Rice-husk-based porous silicon carbide ceramic material and preparing method thereof

A technology of silicon carbide ceramics and porous silicon carbide, which is applied in the field of ceramic materials, can solve problems such as complex technical conditions, pore size distribution, mechanical strength, silicon carbide microstructure and morphology, and limited practical application range, and achieve simple and easy control of the process, The effect of reduced preparation cost, broad development space and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

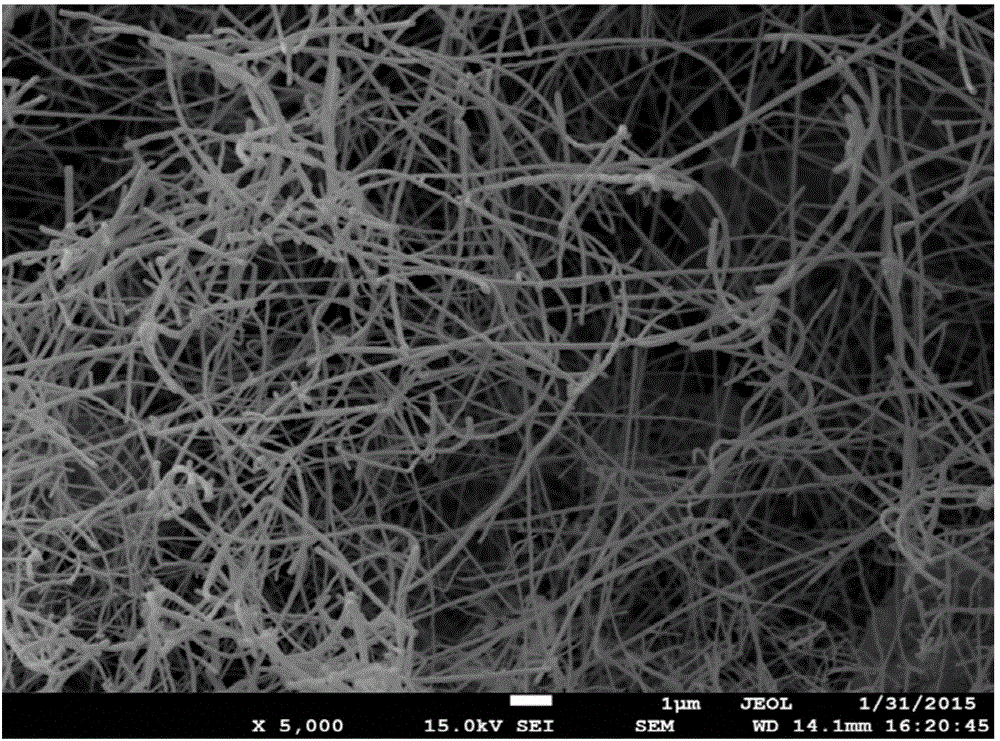

Image

Examples

Embodiment 1

[0033] The rice husk-based porous silicon carbide ceramic material of this embodiment is prepared from rice husk, water and a mixture, the quality of the mixture is 40% of the mass of the rice husk; the mixture consists of the following components in mass percentage: Silicon powder 26%, graphite 37%, NaCl 6%, dextrin powder 31%; according to the ratio, take the raw materials and mix them in a ball mill mixer for 1 hour to obtain the mixture.

[0034] The preparation method of the rice husk-based porous silicon carbide ceramic material of this embodiment adopts the following steps:

[0035] 1) Add the rice husk powder into the blender, add water with 45% weight of the rice husk powder, and stir to make the rice husk powder fully wet; then add the mixture, and stir for 5 minutes to make a billet;

[0036] 2) The billet was machine-pressed under low pressure, the molding pressure was 1 MPa, and the holding time was 20s to obtain the green body; the green body was dried at 110°C f...

Embodiment 2

[0038] The rice husk-based porous silicon carbide ceramic material of this embodiment is prepared from rice husk, water and a mixture, the quality of the mixture is 65% of the mass of the rice husk; the mixture consists of the following components in mass percentage: Silicon powder 2%, carbon black 40%, Fe3%, Fe 2 o 3 5%, dextrin powder 28%, gelatin 22%; take the raw materials according to the ratio and mix them in a ball mill mixer for 1 hour to get the mixture.

[0039]The preparation method of the rice husk-based porous silicon carbide ceramic material of this embodiment adopts the following steps:

[0040] 1) Add the rice husk powder into the blender, add water with 57% of the weight of the rice husk powder, and stir to make the rice husk powder fully wet; then add the mixture, and stir for 5 minutes to make a billet;

[0041] 2) The billet was machine-pressed under low pressure, the molding pressure was 3MPa, and the pressure holding time was 10s to obtain the green bo...

Embodiment 3

[0043] The rice husk-based porous silicon carbide ceramic material of this embodiment is prepared from rice husk, water and a mixture, the quality of the mixture is 50% of the mass of the rice husk; the mixture consists of the following components in mass percentage: 3% silicon powder, 25% anthracite, 8% graphene, 6% NaCl, 45% pulp powder, 13% polyvinyl butyral; take the raw materials according to the proportion and mix them in a ball mill mixer for 1 hour to obtain the mixture.

[0044] The preparation method of the rice husk-based porous silicon carbide ceramic material of this embodiment adopts the following steps:

[0045] 1) Add the rice husk powder into the blender, add water with 55% weight of the rice husk powder, and stir to make the rice husk powder fully wet; then add the mixture, and stir for 5 minutes to make a billet;

[0046] 2) The billet was machine-pressed under low pressure, the molding pressure was 2 MPa, and the pressure holding time was 15s to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com