Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183 results about "Micro morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term micromorphology was originally used to refer to that field of micropedology dealing with fabric analysis only, but soon both were used as synonyms. Micromorphology, as a general term, comprises both the qualitative and the quantitative analysis of the soil; the latter is commonly referred to as micromorphometry. The...

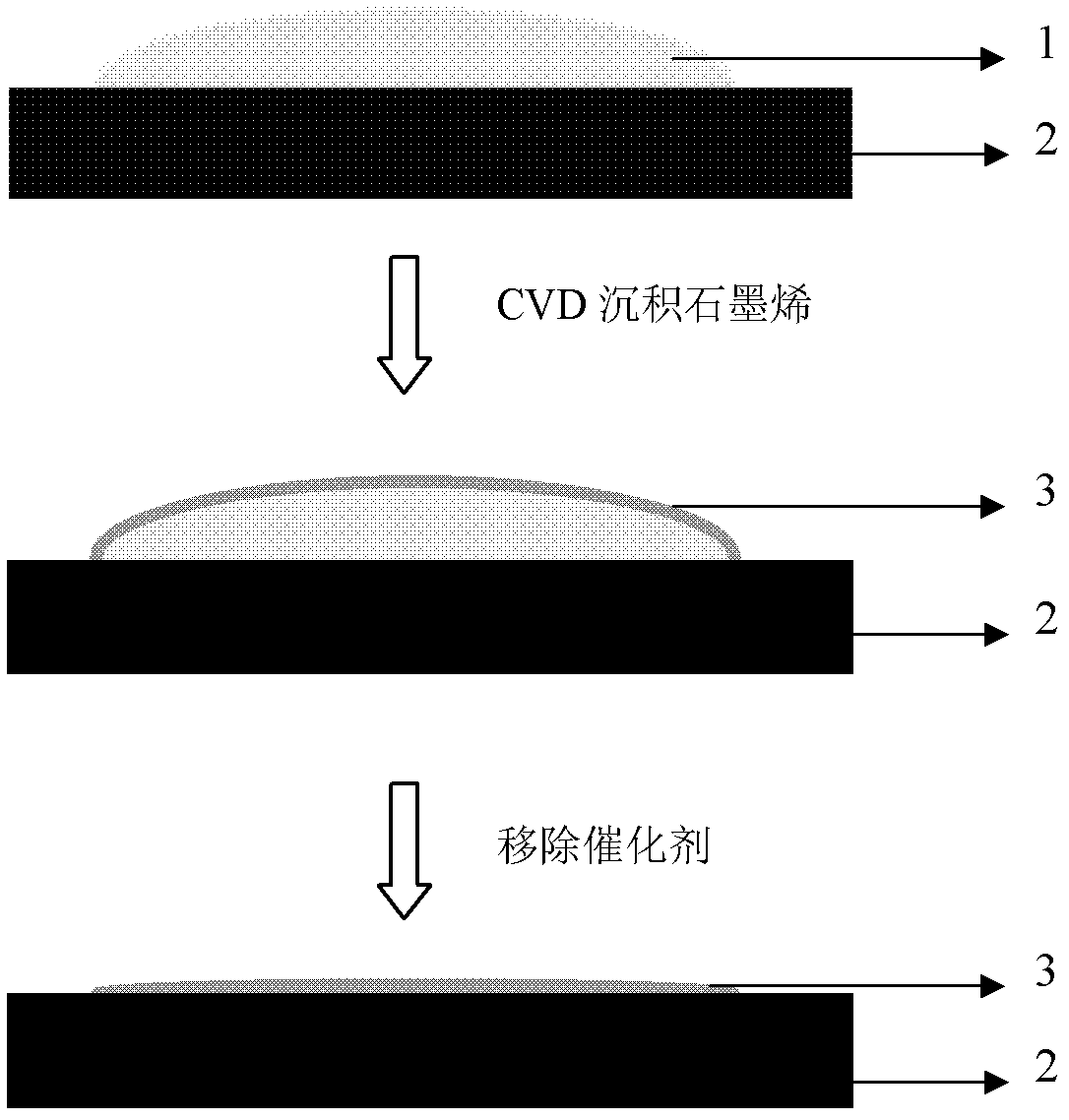

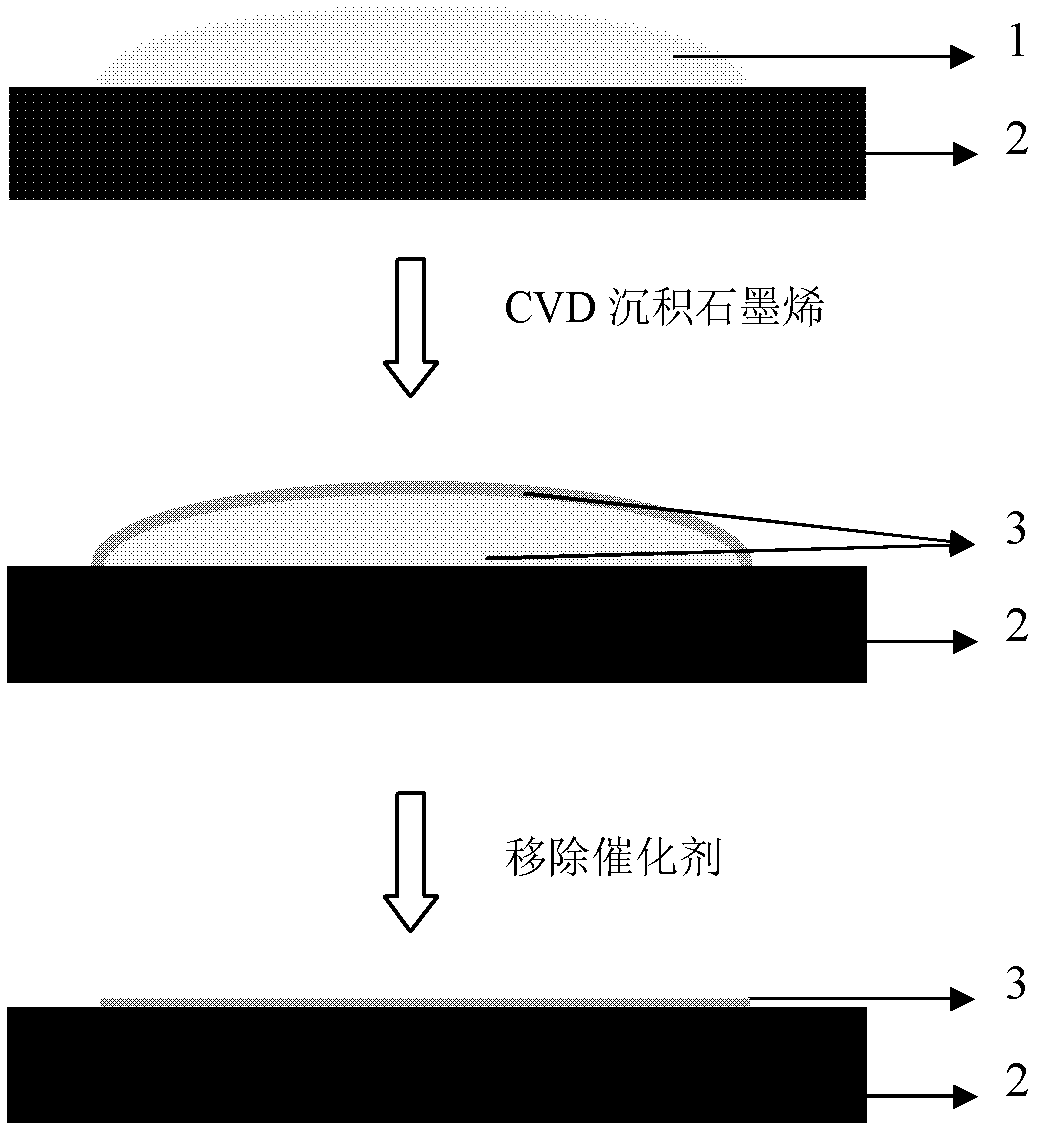

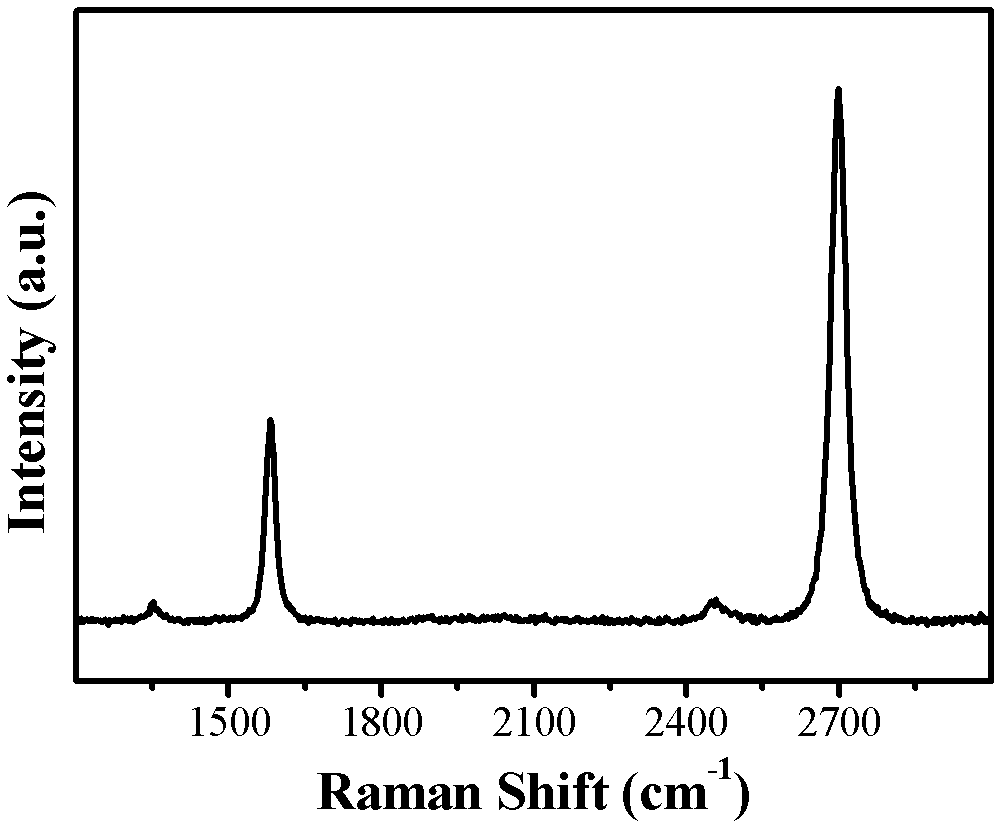

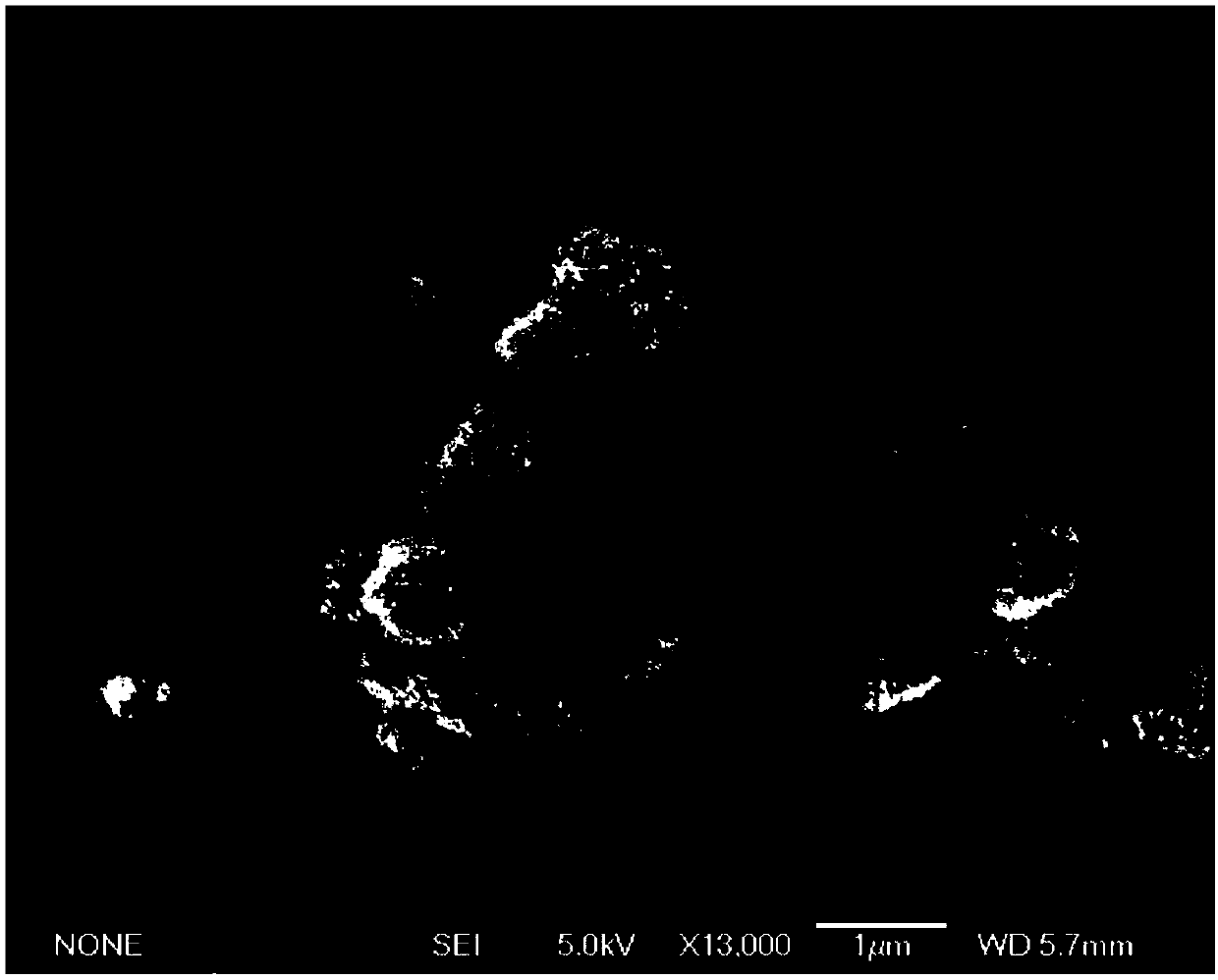

Method for preparing graphene by adopting liquid catalyst aided chemical vapor deposition

ActiveCN102583359ARealize layer controlMolecular activityMaterial nanotechnologyGrapheneIndiumLiquid metal

The invention discloses a method for preparing a graphene film by using a liquid metal or alloy as a catalyst and adopting chemical vapor deposition. The metal with low melting point comprises typical gallium, tin, indium and the like; and the alloy with low melting point comprises gallium-copper, gallium-nickel, indium-copper, indium-nickel, tin-copper, tin-nickel, copper-silver-tin and the like. The chemical vapor deposition is performed above the melting point of the metal or alloy catalyst, so that the continuous graphene film is formed on the surface of the catalyst and the interface of the catalyst and a substrate. Compared with the graphene grown on the surface of a solid catalyst such as copper and nickel, the invention has the advantages that the prepared graphene is controllable in layer number, low in requirement for the micro morphology of the surface of the substrate and suitable for multiple substrate materials, and the catalyst is very easy to remove. The obtained graphene positioned on the surface of the liquid has unique application value.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

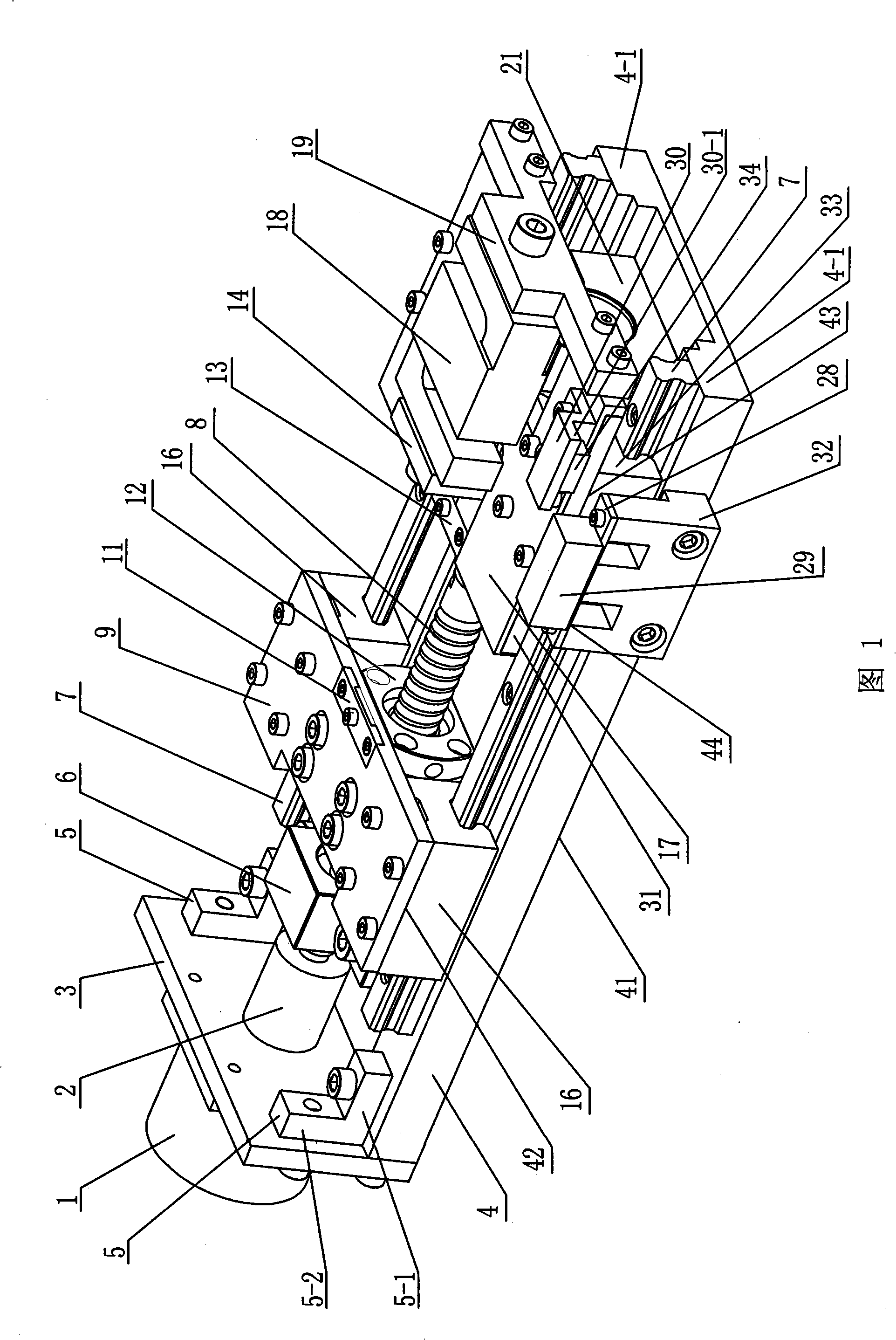

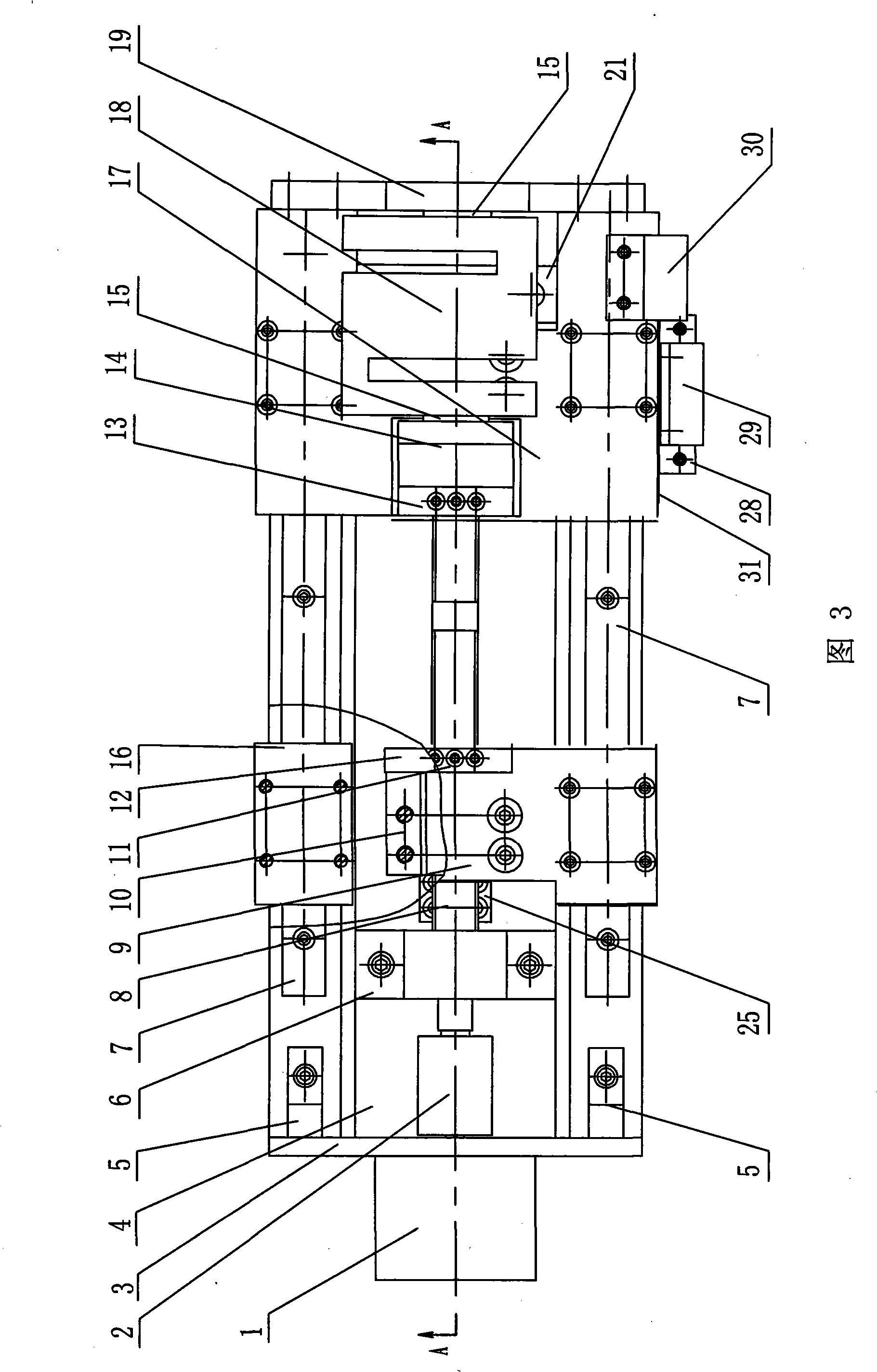

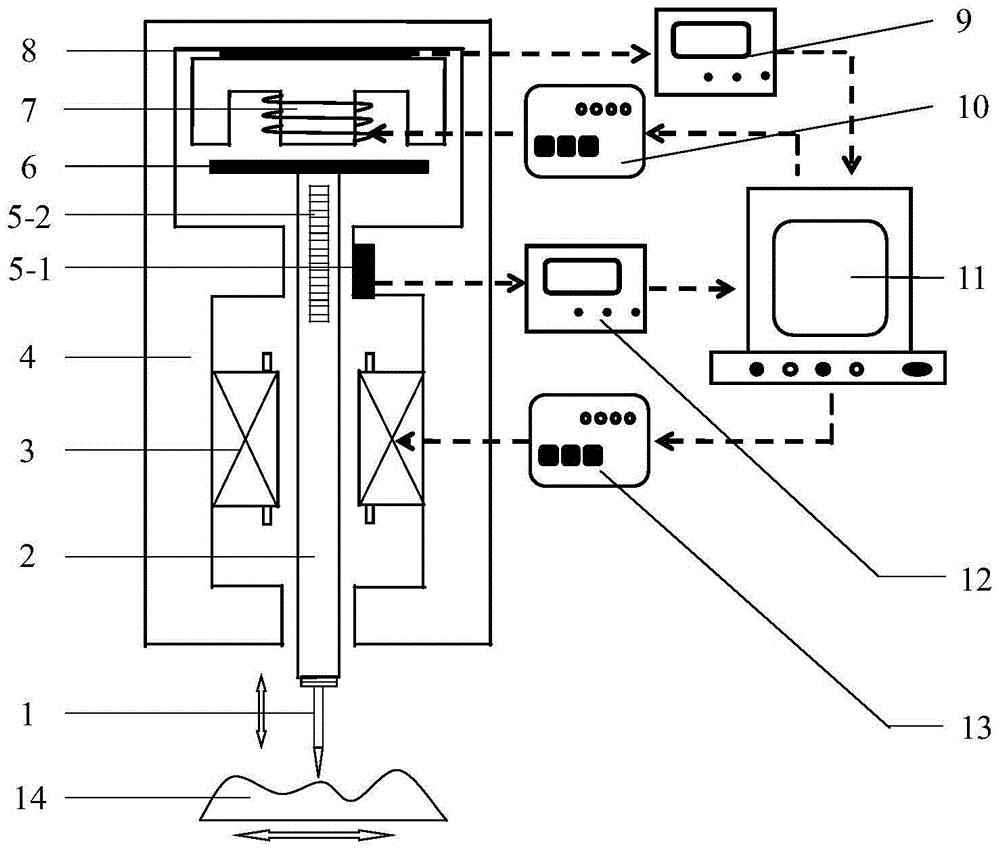

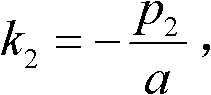

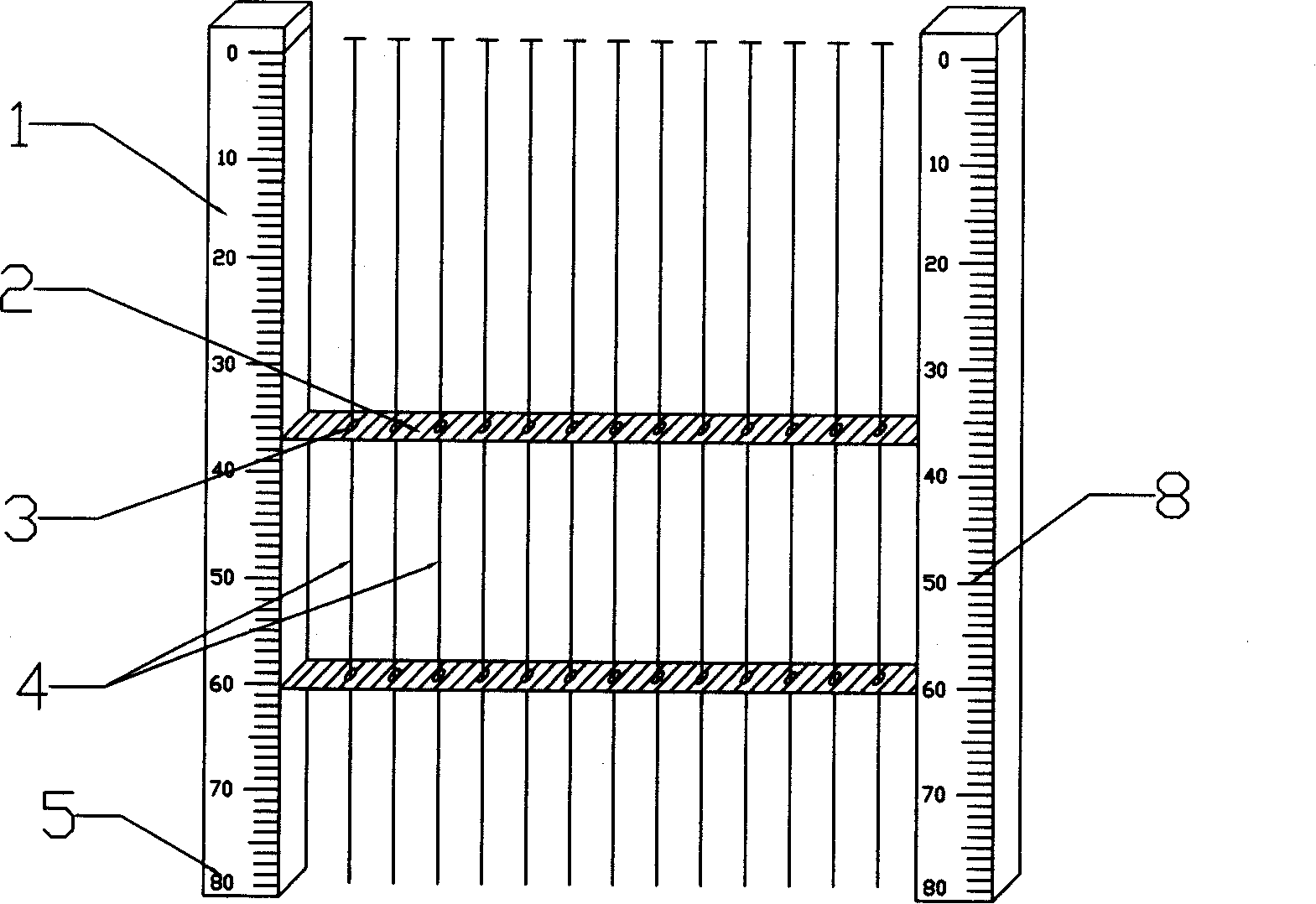

In situ nanometer stretching experiment measuring detection device

InactiveCN101285747ASurface/boundary effectMaterial strength using tensile/compressive forcesVehicle frameCoupling

The invention relates to a tension experiment measuring and detecting device, in particular to an in-situ nano tension experiment measuring and detecting device. The invention solves the problem in the prior art that measurement of mechanical properties and detection of micro-morphology are two independent and separate processes. An output shaft of a stepper motor (1) of the device is fixedly connected with a coupler (2); a guide rail (7) is fixed on a stander soleplate (4); a left frame set (42) and a right frame set (43) are arranged on the guide rail (7); both ends of a left and right rotary screw (8) are respectively connected with the coupler (2) and a bearing support (21); a left end face and a right end face of a force sensor (18) are respectively and fixedly connected with a right clamp connecting block (14) and a force sensor holder (19); a reading device (44) is arranged on the stander soleplate (4); and a tension measuring device (41) is fixed on a worktable (46) of the detection device. The in-situ nano tension experiment measuring and detecting device promotes further development of the research area of dynamic observation required on the micro-morphology variation of a sample under the state of stress, and has important theoretical significance and good application prospect on measurement of the mechanical properties and detection of the micro-morphology of composite functional nanophase materials.

Owner:HARBIN INST OF TECH

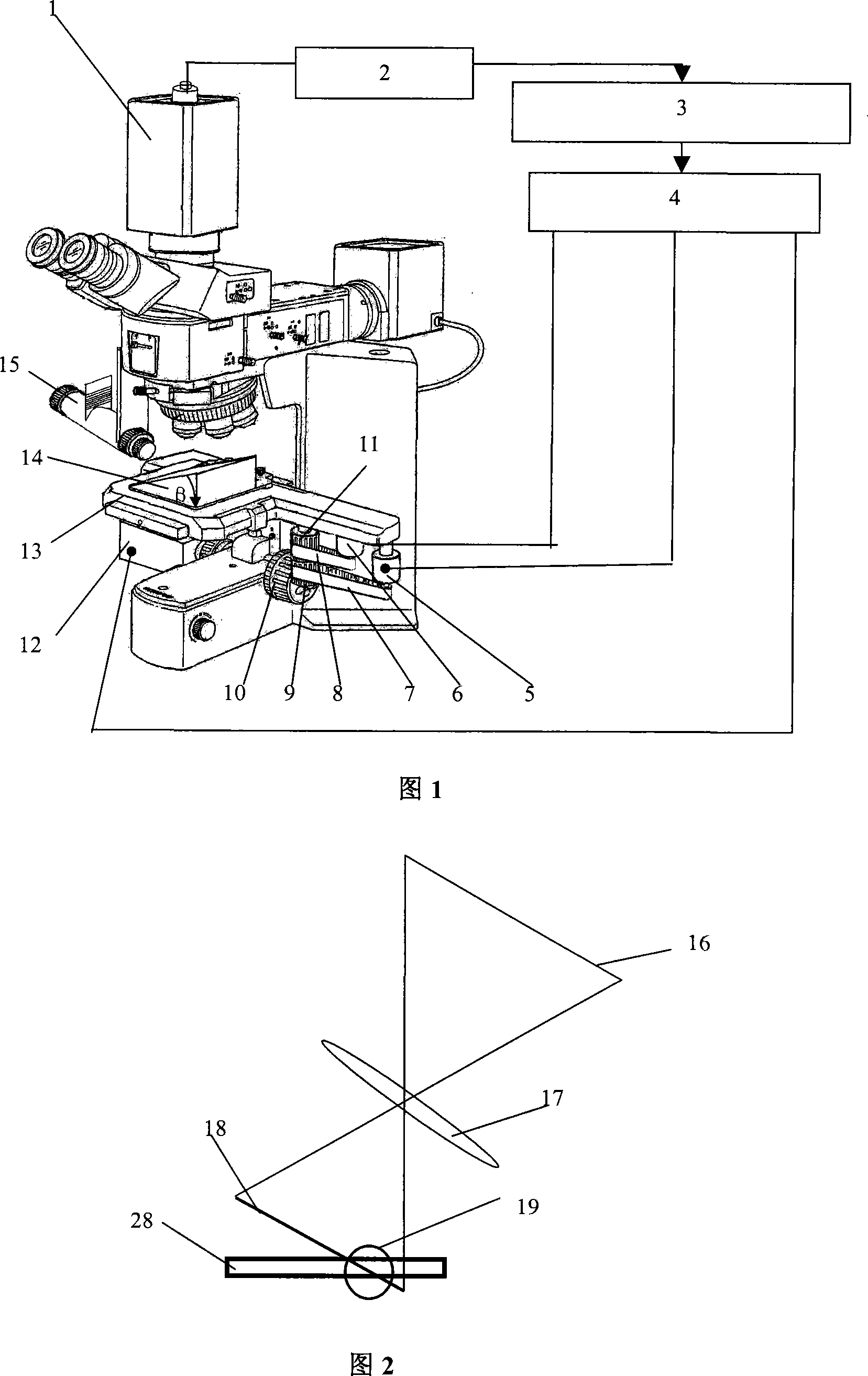

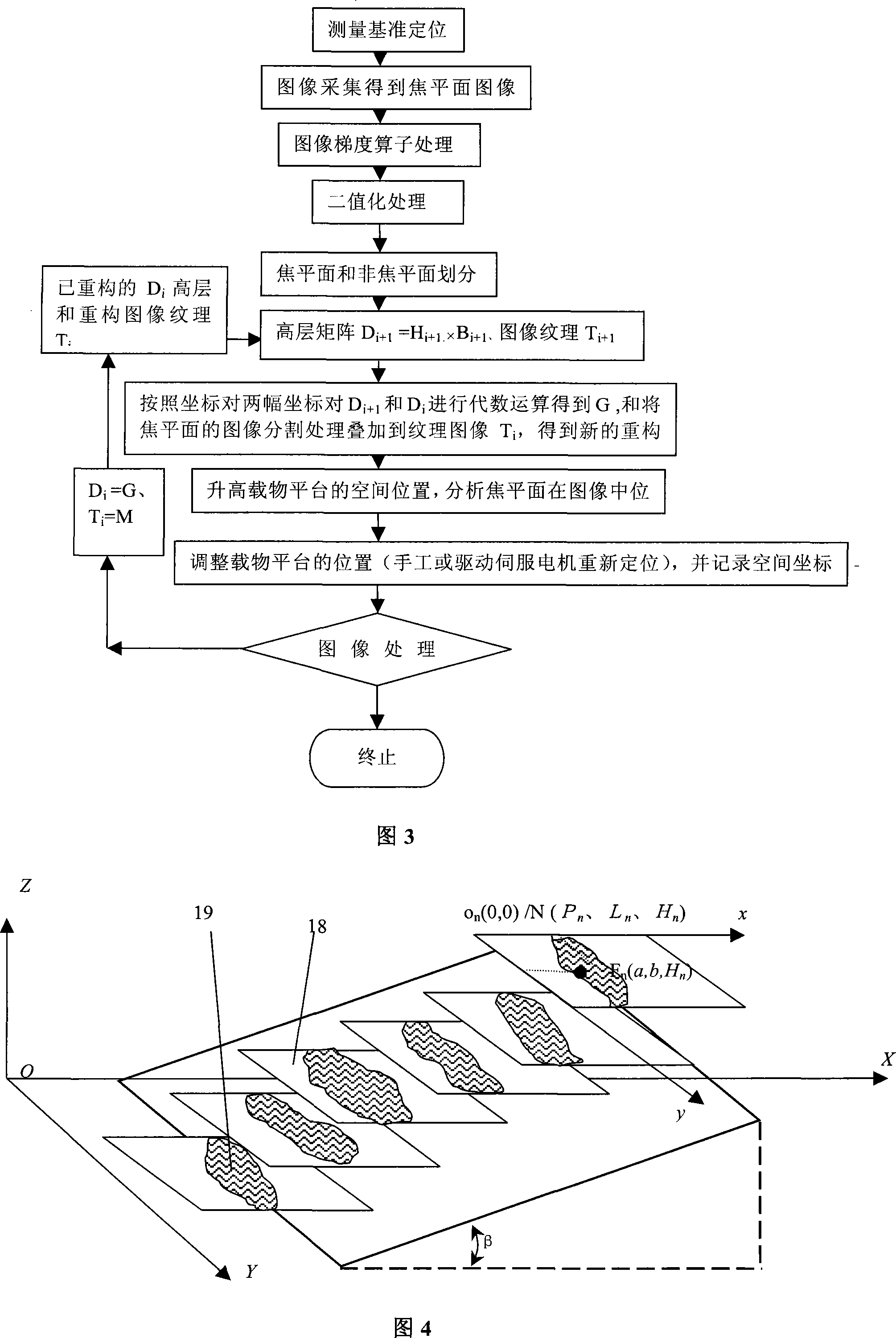

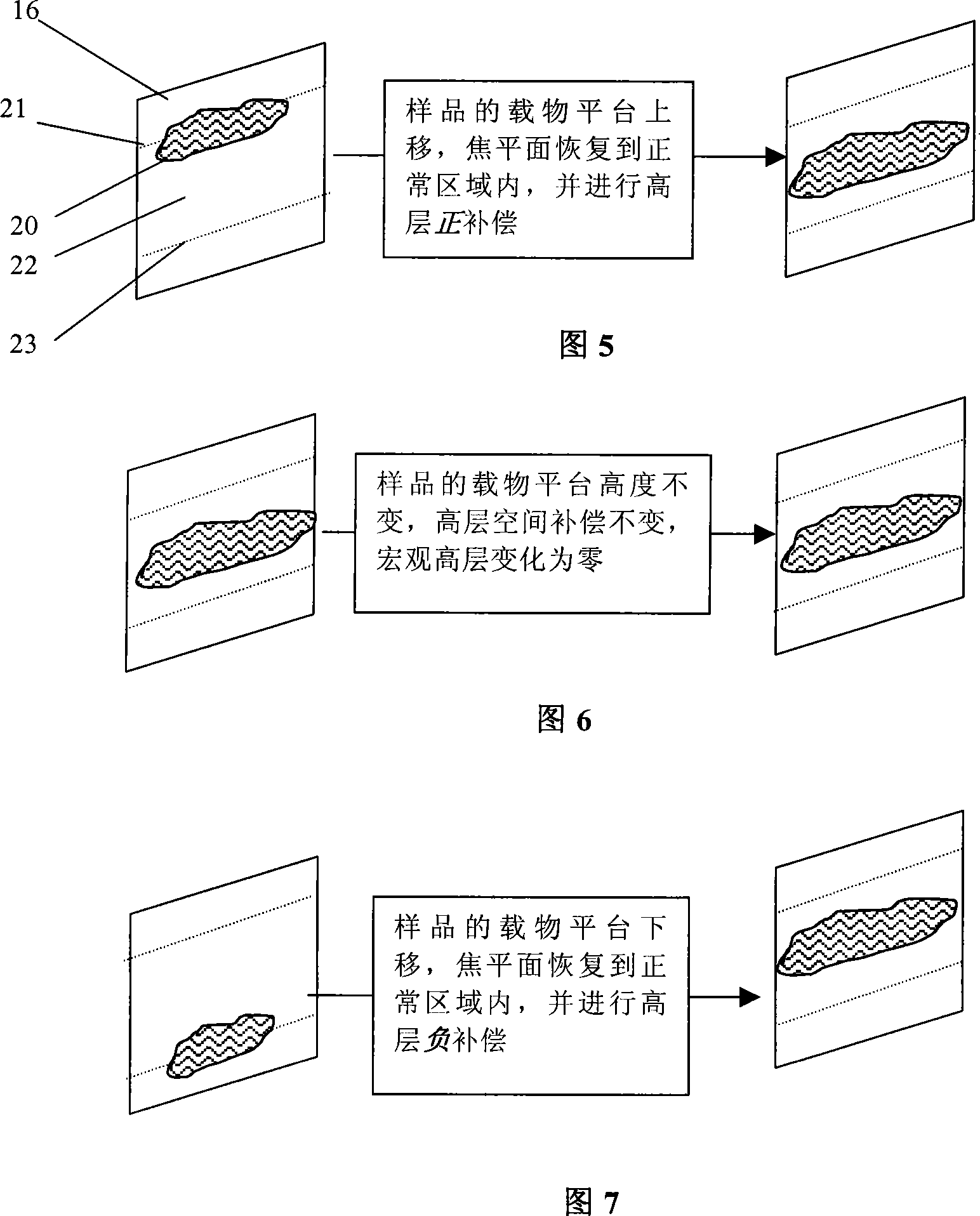

Three-dimensional microcosmic appearance inclined scanning method and apparatus

InactiveCN101226052AReduce scan timeSolve the slow scanning speedUsing optical means3D modellingThree dimensional morphologyDrift angle

The invention relates to a three-dimensional micro-morphology oblique scanning method and a corresponding device. The method is characterized in that the position of a focus object is adjusted by three stepping motors controlled by a computer, ensuring the object always at the central place in the oblique scanning and obtaining image texture and high-level information of the focus surface of the object, then obtaining a lager three-dimensional morphology image through synthesis and restructure. The device comprises the computer, a microscope and a camera (1); wherein, the camera is arranged on the microscope, an object-carrying platform (13) of the microscope is provided with an object-carrying wedge-shaped platform (14), the object-carrying wedge-shaped platform and a drift angle of the object-carrying platform forms a oblique focus surface when the drift angle Beta is 5 to 40 degrees, the three-dimensional movement space coordinate of the object and the image of the camera at the space coordinate are inputted to the computer at the same time, then restructuring the three-dimensional micro-morphology high-level and texture information on the basis. The three-dimensional micro-morphology oblique scanning method and a corresponding device has the advantages of avoiding useless work in non-focus area, reducing scanning time and improving scanning speed and efficiency.

Owner:武汉交通科技研究院有限责任公司

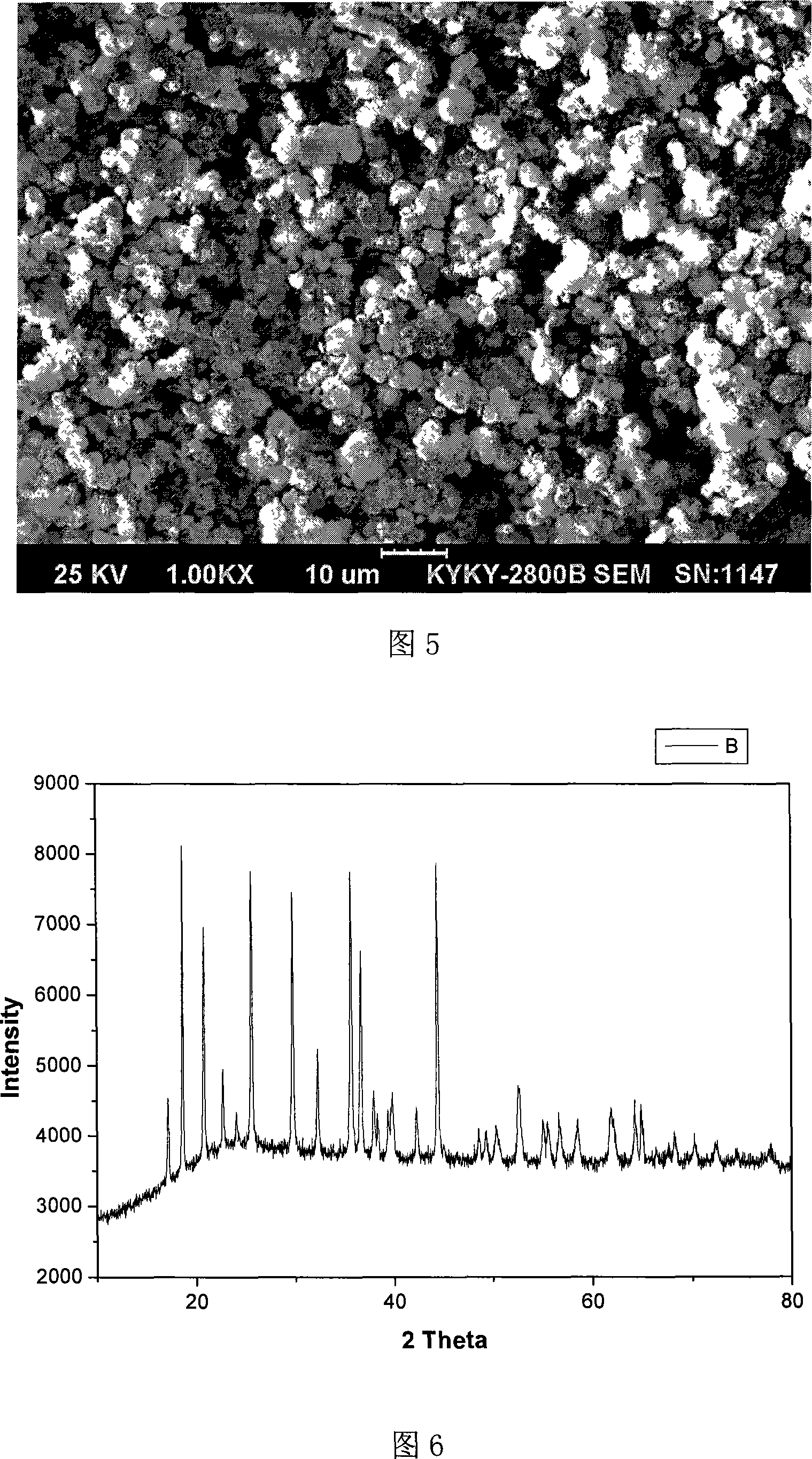

Preparation method of high-purity AlON transparent ceramic powder

InactiveCN105622104AInhibition of agglomerationThe original microscopic shape is maintainedWater basedMetallurgy

The invention belongs to the technical field of synthesis and preparation of ceramic material powder, and in particular, relates to preparation of a high-purity gamma-AlON transparent ceramic powder. The preparation includes the following steps: (1) weighing raw material; (2) preparing a pre-mixed solution; (3) preparing a slurry; (4) carrying out freeze drying; (5) carrying out low temperature calcination; and (6) carrying out high temperature reaction synthesis, to obtain the gamma-AlON transparent ceramic powder. By using the freeze drying technology, water is sublimated at lower temperature, so that nano powder agglomeration in a water-based system can be effectively inhibited, an initial micro-morphology of the raw material can be maintained, and the mixed powder with fluffy organizational structure is obtained; compared with traditional spray drying, the freeze drying technology can reduce the loss of the raw material powder, can improve the utilization rate of the powder, and reduces the preparation cost.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

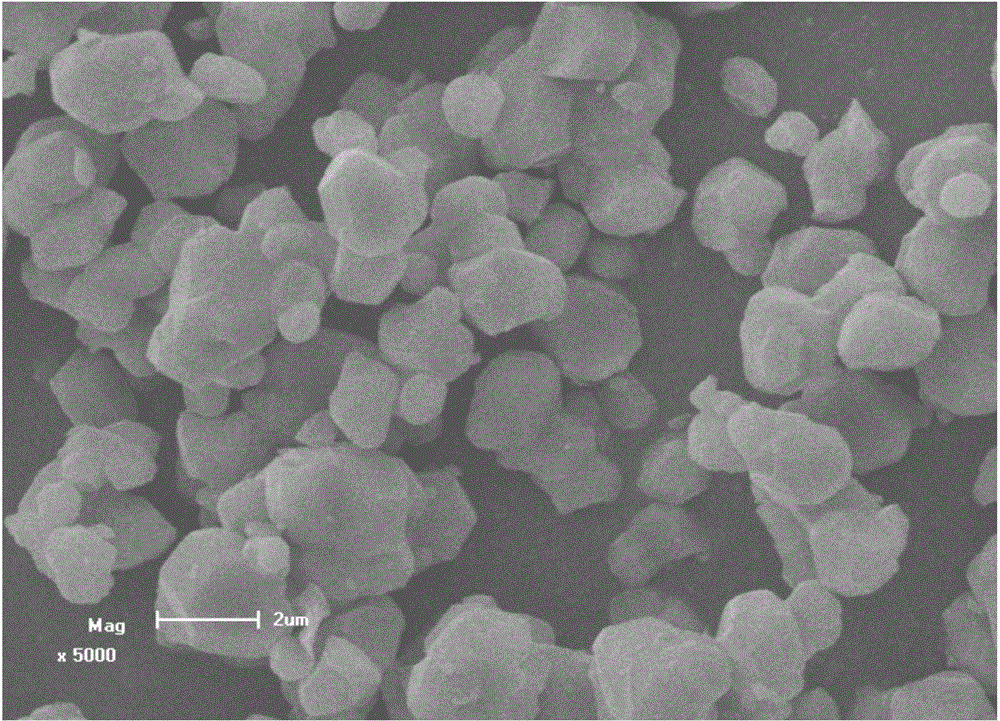

A kind of bismuth oxycarbonate material of nano-micro scale plate and its preparation method

The invention discloses a nano / micro-scale sheet bismuthyl carbonate material and a preparation method thereof. Micro-morphology of the nano / micro-scale sheet bismuthyl carbonate material is in the shape of a sheet-like particle. The particle size is in a range of 10 to 1000 nm. The preparation method comprises that urea is prepared into a urea aqueous solution; the urea aqueous solution and bismuth nitrate pentahydrate are mixed according to a certain proportion; the mixed solution is maintained at a temperature of 100 to 200 DEG C under the pressure above 3MPa for 1 to 4 hours to undergo a reaction; after the reaction, the reaction products are cooled in air to room temperature; and the cooled products are filtered by a pump, washed by water and dried at room temperature to form the nano / micro-scale sheet bismuthyl carbonate material. The nano / micro-scale sheet bismuthyl carbonate material has the advantages of good dispersibility, high purity, high bismuth recovery rate above 90%, no need of addition of any organic solvent in preparation, and no damage on human bodies and the environment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

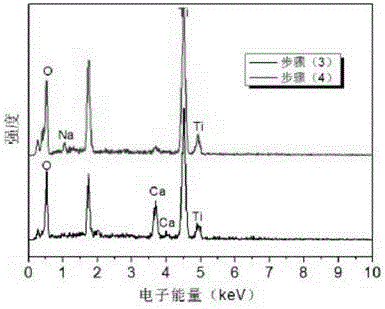

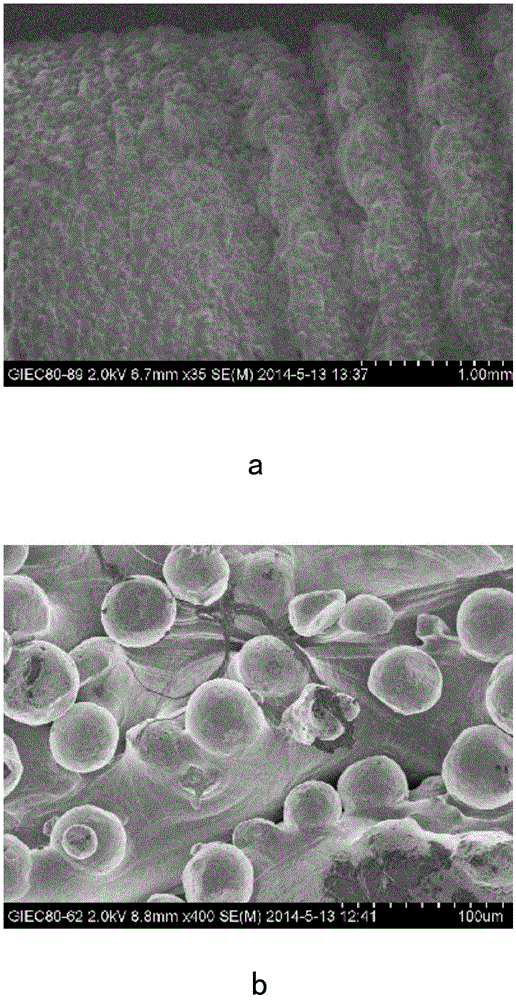

Surface treatment method for SLM molded titanium implant

ActiveCN105537589AImprove microscopic morphologyImprove hydrophilicityAdditive manufacturingPharmaceutical delivery mechanismMicro nanoCalcification

The invention discloses a surface treatment method for an SLM molded titanium implant. The surface treatment method comprises the following steps: carrying out SLM molding on the titanium implant; carrying out sand blasting treatment: adopting corundum or titanium dioxide to carry out surface sand blasting treatment on the surface of the SLM molded titanium implant; picking to remove impurities: putting the SLM molded titanium implant subjected to the sand blasting treatment into a pickling solution to carry out pickling treatment; carrying out alkali thermal treatment: putting the SLM molded titanium implant subjected to the pickling treatment into an alkali solution to carry out hydro-thermal treatment; carrying out calcification treatment: taking a calcium salt solution as a cationic exchange fluid, putting the SLM molded titanium implant subjected to the alkali thermal treatment into the cationic exchange fluid at a temperature of 100-200 DEG C to carry out hydro-thermal treatment for 1-5 hours; and after teach step, sequentially putting the SLM molded titanium implant into acetone, 95% alcohol and deionized water to respectively ultrasonically clean and dry. The surface treatment method is simple in step, and is easy to operate; and the surface, with a micro-nano grading structure, of the SLM molded titanium implant is constructed, so that the roughness, the microstructure, the mineralization characteristics and the biological activity of the surface of the SLM molded titanium implant are effectively improved.

Owner:广东中科安齿生物科技有限公司

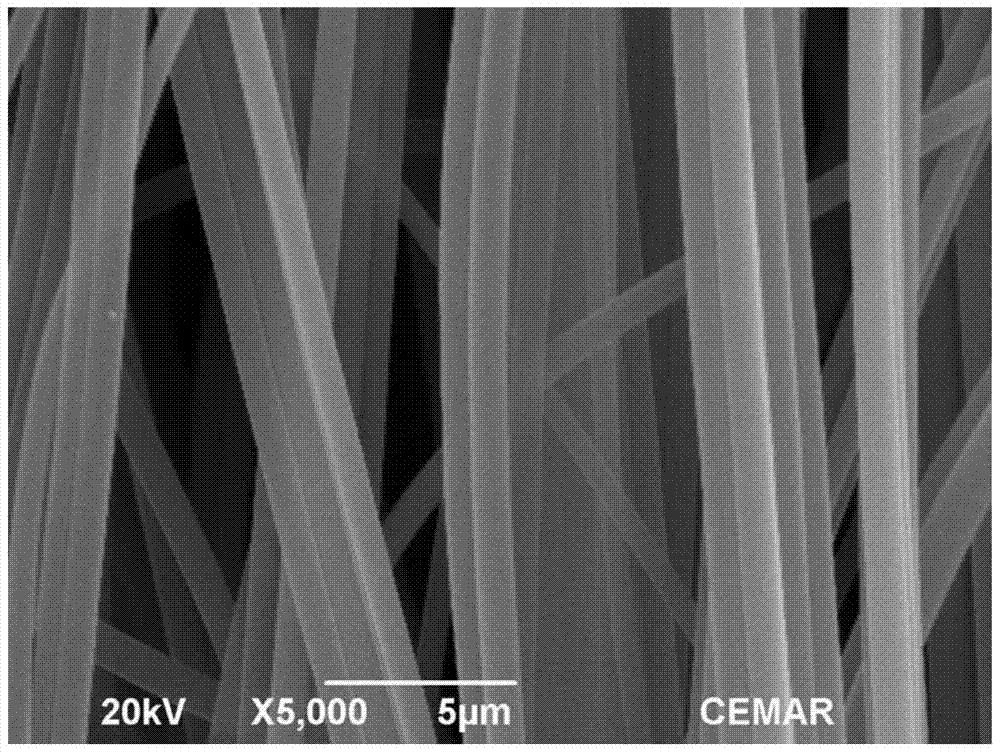

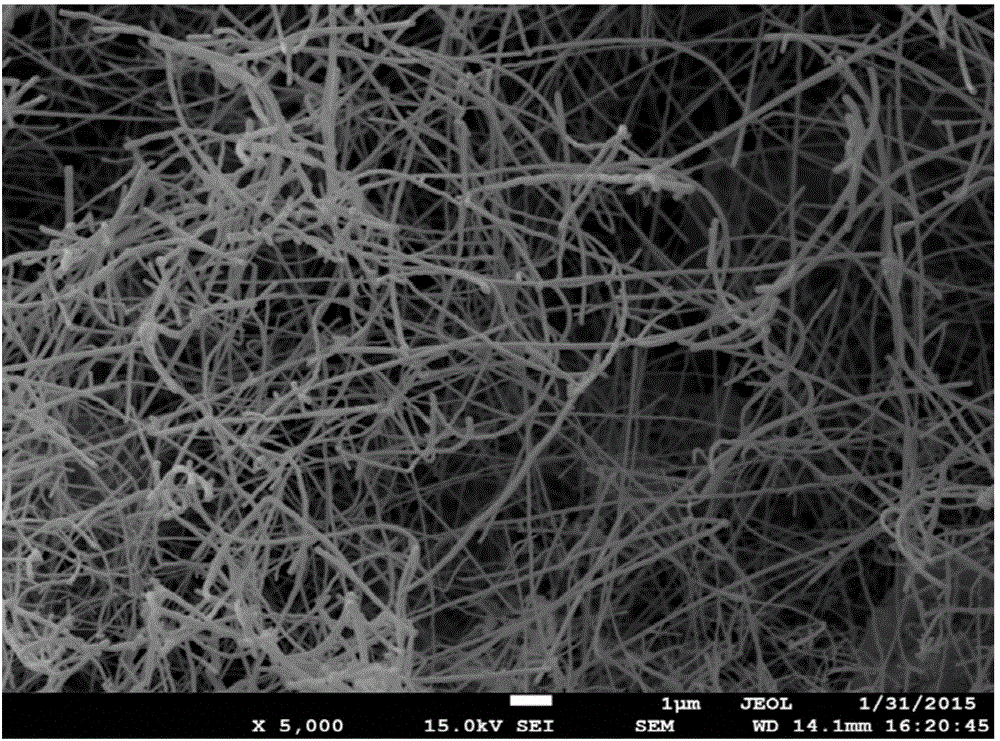

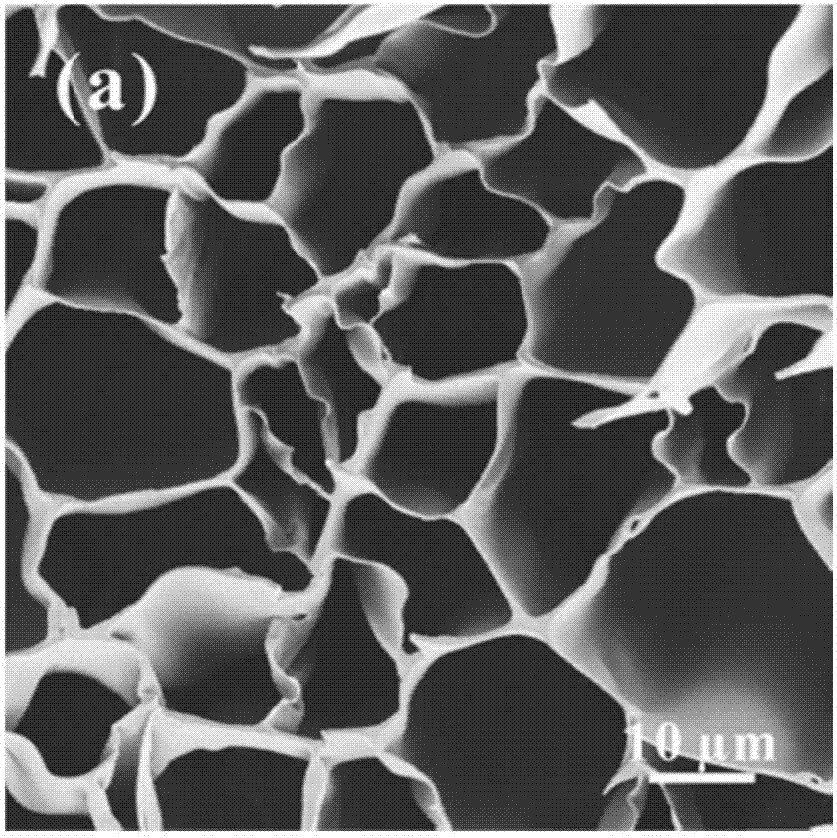

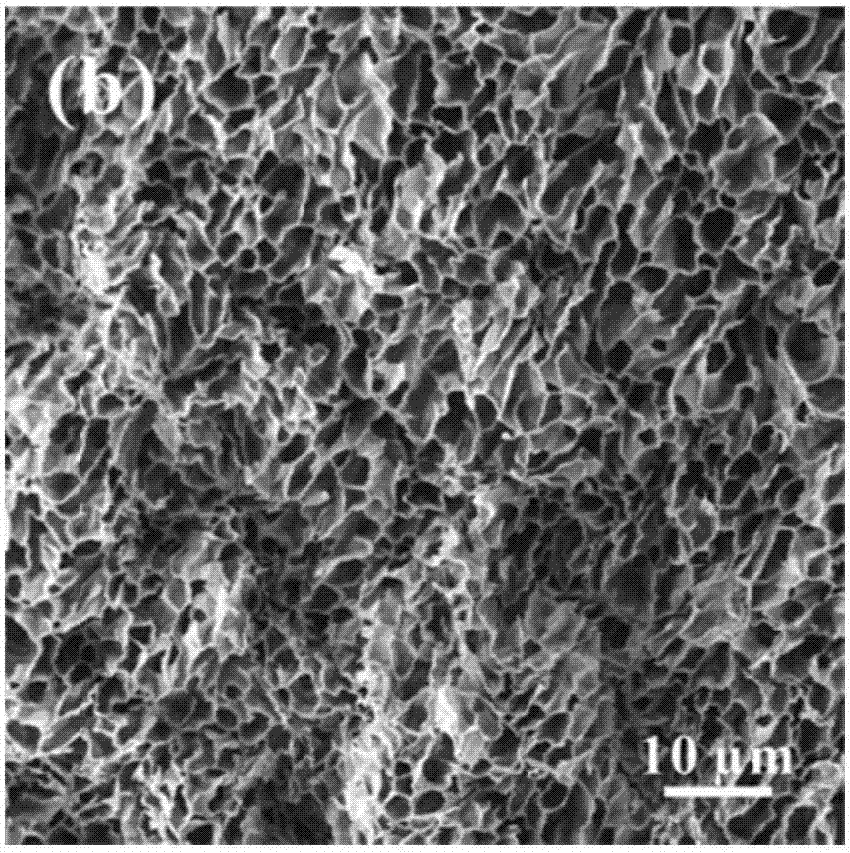

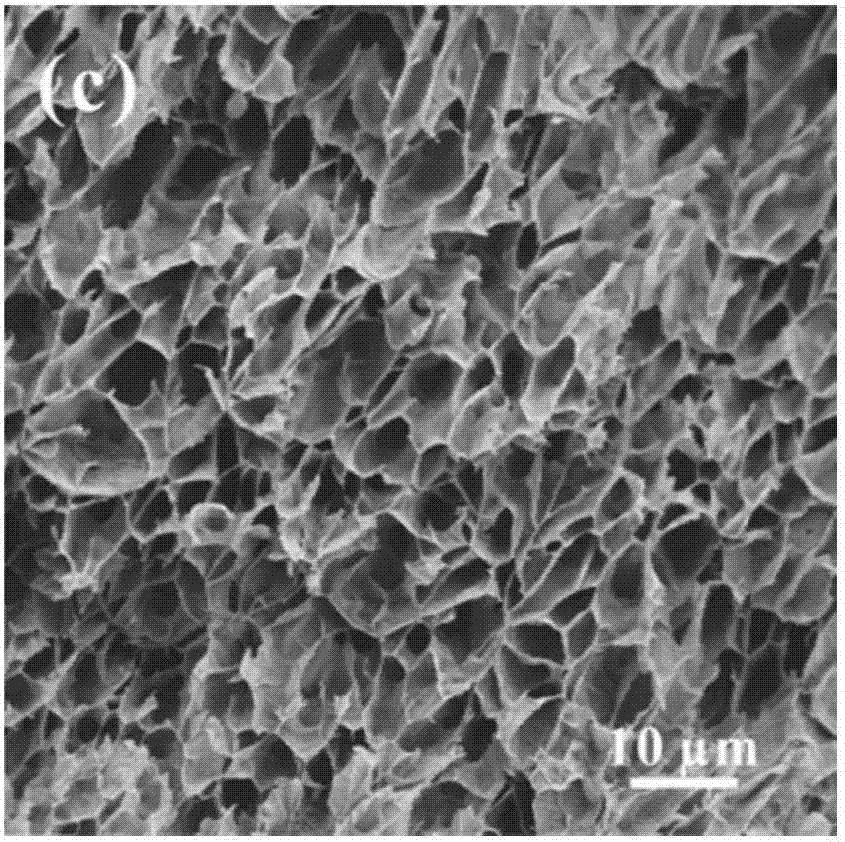

Controllable-morphology high-porosity porous ceramic membrane supporting body and preparation method thereof

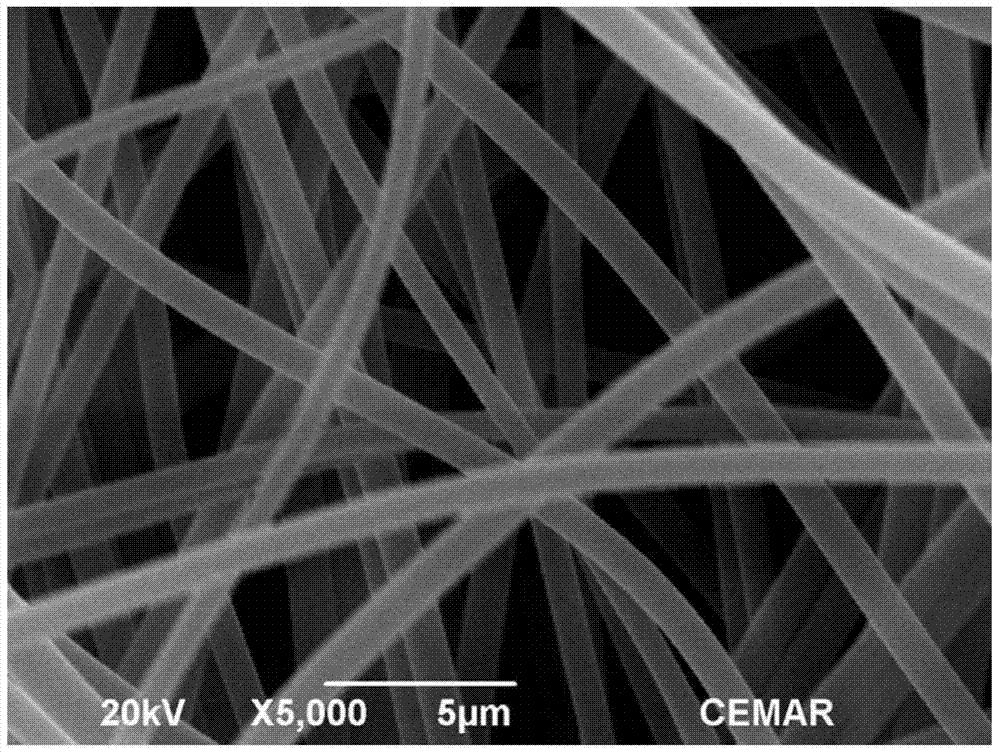

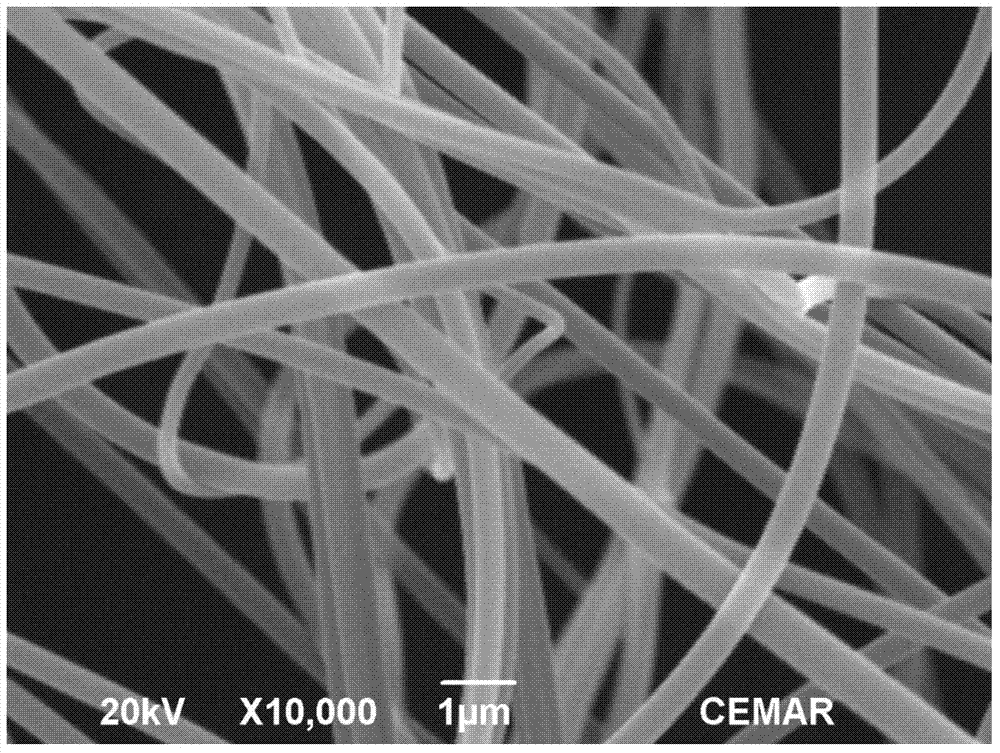

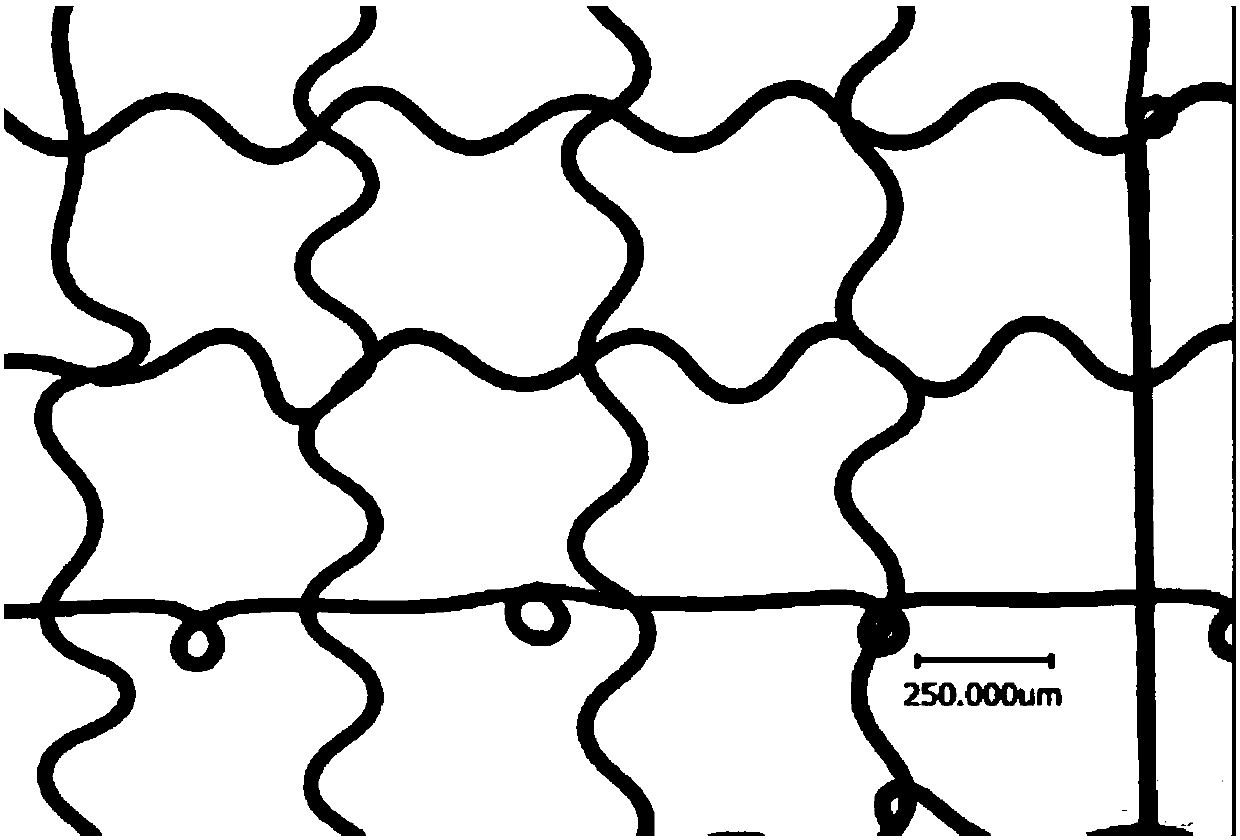

The invention relates to a controllable-morphology high-porosity porous ceramic membrane supporting body and a preparation method thereof. Electrostatic spinning is used for preparation of a ceramic material / polymer micro / nano composite fiber, and a new method for directly sintering a composite fibrofelt into ceramics is used for preparation of the controllable-morphology high-porosity porous ceramic membrane supporting body. Compared with a method for construction and preparation of high-penetration ceramic supporting body by using a ceramic fiber, the preparation method has no need of secondary sintering, the process flow can be simplified, energy consumption can be saved, and moreover, the shape and micro-morphology of the supporting body can be controlled. By regulating electrostatic spinning parameters, the diameter of the composite fiber can be controlled to be nano or micron level and the fiber stacking density can be controlled, so as to control the microstructure of the ceramic membrane supporting body, and thus the pore size and porosity of the supporting body can be controlled. With use of the new preparation route, the high-porosity porous ceramic membrane supporting body having the pore size of 0.1-10 [mu]m, the porosity of 50-85% and the pure water flux of 1700-2500 L / m<2>.h under the pressure of 0.5 bar is obtained.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

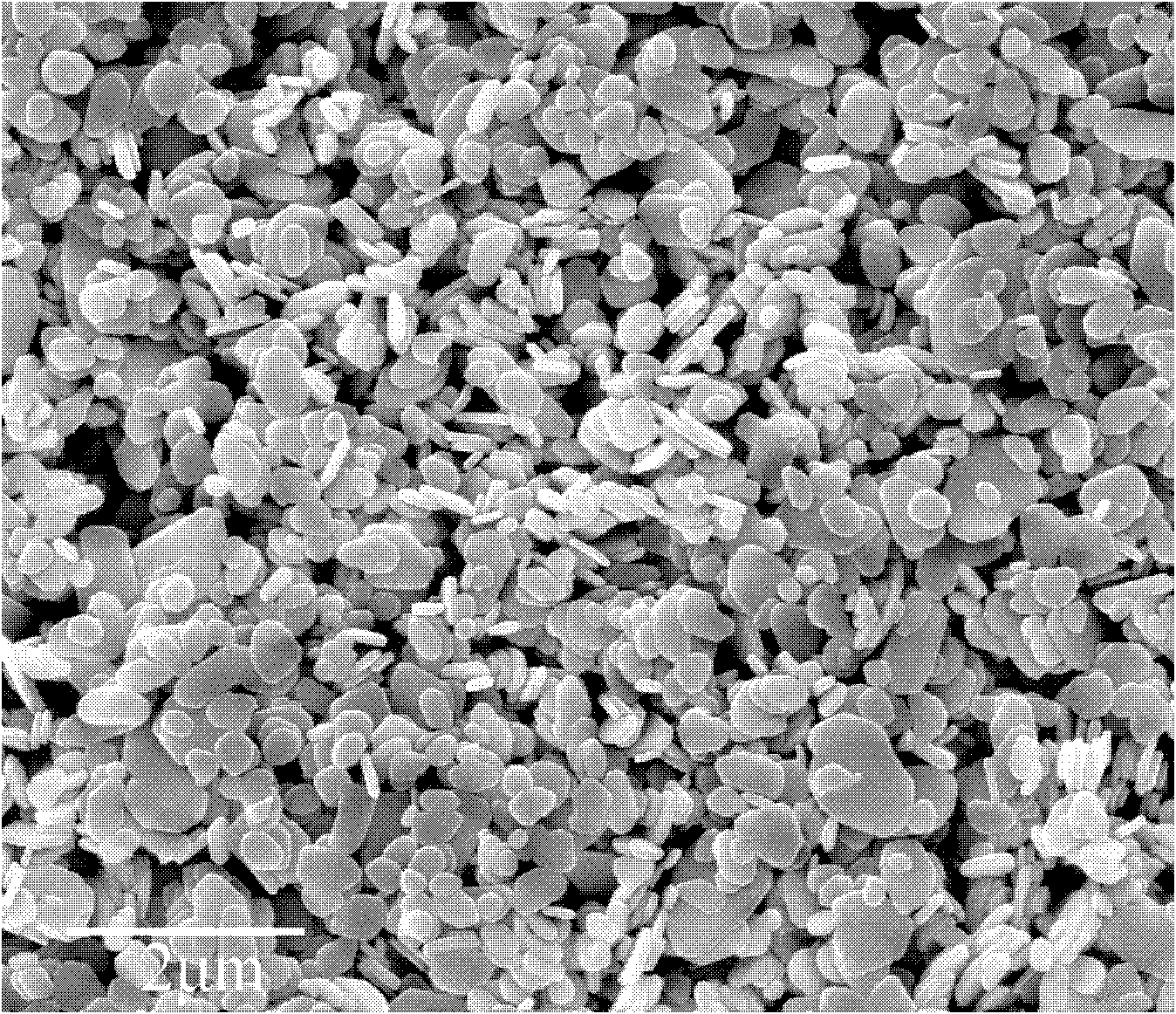

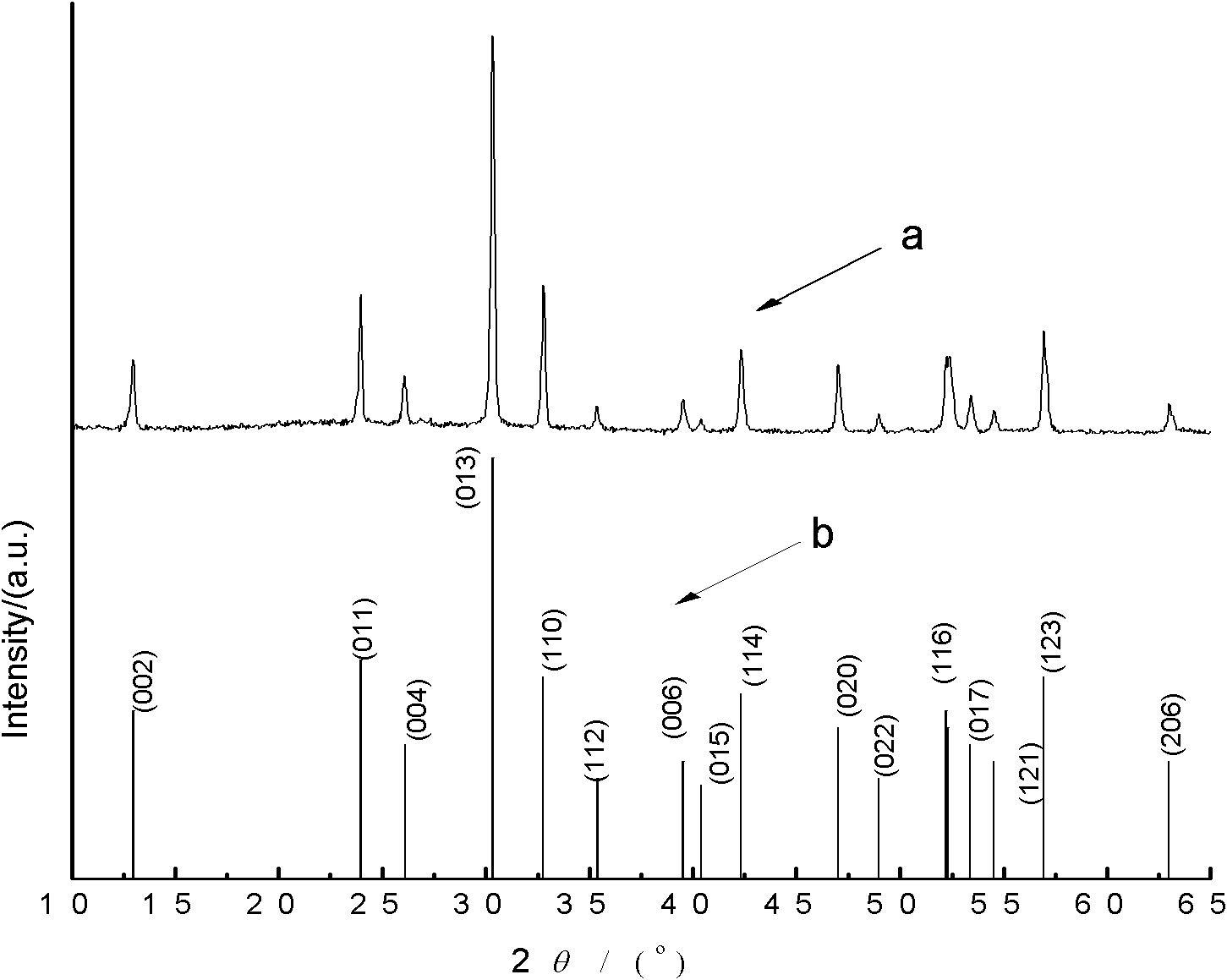

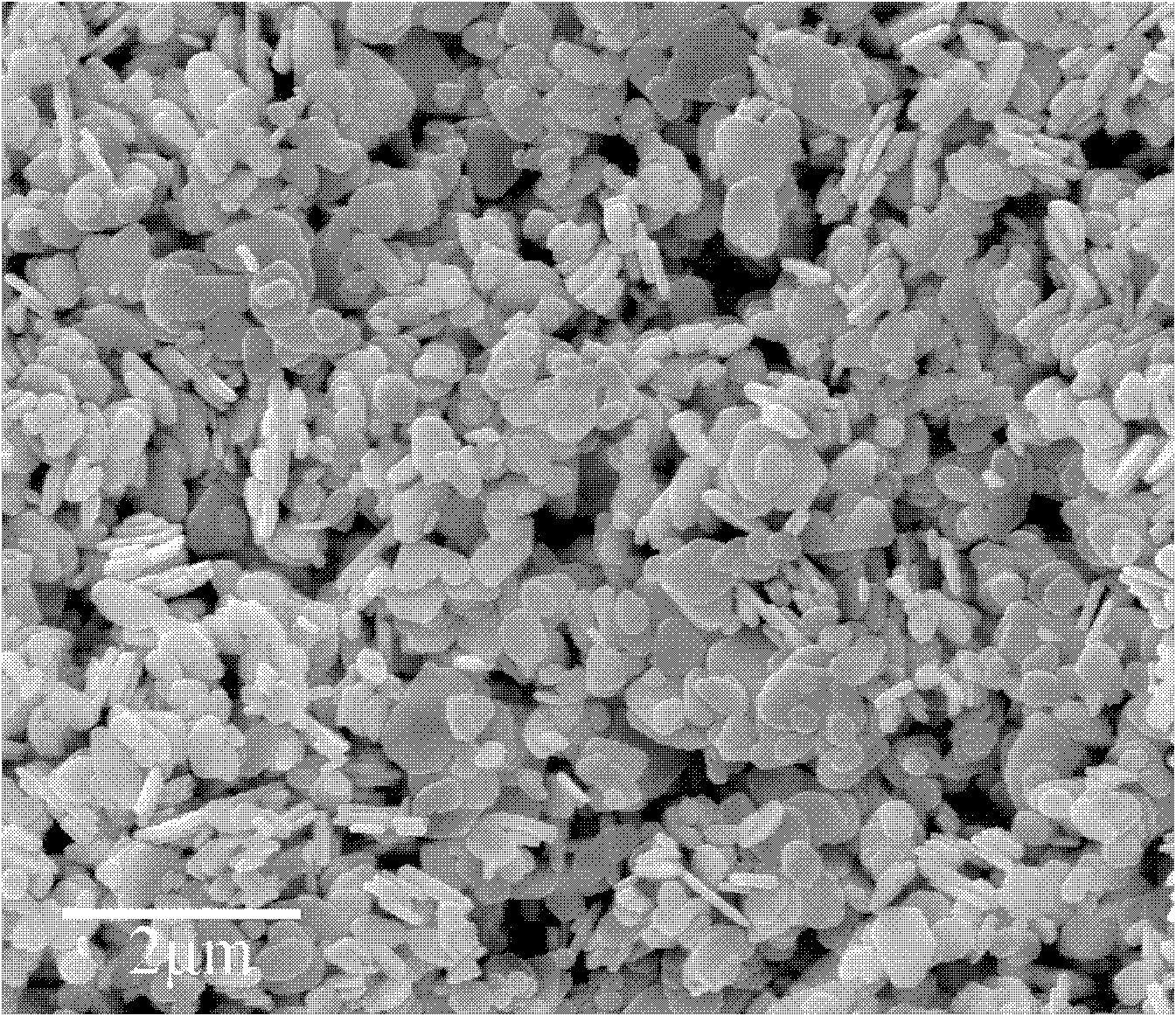

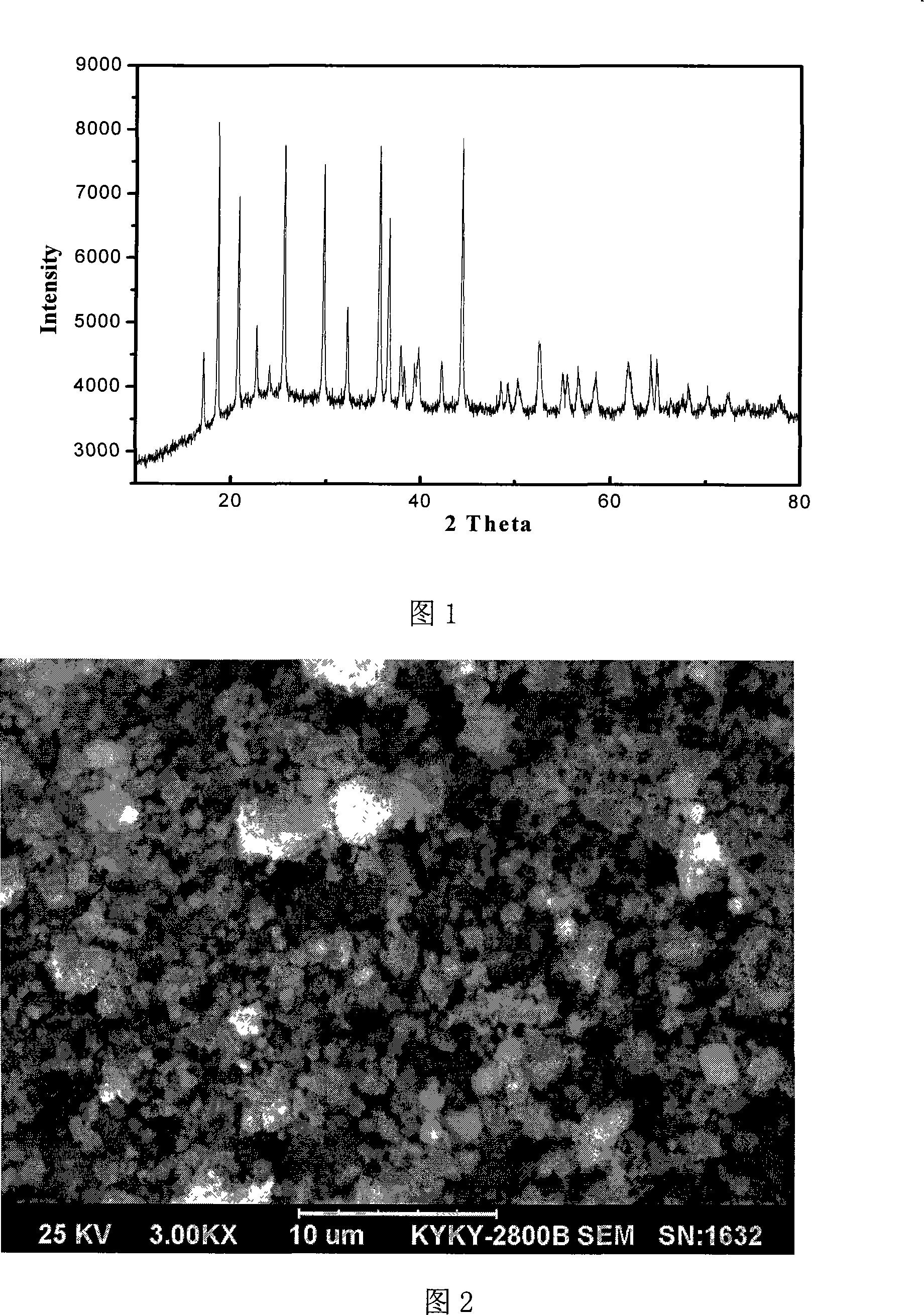

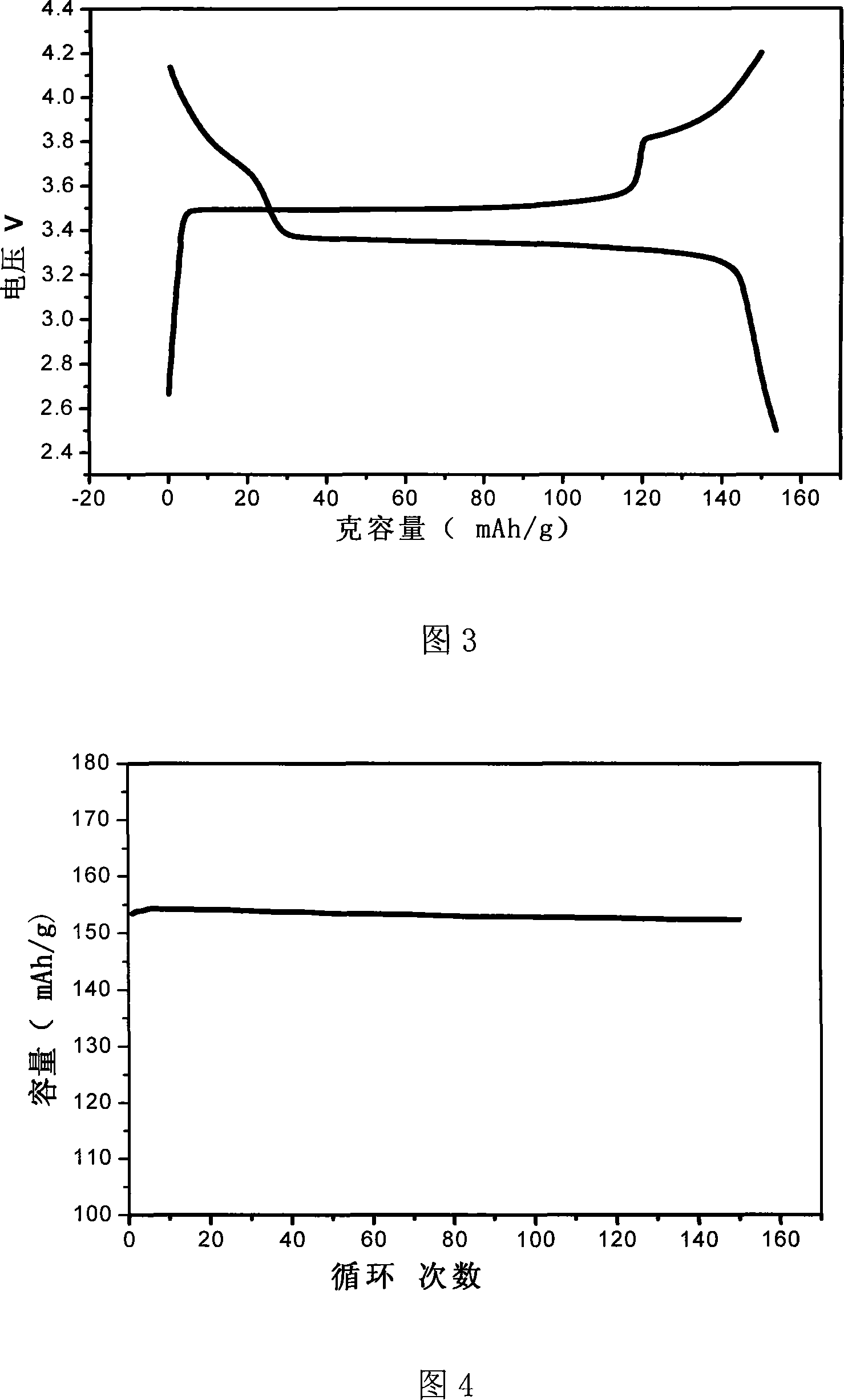

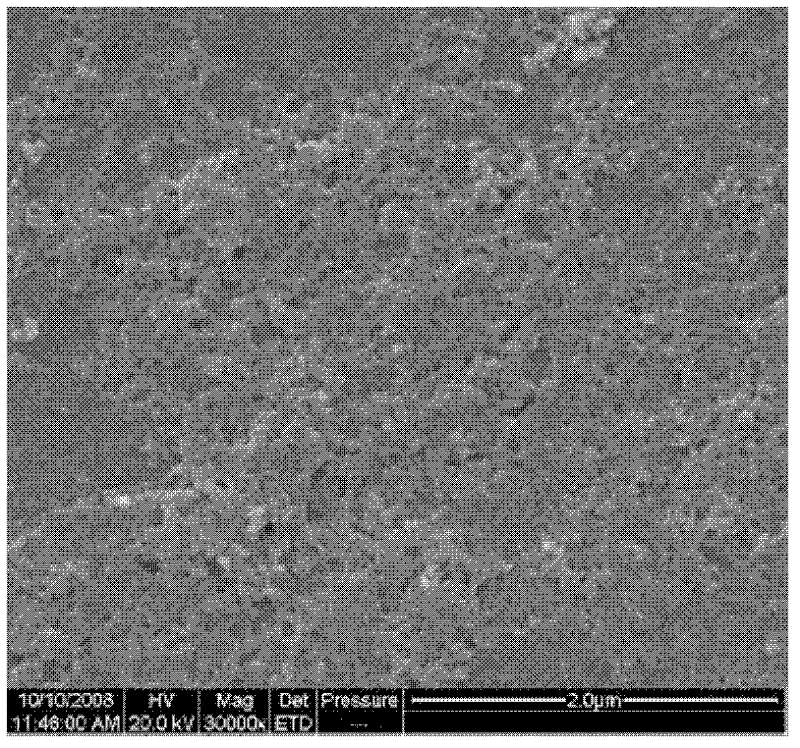

Fe base lithium sale compound anode materials and its making method

ActiveCN101188293AStable structureHigh voltage platformElectrode manufacturing processesChemical/physical/physico-chemical processesHigh rateManganese

The invention discloses a ferrous lithium salt composite anode material and thepreparation method thereof. The technical problems which are needed to be solved are to enhance the high-rate electricity discharging of the anode material, and the manufacturing and the processing performances of battery electrodes are improved. The ferrous lithium salt composite anode material has lithium iron phosphate, and forms the composite material by adulterated with or covered by nickel-cobalt-manganese-lithium or nickel-cobalt-aluminum-lithium material. The weight ratio of the lithium iron phosphate and the nickel-cobalt-manganese-lithium or the nickel-cobalt-aluminum-lithium material is 9 to 7 : 1 to 3, and the micro-morphology is in a sphericity , or is like a sphericity, with a ration between a horizontal length and a vertical length of 1.2 to 2.5. The crystal is in the structure of an olivine type, a space group is Pbnm, and a particle diameter is 1 to 20microns. The preparation method comprises mixture, fusion processing and screen separation. Compared with the prior art, the ferrous lithium salt composite anode material has the advantages of capable of lowering specific surface area, capable of enhancing the voltage platform of the anode material, favorable processing performance, high tap density, favorable conductivity, favorable rate discharge performance and safe performance, capable of improving high and low temperature cycling performance, and favorable compatibility with various cathodes and electrolytes.

Owner:常州锂源新能源科技有限公司

Rice-husk-based porous silicon carbide ceramic material and preparing method thereof

The invention discloses a rice-husk-based porous silicon carbide ceramic material and a preparing method thereof. The rice-husk-based porous silicon carbide ceramic material is mainly prepared from rice husks and a mixture, and mass of the mixture is 30%-70% of that of the rice husks; the mixture is prepared from, by mass, 1%-30% silicon powder, 5%-40% carbon source, 1%-15% catalyst and 30%-70% binding agent. Agricultural residue rice husk serves as the main raw material of the rice-husk-based porous silicon carbide ceramic material, and is mixed with silicon powder, carbon source, catalyst and binder to prepare a semi-finished product after formation, drying and calcination; the source of the raw material which are used has wide source and low cost, the prepared product has the advantages of high porosity, big mechanical strength, good filtering effect, excellent thermal shock resistance, micro and fine hole diameter of pore, adjustable micro-morphology and the like, has wide development space and application prospect, and is suitable for industrial popularization and application.

Owner:马琰珂

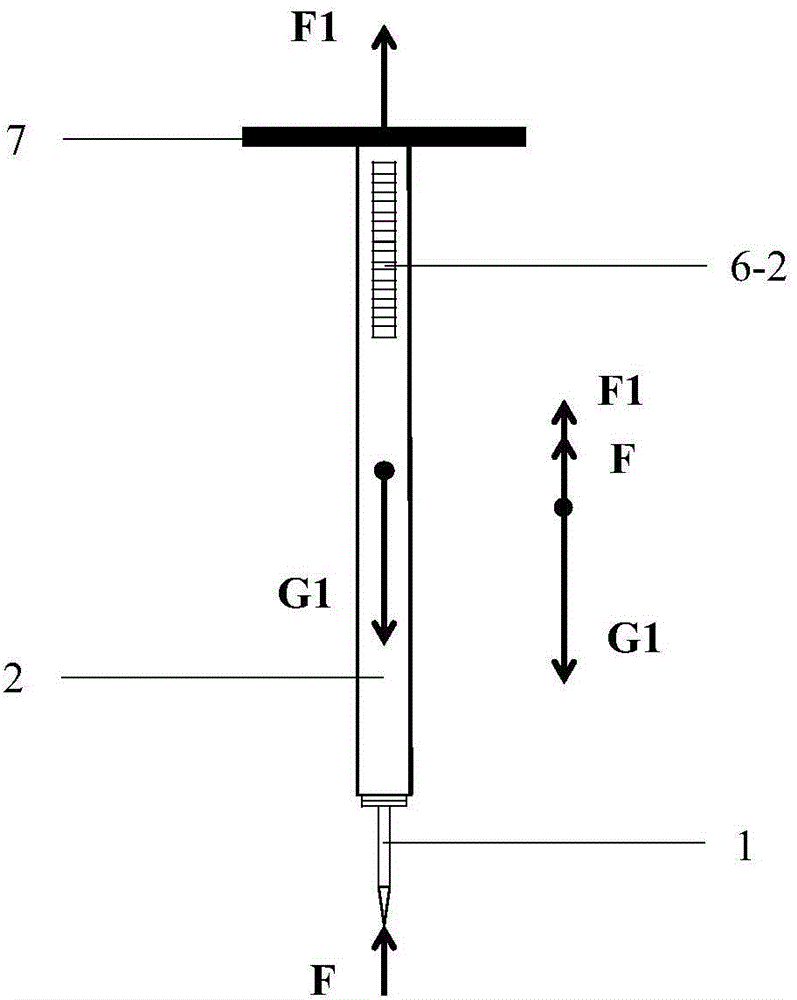

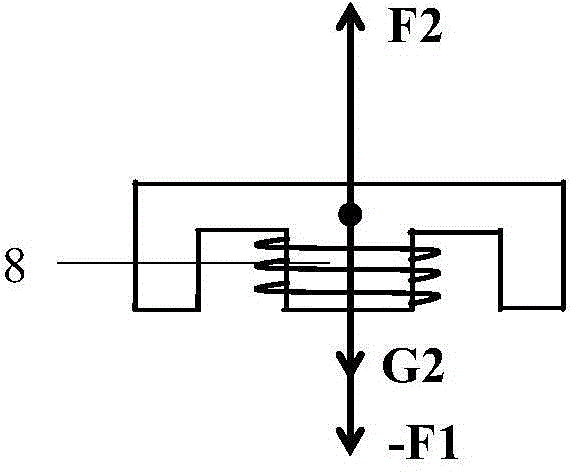

Measuring force-controllable contact probe type displacement sensor used for micro morphology detection

InactiveCN104897099AChanging the measuring force is unmeasurable,Change technical defects that are difficult to controlMeasurement devicesProbe typeForce sensor

The invention discloses a measuring force-controllable contact probe type displacement sensor used for micro morphology detection, and relates to the technical field of microstructure surface quality testing. The sensor mainly comprises a measuring head module, a measuring head support module, a displacement detection module and a measuring force control module; the measuring head module consists of a probe and a probe rod, and can move with a change of a surface of a measured sample, the measuring head support module is used for providing radial support force for the measuring head module, and the displacement detection module is used for measuring displacement information of a measuring head; and the measuring force control module includes an armature, an electromagnet and a micro tension and pressure sensor, and can detect and control measuring force. By adjusting electromagnetic force to control the measuring force to be within a certain range, the measuring force-controllable contact probe type displacement sensor can guarantee good contact of the probe and the sample without damaging the sample, measurement accuracy of the contact probe type displacement sensor is improved, and the technical defect of a conventional contact probe type displacement sensor that measuring force cannot be measured and is not easy to control is completely changed.

Owner:SICHUAN UNIV

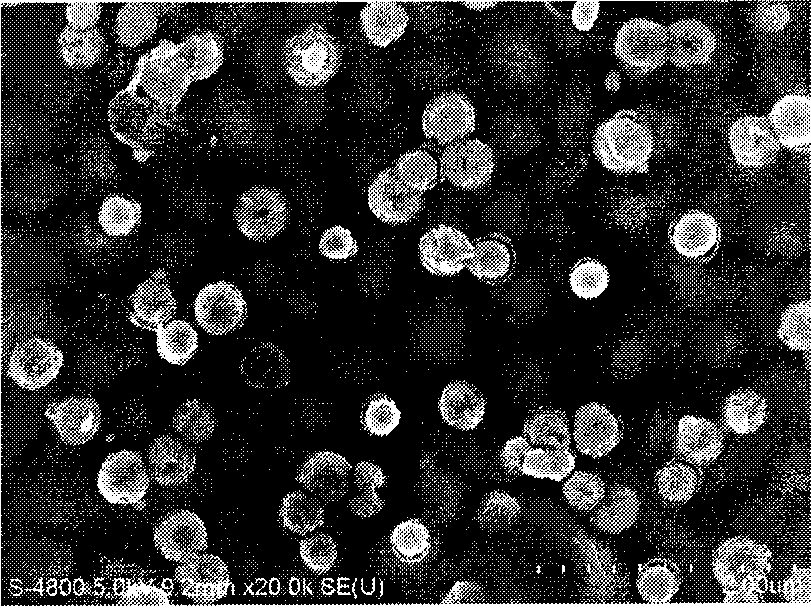

Photochromic WO3 film with hollow microsphere as micro-morphology and preparation method thereof

InactiveCN101417819AIncrease profitEnhance photochromic reactivityTungsten oxides/hydroxidesTenebresent compositionsTungstateMicrosphere

The invention discloses a photochromic WO3 film with the microcosmic appearance of censphere and a preparation method thereof, wherein the method comprises the following steps of: (1) confecting 0.05-3mol / L of tungstate solution; (2) preparing tungstenic acid solution by the tungstate solution through cation exchange resin; (3) regulating the pH value to 0.8-2.0 by the concentrated hydrochloric acid with 37-38 percent of weight percent concentration; (4) adding a dispersant and a stabilizer based on 1.0: 0.1-2.0: 0.1-1.0 volume ratio of the tungstate solution, the disperant and the stabilizer; (5) adding a nucleating agent based on 1.0: 0.1-1.0 volume ratio of the tungstate solution and the nucleating agent; (6) film coating and drying; and (7) carrying out thermal treatment to obtain the WO3 film with the microcosmic appearance of censphere. The microcosmic appearance is censphere and the grain diameter is 200-600nm. The prepared WO3 film can generate favorable color changing effect under the condition of low-power excitation light source, thus improving the photochromic performance of the WO3 film.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

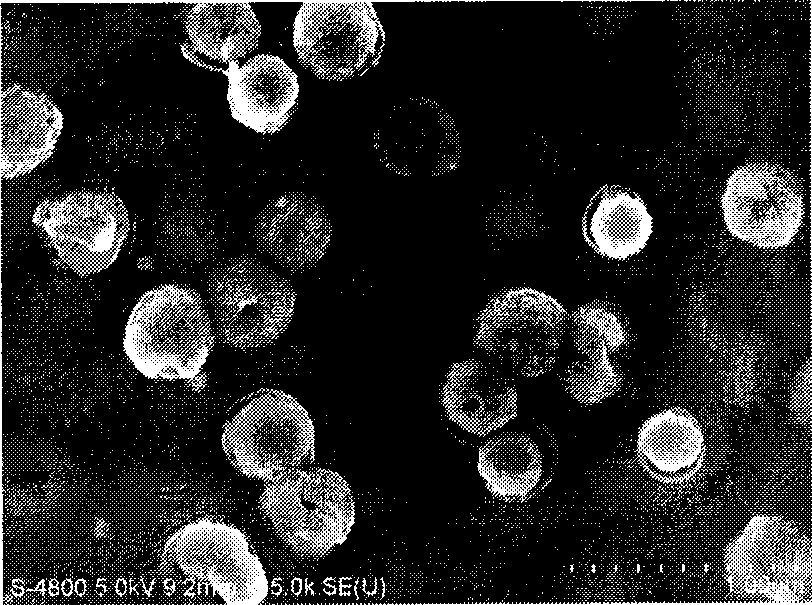

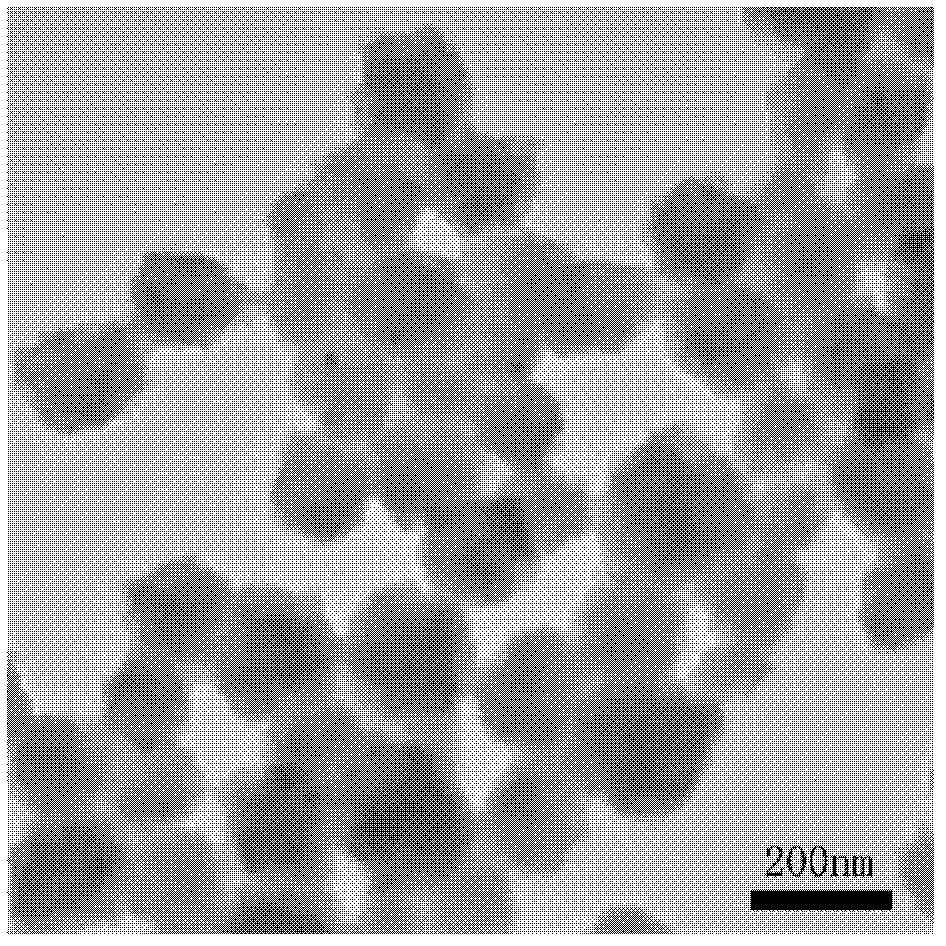

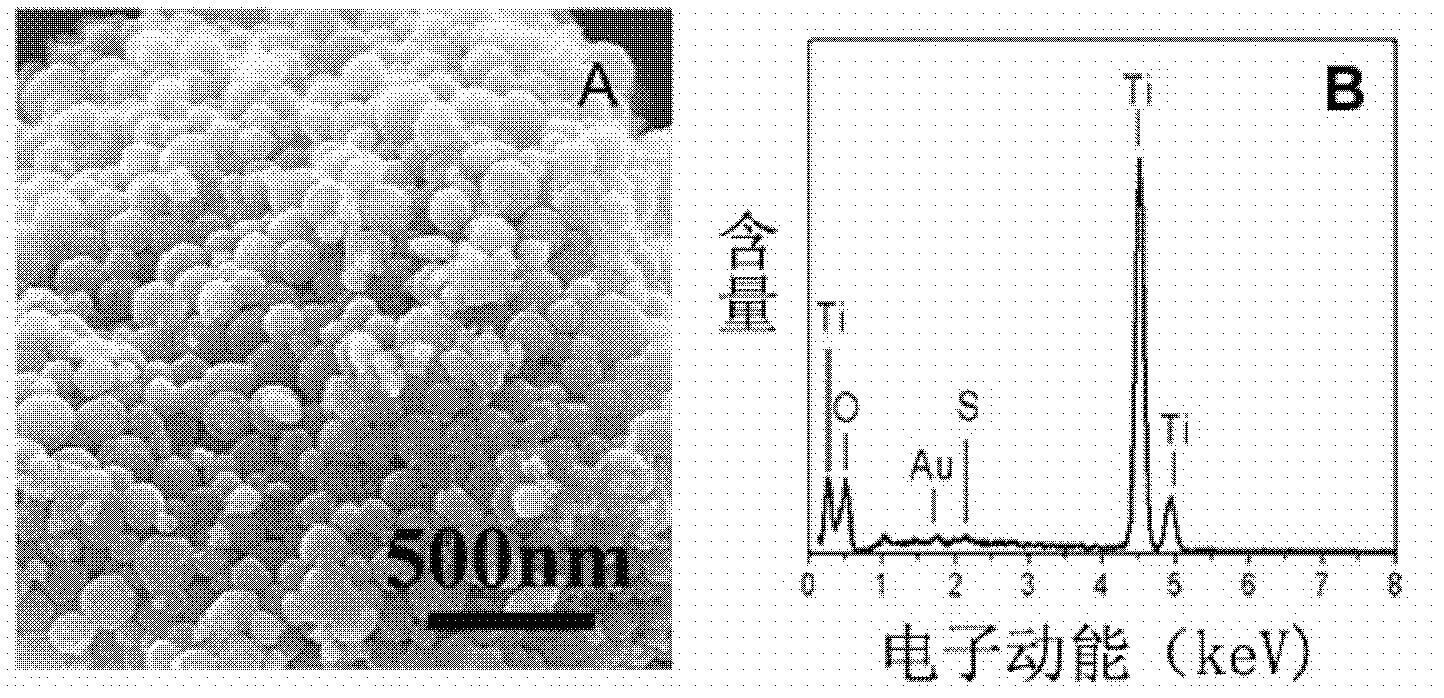

Preparation method of nano-sized gold/ titanium dioxide compound mesoporous microspheric photocatalyst

InactiveCN102527381AVisible light catalytic activity is highEffective dispersionWater/sewage treatment by irradiationEnergy based wastewater treatmentPhotocatalytic reactionMicrosphere

The invention discloses a preparation method of nano-sized gold / titanium dioxide compound mesoporous microspheric photocatalyst, and belongs to the technical field of catalysts. The preparation method comprises the following steps: mixing monodisperse oil-phase titanium dioxide nanocrystal and a monodisperse oil-phase gold nanocrystal in a mass ratio of gold to titanium dioxide of (0.5-15): 100; adding the mixture into an aqueous solution in which sodium dodecyl sulfate is dissolved; crushing the mixture by using an ultrasonic crushing device to obtain a microemulsion; completely evaporating an organic solvent in an oil bath at 50-80 DEG C, centrifugating, eluting and drying; and calcining dried powder to obtain the gold-doped nano-sized titanium dioxide mesoporous sphere. Components of the prepared nano-sized gold / titanium dioxide compound mesoporous microsphere keep respective microscopic shapes; and the two nanocrystals are assembled by the microemulsion method to form a special mesoporous structure, so that the specific surface is large, the mass transfer is easy and the photocatalysis easily occurs on the surface of the catalyst.

Owner:BEIJING UNIV OF CHEM TECH

Martensite high-alloy heat resistant steel metallography detection polishing agent and application thereof

InactiveCN101831653AThe preparation method is simple and easyImprove polishing effectPreparing sample for investigationMaterial analysis by optical meansOXALIC ACID DIHYDRATEMetallography

The invention relates to a Martensite high-alloy heat resistant steel metallography detection polishing agent, and the polishing agent comprises the following components in parts by weight: 1.8-2.2 parts of oxalic acid, 0.8-1.2 parts of hydrofluoric acid, 10-30 parts of water and 30-50 parts of hydrogen peroxide. The invention also relates to the application of the polishing agent in metallography detection, which comprises the following steps: (1) abrading; (2) polishing; (3) corrosion: a test surface of Martensite high-alloy heat resistant steel is corroded by chemical etchant, thus displaying a microscopic metallographic structure; (4) replication: a medical film is applied to the test surface of the Martensite high-alloy heat resistant steel, and micro morphology of the metallographic structure is extracted; and (5) observation: taking pictures and evaluation. The Martensite high-alloy heat resistant steel metallography detection polishing agent and the application have scientific compatibility, simple fabrication process, good polishing effect and high innovation and can effectively prevent pseudophase from generating in polishing.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

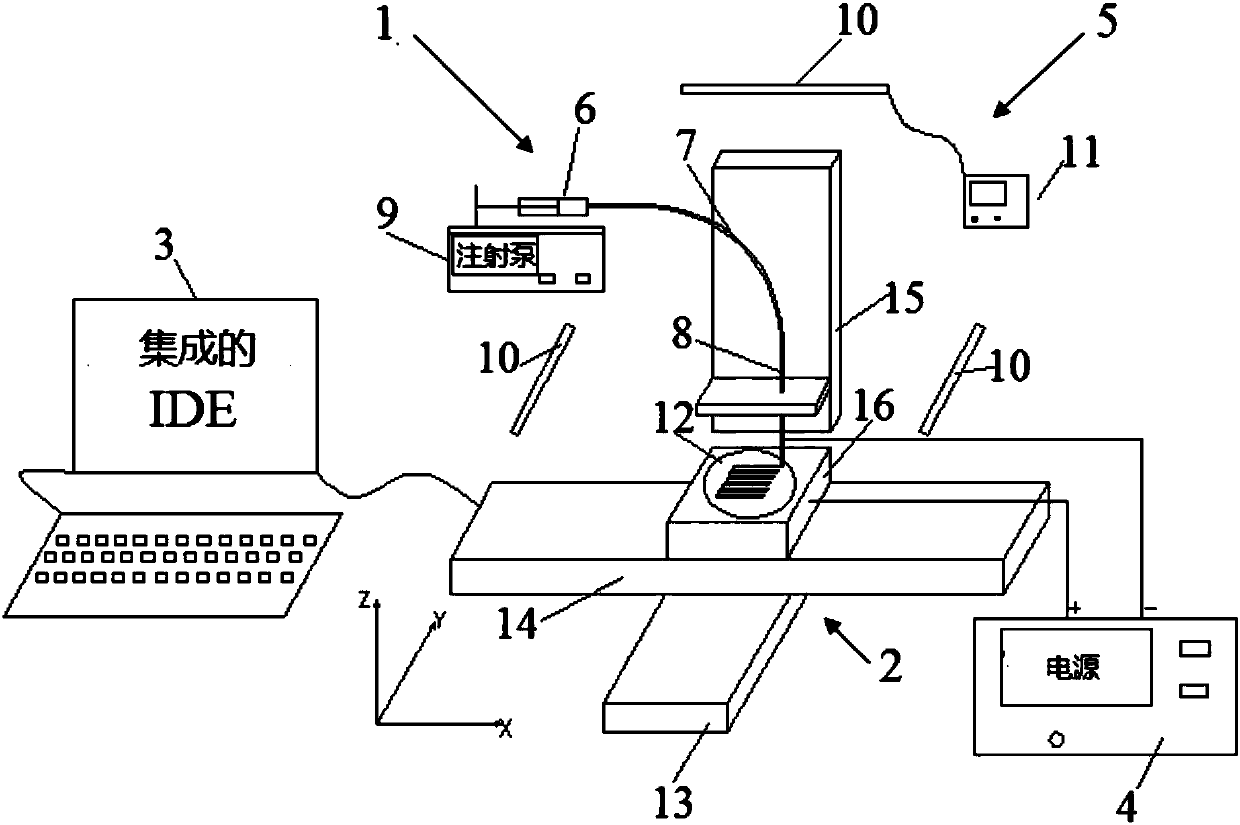

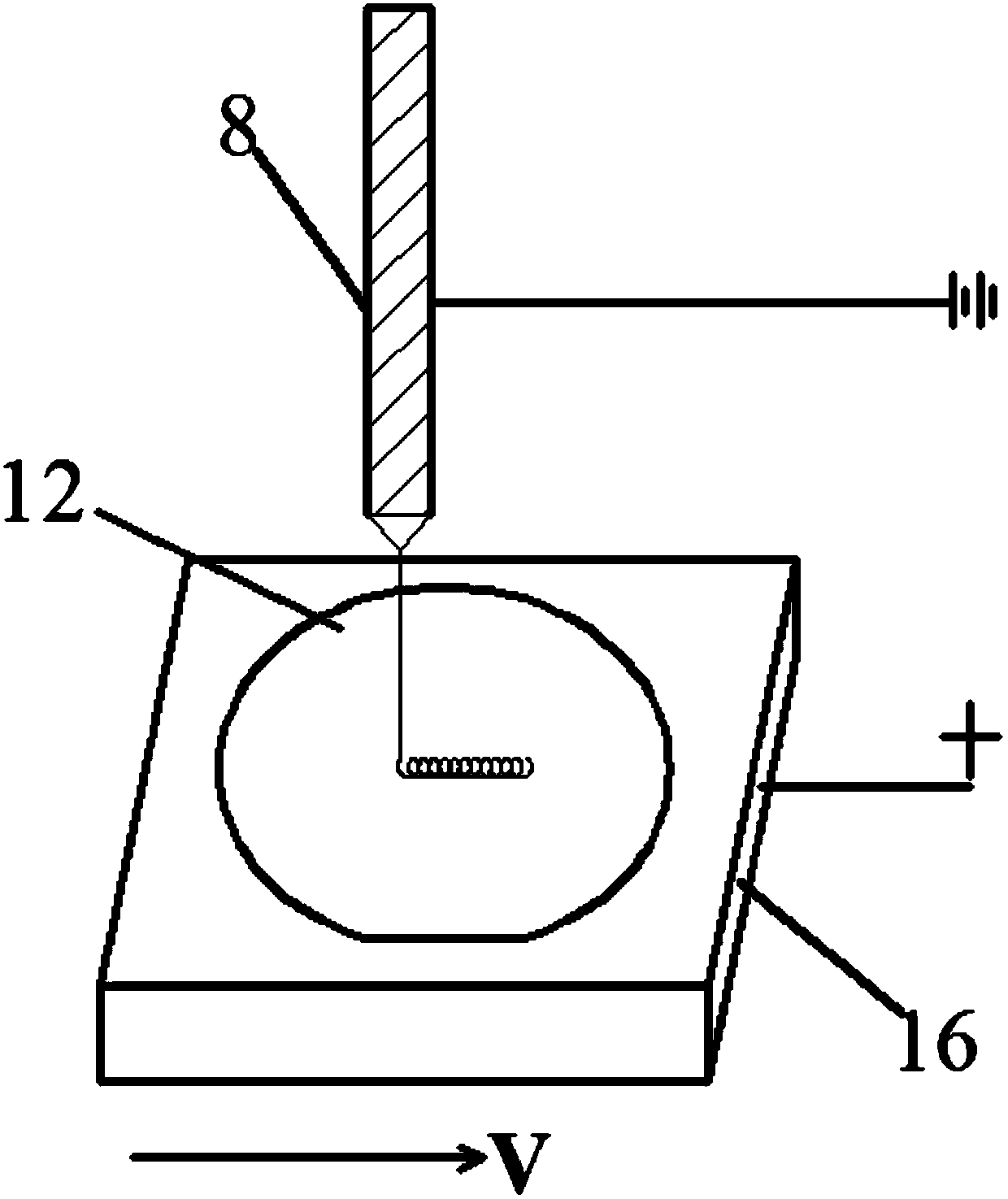

Electrofluid spraying device and method for printing three-dimensional biological scaffold

InactiveCN107718531AImprove adsorption capacityExcellent adsorptionManufacturing platforms/substratesManufacturing driving meansPorosityEngineering

The invention discloses a device and method for printing a three-dimensional biological scaffold. The printing method comprises the following steps that an polycaprolactone (PCL) solution after beingmixed with glacial acetic acid evenly is added into a solution supplying system; the motion speed and path of a motion platform during printing are set through a motion control system, the distance between a spraying needle and a polished silicon crystal substrate is adjusted, and the solution injection rate is set; and a power supply is adjusted, and voltage is exerted between the spraying needleand a loading platform. The three-dimensional biological scaffold which is printed by the method and has various helical structure micro morphologies has higher strength, greater contact area and higher porosity, and thus is more favorable for cell adsorption during cell seeding and differentiation and multiplication during cell culture.

Owner:NAT UNIV OF SINGAPORE SUZHOU RES INST +1

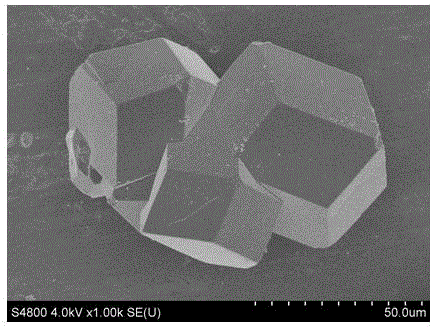

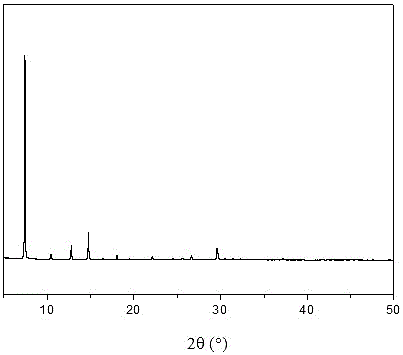

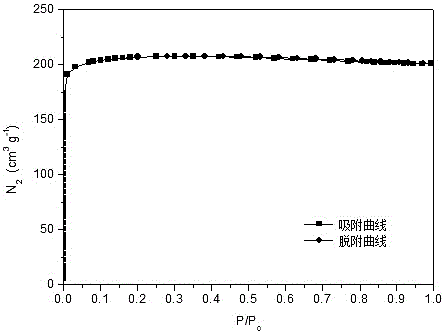

Preparation method and application of super-hydrophobic zeolite imidazole metal-organic framework F-ZIF-90

InactiveCN106317086AImprove hydrophobicityKeep shapeFatty/oily/floating substances removal devicesOther chemical processesMetal-organic frameworkMicro morphology

The invention discloses a preparation method and application of a super-hydrophobic zeolite imidazole metal-organic framework F-ZIF-90. The preparation method comprises the following steps: first, performing covalent bond modification on an organic ligand imidazole-2-formaldehyde (ICA) for synthesizing ZIF-90 through an amine condensation reaction to obtain fluorine-functionalized imidazole-2-formaldehyde (F-ICA); then, preparing the zeolite imidazole metal-organic framework F-ZIF-90 with a super-hydrophobic property by using the F-ICA. According to the novel super-hydrophobic zeolite imidazole metal-organic framework F-ZIF-90 prepared by the preparation method, on one hand, the micro-morphology and structure and the crystal structure of the zeolite imidazole metal-organic framework F-ZIF-90 are maintained, the hydrothermal stability and the specific surface are high; on the other hand, the hydrophobic property of the ZIF-90 is greatly improved (the water contact angle is up to 159.1 degrees), and the super-hydrophobic zeolite imidazole metal-organic framework F-ZIF-90 has a broad application prospect in a plurality of fields, such as oil water separation, removal of organic pollutants from a water body, biological alcohol extraction and concentration.

Owner:EAST CHINA NORMAL UNIV

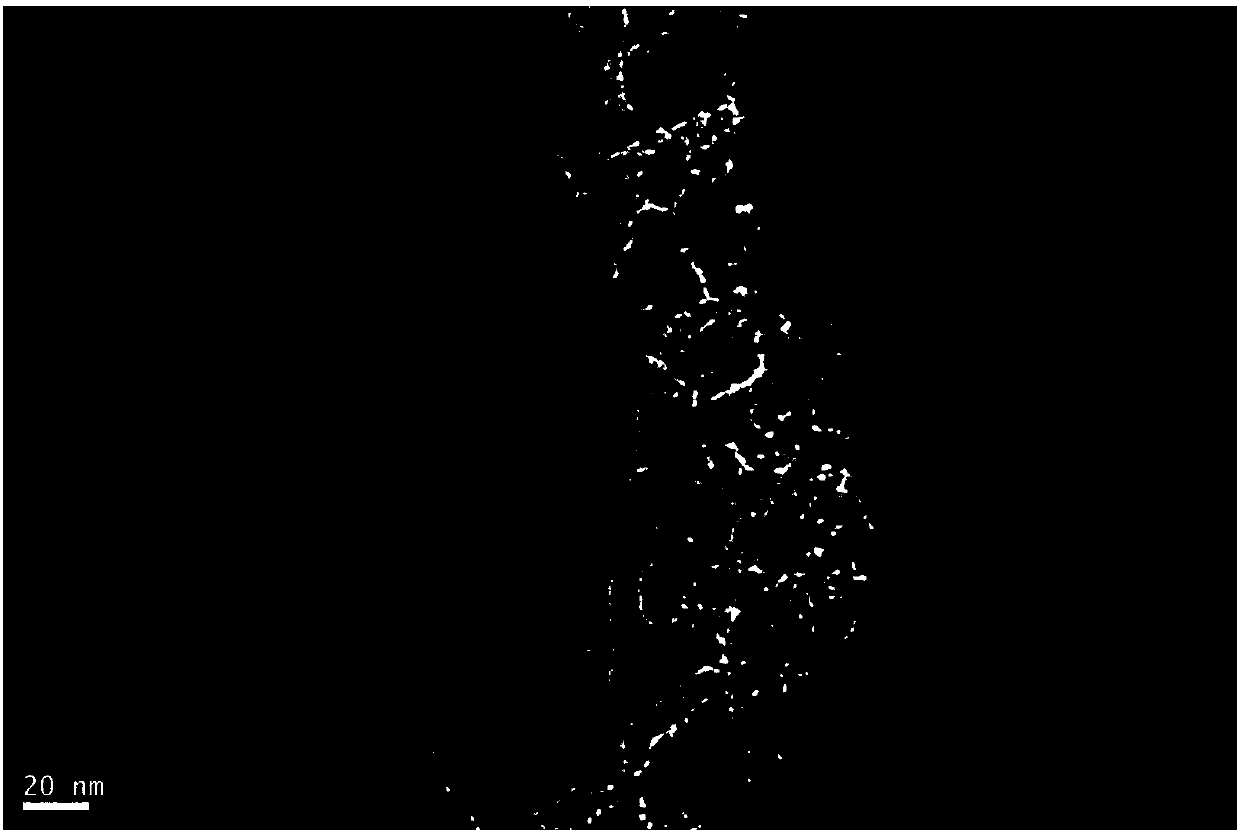

Carbon nanotube encapsulated cobalt and oxide nanosphere absorbing material thereof and preparation method thereof

InactiveCN107592782AExcellent electromagnetic wave absorption performanceStrong electromagnetic wave absorption effectMagnetic/electric field screeningMagnetizationCarbon nanotube

The present invention relates to a carbon nanotube encapsulated cobalt and oxide (CoO and Co3O4) nanosphere absorbing material thereof and a preparation method thereof, and belongs to the electromagnetic wave absorbing material technology field. The micro-morphology of the absorbing material is a hollow rhombic dodecahedron structure composed of the carbon materials, the carbon nanotubes grow on the surface of the rhombic dodecahedron structure, and a cobalt and an oxide nanosphere thereof are encapsulated at the end at the outer side of each carbon nanotube. The size of the rhombic dodecahedron structure is 400-550nm, the external diameter of each carbon nanotube is 14-16 nm, and the internal diameter is 11-13 nm; the diameters of the cobalt and the oxide nanosphere thereof are 11-13 nm,the proportion of the amorphous carbon and the graphitized carbon in the absorbing material is 1: 0.79-1.17, and the saturation magnetization intensity of the absorbing material is 27.83-39.4 emu / g; the maximum electromagnetic wave absorption exceeds -40 dB, and an effective absorption range exceeds 4.5 GHz. After using the 1M sulfuric acid or 1M ammonia to process 6-12 hours, the maximum electromagnetic absorption of the absorbing material still exceeds -40 dB, and the effective absorption range exceeds 4.5 GHz, thereby having the immense potential at the aspect of the electromagnetic wave absorbing material.

Owner:JILIN UNIV

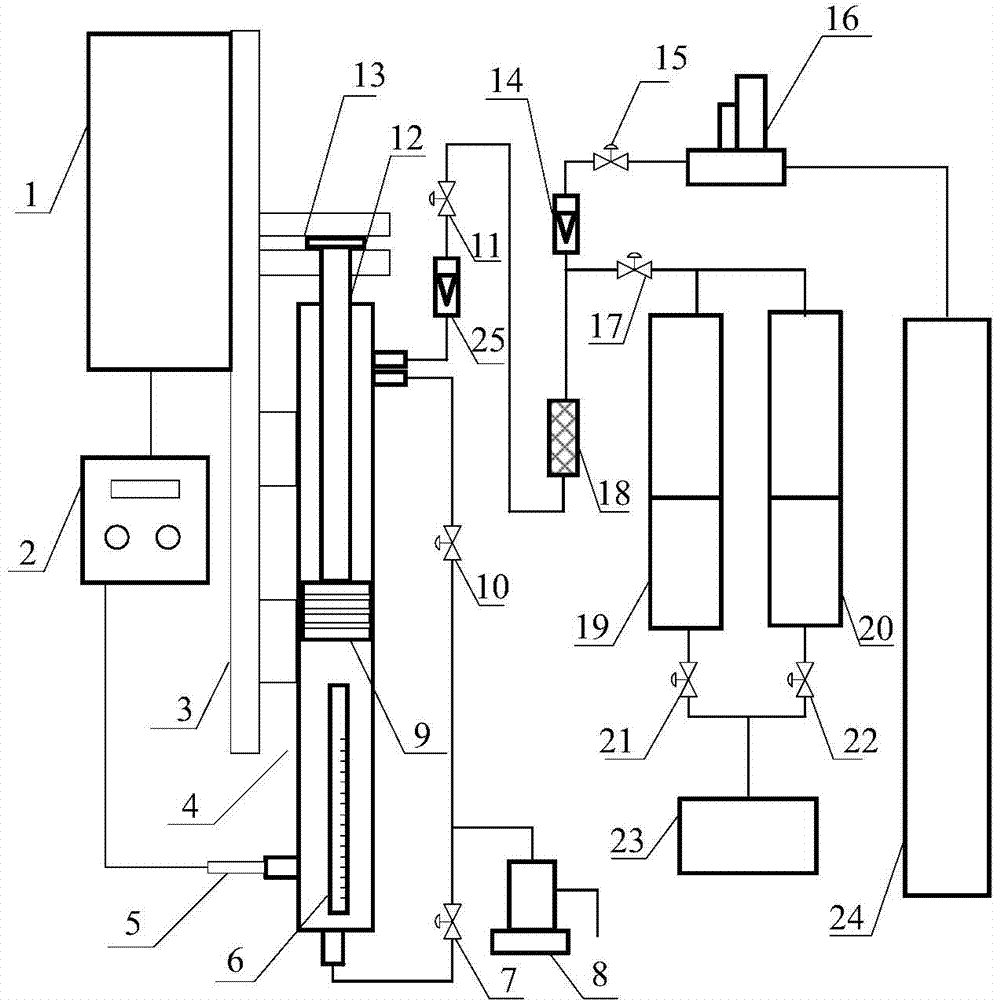

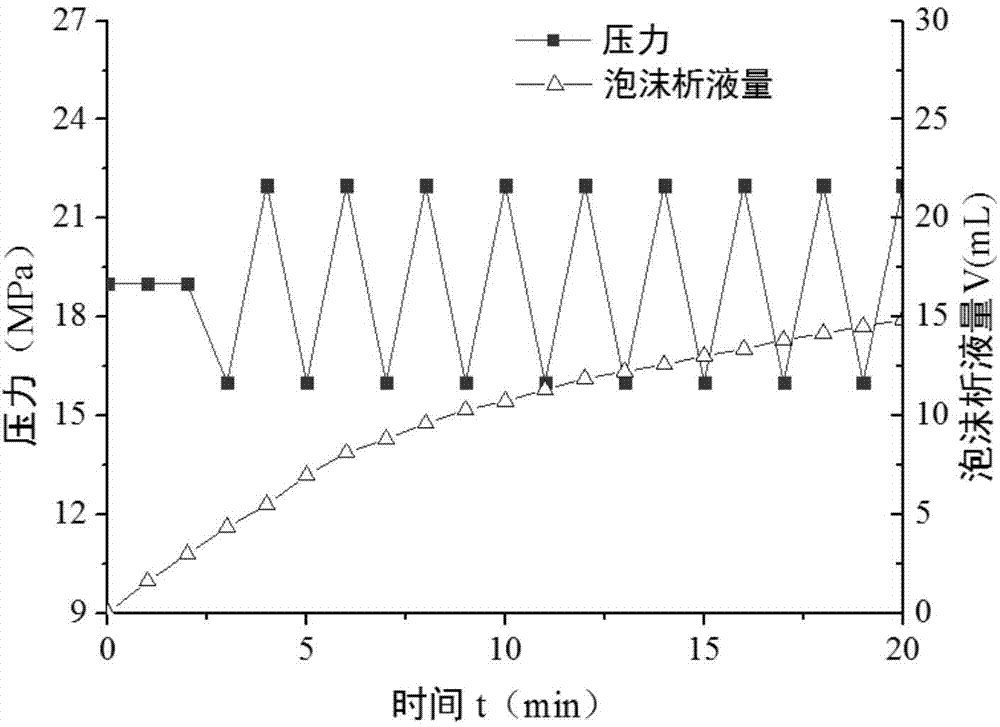

Foam stability test device under pressure fluctuation and working method thereof

ActiveCN104502059AMake up for the defect that the influence of variable pressure is not consideredRealize visual observationHydrodynamic testingMicro morphologyEngineering

Provided is a foam stability test device under pressure fluctuation. The foam stability test device comprises a foam generation part, a foam test part, a pressure regulation and control part and a cleaning part. The foam generation part, the pressure regulation and control part and the cleaning part are respectively connected in parallel with the foam test part, which is realized via valve control. The foam generation part and the foam test part are connected in series independently. The pressure regulation and control part and the foam test part are connected in series independently. The cleaning part and the foam test part are connected in series independently. Foam stability testing under the condition of pressure fluctuation is realized so that a defect that influence of variable pressure is not considered by the existing foam stability evaluation technology in the field of oil and gas fields is compensated. Visualized observation of the foam state under the condition of variable pressure is realized so that the foam stability test device under pressure fluctuation has important meaning in further research of change of the foam micro-morphology under the condition of foam variable pressure. The foam stability test device under pressure fluctuation is high in pressure resistance, data testing is completed under the pressure state, and the experimental data are closer to the production site of the oil and gas fields so that reliability is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

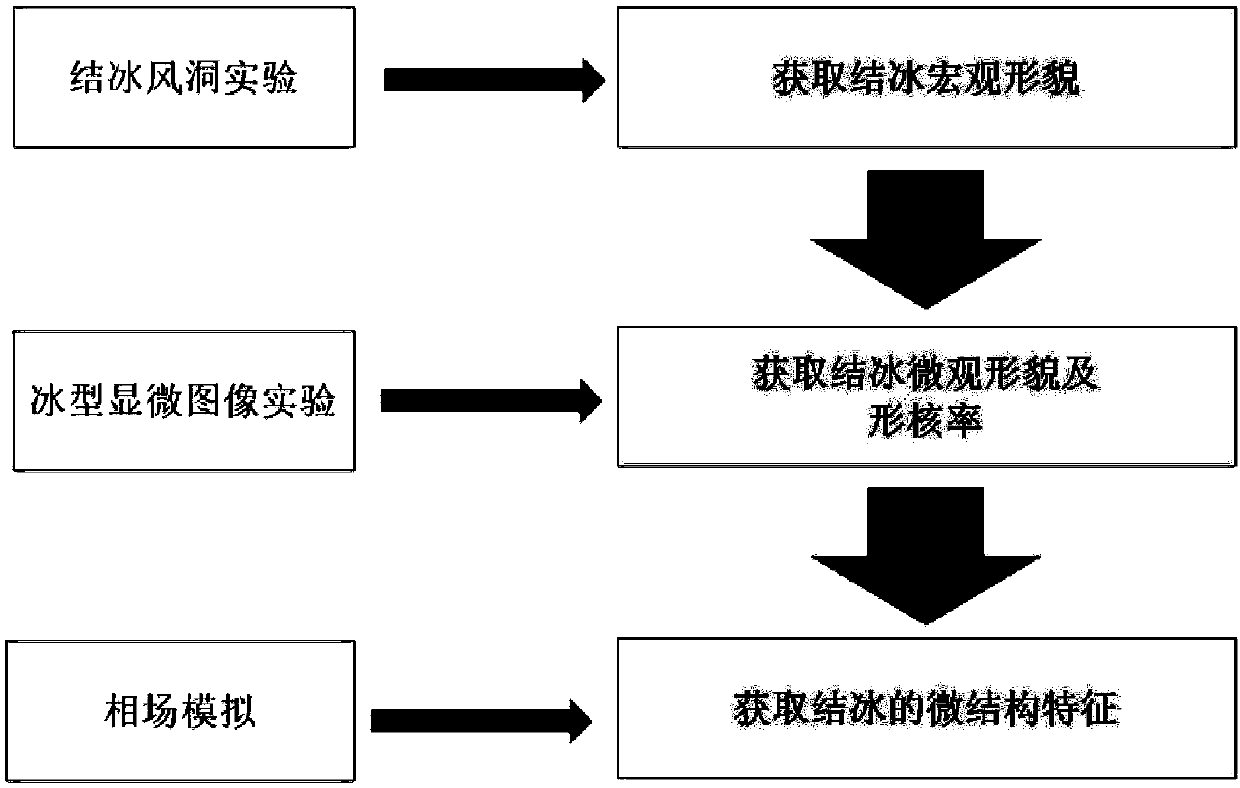

Method for predicting characteristics of dynamic icing ice type microstructure of aircraft

ActiveCN107702879AImprove efficiencyImprove flight safetyAerodynamic testingMicroscopic imagePredictive methods

The invention discloses a method for predicting characteristics of a dynamic icing ice type microstructure of an aircraft. The method comprises a first step of acquiring an icing macro morphology by an icing wind tunnel experiment; a second step of acquiring an icing micro morphology and the nucleation density through an ice type microscopic image experiment; and a third step of acquiring characteristics of an icing ice type microstructure through the phase field simulation. Compared with the prior art, the invention has the positive effects that with the invention, the method for predicting the characteristics of the icing microstructure can be established, the shortcoming that the current prediction of the icing characteristics is mainly macro prediction is effectively overcome, and therefore technical support is further provided for establishing a method for quantitative characterization of icing physical characteristics, increasing the refinement level of icing prediction, developing a high efficiency, low redundancy aircraft anti-icing / deicing system, and improving the safety flight capability of the aircraft under icing conditions.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

Model compensating method for controlling thin film deposition rate in physical gaseous phase thin film deposition process

ActiveCN102492931ATo achieve thickness control requirementsStable deposition rateVacuum evaporation coatingSputtering coatingRelational modelGas phase

The invention discloses a model compensating method for controlling thin film deposition rate in physical gaseous phase thin film deposition process, which is characterized by creating a relational model between the deposition rate and target material consumption amount on the basis of off-line measurement. Process control parameters including electric power in the thin film deposition process iscompensated by using the relational model, and relatively stable thin film deposition rate and thin film performance of products in different batches are achieved. The model compensating method is used for compensating main control parameters, so that stable thin film deposition rate is achieved, and adjustment of thin film micro-morphology and material performance is expected to be achieved through control of deposition rate. The model compensating method does not need to use complicated real-time observation systems.

Owner:上海鼎弈材料科技有限公司

High-temperature and high-confining-pressure fluid-solid mutual effect testing device and testing method

ActiveCN105911229AChange componentsNo change in compositionRaman scatteringSimultaneous control of multiple variablesChemical reactionTest sample

The invention discloses a high-temperature and high-confining-pressure fluid-solid mutual effect testing device and a testing method. The high-temperature and high-confining-pressure fluid-solid mutual effect testing device comprises a pressure container, wherein two axial pressing rods, which are symmetrically sealed, are arranged in the pressure container in the horizontal direction; a test sample is arranged between the two pressing rods; a heating device for heating the test sample sleeves the outer side of the pressure container; a liquid pressing hole and an optical window are arranged on the surface of the pressure container; the heating device is arranged in a groove of a base; a temperature sensor is arranged on a contact surface between the heating device and the pressure container; theliquidpressing hole is communicated to a test sample placement part; and the optical window is aligned to the center of the test sample and is provided with an optical measurement system for observing a test sample light spectrum. According to the testing device and testing method, by carrying out chemical reaction and light spectrum measurementon the test sample under high-confining-pressure and high-temperature conditions, the micro morphology characteristics and spectrum collection of solid samples can be observed in situ under high-temperature high-pressure fluid condition, the interaction product of the solid and fluid can be measured in situ, measured data is closer to actual data, the measured data is more accurate and reliable and the accurate practice, and utilization and analysis of the test sample can be more easily guided.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Surface micro-morphology processing method of gear composite plastic forming die

ActiveCN109158523AExtend your lifeImprove mechanical propertiesForging/hammering/pressing machinesMicro textureMachining process

The invention relates to a surface micro-morphology processing method of a gear composite plastic forming die. The surface micro-morphology processing method comprises the following step that S1, a large area of the forming pressure of the mold in the machining process is determined, and a micro-pit is machined in the area where the forming pressure is larger; S2, the micro-pit with nanometer molybdenum disulfide is filled. The micro-pit morphology is based on the forming mechanism of the mold, the surface micro-textures processed by the maximum forming pressure area are selected, a lubricantcan be effectively provided under the condition of boundary lubrication and lean oil, the mechanical performance and the friction lubricating performance of the precision forging gear in the forming process are improved, the abrasion amount of the precision forging die is reduced, so that the service life of the die is prolonged; the micro-morphology processing method is efficient, precise and controllable, pollution-free to the environment, low in cost and the like.

Owner:南京江峰新能源科技有限公司 +2

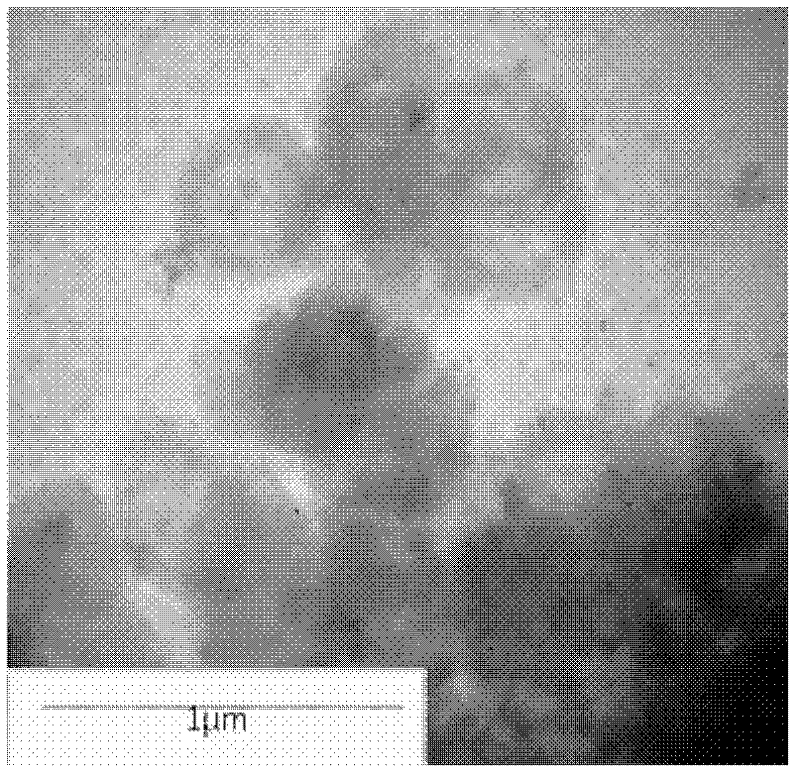

Preparation method for polyaniline/ferroferric oxide compound with nucleus-shell structure

InactiveCN102408562AIncrease component contentGood absorbing functionOrganic/organic-metallic materials magnetismWater basedPolyethylene glycol

The invention discloses a preparation method for polyaniline / ferroferric oxide compound with nucleus-shell structure, which comprises the steps as follows: a, 1.5-2.5 portions of polyethylene glycol and 1 portion of tetrahydrate ferrous chloride are respectively dissolved into water and mixed to obtain hydrosol; the pH value of the hydrosol is adjusted to 12.0-13.0, then 0.05 portion of hydrogen peroxide is added to stir and react for 4h under 55-65 DEG C to obtain water-based ferrofluid dispersed with polyaniline / ferroferric oxide grains; b, ammonium persulfate is added into the water-based ferrofluid to stir and stew for 8-32h so as to complete the absorption of a colloid shell on the ammonium persulfate; c, aniline monomer is added into the water-based ferrofluid after the step b and stewed for 5h under an ice-bath condition of 0-5 DEG C, washed and filtered to obtain a solid object; d, the solid object is dried under a temperature of 40-50 DEG C, thus obtaining the polyaniline / ferroferric oxide compound. The method is easy to control the components and micro morphology of the compound; moreover, the wave absorption substance content in the compound is high and the wave absorption performance is good.

Owner:SOUTHWEST JIAOTONG UNIV

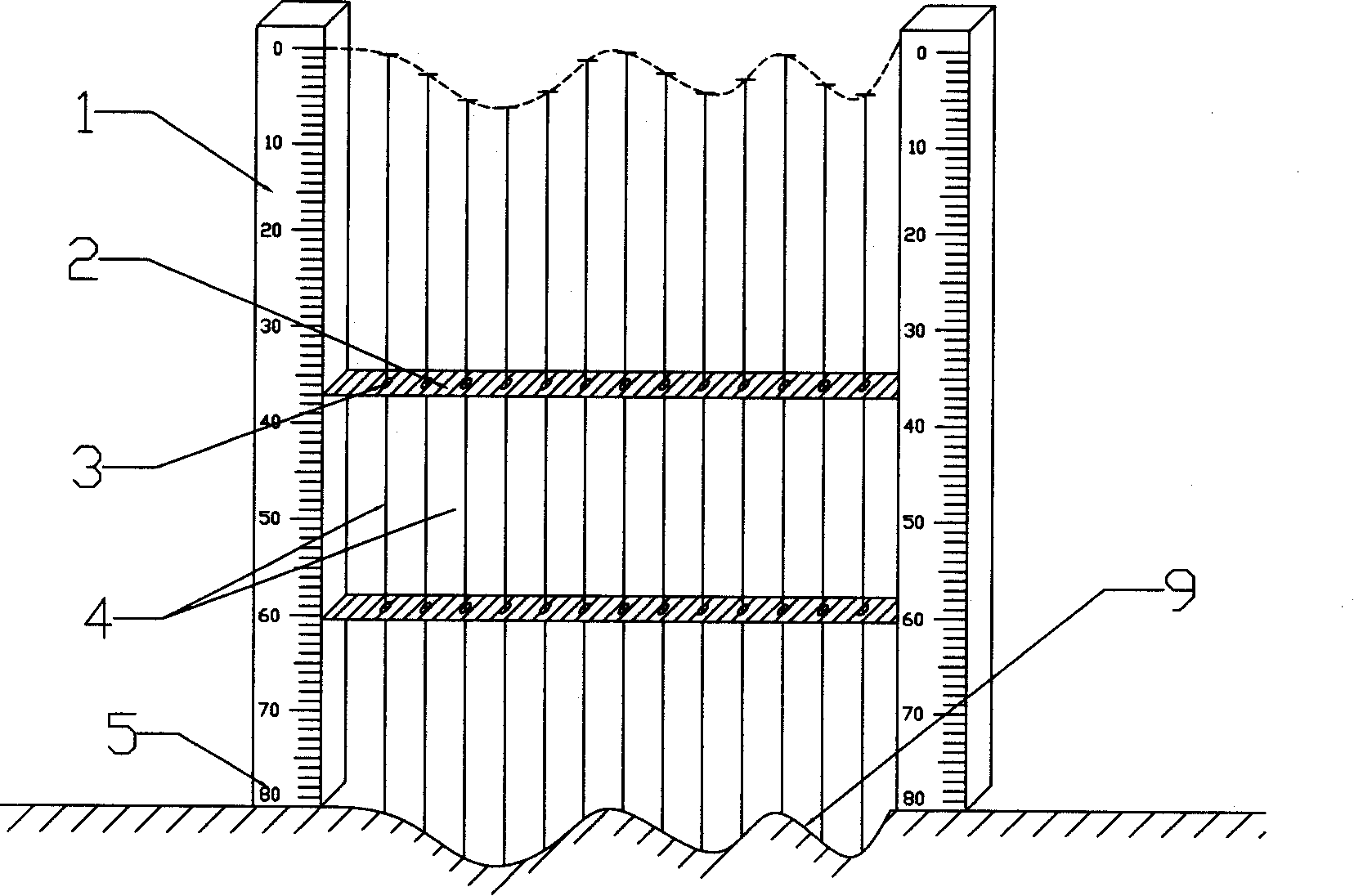

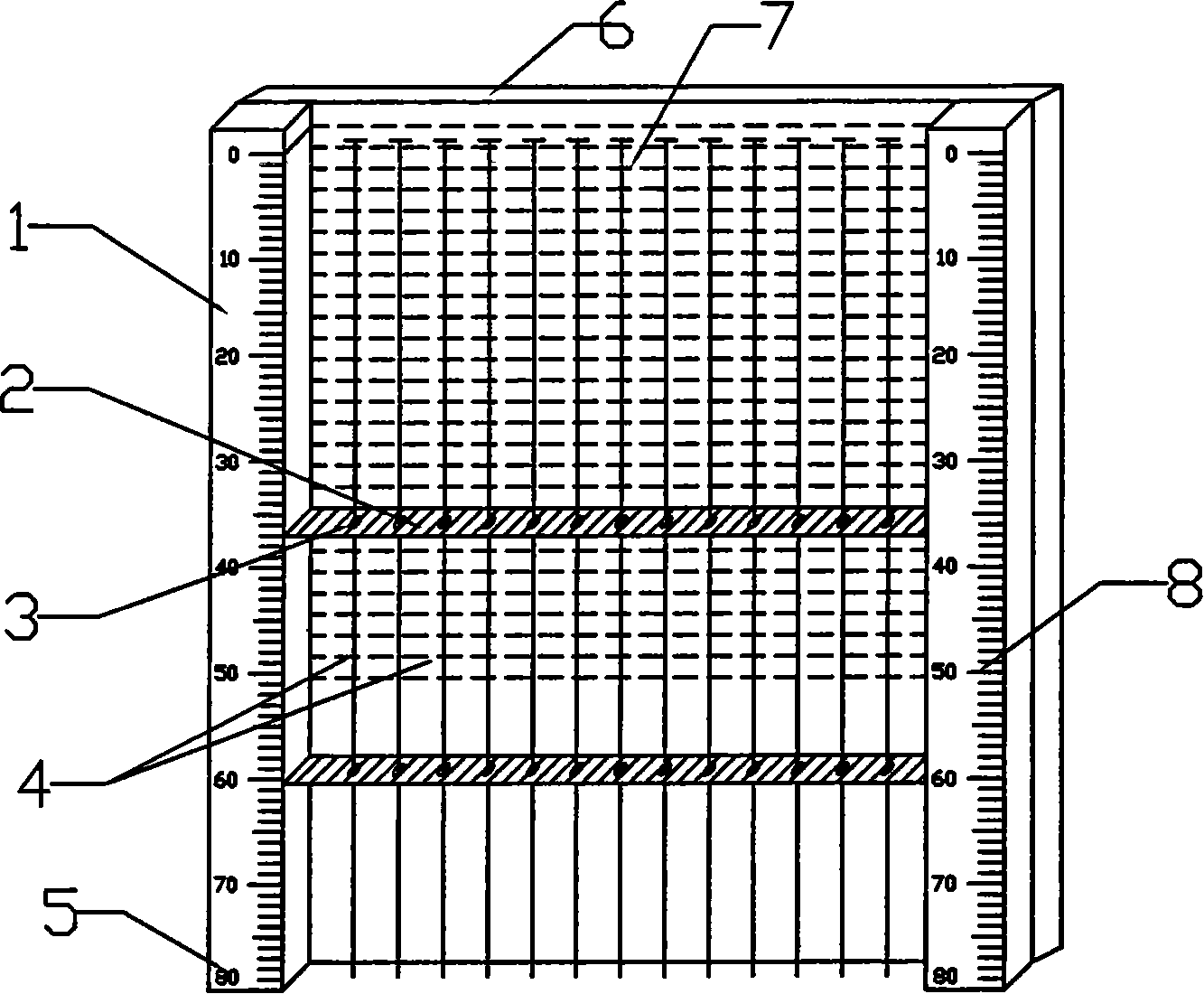

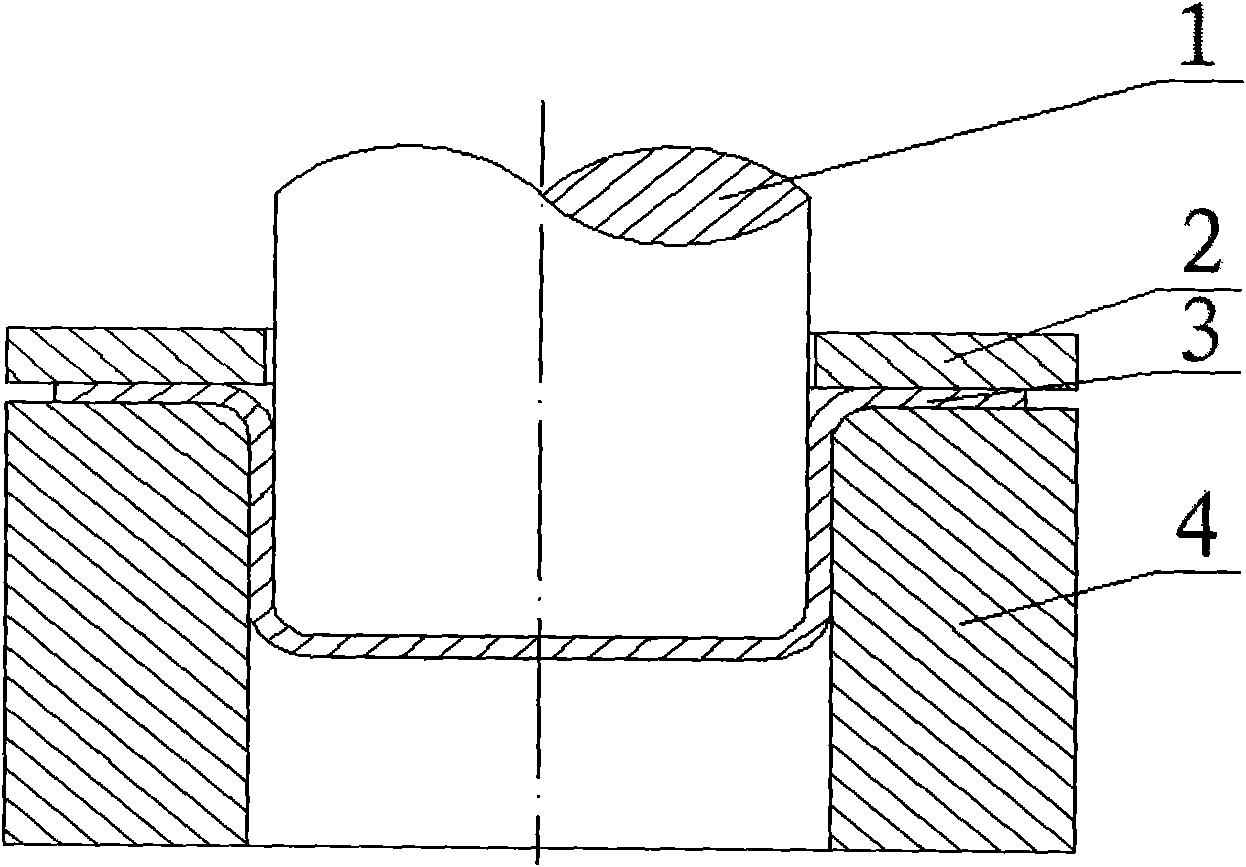

Earth surface micro-configuration measurement mechanism and method of use thereof

InactiveCN101158566ASimple and fast operationSimple structurePhotogrammetry/videogrammetryUsing optical meansVertical barMeasurement device

Owner:FUJIAN NORMAL UNIV

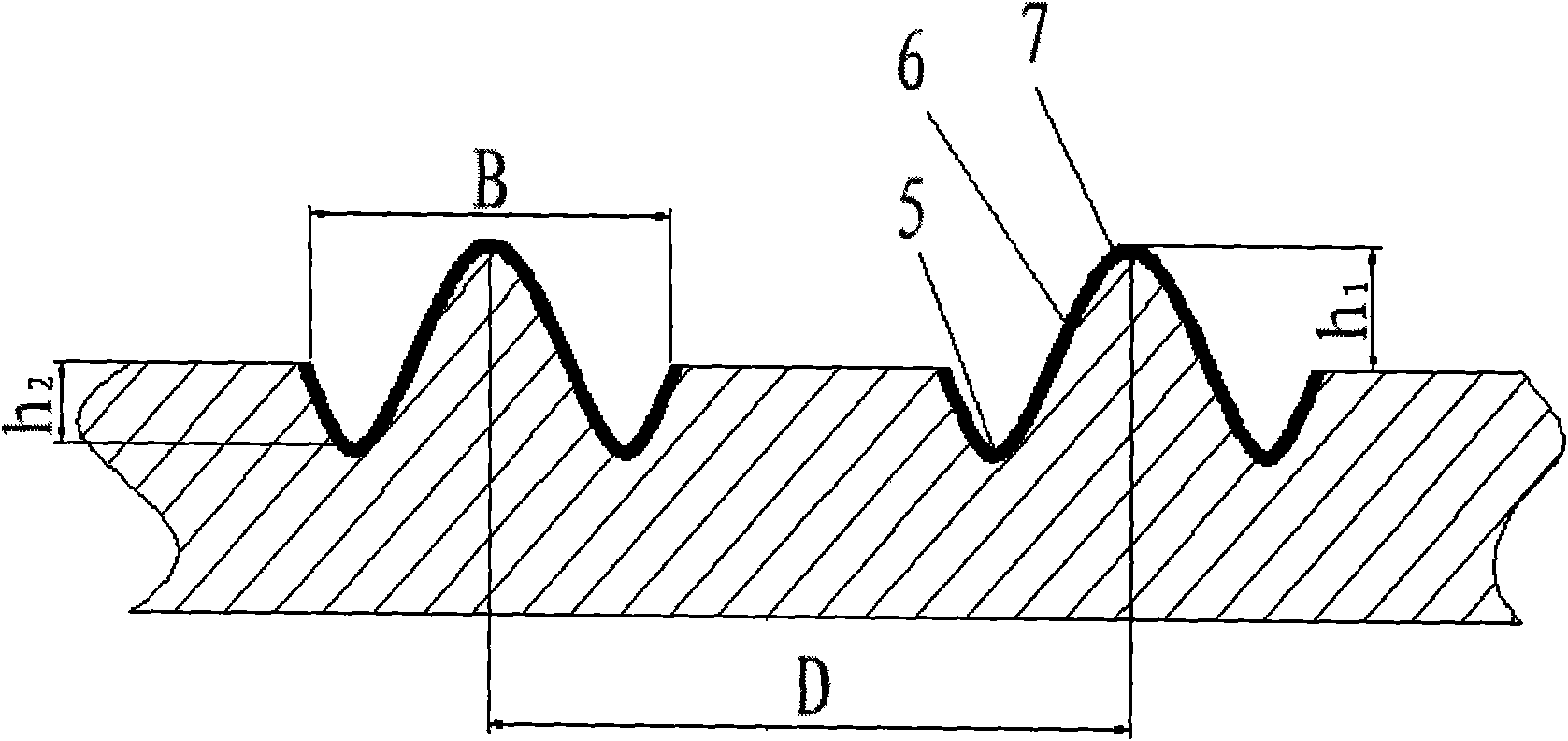

Upgrading and modifying method for laser surface of drawing mould

InactiveCN101537537AGood repeatability of microtopographyNo pollution in the processShaping toolsFurnace typesMicrosphereSurface level

The invention discloses an upgrading and modifying method for a laser surface of a drawing mould. Laser machining equipment is adopted to drive a pulsed laser, and pulsed lasers irradiate the working surface of the drawing mould; the working surface of the drawing mould moves along the pulsed lasers to blow out auxiliary gas; each microsphere coronary unit body consisting of a pit and a pit side lug boss is formed on the working surface of the drawing mould, the height difference of each microsphere coronary unit body and the working surface of the drawing mould is ranged from 2.86 microns to 3.58 microns, and the microsphere coronary unit bodies are continuously and uniformly arranged on the working surface of the drawing mould. The height difference of the pit and the working surface of the drawing mould is ranged from 2.15 microns to 2.69 microns, the diameter of each microsphere coronary unit body is ranged from 210 microns to 280 microns, and the distance between every two adjacent microsphere coronary unit bodies is ranged from 300 microns to 500 microns. The invention adopts the upgrading and modifying technology for the laser surface, manufactures micro-morphology arrangement of micro pits and micro lug bosses on the surface of the drawing mould, has no pollution in a machining process, and can remarkably improve the wear resistance and the demoulding performance of the surface of the drawing mould.

Owner:JIANGSU UNIV

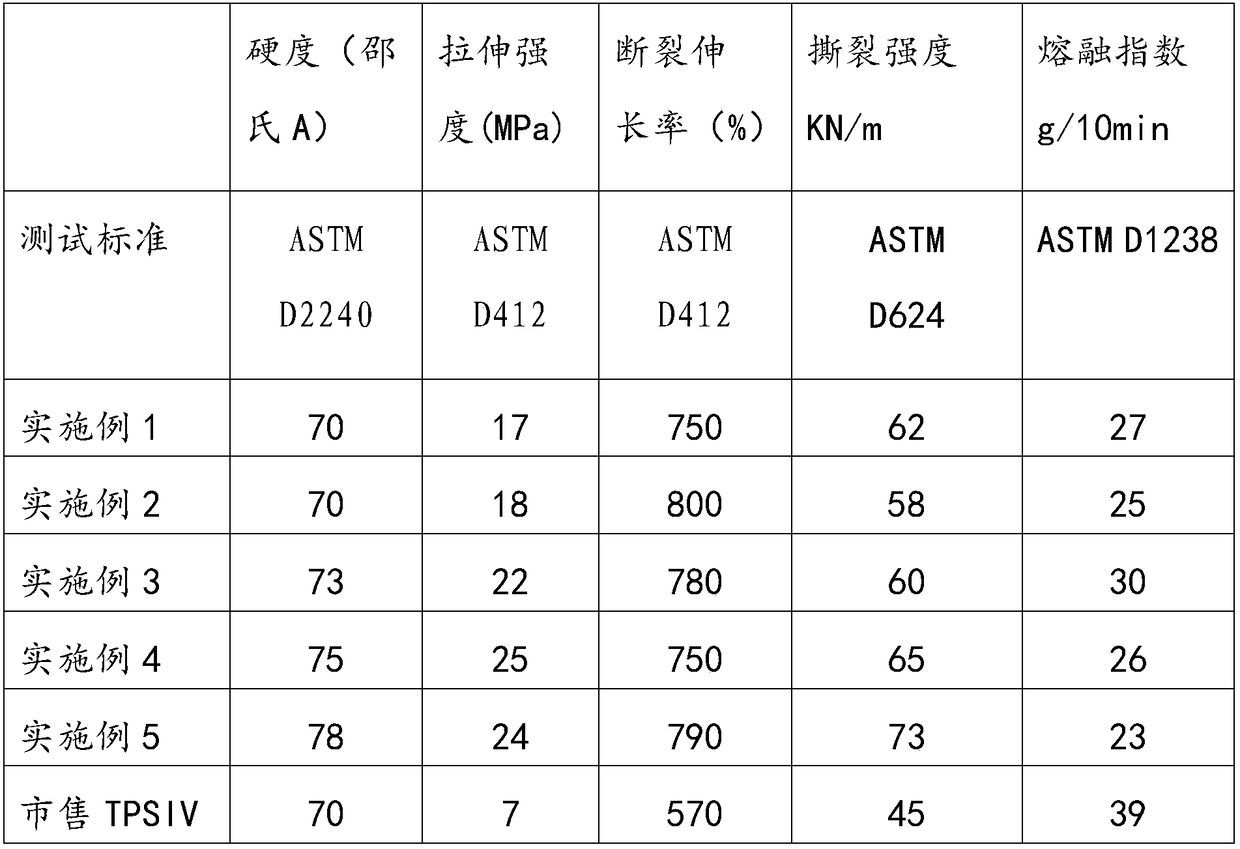

Preparation method of silicone rubber polyurethane thermoplastic elastomer

InactiveCN108641057AEvenly dispersedDoes not affect the synthesis reactionPolyolThermoplastic elastomer

The invention relates to a silicone rubber polyurethane thermoplastic elastomer and a preparation method thereof. The silicone rubber polyurethane thermoplastic elastomer comprises the following components in parts by weight: 50-80 parts of polyol, 10-30 parts of dual-component liquid organic silicone rubber, 15-40 parts of diisocyanate, 3-10 parts of a chain extender and 0.1-2 parts of an auxiliary agent. The silicone rubber polyurethane thermoplastic elastomer product is synthesized by a one-step reactive extrusion process. The obtained thermoplastic elastomer product has excellent properties of both organosilicone and polyurethane materials, has the advantages of fine micro-morphology structure, smooth touch sense, and excellent mechanical properties and elasticity, and can be widely applied in medical devices, intelligent wearing equipment and other fields.

Owner:MIRACLL CHEM

Time domain finite difference based microwave part passive inter-modulation numerical analysis method

ActiveCN105069247ASolve the problem of lack of numerical analysis meansAccurate analysisSpecial data processing applicationsTime domainMicrowave

The present invention discloses a time domain finite difference based microwave part passive inter-modulation numerical analysis method, and discloses a method for introducing a micro-morphology and contact-state metallic contact nonlinear model of a metallic contact part of a microwave part. By adopting the method, the electromagnetic field analysis of a microwave part taking metallic contact non-linearity into consideration is realized, the electromagnetic field of an output port of a microwave part not taking metallic contact non-linearity into consideration is computed by adopting a time domain finite difference method and two signals are subjected to time domain cancellation, so that the interference of errors in numerical computation is reduced, a passive inter-modulation small signal is highlighted, a computation result of a passive inter-modulation product of the microwave part is more accurate, and the difficult problem that the passive inter-modulation of the microwave part is short of a numerical analysis means is solved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

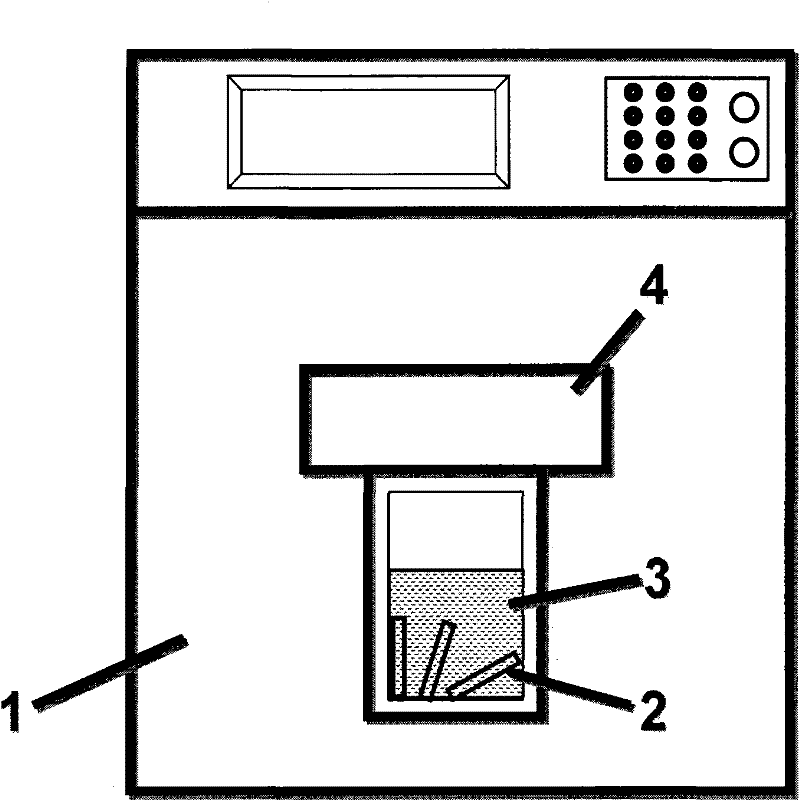

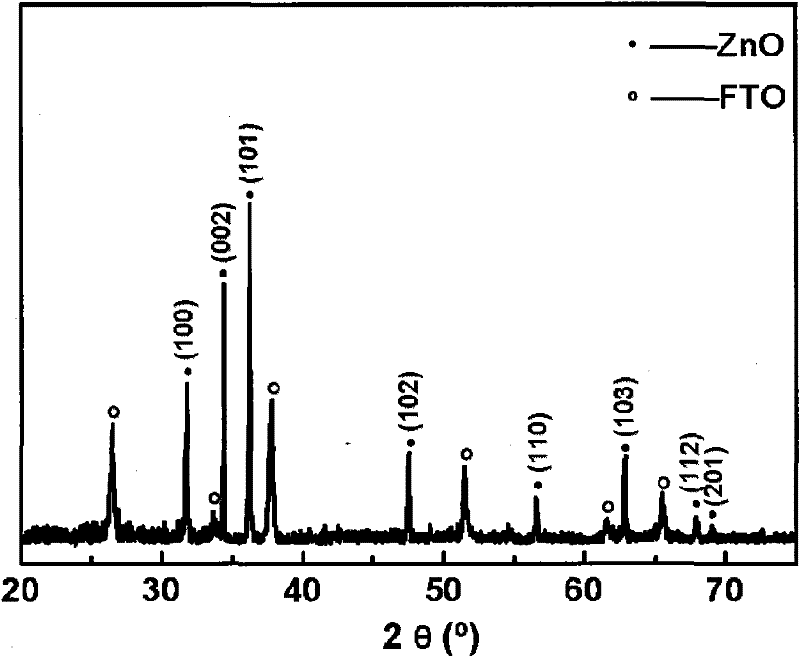

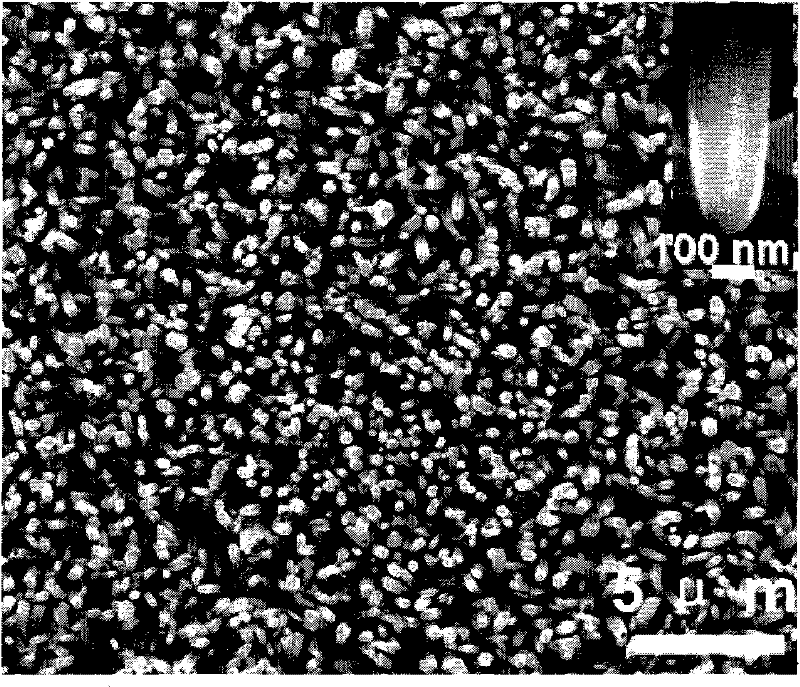

A Microwave Synthesis Method of ZnO Thin Films with Oriented Nanorod Structure

InactiveCN102260046AHigh crystallinityGood orientationZinc oxides/hydroxidesSynthesis methodsCrystallinity

The invention relates to the synthesis of low-dimensional nanomaterial films, and provides a microwave synthesis method of a zinc oxide film with an oriented nanorod structure. The method is characterized in that a microwave-hydrothermal deposition method is adopted, a zinc salt solution with a molar concentration of 1-150 mM and a hexamethylene tetramine solution are used as raw materials, a blank substrate is placed inside a microwave digestion container, then the container is sealed and placed in a microwave digestion instrument, and after the reaction is carried out at 50-180 DEG C for 0-4 hours, natural cooling is carried out so as to realize the oriented growth of a high-crystallinity film composed of ZnO nanorod arrays on the substrate, wherein the diameter of the nanorods is about50-300 nm. The microwave-hydrothermal method provided by the invention combines the advantages of microwave and hydrothermal methods, improves the film crystallinity, and significantly improves the film quality. The synthesis method has the advantages of short synthesis time, low synthesis temperature and no need for induced hydrothermal deposition of seed crystals; and the grown ZnO film with the nanorod structure has the advantages of uniform micro morphology, good crystallinity and growth direction perpendicular to the substrate, and is suitable for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Light diffusion membrane for display and preparation method thereof

ActiveCN104730605AEasy to prepareHigh potential application valueDiffusing elementsPolyurea/polyurethane coatingsPhotoluminescenceFluorescence

The invention relates to a light diffusion membrane for display and a preparation method thereof. The light diffusion membrane is obtained by scattering a light diffusant of a core-shell structure in acrylate resin and carrying out ultraviolet light polymerization. Cores of the light diffusant are polysiloxane microballoons, shells of the light diffusant are made of quantum dot hybrid materials of organopolysiloxane zinc oxide, and the micromorphology of the light diffusant is of the inner layer and outer layer core-shell microballoon structure. The partical size of the microballoons ranges form 5mum to 8mum, the thickness of shell layers ranges from 100nm to 400nm, the light diffusant has the obvious photoluminescence phenomenon and presents yellow green fluorescence under an 365nm ultraviolet lamp, and a wave band near the microballoons has adjustability. The light diffusion membrane prepared through the method has an excellent light diffusion effect, the photoluminescence character is also presented in the membrane, and the light diffusion membrane can be used as a novel light diffusion membrane in a liquid crystal display backlight module. The light diffusion membrane is good in mechanical property and ageing-resistant performance and low in cost; the preparation method of the light diffusion membrane is simple, production is easy to expand, and the preparation process is friendly to the environment.

Owner:NANJING BREADY ELECTRONICS CO LTD

Preparation method for polyimide-based composite aerogel and polyimide-based composite aerogel

The invention discloses a preparation method for polyimide-based composite aerogel and the polyimide-based composite aerogel product. Raw material components for preparing the polyimide-based composite aerogel comprise one or more water-soluble polyimide precursors polyamic acids, and oxidized graphene. The preparation method comprises the following steps: (1) an aqueous dispersion liquid of the oxidized graphene and the water-soluble polyimide precursor polyamic acid are uniformly mixed according to a certain proportion, a sol-gel process and a lyophilization technology are used, and therefore oxidized graphene-polyamic acid aerogel is obtained; and (2) the graphene-polyimide aerogel is prepared through a thermal imidization process. The method for preparing the polyimide-based composite aerogel is simple and easy to implement, the prepared composite aerogel is controllable in micro morphology and adjustable in performance; and besides, the prepared polyimide-based composite aerogel has excellent flame retardance, and is an ideal heat-insulation material and a flame-retardant material.

Owner:FUDAN UNIV +1

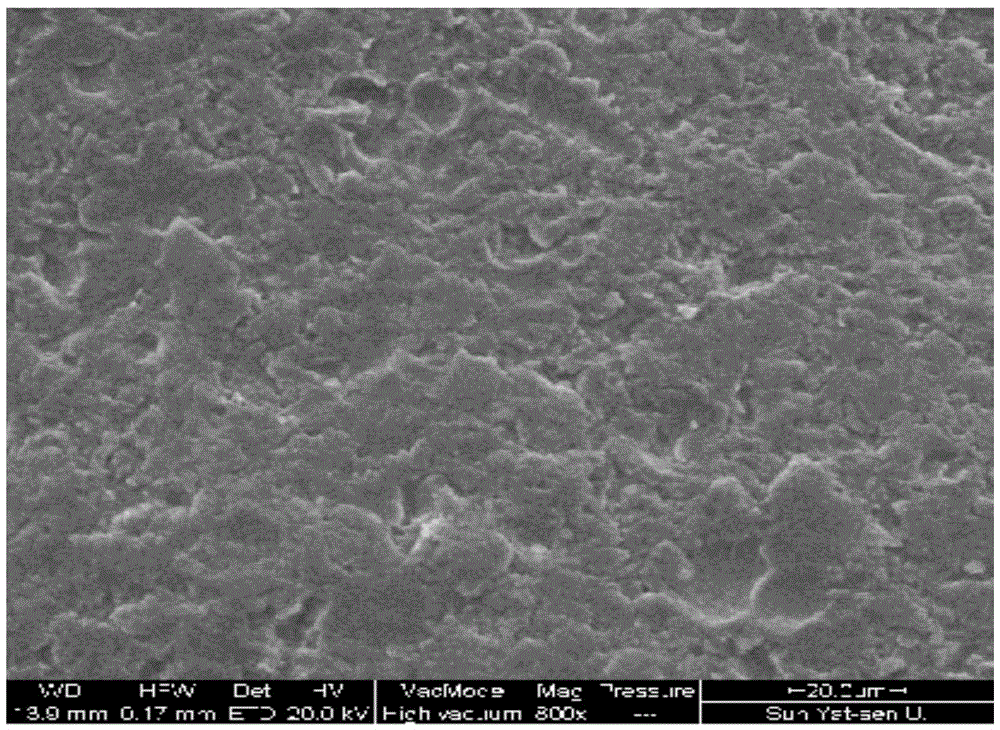

Method for improving chemical stability of proton exchange membrane

InactiveCN102479956AMitigate degradation behaviorLow water absorptionCell electrodesIon clustersPhysical chemistry

The invention provides a method for improving chemical stability of a proton exchange membrane. According to the invention, a perfluorosulfonic acid proton exchange membrane is immersed in a solution containing one or more than two metal ions selected from the group consisting of Zr<4+>, Ca<2+>, Mg<2+> and Al<3+>, and introduction of one metal ion or more than two metal ions selected from the group consisting of Zr<4+>, Ca<2+>, Mg<2+> and Al<3+> into the perfluorosulfonic acid proton exchange membrane is realized through ion exchange. The method provided in the invention improves resistance of the proton exchange membrane to chemical degradation by modifying micro-morphology of ion clusters of the membrane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com