Surface treatment method for SLM molded titanium implant

A titanium implant and surface treatment technology, which is applied in the field of surface treatment of SLM-molded titanium implants, can solve the lack of micro-nano composite surface microstructure of titanium implants, unsatisfactory preparation of surface active components, and poor surface hydrophilicity. Ideal and other issues, to achieve the effect of improving mineralization characteristics and biological activity, improving microscopic morphology, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for surface treatment of SLM formed titanium implants, comprising the following steps:

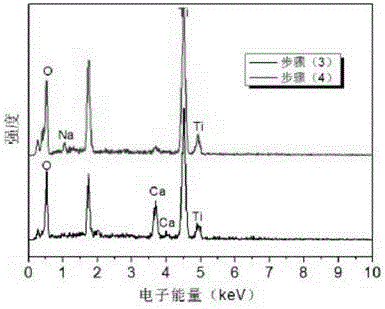

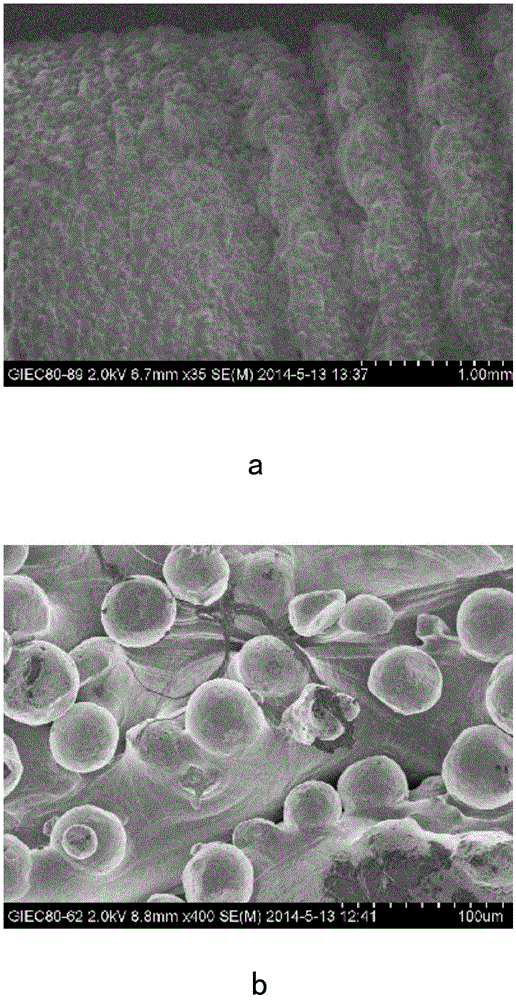

[0033] (1) SLM molding of titanium implants: using titanium metal powder as raw material, the titanium implants with micron-scale structure on the surface were printed by SLM molding 3D printing, and the surface roughness Ra of the titanium implants after SLM molding was controlled to be 7 μm. Surface morphology such as figure 1 shown;

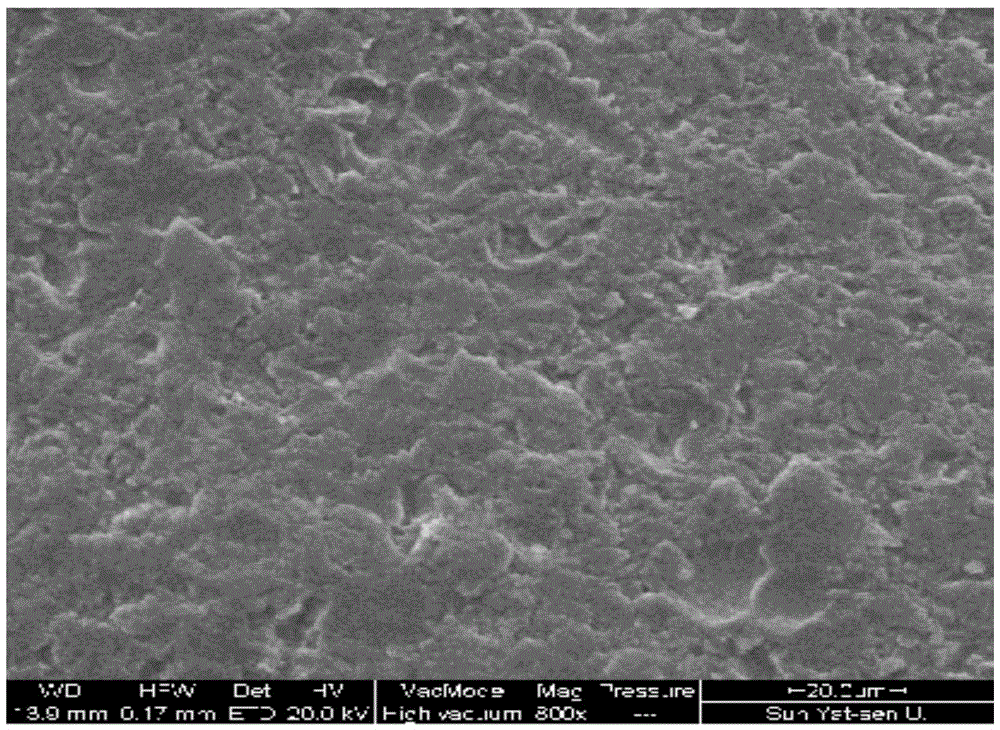

[0034] (2) Sandblasting: 60-mesh corundum or titanium dioxide was used for surface blasting of SLM-formed titanium implant samples. Sandblasting process conditions: compressed air pressure is 6bar, spraying distance is 60mm, spraying time is 10s, and its surface appearance is as follows: figure 2 shown. After sandblasting, the SLM-formed titanium implants were placed in acetone, 95% ethanol, and deionized water for 10 minutes, respectively, and then dried;

[0035] (3) Pickling to remove impurities: put the SLM-shaped titanium implant ...

Embodiment 2

[0041] A method for surface treatment of SLM formed titanium implants, comprising the following steps:

[0042] (1) SLM molding of titanium implants: using titanium metal powder as raw material, the titanium implants with a micron-scale structure on the surface are printed by SLM molding 3D printing, and the surface roughness Ra of the titanium implants after SLM molding is controlled to be 8 μm;

[0043] (2) Sand blasting treatment: 80-mesh corundum or titanium dioxide was used to perform surface blasting treatment on the SLM-formed titanium implant samples. Sandblasting process conditions: compressed air pressure is 6bar, spraying distance is 50mm, and spraying time is 20s. After sandblasting, the SLM-formed titanium implants were placed in acetone, 95% ethanol, and deionized water for 10 minutes, respectively, and then dried;

[0044] (3) Pickling to remove impurities: put the SLM-shaped titanium implant prepared in step (2) into the pickling solution for pickling treatment....

Embodiment 3

[0049] A method for surface treatment of SLM formed titanium implants, comprising the following steps:

[0050] (1) SLM molding of titanium implants: using titanium metal powder as raw material, the titanium implants with a micron-scale structure on the surface are printed by SLM molding 3D printing, and the surface roughness Ra of the titanium implants after SLM molding is controlled to 9 μm;

[0051] (2) Sandblasting: 60-mesh corundum or titanium dioxide was used for surface blasting of SLM-formed titanium implant samples. Sandblasting process conditions: compressed air pressure is 4bar, spraying distance is 70mm, and spraying time is 15s. After sandblasting, the SLM-formed titanium implants were placed in acetone, 95% ethanol, and deionized water for 10 minutes, respectively, and then dried;

[0052] (3) Pickling to remove impurities: put the SLM-shaped titanium implant prepared in step (2) into the pickling solution for pickling treatment. The pickling solution is prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com