Carbon nanotube encapsulated cobalt and oxide nanosphere absorbing material thereof and preparation method thereof

A technology of carbon nanotubes and wave-absorbing materials, applied in magnetic/electric field shielding, electrical components, etc., can solve problems such as practical difficulties, difficulties, and complexity of preparation processes, and achieve controllable shape, good effect, and good electromagnetic wave absorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 1.2g of cobalt nitrate hexahydrate in 24g of methanol solution, called solution A, and dissolve 0.03g of cetyltrimethylammonium bromide and 1.5g of 2-methylimidazole in 24g of methanol solution, called solution B, Solution A was added dropwise to solution B under stirring, stirred for 2 hours, washed with methanol by centrifugation, and dried in an oven at 60°C for 6 hours to obtain nano-sized ZIF-67 with a product mass of 1.17 g.

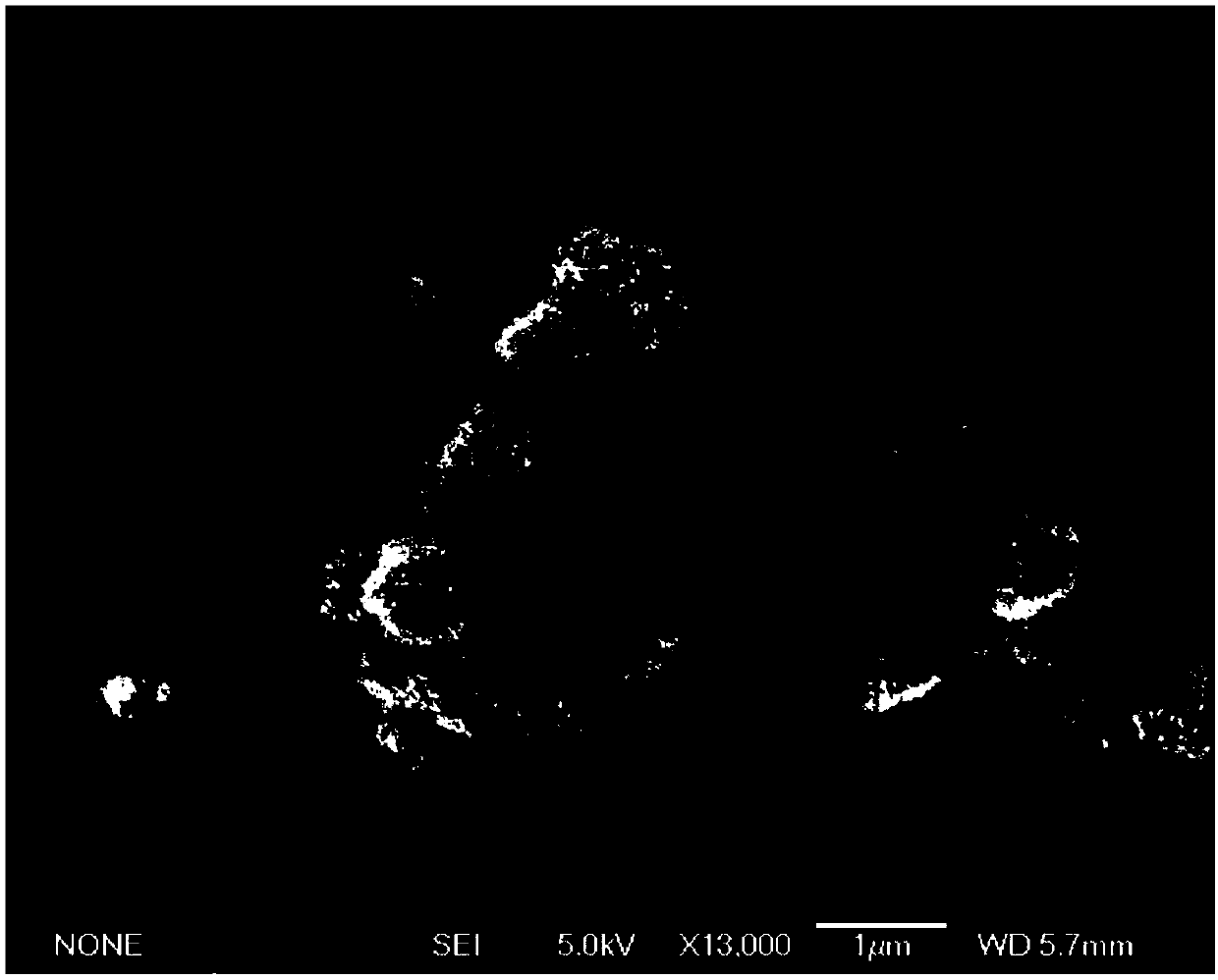

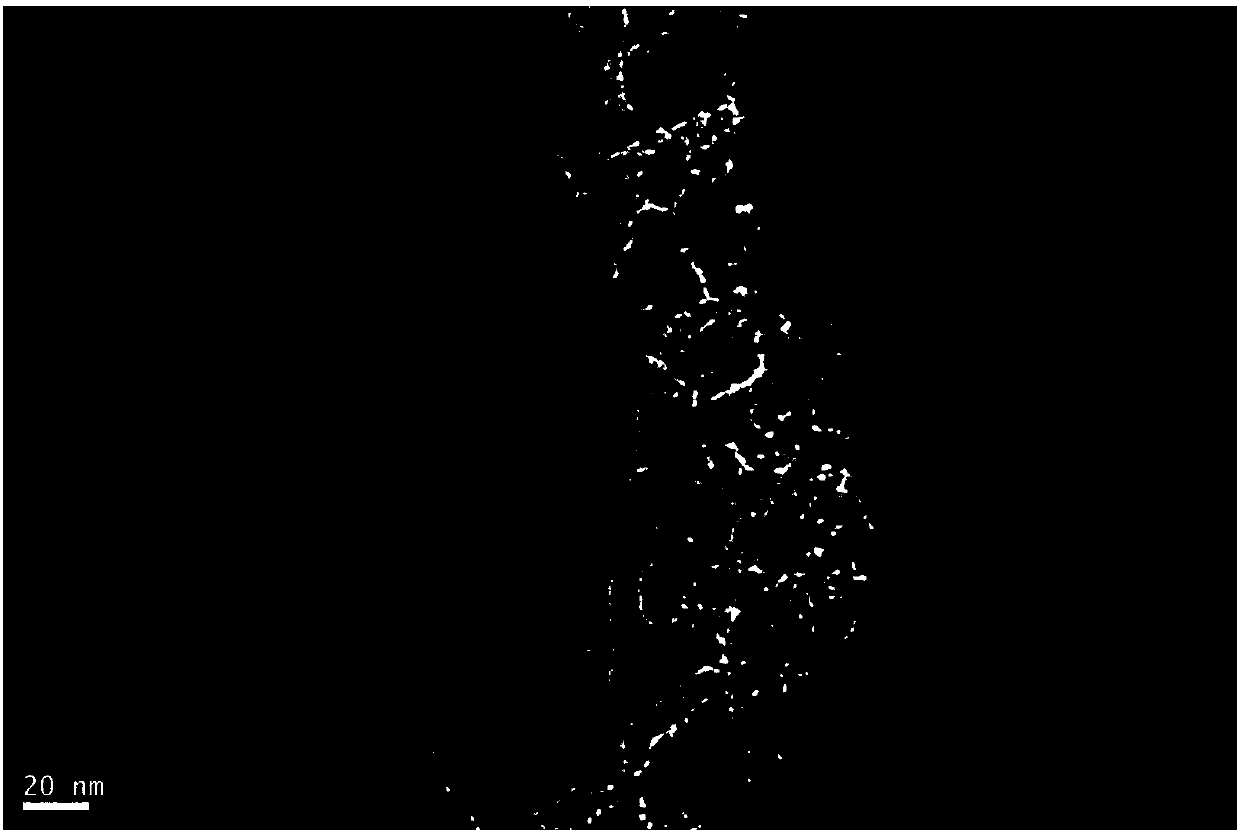

[0035] Put the prepared nanometer-sized ZIF-67 into a tube furnace, rise to 400°C at 0.5°C / min under the protection condition of nitrogen-hydrogen mixed gas (10% volume hydrogen), keep the temperature for 1 hour, and then naturally cool to room temperature to obtain carbon Nanotube-encapsulated cobalt and its oxide nanosphere absorbing material, the product quality is 587mg. figure 1 A scanning electron micrograph of nanometer-sized ZIF-67 is given, which is a rhombic dodecahedral structure with a size of about 600 nanometers. fig...

Embodiment 2

[0038] Dissolve 1.7g of cobalt nitrate hexahydrate in 32g of methanol solution, called solution A, and dissolve 0.03g of cetyltrimethylammonium bromide and 1.9g of 2-methylimidazole in 32g of methanol solution, called solution B, Solution A was added dropwise into solution B under stirring, stirred for 6 hours, washed by centrifugation, and dried in an oven at 60°C for 6 hours. Nano-sized ZIF-67 was obtained with a product mass of 1.7 g.

[0039] Put the prepared nano-sized ZIF-67 into a tube furnace, raise it to 500°C at 1°C / min under the protection condition of nitrogen-hydrogen mixed gas (10% volume hydrogen), keep the temperature at a constant temperature for 2 hours, and naturally cool to room temperature to obtain the product carbon Nanotube-encapsulated cobalt and its oxide nanosphere absorbing material, the product quality is 839mg.

[0040] Figure 8 A scanning electron microscope photo of nanometer-sized ZIF-67 is given, which is a rhombic dodecahedron with a size ...

Embodiment 3

[0043] Dissolve 3.2g of cobalt nitrate hexahydrate in 60g of methanol solution, called solution A, and dissolve 0.04g of cetyltrimethylammonium bromide and 3.6g of 2-methylimidazole in 60g of methanol solution, called solution B, Solution A was added dropwise to solution B under stirring, stirred for 12 hours, washed by centrifugation, and dried in an oven at 60°C for 6 hours. Nano-sized ZIF-67 was obtained with a product mass of 2.98 g.

[0044] Put the prepared nanometer-sized ZIF-67 into a tube furnace, raise it to 600°C at 5°C / min under the protection condition of nitrogen-hydrogen mixed gas (10% volume hydrogen), keep the temperature at a constant temperature for 5 hours, and naturally cool to room temperature to obtain the product carbon Nanotube-encapsulated cobalt and its oxide nanosphere absorbing material, the product mass is 1.03g.

[0045] Figure 15 A scanning electron micrograph of nanometer-sized ZIF-67 is given, which is a rhombic dodecahedron with a size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com