Method for preparing C-SiO2-Fe/M magnetic mesoporous composite material for electromagnetic wave adsorption coating

A technology of c-sio2-fe and composite materials, applied in radiation-absorbing coatings, magnetic properties of inorganic materials, etc., can solve problems such as difficult dispersion of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0022] (1) On the basis of the soft template self-assembly method, mix 1g of surfactant F127, 0.5mL of furfuryl alcohol, 0.001mol of ferric chloride and 1g of ethyl orthosilicate;

[0023] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent overnight at room temperature, put it in an oven at 70°C for thermal polymerization for 24 hours, and form a tan film;

[0024] (3) Scrape it off and put it into a porcelain boat for carbonization. Carbonization is carried out in an atmosphere tube furnace with a nitrogen gas flow, and the temperature is kept at 350°C for 3 hours, and at 500°C for 2 hours, and the heating rate is strictly controlled at 1°C / min;

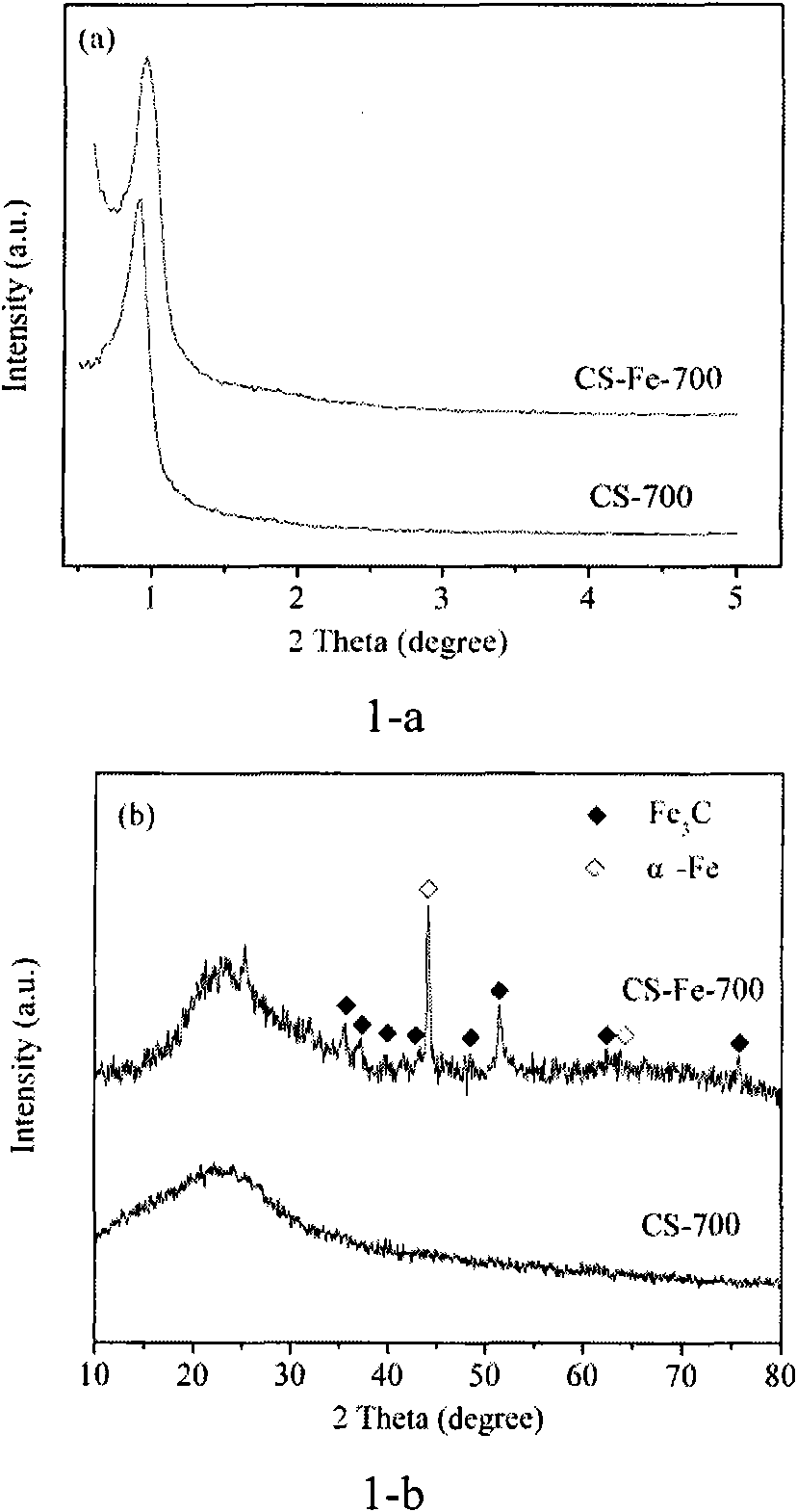

[0025] (4) Label the product in the form of CS-xFe-y, wherein x represents the amount of the substance added with iron salt (mmol), and y represents the calcination temperature, and the sample is named CS-Fe-500.

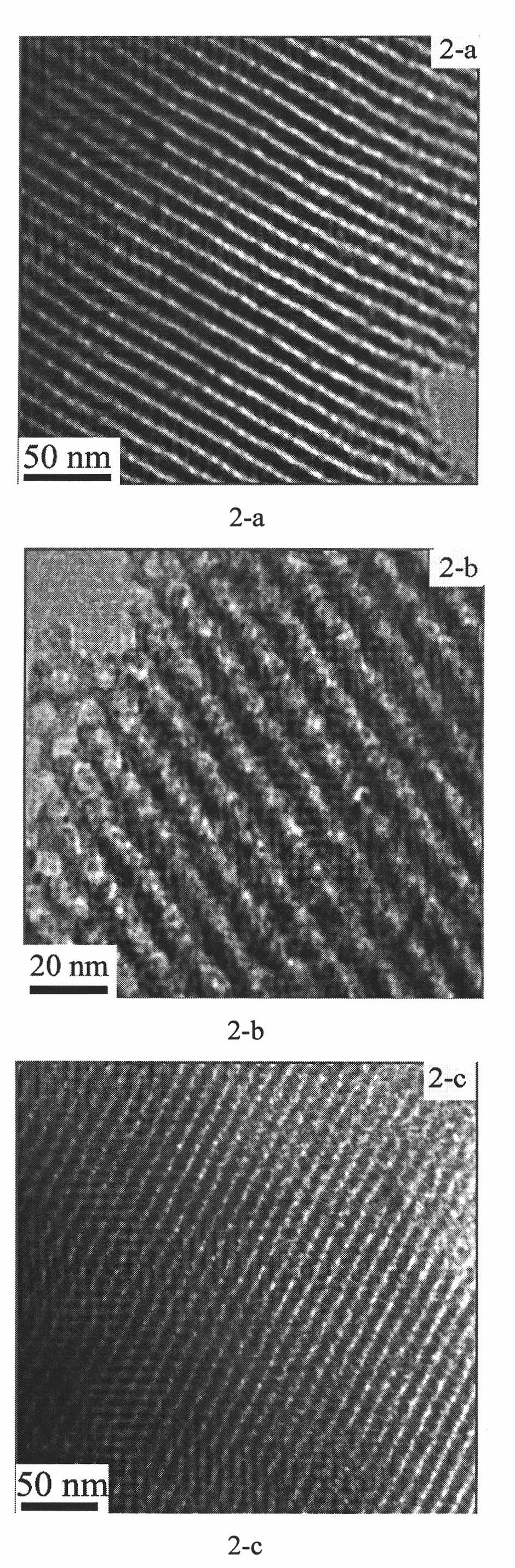

[0026] The method is simple and easy, and the preparation cost is low. In the obtaine...

specific Embodiment 2

[0027] (1) On the basis of the soft template self-assembly method, mix 1g of surfactant F127, 0.5mL of furfuryl alcohol, 0.001mol of ferric chloride and 1g of ethyl orthosilicate;

[0028] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent overnight at room temperature, put it in an oven at 70°C for thermal polymerization for 24 hours, and form a tan film;

[0029] (3) Scrape it off and put it into a porcelain boat for carbonization. Carbonization is carried out in an atmosphere tube furnace with a nitrogen gas flow, and the temperature is kept at 350°C for 3 hours, and at 700°C for 2 hours, and the heating rate is strictly controlled at 1°C / min;

[0030] (4) Label the product in the form of CS-xFe-y, where x represents the amount of the substance added with iron salt (mmol), and y represents the calcination temperature. The sample is named CS-Fe-700.

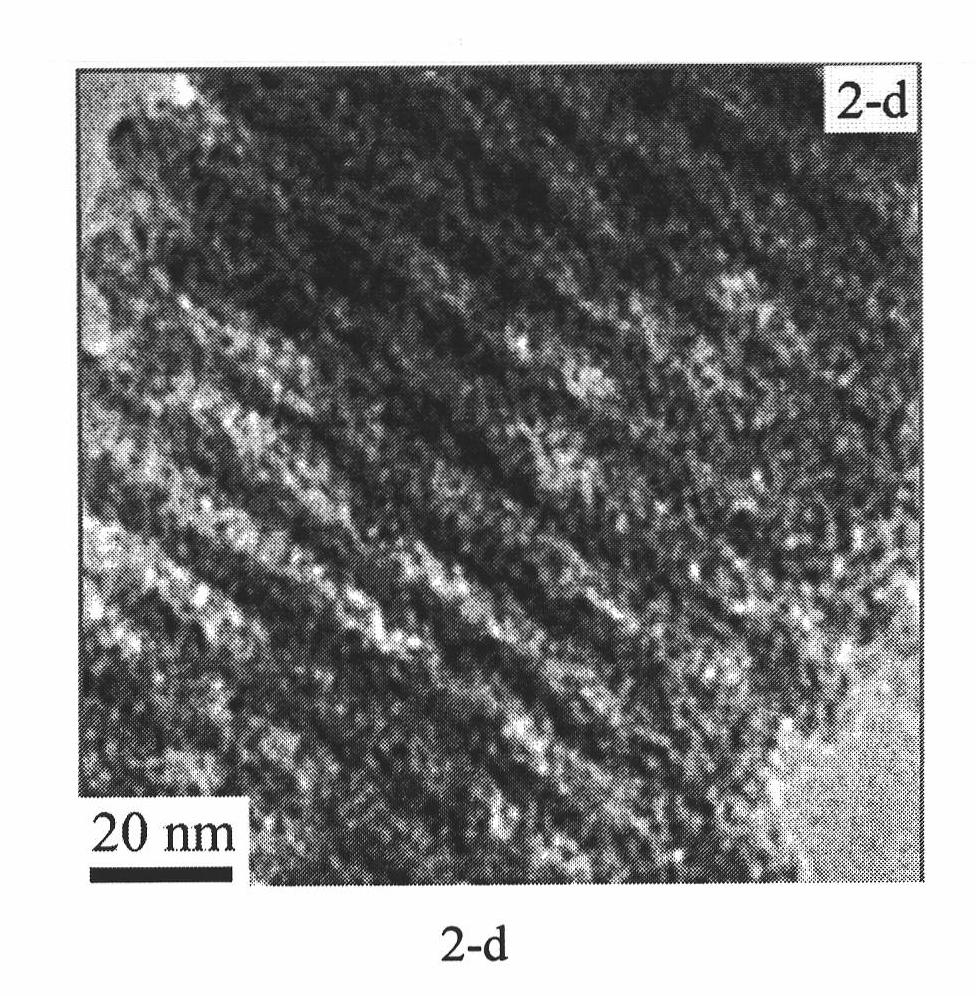

[0031] The method is simple and easy, and the preparation cost is low. In the obtained CS...

specific Embodiment 3

[0032] (1) On the basis of the soft template self-assembly method, mix 1g of surfactant F127, 0.5mL of furfuryl alcohol, 0.002mol of ferric chloride and 1g of ethyl orthosilicate;

[0033] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent overnight at room temperature, put it in an oven at 120°C for thermal polymerization for 24 hours, and form a tan film;

[0034] (3) Scrape it off and put it into a porcelain boat for carbonization. Carbonization is carried out in an atmosphere tube furnace with a nitrogen gas flow, and the temperature is kept at 350°C for 3 hours, and at 700°C for 2 hours, and the heating rate is strictly controlled at 1°C / min;

[0035] (4) Label the product in the form of CS-xFe-y, wherein x represents the amount of the substance added with iron salt (mmol), and y represents the calcination temperature. The sample is named CS-2Fe-700.

[0036] This method is simple and easy to implement, and the preparation cost is low. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com