Preparation method of polyurethane prepolymer-toughened modified phenolic foam plastic

A technology of polyurethane prepolymer and phenolic foam, which is applied in the field of preparation of polyurethane prepolymer toughened and modified phenolic foam, can solve the problems of high brittleness of phenolic foam, low viscosity of phenolic resin, and easy pulverization, etc., to achieve Good flame retardancy, improved toughness, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

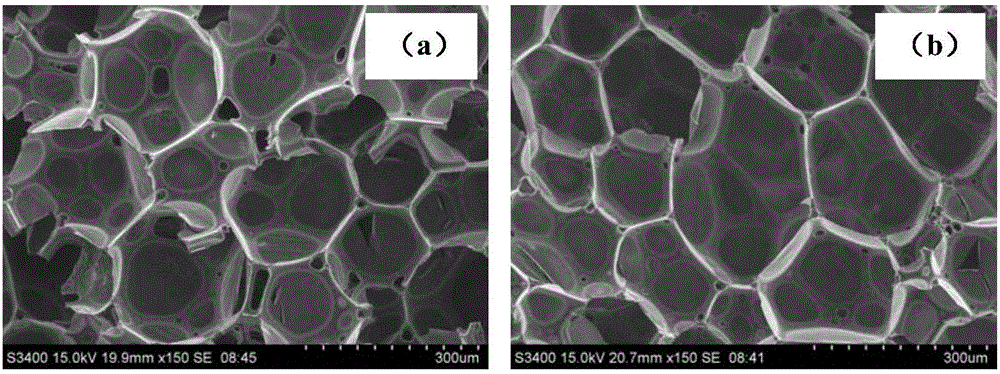

Image

Examples

Embodiment 1

[0030] (1) Preparation of toughening agent polyurethane prepolymer: firstly, the polyether oxide propylene glycol (PPG 2000) was vacuumized at 110 °C for 2 h to remove moisture, and 85 g of dehydrated polyether oxide propylene glycol (PPG 2000) 2000) was added dropwise into 32 g of diphenylmethane diisocyanate (MDI), reacted for 2 h at 75 ° C, and then added 1.2 g of chain extender 1,4-butanediol and reacted for 30 min to prepare the toughening agent polyurethane preprepared polymer with an isocyanate content of 4.5 %.

[0031] (2) Toughened phenolic foam: adjust 100 parts of basic resole phenolic resin to pH 7.0 with phosphoric acid in parts by mass (Kg), and then add 6 parts of toughening agent polyurethane prepolymerization prepared in step (1) to the resin Body, 6 parts of surfactant Tween-80, 8 parts of foaming agent petroleum ether and 12 parts of composite acid curing agent (wherein the mass ratio of phosphoric acid, p-toluenesulfonic acid, concentrated sulfuric acid an...

Embodiment 2

[0039] (1) Preparation of toughening agent polyurethane prepolymer: First, vacuumize polyethylene glycol (PEG 6000) at 110 °C for 2 h to remove moisture, then add 300 g of dehydrated polyethylene glycol (PEG 6000) dropwise Add 26 g of diphenylmethane diisocyanate (MDI), react at 60 ° C for 3 h, then add 3.3 g of chain extender ethylene glycol and react for 40 min to prepare a toughening agent polyurethane prepolymer, wherein the isocyanate content is 2.5%;

[0040] (2) Toughened phenolic foam: adjust 100 parts of basic resole phenolic resin to pH 7.0 with sulfuric acid in parts by mass (Kg), then add 9 parts of toughening agent polyurethane prepolymer and 4 parts of surfactant to the resin Nonylphenol polyoxyethylene ether, 7 parts of blowing agent n-pentane and 16 parts of composite acid curing agent (wherein the mass ratio of phosphoric acid, p-toluenesulfonic acid, concentrated sulfuric acid and water is 0.2:0.3:2.4:1), to obtain Foaming system;

[0041] (3) The foaming s...

Embodiment 3

[0048] (1) Preparation of toughening agent polyurethane prepolymer: firstly, polyethylene adipate (number average molecular weight 710) was vacuumized at 110 °C for 2 h to remove moisture, and 71 g of dehydrated polyethylene adipate Ethylene glycol ester (number average molecular weight 710) was added dropwise to 87 g of 1,6-hexamethylene diisocyanate (HDI), reacted at 70°C for 2.5 h, and then added 8.0 g of chain extender glycerol for 20 min to prepare the chain extender Toughener polyurethane prepolymer with an isocyanate content of 10.5%.

[0049] (2) Toughened phenolic foam: adjust 100 parts of basic resole phenolic resin to pH 7.0 with hydrochloric acid in parts by mass (Kg), then add 12 parts of toughening agent polyurethane prepolymer and 11 parts of surfactant to the resin Fatty acid methyl ester ethoxylate series, 9 parts of foaming agent dichloromethane and 18 parts of compound acid curing agent (the mass ratio of phosphoric acid, p-toluenesulfonic acid, concentrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com