PLA (polylactic acid) resin-ABS (acrylonitrile-butadiene-styrene) resin composite material and method for preparing same

A resin composite material, polylactic acid resin technology, applied in the field of polylactic acid-ABS resin composite material and its preparation, can solve the problems of poor impact resistance and low heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

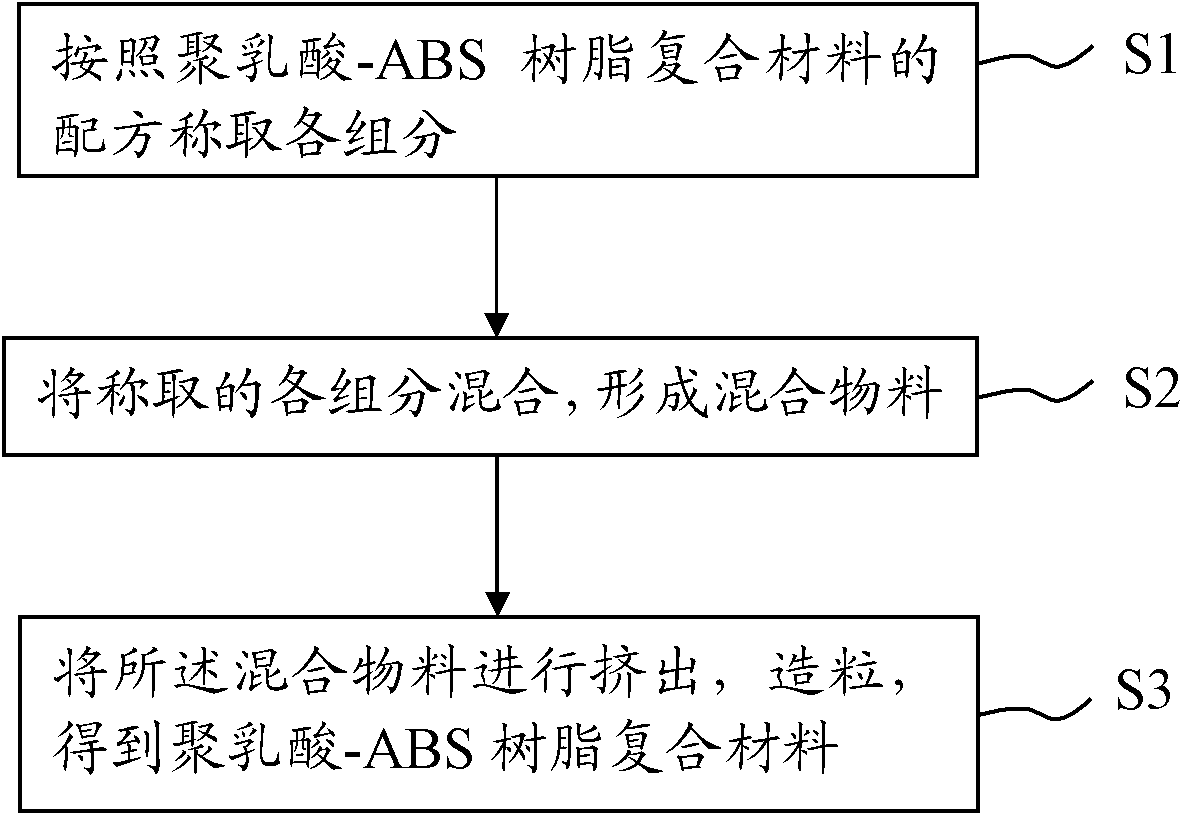

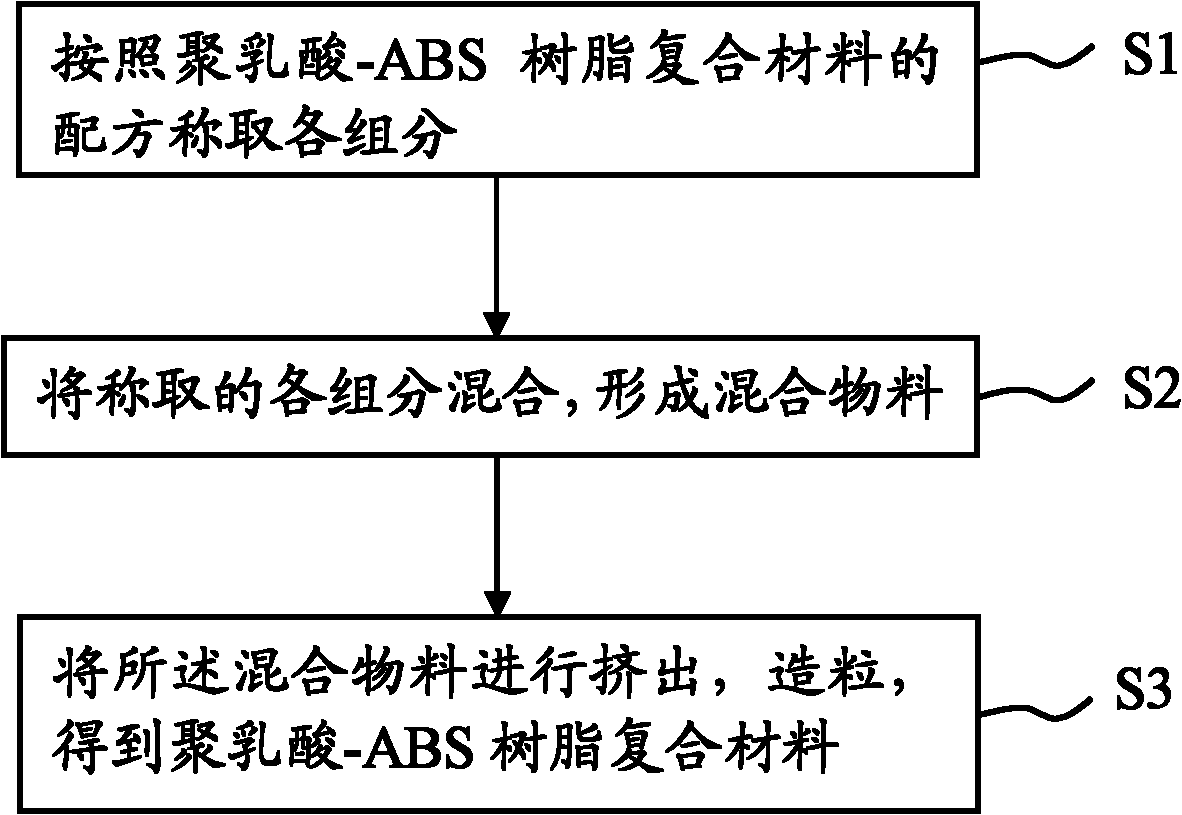

[0046] The present invention also provides the preparation method of the above-mentioned polylactic acid-ABS resin composite material, its technological process is as follows figure 1 shown. The method comprises the steps of:

[0047] S1: Weigh each component according to the above formula of polylactic acid-ABS resin composite material;

[0048] S2: Mix the weighed components to form a mixed material;

[0049] S3: extruding and granulating the mixed material to obtain the polylactic acid-ABS resin composite material.

[0050]Specifically, in step S1 of the above-mentioned polylactic acid-ABS resin composite material preparation method, the formulation of the polylactic acid-ABS resin composite material is as described above without additives or the formulation of another preferred embodiment containing additives . In order to save space, details are omitted here. Among them, before weighing each component according to the above formula, it is preferable to dry the polyla...

Embodiment 1

[0056] The formula component of polylactic acid-ABS resin composite material weight percent is as follows:

[0057] 60% of polylactic acid resin and its copolymer with a molecular weight of preferably 300,000, 30% of ABS resin, 4% of compatibilizer of SEBS grafted maleic anhydride, 5% of toughening agent of polyethylene octene co-elastomer, particle size is 2000 mesh, 0.5% talcum powder with a whiteness of 95%, and 0.5% coupling agent of γ-aminopropyltriethylsilane.

[0058] The preparation method of polylactic acid-ABS resin composite material is as follows:

[0059] S11: First put the polylactic acid resin and its copolymer, ABS resin, and talc powder into a drying oven, wherein the polylactic acid resin and its copolymer are dried at 80°C for 4 hours, and the talc powder is dried at 110°C. Dry for 3 hours, then weigh each component according to the formula of the above-mentioned polylactic acid-ABS resin composite material;

[0060] S12: Mix the weighed components and put...

Embodiment 2

[0063] The formula component of polylactic acid-ABS resin composite material weight percent is as follows:

[0064] 65% of polylactic acid resin and its copolymer with molecular weight preferably 50,000, 20% of ABS resin, 5% of compatibilizer of POE grafted maleic anhydride, 8% of toughening agent of thermoplastic polyurethane elastomer, particle size of 4000 mesh, 1% of talc powder with whiteness of 98%, 1% of coupling agent of γ-ureidopropyltriethoxysilane.

[0065] The preparation method of polylactic acid-ABS resin composite material is as follows:

[0066] S11: First put the polylactic acid resin and its copolymer, ABS resin, and talc powder into a drying oven, wherein the polylactic acid resin and its copolymer are dried at 80°C for 4 hours, and the talc powder is dried at 110°C. Dry for 3 hours, then weigh each component according to the formula of the above-mentioned polylactic acid-ABS resin composite material;

[0067] S12: Mix the weighed components and put them i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com