Upgrading and modifying method for laser surface of drawing mould

A technology for surface modification and deep drawing of dies, applied in laser welding equipment, forming tools, furnace types, etc., can solve problems such as metal-to-metal adhesion, lubricating oil film crushing, wear failure, etc., to improve the lubrication condition of the die surface, Good repeatability of microtopography and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

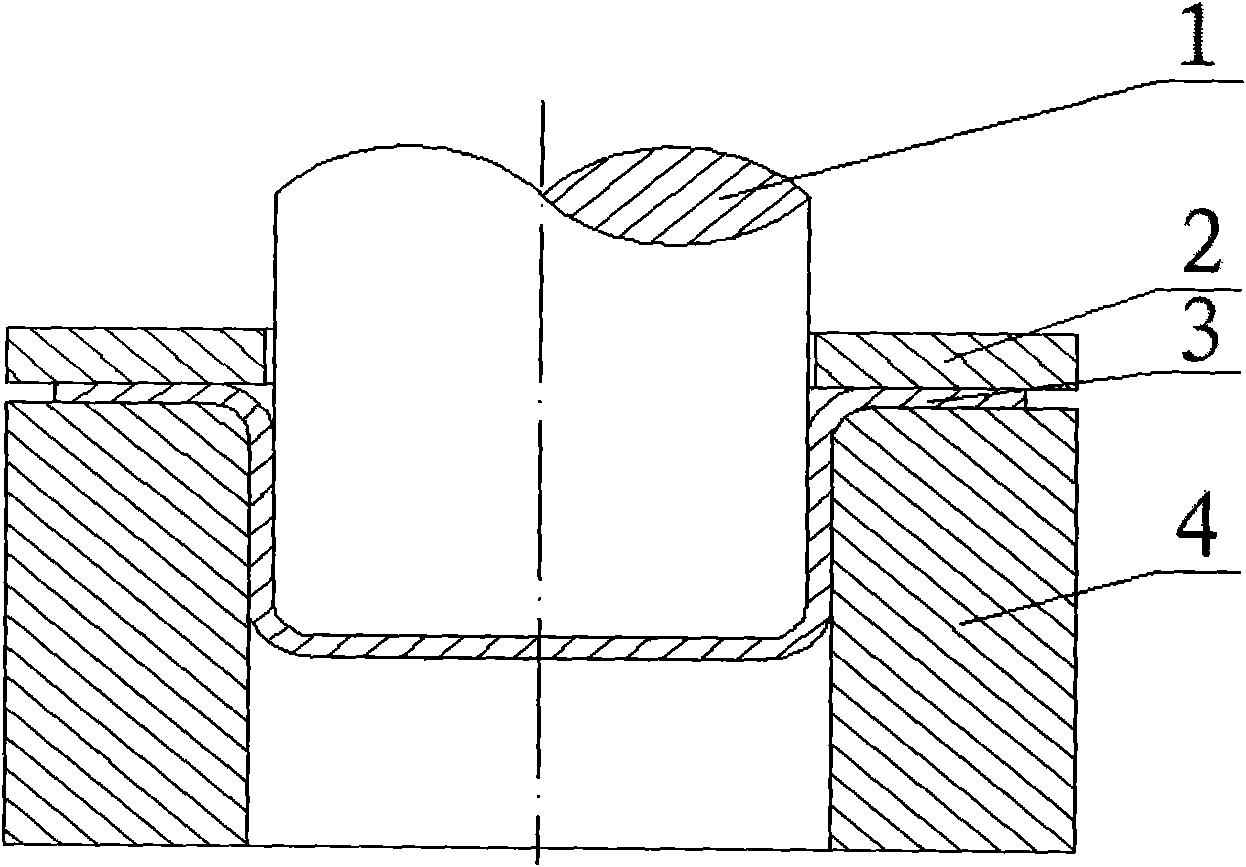

[0016] Such as figure 1 , The drawing die is composed of three parts: the die 4 , the punch 1 and the blank holder 2 , and the workpiece 3 is located between the die 4 and the punch 1 . Implementation steps of the present invention are:

[0017] 1. Select laser processing equipment. The laser processing equipment uses Nd-doped yttrium aluminum garnet laser (Nd:YAG pulsed laser), its basic parameters are: the maximum average power is 500W, the pulse width is 0.5-9ms, and the pulse frequency range is 1-100Hz.

[0018] 2. Select the base of the drawing die. The drawing die material is high carbon chromium bearing steel, namely GCr15.

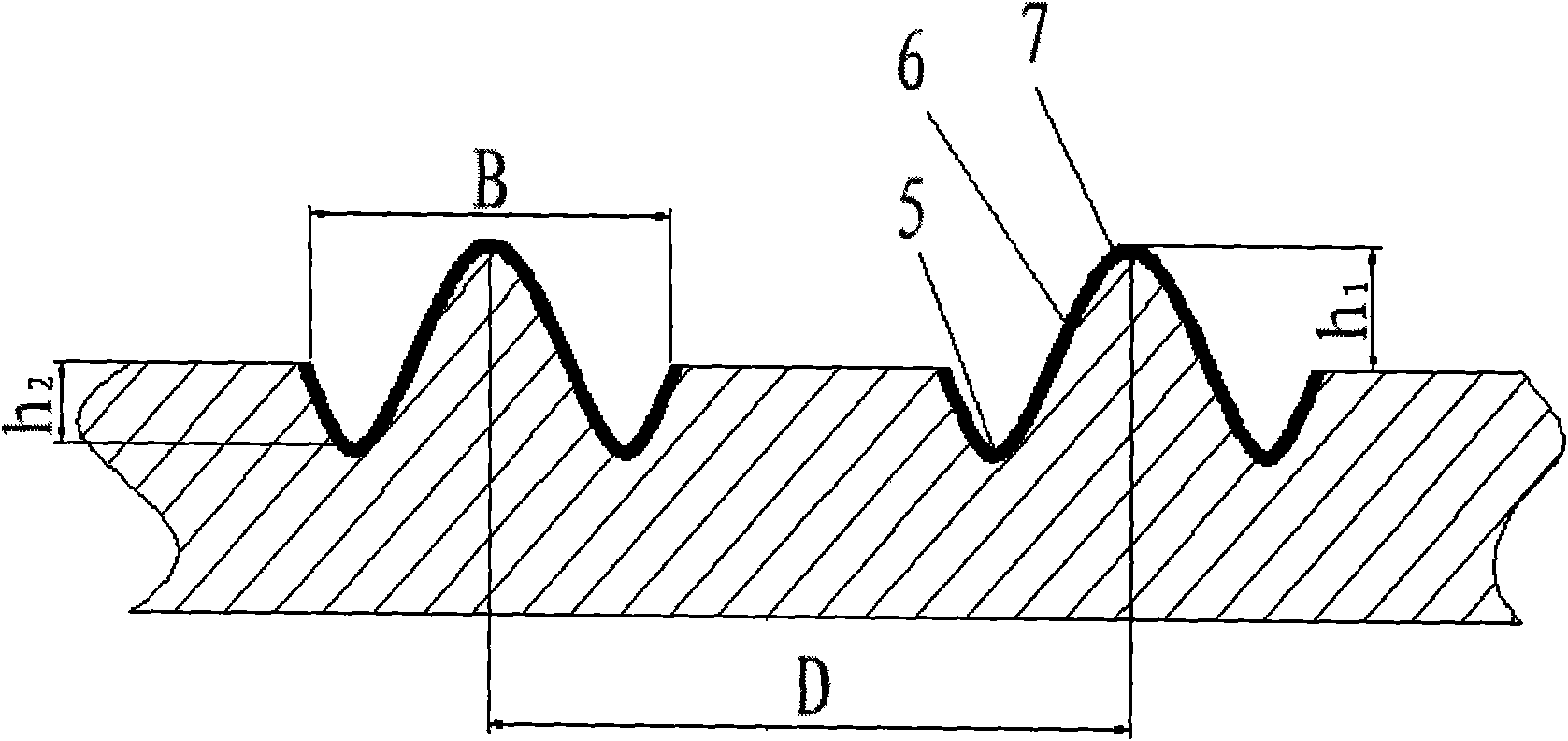

[0019] 3. Drive the laser and adjust the laser power density to 10 4 ~10 6 W / cm 2 , pulse width, pulse frequency and other laser parameters, so that the pulse laser with high energy density and high repetition frequency irradiates the working surface of the drawing die, and at the same time the working surface of the drawing die moves along t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com