Preparation method of lignin-phenol-formaldehyde resin and preparation method of lignin-phenol-formaldehyde resin foam

A phenolic resin and lignin technology, which is applied in the preparation of lignin phenolic resin and the preparation of lignin phenolic resin foam, can solve the problems of increasing the viscosity of phenolic resin, reducing the strength of phenolic foam, improving foaming difficulty, etc., and achieving low water absorption efficiency, increasing added value, and improving the level of processing and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of lignin phenolic resin, comprises the following steps:

[0023] A) Mix and react lignin, phenolic compound and nucleophile to obtain lignin phenolate;

[0024] B) adjusting the pH value of the lignin phenolate obtained in step A) to alkaline, and then mixing and reacting with aldehyde to obtain a lignin phenolic resin.

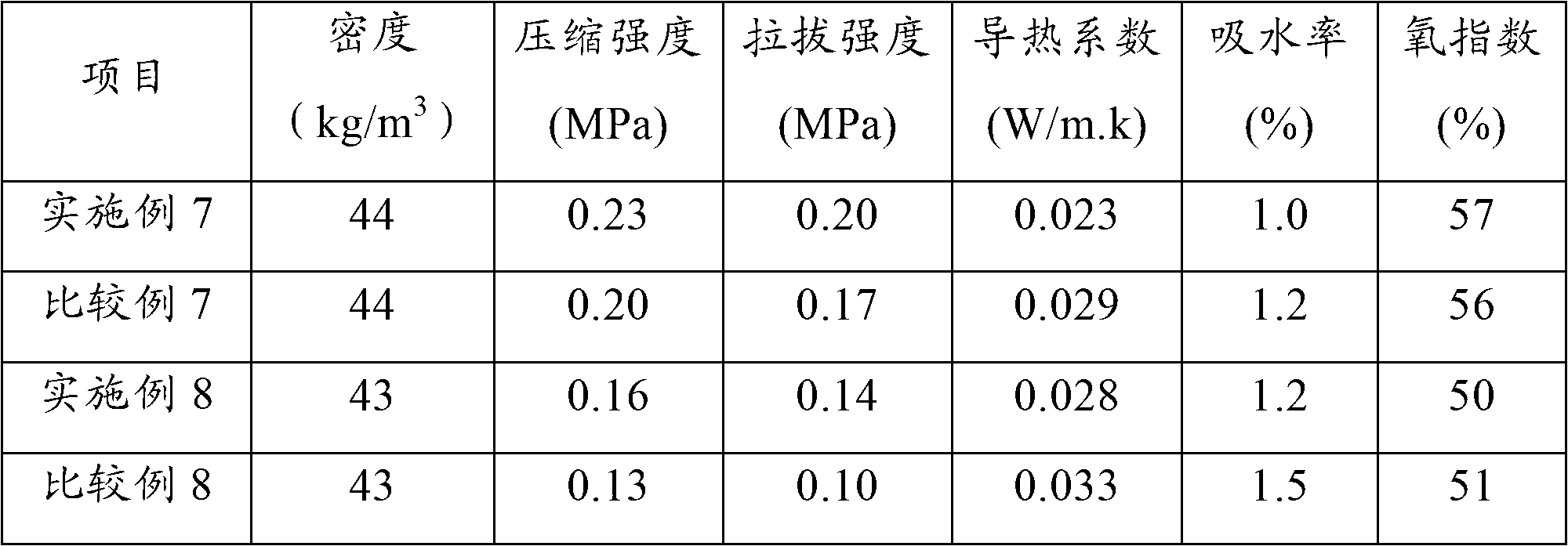

[0025] After the lignin phenolic resin is prepared, it is mixed with a foaming agent, a curing agent and a surfactant, and foamed and cured to obtain a lignin phenolic resin foam.

[0026] Compared with the prior art, the present invention uses phenolic compounds as solvents, and then adds nucleophilic reagents to convert α-aryl ethers, α-alkyl ethers, phenolic β-aryl ethers, α- The non-phenolic β-aryl ether of the alcoholic hydroxyl group and the ether bond in the methyl aryl ether are broken, so that the lignin macromolecule can be degraded better, and the lignin liquefaction product with high rea...

Embodiment 1

[0045] Add the corn stalks to the aqueous sodium hydroxide solution after crushing, and cook to obtain a solution in which lignin and hemicellulose are dissolved, filter the obtained solution to remove cellulose insolubles, and obtain lignin black liquor; to lignin black Add hydrochloric acid to the liquid, adjust the pH value to 4, keep warm at 80°C, the lignin black liquor is flocculated and stratified, filtered through pressure, washed with hot water, and dried at low temperature to obtain lignin. After testing, its solid content is 97.5%.

Embodiment 2

[0047] Mix 1 g of lignin prepared in Example 1 with 5 g of molten phenol, add 0.001 g of nucleophile NaOH under stirring conditions, heat the reaction system to 140 ° C, react at a constant temperature for 6 h, and cool down to obtain lignin phenolate; Raise the temperature to 70°C, adjust the pH value to 7.50 with hydrochloric acid, add 2.2g of formaldehyde to the lignin phenolate in batches within 1 hour, and react for 6 hours to obtain the lignin phenolic resin.

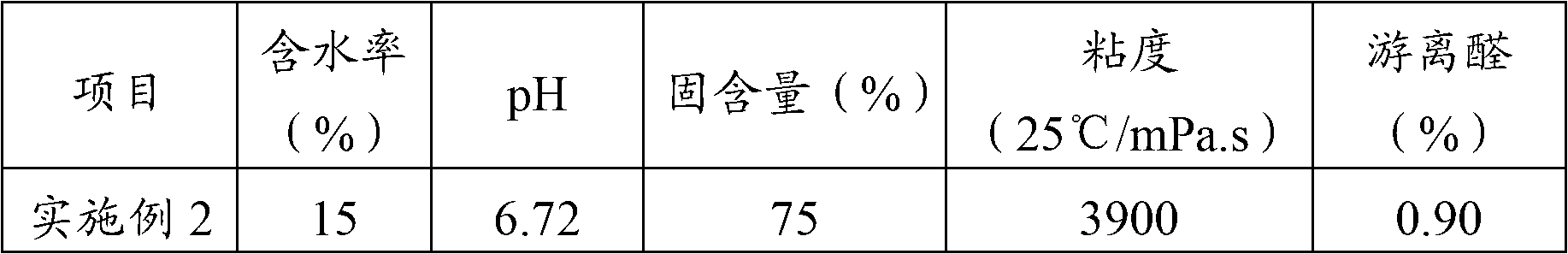

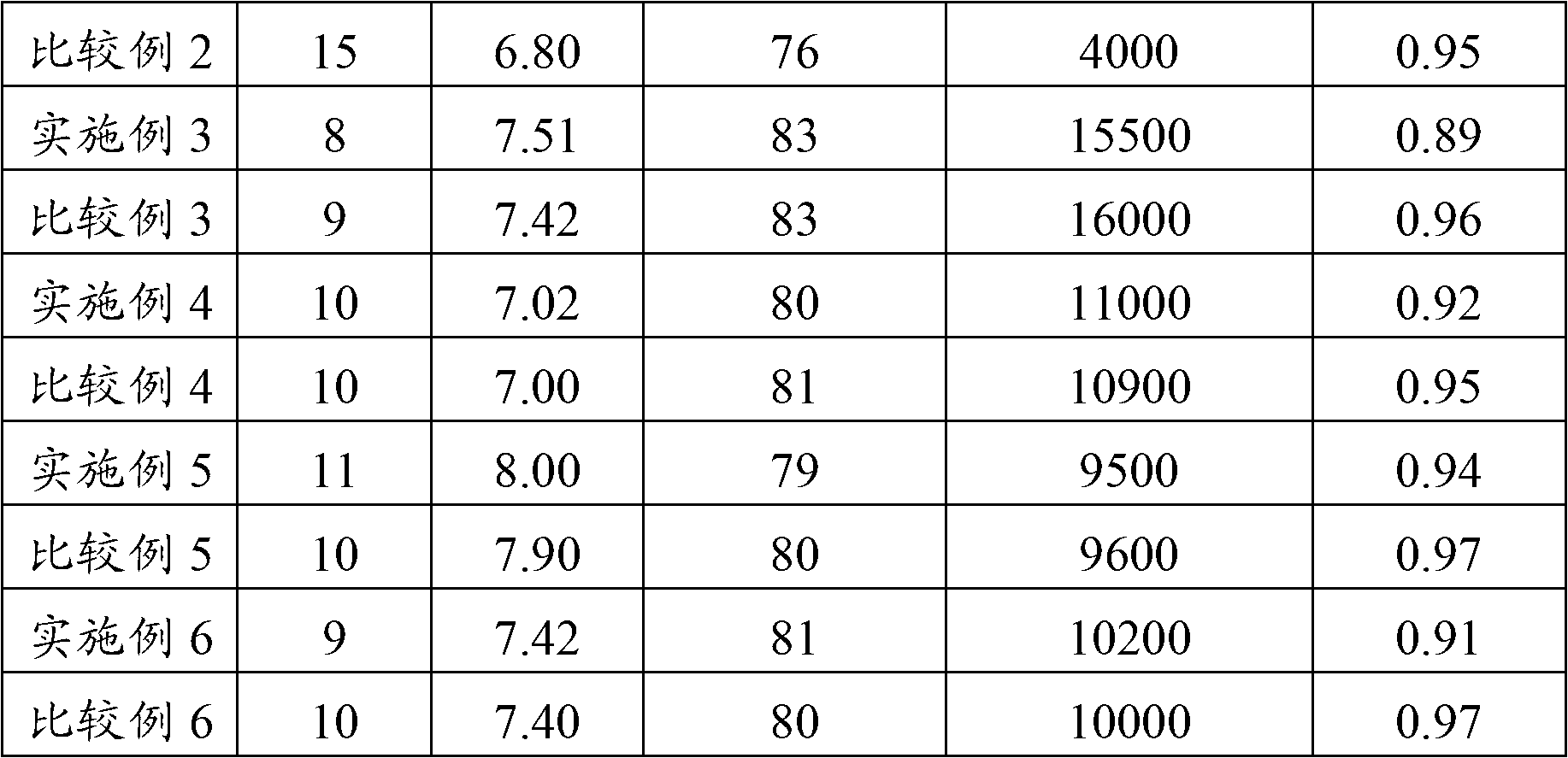

[0048] Performance tests were performed on the obtained lignin phenolic resins, and the results are shown in Table 1. Table 1 shows the performance parameters of the phenolic resins prepared in the examples and comparative examples of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com