Method for preparing series silver nano-sheets in batch

A silver nanosheet and a series of technologies are applied in the field of preparation of silver nanomaterials, which can solve the problems of small single preparation amount, small reaction amount, increased cost, etc., and achieve a wide range of size regulation, good monodispersity, and simple reaction device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First prepare 100 ml of mixed solvent of ethylene glycol and dimethylformamide in a volume ratio of 1:1 for later use; then weigh 1 g of polyvinylpyrrolidone (average molecular weight: 33,000) and add it to 50 ml of mixed solvent for stirring or ultrasonic dissolution before adding 6 mg of potassium bromide and 6 mg of cupric chloride, stirred or ultrasonically dissolved to obtain solution A, and set aside; then prepare a mixed solution of mixed solvent and silver nitrate: weigh 1 g of silver nitrate and add it to 50 ml of mixed solvent, stir or shake to dissolve Uniform solution B, set aside.

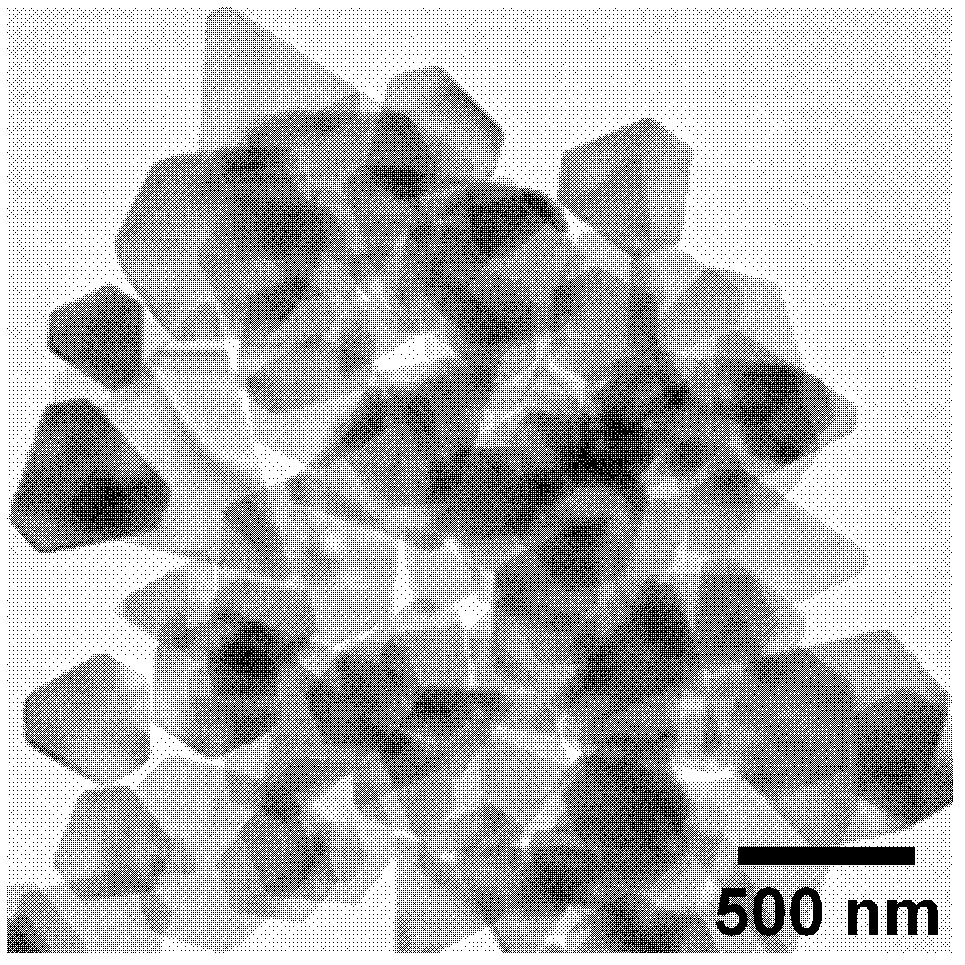

[0028] Mix solution A and solution B uniformly at a volume ratio of 1:1 and transfer to a flask, heat up to boiling and reflux and keep for 3 hours, then stop heating. After the reaction is stopped, wash with 100 ml of water and 100 ml of ethanol and centrifuge, and finally dry the obtained precipitate to obtain dry powder silver nanosheets with a side length of 40 nanometers an...

Embodiment 2

[0030] Similar to the process of Example 1, but when preparing silver nanosheets, the inorganic salt containing halogen ions is replaced by potassium bromide to potassium chloride, and the dosage is reduced to 4 mg; while the copper-containing inorganic salt is replaced by copper chloride For copper nitrate, and reduce the dosage to 4 mg, other conditions remain unchanged. After the reaction is finished, wash and centrifuge with ethanol and ultra-pure water, and dry the precipitate at low temperature until it becomes a dry powder, so as to obtain silver nanosheets with a side length of 80 nanometers and a thickness of 10-15 nanometers. figure 2 Scanning electron microscope image of silver nanosheets with a side length of 80 nm, by figure 2 It can be seen that the silver nanosheets with a side length of 80 nanometers still have good dispersion and uniformity.

Embodiment 3

[0032] Similar to the process of Example 1, but when preparing silver nanosheets, polyvinylpyrrolidone was replaced with polydiallyl dimethyl ammonium chloride, and the amount was increased to 2 grams; the amount of silver nitrate was increased to 1.5 grams; heating and boiling reflux The post-hold time was extended to 4 hours, and other conditions remained unchanged. After the reaction is finished, wash and centrifuge with ethanol and ultrapure water, and dry the precipitate at low temperature until it becomes a dry powder, so as to obtain silver nanosheets with a side length of 100 nanometers and a thickness of 20 to 30 nanometers. image 3 Scanning electron microscope image of silver nanosheets with a side length of 100 nm, by image 3 It can be seen that while the side length of the silver nanosheet increases, the thickness also increases slightly, but still maintains high purity and high monodispersity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com