Antistatic PC-ABS (polycarbonate-acrylonitrile butadiene styrene) alloy material and preparation method thereof

A technology of PC-ABS and alloy materials, applied in the field of alloy materials, can solve the problems of abnormal operation of integrated circuit chips, loss of antistatic effect, short antistatic time, etc., and achieve improved anti-aging performance, good mechanical properties, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

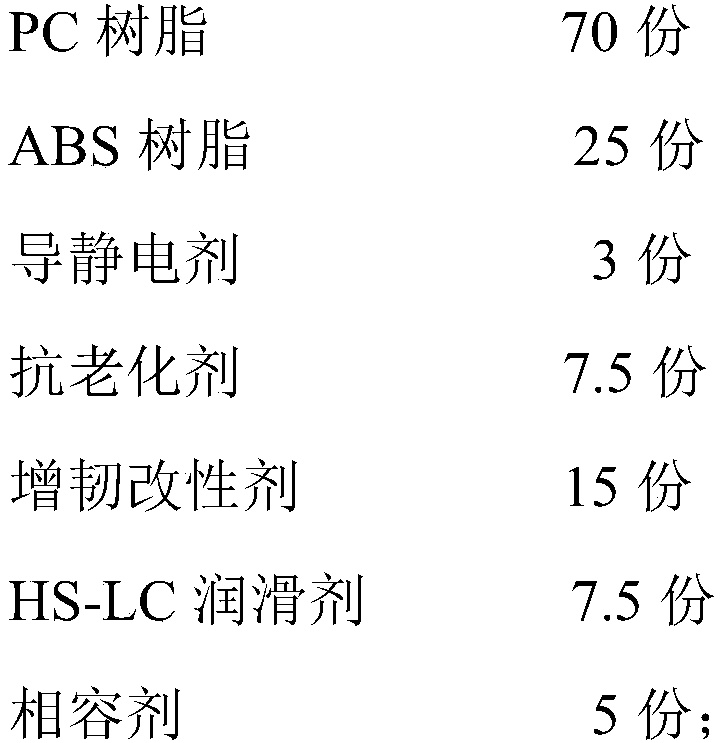

[0056] A kind of antistatic PC-ABS alloy material, comprises the raw material of following weight portion:

[0057]

[0058] Wherein, the static conductive agent is single-layer graphene.

[0059] Wherein, the preparation method of above-mentioned graphene comprises the following steps:

[0060] (1) 5 parts by weight of 4,4'-diaminobiphenyl stripping aid are mixed with 40 parts by weight of N-methylpyrrolidone organic solvent to obtain a stripping aid dispersion;

[0061] (2) 10 parts by weight of natural graphite powder was added to the exfoliation aid dispersion in the step (1), and then stirred at a stirring rate of 2200r / min for 0.5h to obtain graphene.

[0062] Wherein, the anti-aging agent is a mixture of modified nano-titanium dioxide and UV-770 hindered amine light stabilizer in a weight ratio of 4:2.

[0063] Wherein, the preparation method of above-mentioned modified nano titanium dioxide comprises the following steps:

[0064] A. Add 3 parts by weight of KH550...

Embodiment 2

[0079] A kind of antistatic PC-ABS alloy material, comprises the raw material of following weight portion:

[0080]

[0081] Wherein, the static conductive agent is graphene with 10 layers.

[0082] Wherein, the compatibilizer is methyl methacrylate-butadiene-styrene copolymer.

[0083] Wherein, the preparation method of above-mentioned graphene comprises the following steps:

[0084] (1) the 3,3 ', 5,5'-tetramethylbenzidine stripping aid of 7 parts by weight is mixed with the ethanol organic solvent of 50 parts by weight, to obtain the stripping aid dispersion;

[0085] (2) 12.5 parts by weight of natural graphite powder were added to the exfoliation aid dispersion in the step (1), and then stirred at a stirring rate of 2500r / min for 0.75h to obtain graphene.

[0086] Wherein, the anti-aging agent is a mixture of modified nano-titanium dioxide and hindered amine light stabilizer 622 in a weight ratio of 5:2.

[0087] Wherein, the preparation method of above-mentioned mo...

Embodiment 3

[0102] A kind of antistatic PC-ABS alloy material, comprises the raw material of following weight portion:

[0103]

[0104] Wherein, the static conductive agent is graphene with layers between 20 layers.

[0105] Wherein, the compatibilizer is maleic anhydride grafted acrylonitrile-butadiene-styrene terpolymer

[0106] The preparation method of above-mentioned graphene comprises the following steps:

[0107] (1) 9 weight parts of 3,3'-dimethyl-4,4'-diaminobiphenyl stripping aid are mixed with 60 weight parts of acetone organic solvent to obtain stripping aid dispersion;

[0108] (2) Add 15 parts by weight of natural graphite powder into the exfoliation aid dispersion in step (1), then stir for 1 h at a stirring rate of 2800 r / min to prepare graphene.

[0109] Wherein, the anti-aging agent is a mixture of modified nano-titanium dioxide and hindered amine light stabilizer 783 in a weight ratio of 6:2.

[0110] The preparation method of above-mentioned modified nano titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com