Fiber reinforced phenolic foam composite material and preparation method thereof

A phenolic foam and composite material technology, applied in the field of composite materials, can solve the problems of uneven distribution of fibers, uneven distribution of strength, unsatisfactory, etc., and achieve the effects of high strength, widening application fields, and not easy to drop powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

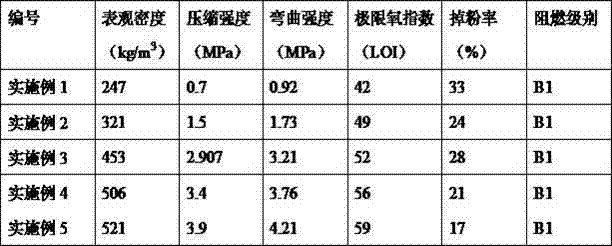

Examples

Embodiment 1

[0030] At room temperature, add 5 parts of F-36 foaming agent, 0.5 part of Tween-80, 0.5 part of DC-190 modifier, and 50 parts of alcohol solvent into 100 parts of phenolic resin, stir at high speed for 5 min, and the stirring speed is 900 r / min, then add 18 parts of curing agent (the curing agent is prepared from toluene-4-sulfonic acid and water in a weight ratio of 2:3), and continue to stir for 1 min to obtain prepreg 1; use the prepared above Prepreg 1 is used as the dipping solution, and 90 parts of fiber mats are impregnated with a dipping machine to obtain prepreg 2; the dipped fiber mat prepreg 2 is put into an oven and heated at a temperature of 40 ℃ The phenolic resin was pre-cured at the same time, and part of the volatile components and excess solvent were removed at the same time to obtain the prepreg III; the obtained prepreg III was put into the molding machine, and kept under the pressure of 0.2 MPa and the temperature of 70 ℃ for 5 minutes. The entire foaming...

Embodiment 2

[0032] At room temperature, 20 parts of 461DU20 foaming agent, 3 parts of Tween-60, 3 parts of DC-193 modifier, and 0 parts of solvent were added to 100 parts of phenolic resin, and stirred at high speed for 10 min at a speed of 1500 r / min, then add 18 parts of curing agent (the curing agent is prepared by toluene-4-sulfonic acid and water in a weight ratio of 2:3), and continue to stir for 2 min to obtain prepreg 1; use prepared prepreg 1 As the dipping solution, use a dipping machine to impregnate 50 parts of the fiber mat to obtain the prepreg II; put the impregnated fiber mat prepreg II into an oven, and process the phenolic resin at a temperature of 80 °C. The pre-curing of the prepreg, while removing part of the volatile components and excess solvent, to obtain the prepreg III; put the obtained prepreg III into the molding machine, and keep it under the pressure of 1.5 MPa and the temperature of 110 ℃ for 30 minutes to complete the whole process. Foaming process, namely...

Embodiment 3

[0034] At room temperature, add 10 parts of F-50D foaming agent, 2 parts of KH-550 and 2 parts of CGY-1 modifier, 200 parts of water solvent into 100 parts of phenolic resin, stir at high speed for 6 minutes, and the stirring speed is 1000 r / min, then add 5 parts of curing agent (the curing agent is prepared by toluene-4-sulfonic acid and water in a weight ratio of 2:3), and continue to stir for 2 minutes to obtain prepreg 1; use the prepared prepreg Material 1 is used as the dipping solution, and 10 parts of the fiber mat are dipped with a dipping machine to obtain the prepreg 2; the dipped fiber mat prepreg 2 is put into an oven, and the prepreg 2 is prepared at a temperature of 80 ℃. Pre-cure the phenolic resin, and remove part of the volatile components and excess solvent at the same time to obtain the prepreg III; put the obtained prepreg III into the molding machine, and keep it under the pressure of 1.0 MPa and the temperature of 120 ℃ for 15 minutes. After completing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com