Manganese spinel nano material as well as preparation method and application of manganese spinel nano material

A nano-material and spinel technology, applied in the field of nano-material preparation, can solve the problems of increasing energy consumption and cost, harsh preparation process, etc., and achieve the effect of less energy consumption, high electrocatalytic efficiency, and improved electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] 1) Amorphous MnO 2 Preparation of nanoparticles

[0032] First accurately prepare 0.04M KMnO 4 and 0.06M MnCl 2 solution. Then the KMnO was mixed under magnetic stirring 4 The solution is quickly added to the MnCl 2 In the solution, stirring was continued for 30 minutes, and finally centrifuged, and the product was washed three times with deionized water and absolute ethanol respectively, and dried under vacuum at 80° C. for 4 hours.

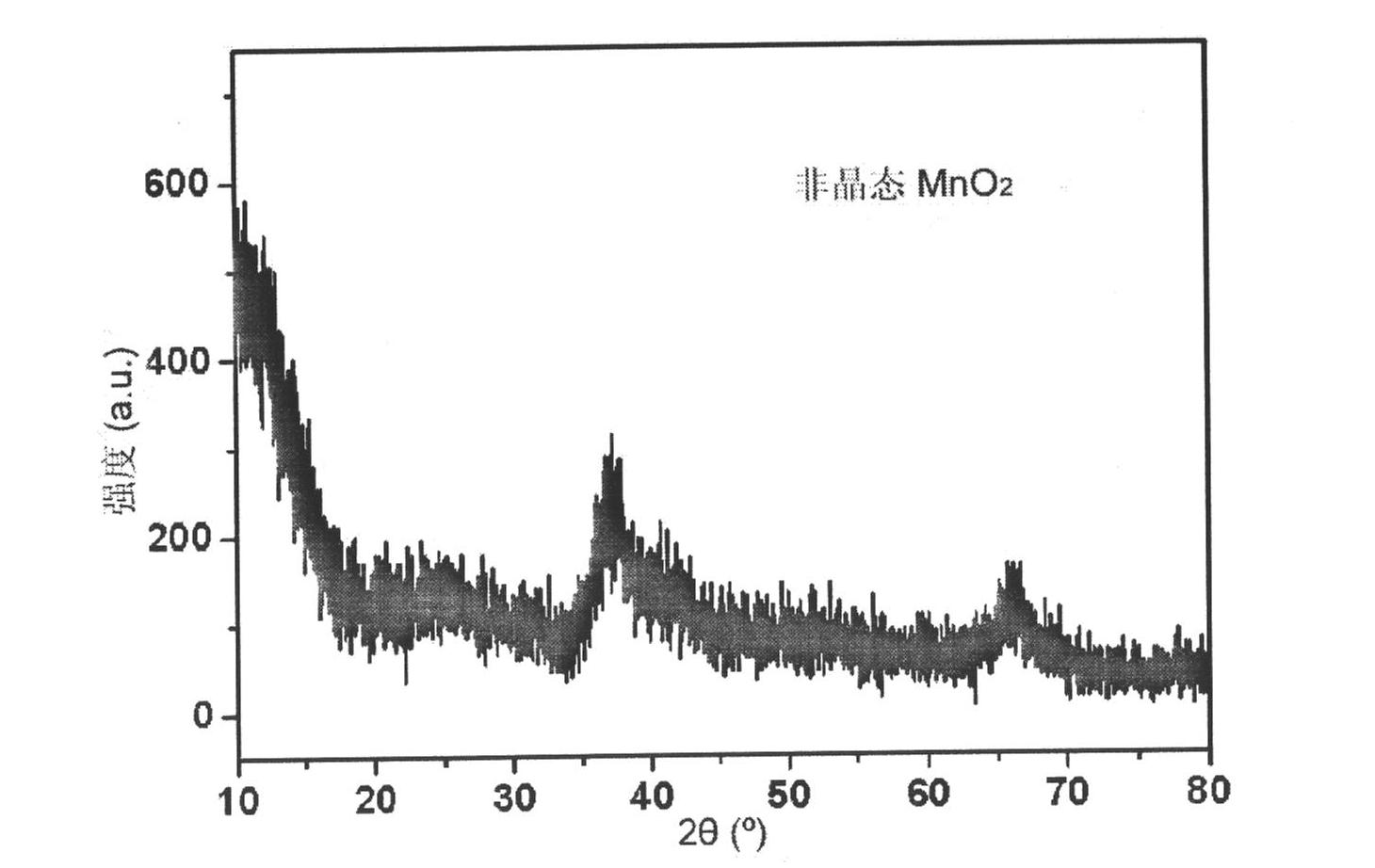

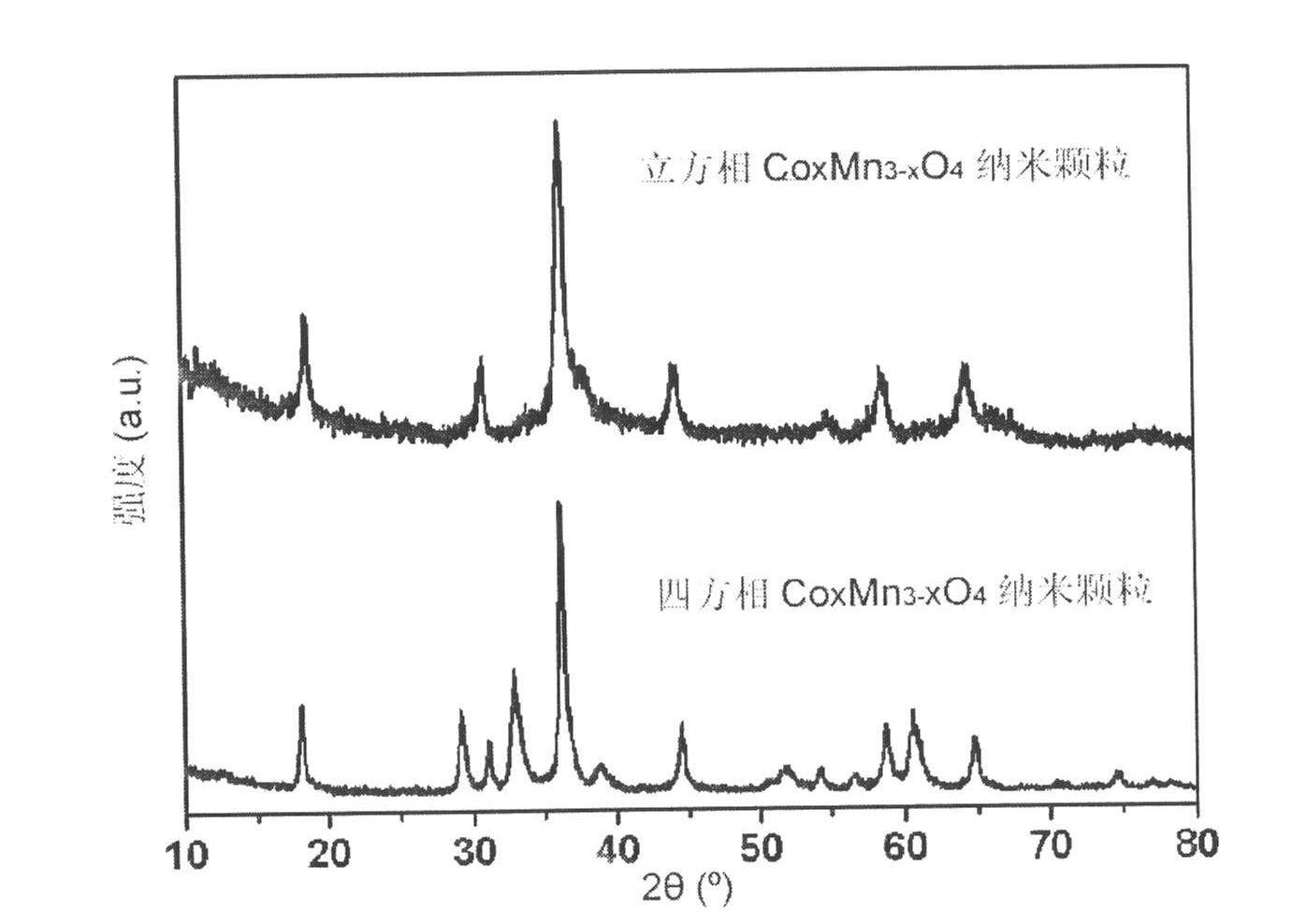

[0033] According to the MnO prepared by the method described in 1) 2 The XRD pattern of nanoparticles is shown in figure 1 As shown, the diffraction peaks are obviously broadened, showing amorphous MnO 2 feature.

[0034] 2) Tetragonal phase Co x mn 3-x o 4 Preparation of nanoparticles

[0035] Accurately weigh 0.1mmolCoCl 2 ·6H 2 O and MnO 2 Nanoparticles, so that the molar ratio of Co:Mn is 1:2. CoCl 2 ·6H 2 O was dissolved in 15 mL of water, and then the MnO 2 Added to the above CoCl 2 In the solution, ultrasonicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com