the above-mentioned raw materials uniformly at room temperature in a high-speed mixer, and then add the obtained mixture into twin-screws to extrude and granulate. The temperature of the twin-screw extruder is: zone 1 125°C, zone 2 170°C, zone 3 175°C, zone 4 185°C, zone 5 185°C, zone 6 185°C, zone 7 175°C, head temperature 165°C, screw The speed is 250rpm, and the aspect ratio is 36:1. Dry the pellets granulated by the extruder in an 80°C blast drying oven for 5 hours, and then extrude and blow the film through a single-screw extruder. The temperatures of the three temperature zones of the blown film machine are: 145°C, 160°C ℃, 170℃, inflation ratio 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com