Controllable-morphology high-porosity porous ceramic membrane supporting body and preparation method thereof

A technology of porous ceramic membrane and high porosity, which is applied in the field of high-porosity porous ceramic membrane support and its preparation, can solve the problems of uncontrollable pore size of the support, insufficient pure water flux, and insufficient porosity, etc. Excellent chemical stability, excellent thermal stability, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example illustrates a method for preparing ceramic powder material / polymer composite fibers.

[0045] Weigh N, N-dimethylformamide (DMF) and ethanol (EtOH) to prepare a mixed solvent at a mass ratio of 1:2.

[0046] Weigh 1.6g of halloysite nanotubes (HNTs) into 17.6g of the above mixed solvent, and ultrasonically disperse until there is no agglomeration. Then add 2.4g of polyvinylpyrrolidone (PVP) and mix thoroughly to obtain a uniform spinning solution.

[0047] The prepared spinning solution was placed in a disposable syringe with a needle inner diameter of 0.4 mm for electrospinning. The electrospinning voltage was set at 5KV, the solution pumping speed was 30 μl / min, the distance from the needle to the collection drum was 10 cm, and the rotation speed of the collection drum with a diameter of 10 cm was 2000 rpm.

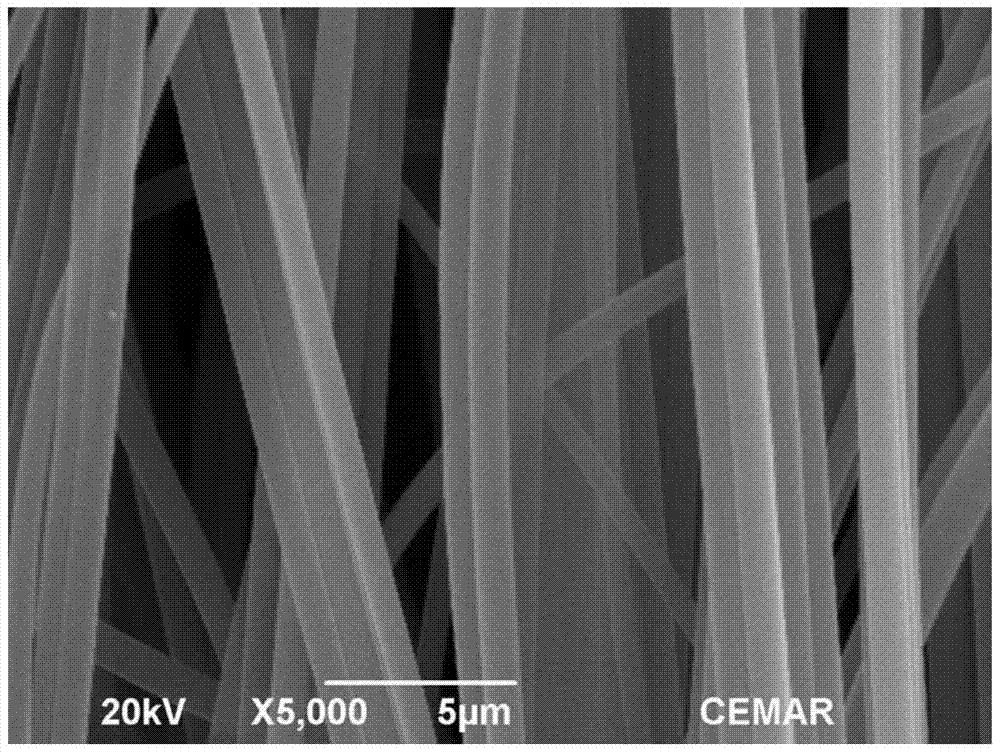

[0048] Observing the obtained composite fiber by scanning electron microscope, we can get Figure 1(a). It can be seen from the figure that the PVP...

Embodiment 2

[0053] This example illustrates a method for preparing a ceramic material precursor / polymer composite fiber.

[0054] Weigh 2.4g of polyvinylpyrrolidone (PVP) into 12g of ethanol (EtOH), and mix well. Then add 1.6 g of isopropyl titanate and mix thoroughly to obtain a uniform spinning solution.

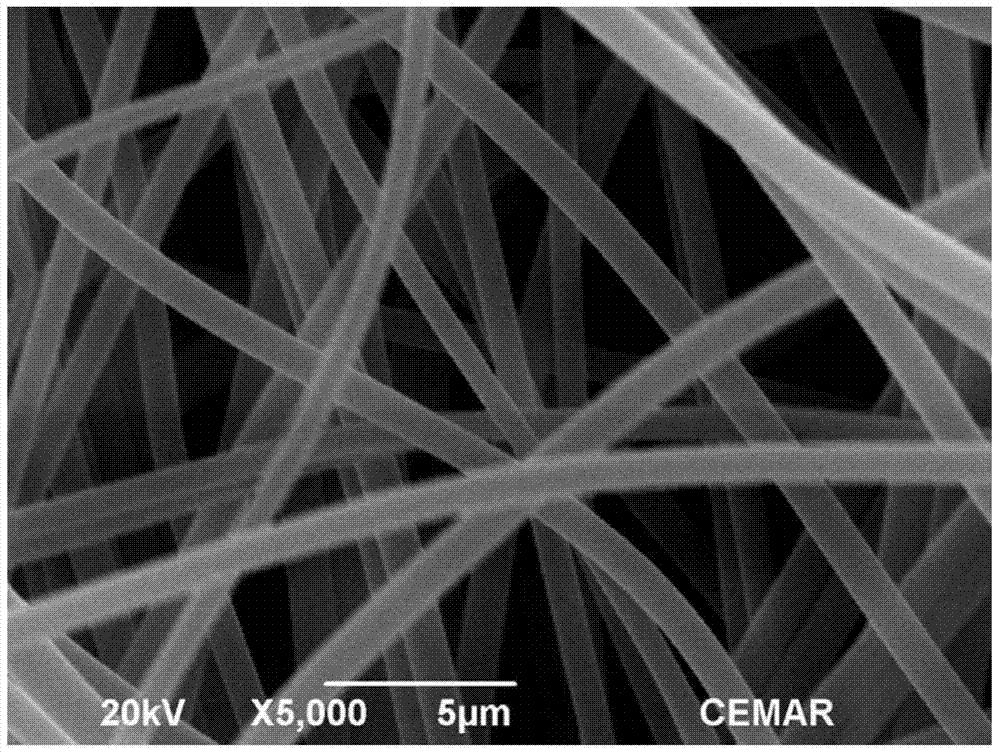

[0055] The prepared spinning solution was placed in a disposable syringe with a needle inner diameter of 0.4 mm for electrospinning. The electrospinning voltage was set at 10KV, the solution pumping speed was 30 μl / min, the distance from the needle to the collection drum was 12 cm, and the rotation speed of the collection drum with a diameter of 10 cm was 40 rpm. The obtained isopropyl titanate / PVP composite fiber membrane was observed by scanning electron microscope, and obtained figure 2 .

Embodiment 3

[0057] This example illustrates a method for preparing ceramic powder material / polymer composite fibers.

[0058] Water and ethanol (EtOH) were weighed to prepare a mixed solvent with a mass ratio of 5:3.

[0059] Weigh 2.4g of nanometer aluminum oxide (Al 2 o 3 ) was added to 24 g of the above mixed solvent, and ultrasonically dispersed to a non-agglomerated state. Then add 2.4g of polyvinylpyrrolidone (PVP) and mix thoroughly to obtain a uniform spinning solution.

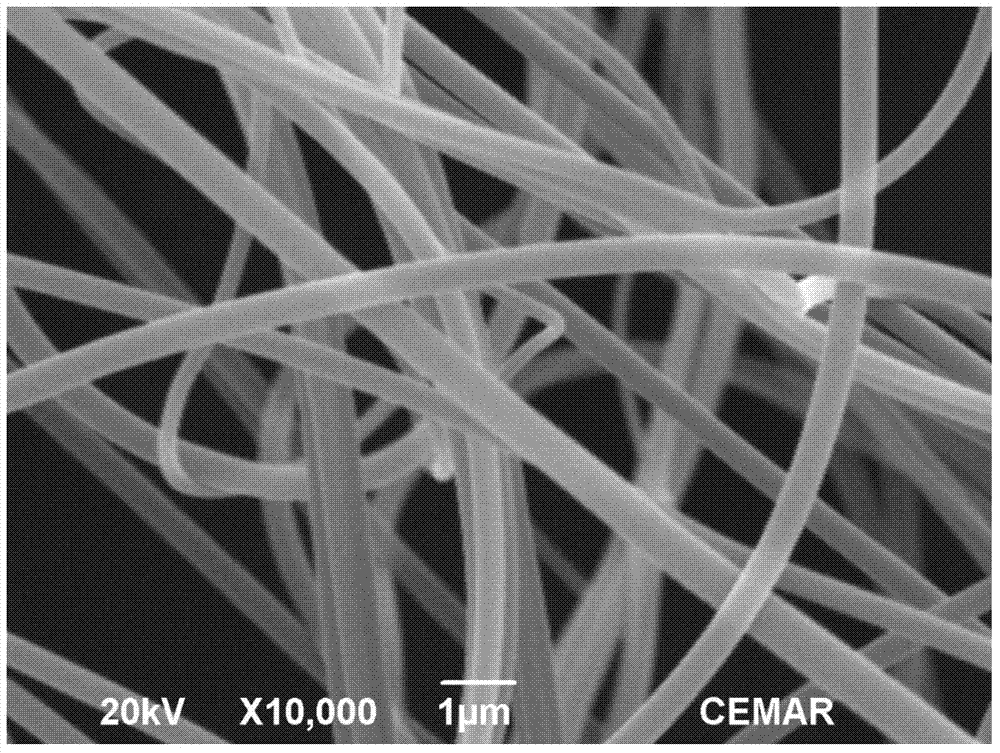

[0060] The prepared spinning solution was placed in a disposable syringe with a needle inner diameter of 0.4 mm for electrospinning. The electrospinning voltage was set at 10KV, the solution pumping speed was 30 μl / min, the distance from the needle to the collection drum was 12 cm, and the rotation speed of the collection drum with a diameter of 10 cm was 40 rpm. will get Al 2 o 3 / PVP composite fiber membrane was observed by scanning electron microscope, and obtained image 3 .

[0061] The above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com