Electrofluid spraying device and method for printing three-dimensional biological scaffold

A three-dimensional biological and spray device technology, applied in coating devices, processing drive devices, manufacturing auxiliary devices, etc., can solve the problem that biological scaffolds are unfavorable for the secretion and formation of extracellular matrix, can not meet the needs of cell adhesion and growth, and are difficult to fiber. Constitute the fiber arrangement direction and other issues to achieve the effect of favorable secretion and formation, good biocompatibility, and good orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

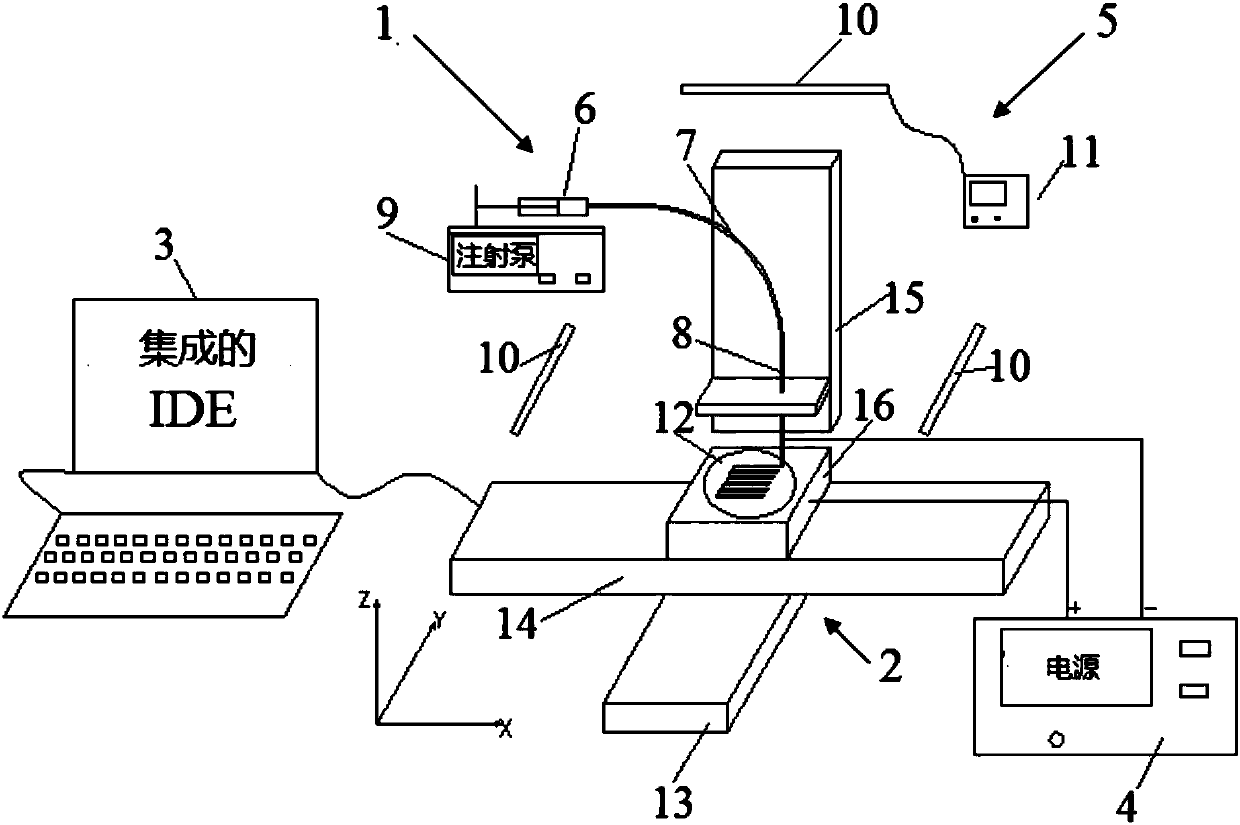

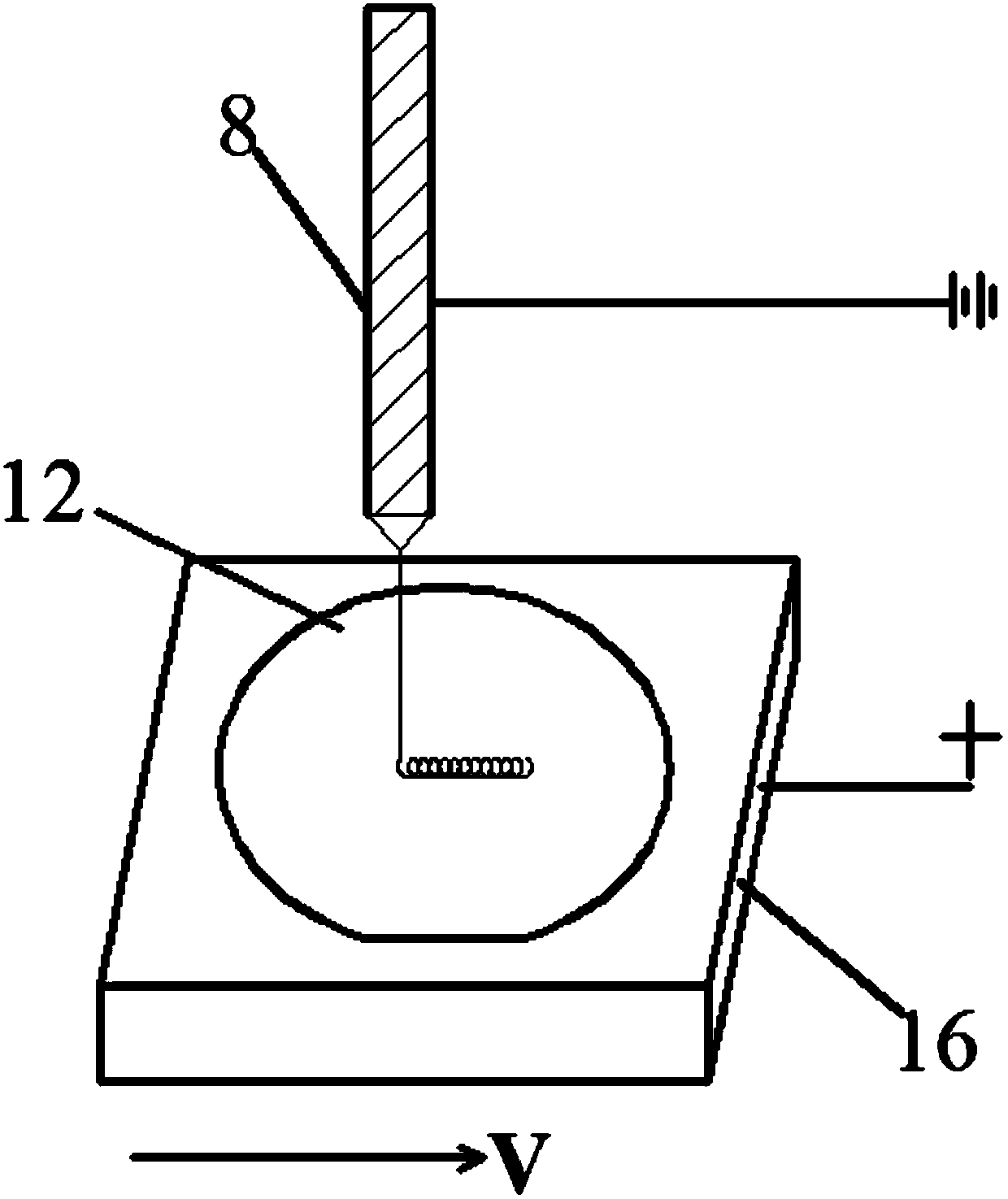

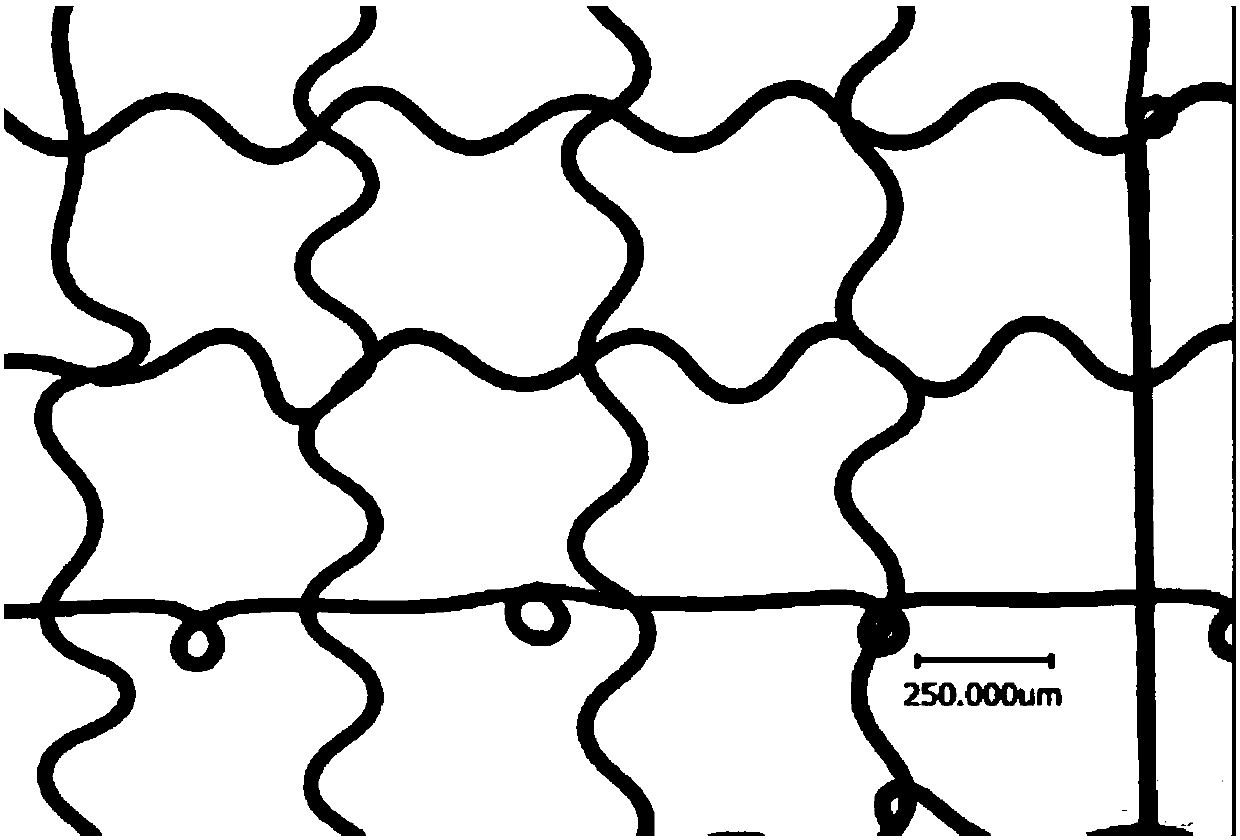

[0073] The above-mentioned electrofluid jetting device is used to print a three-dimensional biological scaffold with a sine wave micro-topography and a multi-level micron-scale structure.

[0074] i) Mix polycaprolactone PCL particles and glacial acetic acid evenly, prepare a PCL solution with a concentration of 70% wt, and add the PCL solution to the syringe;

[0075] ii) Set the distance between the flat spray needle and the polished silicon crystal substrate to D=3.5mm, set the injection rate of the solution to R=1μl / min through the syringe pump, and set the movement speed of the motion platform on the X and Y axes respectively 60mm / s;

[0076] iii) The voltage between the blunt needle and the polished silicon crystal substrate is set to V=2.55kV.

[0077] The pattern of the three-dimensional scaffold printed through the above process is as follows: image 3 As shown, the pattern is characterized by the sinusoidal microtopography of its fibers.

Embodiment 2

[0079] The above-mentioned electrofluid jetting device is used to print a three-dimensional bio-scaffold with a phase-separated circle microtopography and a multi-level micron-scale structure.

[0080] i) Mix polycaprolactone PCL particles and glacial acetic acid evenly, prepare a PCL solution with a concentration of 70% wt, and add the PCL solution to the syringe;

[0081] ii) Set the distance between the flat spray needle and the polished silicon crystal substrate to D=3.5mm, set the injection rate of the solution to R=1μl / min through the syringe pump, and set the movement speed of the motion platform on the X and Y axes respectively 100mm / s;

[0082] iii) The voltage between the blunt needle and the polished silicon crystal substrate is set to V=2.55kV.

[0083] The pattern of the three-dimensional scaffold printed through the above process is as follows: Figure 4 As shown, the pattern is characterized by its fibers having phase-separated circle microtopography.

Embodiment 3

[0085] The above-mentioned electrofluid jetting device is used to print a three-dimensional bio-scaffold with adjacent circle microtopography and multi-level micro-scale structure.

[0086] i) Mix polycaprolactone PCL particles and glacial acetic acid evenly, prepare a PCL solution with a concentration of 70% wt, and add the PCL solution to the syringe;

[0087] ii) Set the distance between the flat spray needle and the polished silicon crystal substrate to D=3.5mm, set the injection rate of the solution to R=1μl / min through the syringe pump, and set the movement speed of the motion platform on the X and Y axes respectively 80mm / s;

[0088] iii) The voltage between the blunt needle and the polished silicon crystal substrate is set to V=2.55kV.

[0089] The pattern of the three-dimensional scaffold printed through the above process is as follows: Figure 5 As shown, the pattern is characterized by the microtopography of its fibers with closely adjacent circles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com