Composite modified asphalt and preparation method thereof

A technology for compounding modified asphalt and bitumen, which is applied to building components, building insulation materials, buildings, etc., can solve problems such as insufficient measures, and achieve the effects of low cost, excellent high and low temperature resistance and aging resistance, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

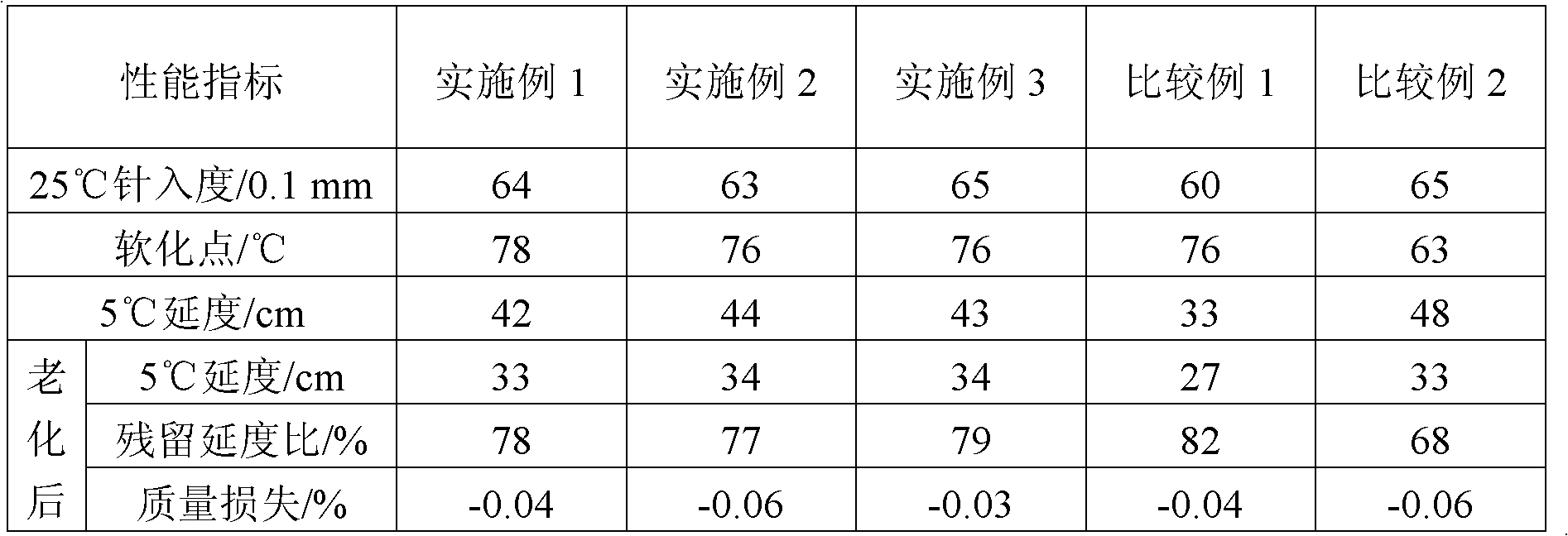

[0021] Based on the base asphalt (100%), in terms of mass percentage, according to SBS: montmorillonite: stabilizer: coupling agent = 4%: 4%: 0.2%: 0.5%. Heat 500g90# road asphalt to 175~180℃, add 20.0g SBS, 1.0g HMD stabilizer, 20.0g montmorillonite and 2.5g titanate coupling agent in sequence at a shear speed of 3000r / min, mixing time It is 2h, the modifier dissolves evenly, and the performance of the modified asphalt is tested. See Table 1.

Embodiment 2

[0023] Based on the base asphalt (100%), in terms of mass percentage, according to SBS: montmorillonite: stabilizer: coupling agent = 4%: 4%: 0.2%: 0.5%. Heat 400g90# road asphalt to 175~180℃, add 16.0g SBS, 0.8g HMD type stabilizer, 16.0g montmorillonite and 2.0g titanate coupling agent at a shear speed of 4000r / min, mixing time For 1.5h, the modifier dissolves evenly, and the performance of the modified asphalt is tested. See Table 1.

Embodiment 3

[0025] Based on the base asphalt (100%), in terms of mass percentage, according to SBS: montmorillonite: stabilizer: coupling agent = 4%: 4%: 0.2%: 0.5%. Heat 350g90# road asphalt to 175~180℃, and add 14.0g SBS, 0.6g HMD type stabilizer, 14.0g montmorillonite and 1.8g titanate coupling agent at a shear speed of 5000r / min, mixing time It is 1h, the modifier is dissolved evenly, and the performance of modified asphalt is tested. See Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com