Environmentally friendly biochar-based fertilizer and application method thereof

A biochar-based fertilizer, an environmentally friendly technology, applied in the direction of fertilization methods, applications, organic fertilizers, etc., can solve the problems of unconsidered removal, etc., and achieve the effects of high survival rate of viable bacteria, reduced safety risks, and long-lasting fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

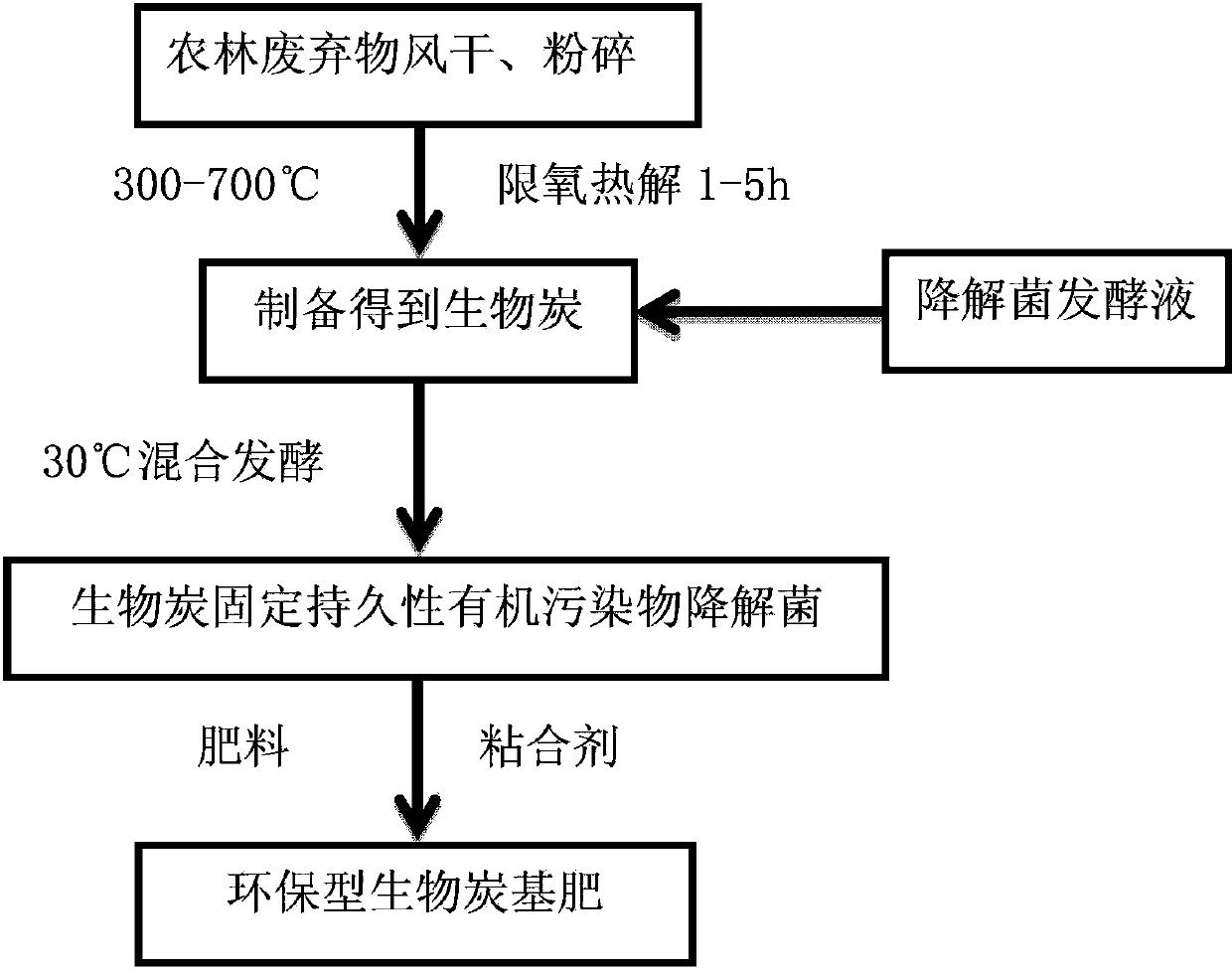

[0031] The preparation process of the environment-friendly biochar-based fertilizer of the present embodiment is as follows: figure 1 As shown, the specific steps are as follows:

[0032] 1. Preparation of biochar: At 500°C, use crushed rice straw under oxygen-limited conditions, use a carbonization furnace to pyrolyze for 4 hours to prepare biochar, grind it, and pass through an 80-mesh sieve;

[0033] 2. Preparation of composite bacterial agent: select Bacillus (CGMCC NO: 1.4255), Pseudomonas (CGMCC NO: 1.3187), and actinomycetes (ATCC NO: 13684) to mix and prepare, and its weight ratio is 1:1: 1. The strains used were commonly used strains, purchased from the China General Microorganism Culture Collection (CGMCC) and the American Type Culture Collection (ATCC).

[0034] 3. Immobilization of biochar: Put the mixed degrading bacteria into the liquid medium for activation; take 5ml into the triangle flask with 500ml medium, shake the flask to culture, and make the seed mediu...

Embodiment 2

[0045] The preparation process of the environment-friendly biochar-based fertilizer of the present embodiment is as follows: figure 1 As shown, the specific steps are as follows:

[0046] 1. Preparation of biochar: 500°C (can be any value between 300°C ~ 700°C, preferably any value between 300°C ~ 500°C), use the pulverized rice straw under oxygen-limited conditions, and use a carbonization furnace to pyrolyze for 4 hours (It can be any value in 1 to 5 hours) Prepare biochar, grind it, and pass through an 80 mesh sieve (it can be 20 to 100 mesh sieve, preferably 80 to 100 mesh sieve);

[0047]2. Preparation of compound bacterial agent: select Bacillus (ATCC NO: 65374), Pseudomonas (CGMCC NO: 1.3187), Actinomyces (ATCC NO: 13684), Klebsiella (CGMCC NO: 1.3718) , mixed preparation; the weight ratio is 1:1:1:1; the strains used are commonly used strains, purchased from China General Microorganism Culture Collection Center (CGMCC) and American Type Culture Collection (ATCC).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com