Hot spraying WC/Co powder and coat preparation

A technology of thermal spraying and powder, which is applied in the direction of coating, metal material coating process, molten spraying, etc., can solve the problems of uneven composition, poor fluidity, irregular shape of tungsten carbide, etc., and achieve uniform composition distribution and fluidity Good, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

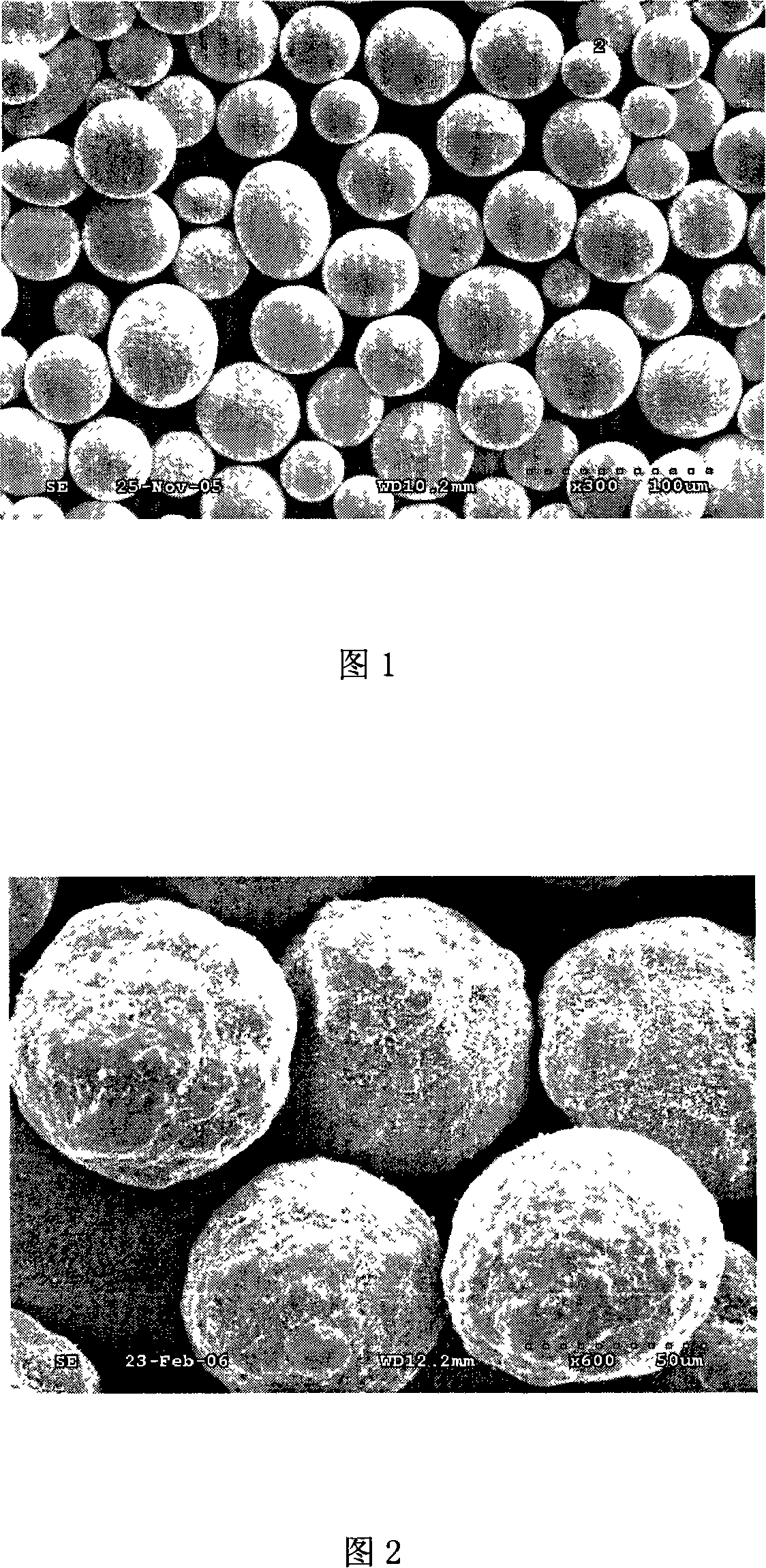

Embodiment 1

[0044] Sieve the pure tungsten powder, and take 500g of tungsten powder in the range of 15-100μm for cleaning and drying. Atmospheric plasma spheroidization is carried out on the above tungsten powder, the working gas is Ar gas, and the powder feeding gas is N 2 Gas, spheroidizing voltage 75V, current 500A, powder feeding speed 55g / min, spray distance 45mm, main air flow 1650. Molten tungsten pellets are sprayed directly into water for cooling. After collection, take spherical tungsten powder with a particle size of 15-90 μm and 25g of carbon black and mix and ball mill for 2 hours. The ball-milled material is put into a carbonization furnace and kept at 2000°C for 4 hours under a hydrogen protective atmosphere, and then ball milled for 1 hour for screening. . Take tungsten carbide powder with a particle size of 15-90 μm for strong acid, strong alkali and sensitization and activation treatment. Then put the prepared cobalt sulfate solution, spheroidized tungsten carbide pow...

Embodiment 2

[0047] Sieve the pure tungsten powder, and take 500g of tungsten powder in the range of 15-100μm for cleaning and drying. Atmospheric plasma spheroidization is carried out on the above tungsten powder, the working gas is Ar gas, and the powder feeding gas is N 2 Gas, spheroidizing voltage 70V, current 500A, powder feeding speed 50g / min, spray distance 50mm, main air flow 1600. Molten tungsten pellets are sprayed directly into water for cooling. After collection, take spherical tungsten powder with a particle size of 15-90 μm and 25g of carbon black and mix and ball mill for 3 hours. The ball-milled material is put into a carbonization furnace and kept at 2000°C for 5 hours under a hydrogen protective atmosphere, and then ball milled for 1 hour for screening. . Take tungsten carbide powder with a particle size of 15-90 μm for strong acid, strong alkali and sensitization and activation treatment. Then put the prepared cobalt sulfate solution, spheroidized tungsten carbide pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com