Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

294results about How to "Evenly distributed ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

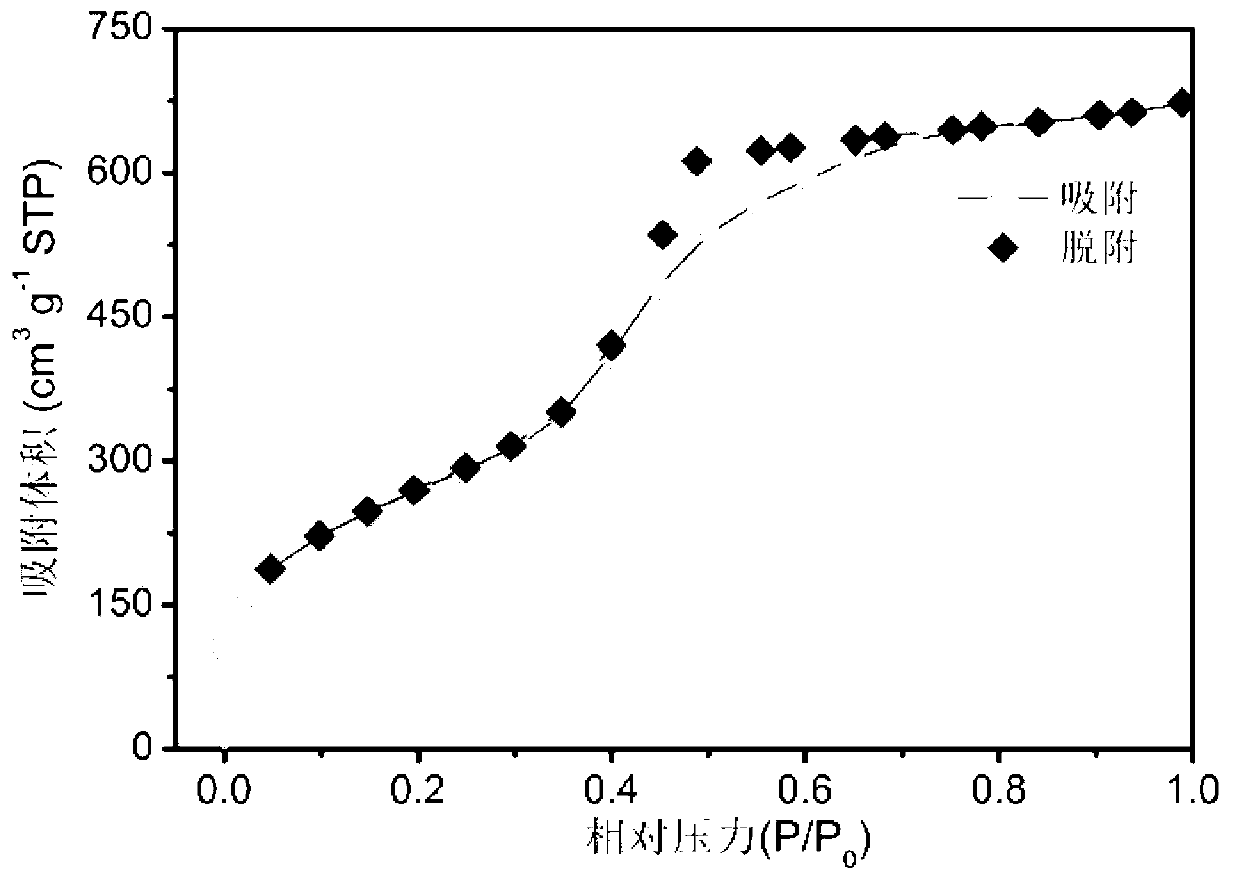

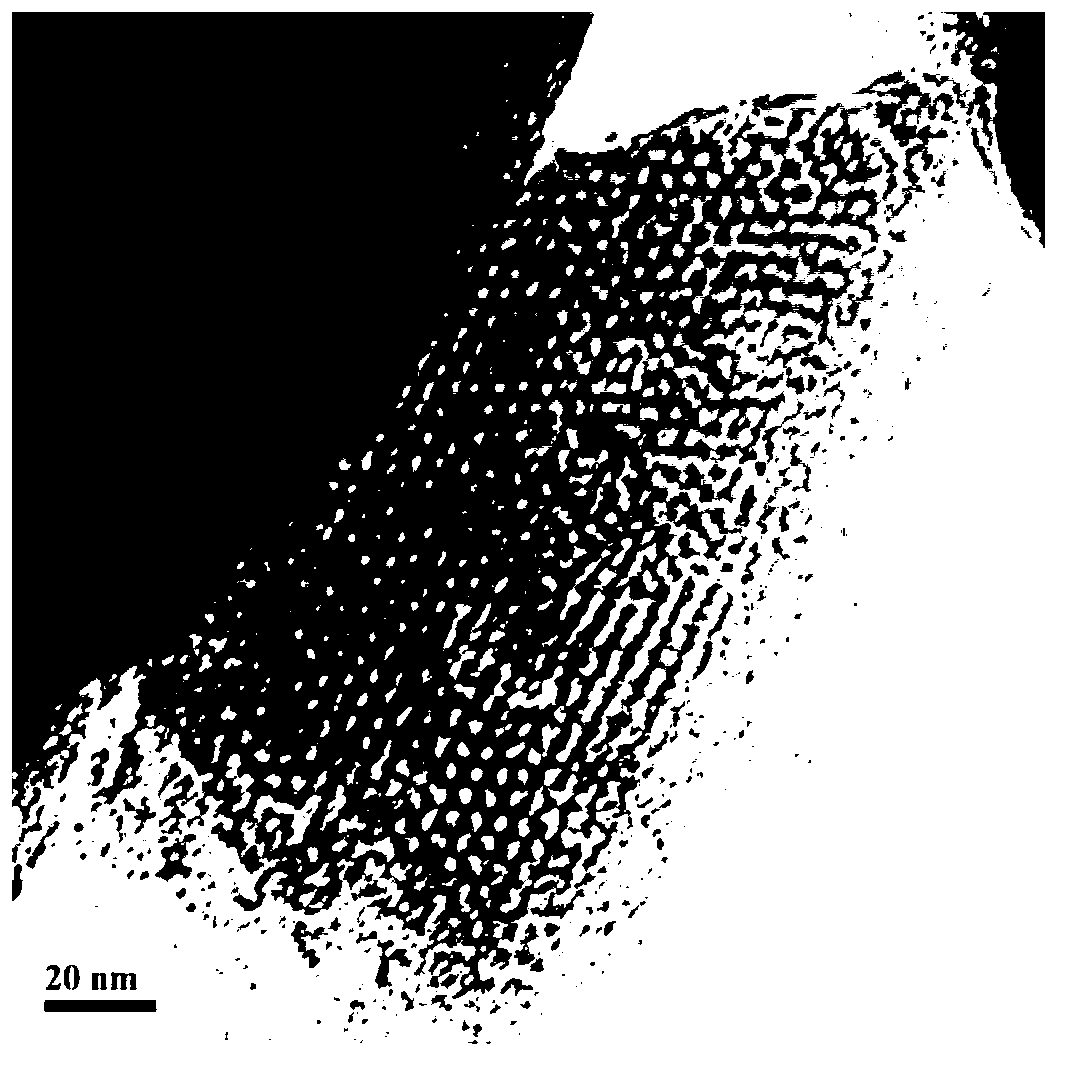

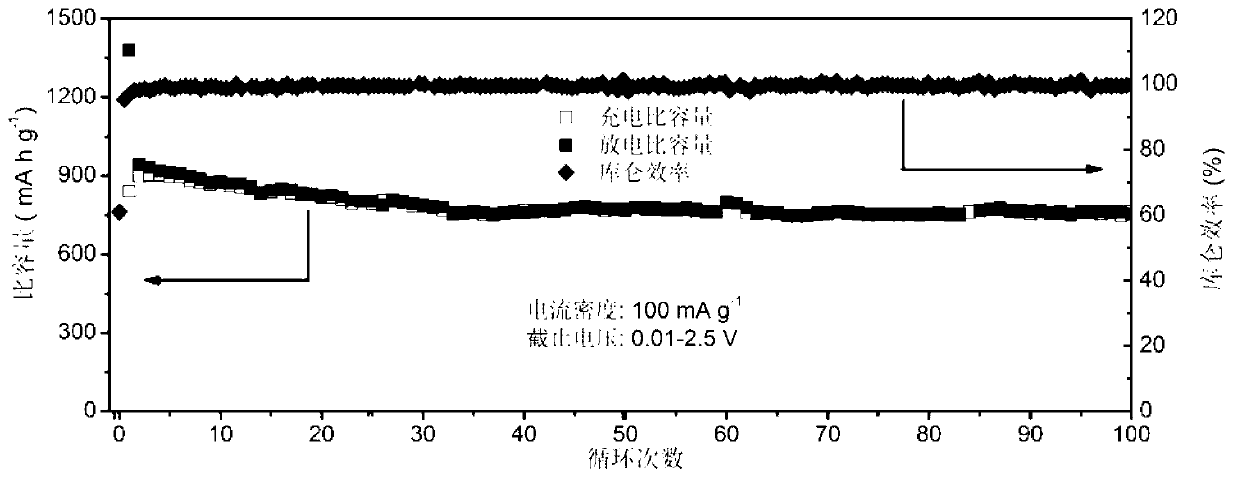

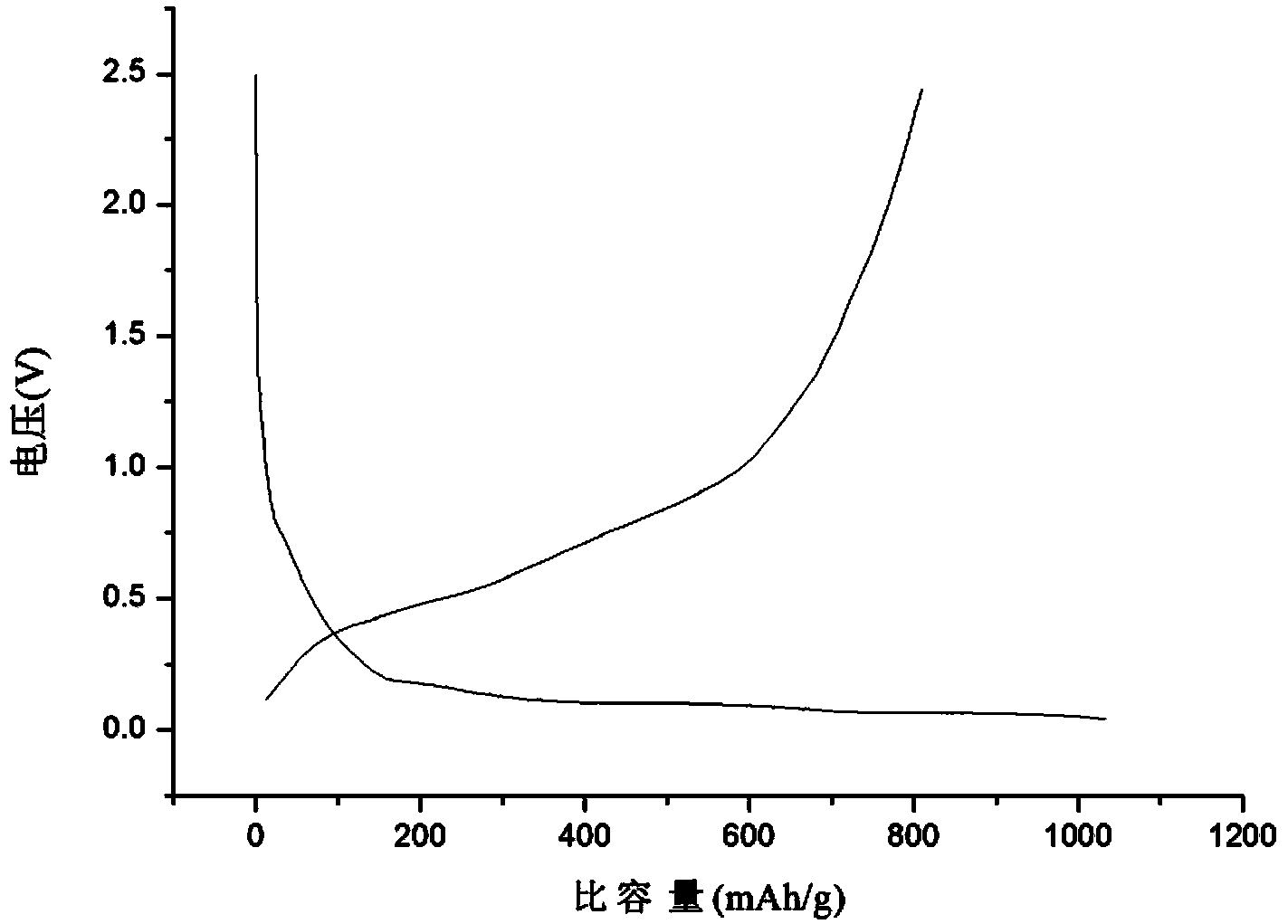

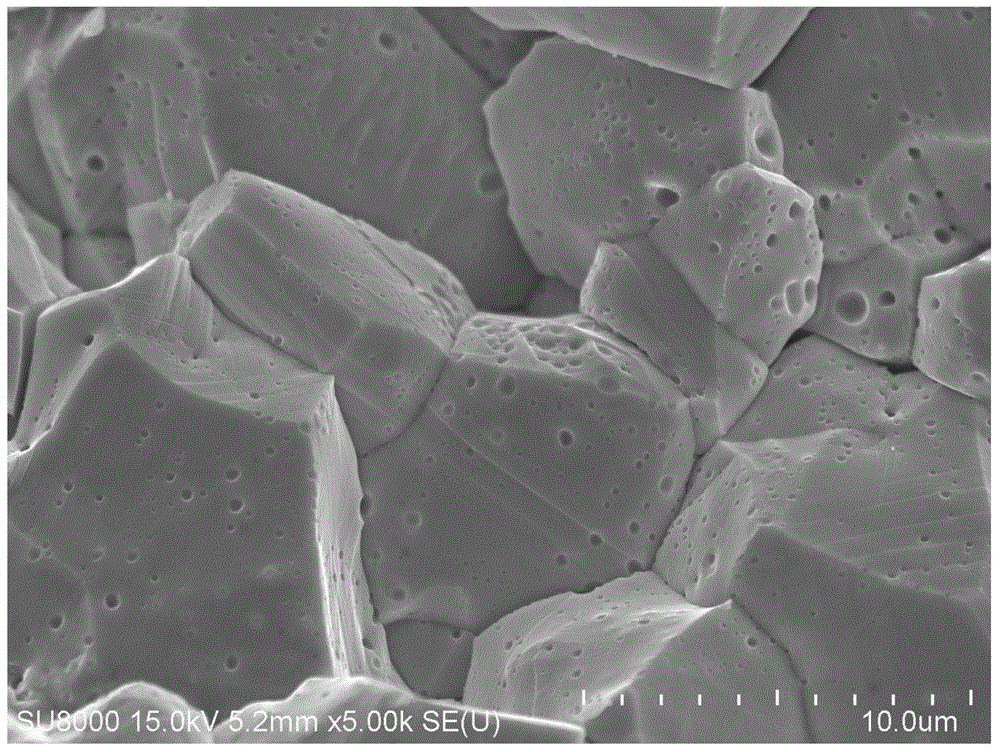

Preparation method of mesoporous SiOx/C composite negative material of lithium-ion battery

ActiveCN103280560ASmall particlesUniform particle sizeCell electrodesMesoporous silicaSurface-active agents

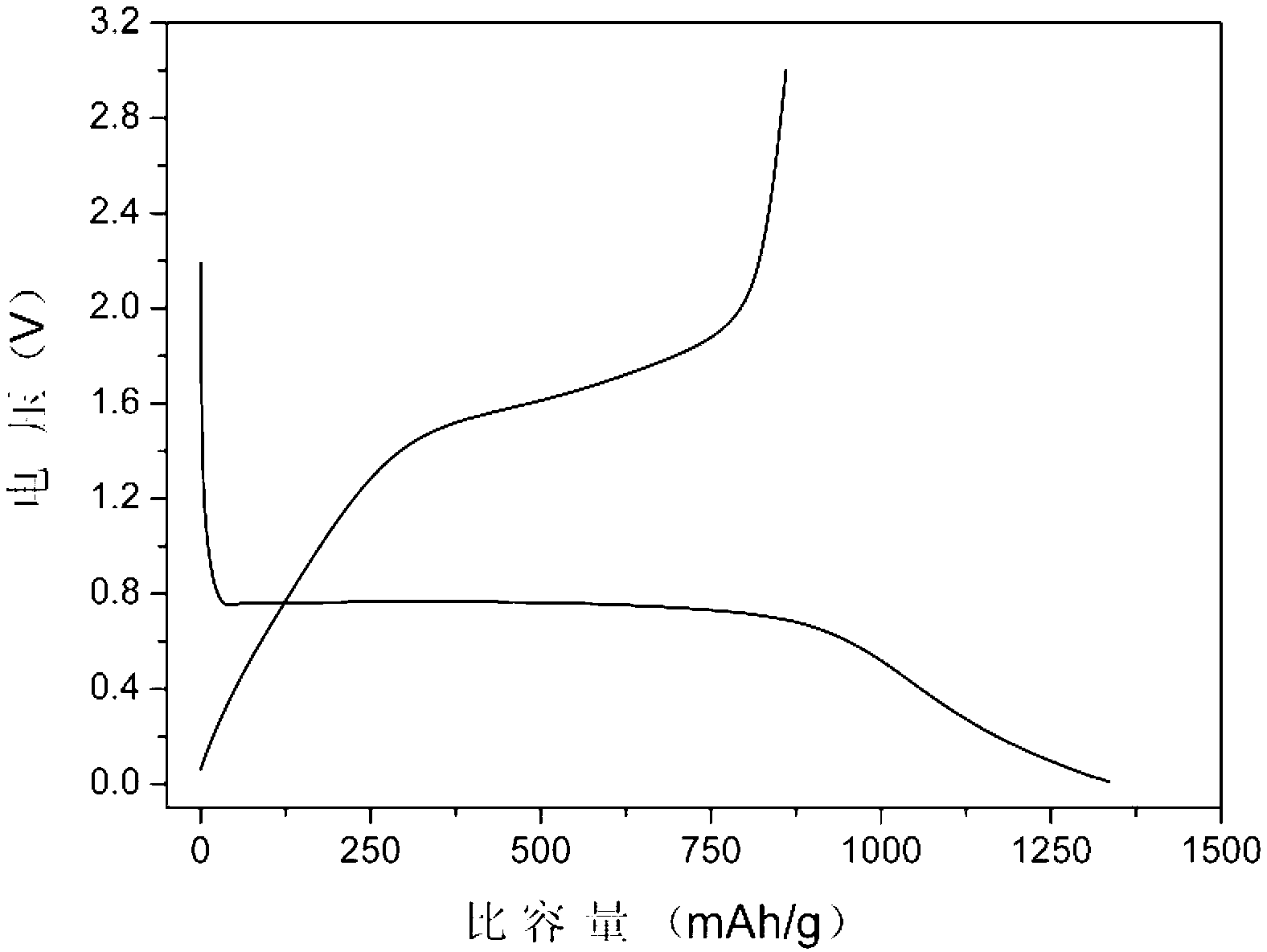

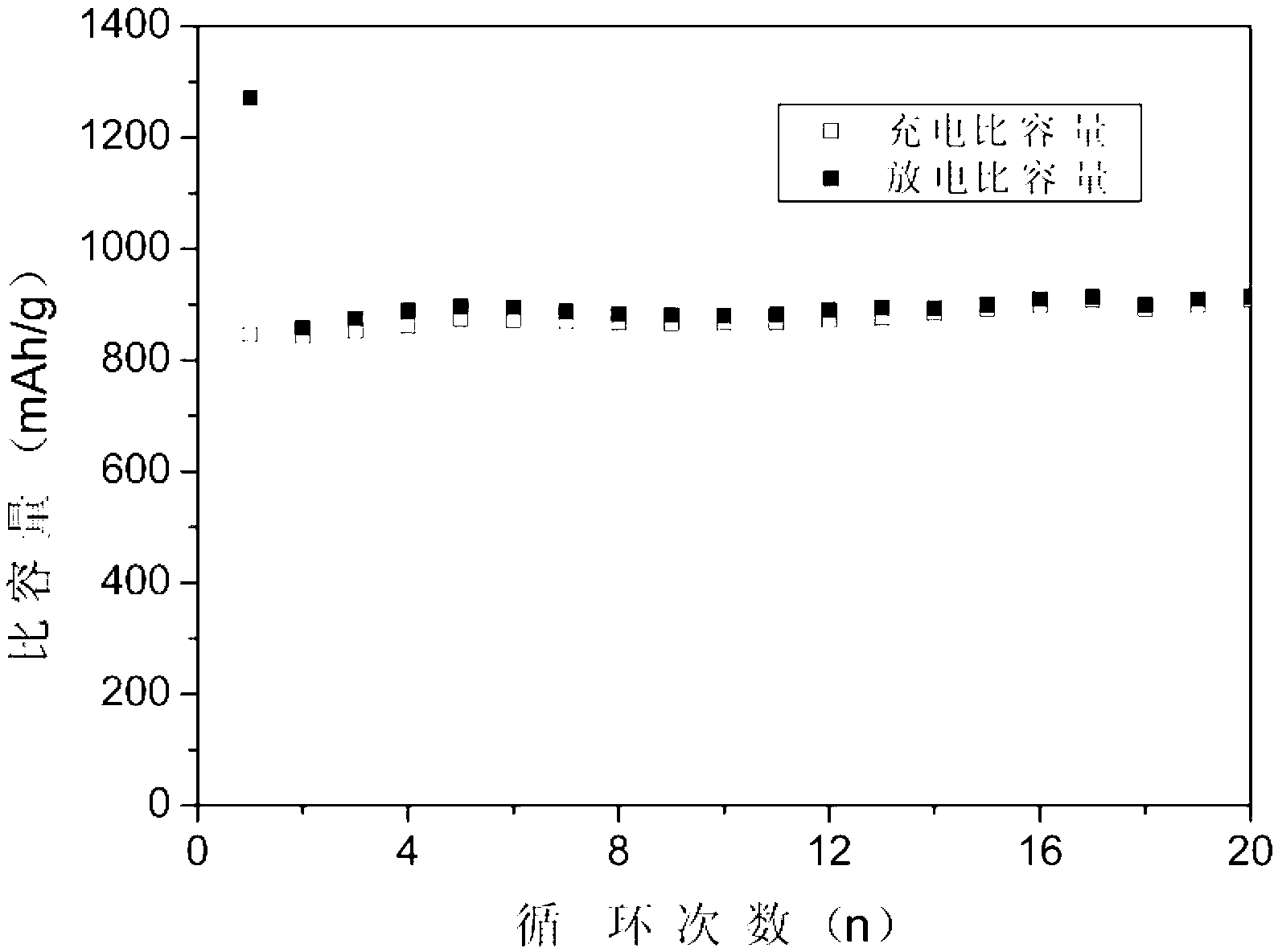

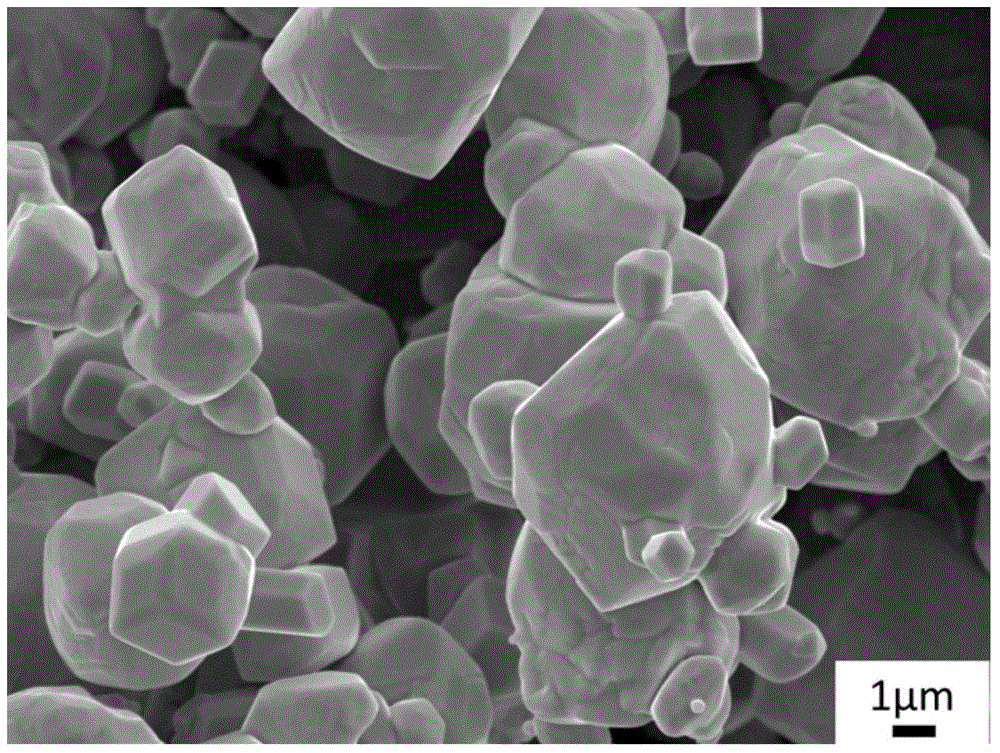

The invention discloses a preparation method of a mesoporous SiOx / C composite negative material of a lithium-ion battery, and belongs to the fields of new materials and electrochemistry. The preparation method comprises the following steps of: taking polyvinylpyrrolidone as an auxiliary template agent, taking an organic surface active agent as a template agent and organic silicon as a silicon source, obtaining mesoporous silica precursor by hydrothermal treatment, adding a carbon source, and preparing SiOx / C composite negative material with a mesoporous structure by carbothermic reduction reaction occurring in the process of high-temperature thermal treatment. The preparation method disclosed by the invention has the advantages that the specific capacity of the material is high, the structure is novel, and simultaneously the cycling stability is good; the yield is high; and the prepared SiOx / C composite material is fine in particle, uniform in particle size and component distribution, high in specific capacity and good in cycling stability, is an ideal composite negative material of the lithium-ion battery, and can be widely applied in the fields such as various portable electronic equipment, electric vehicles and aerospace.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

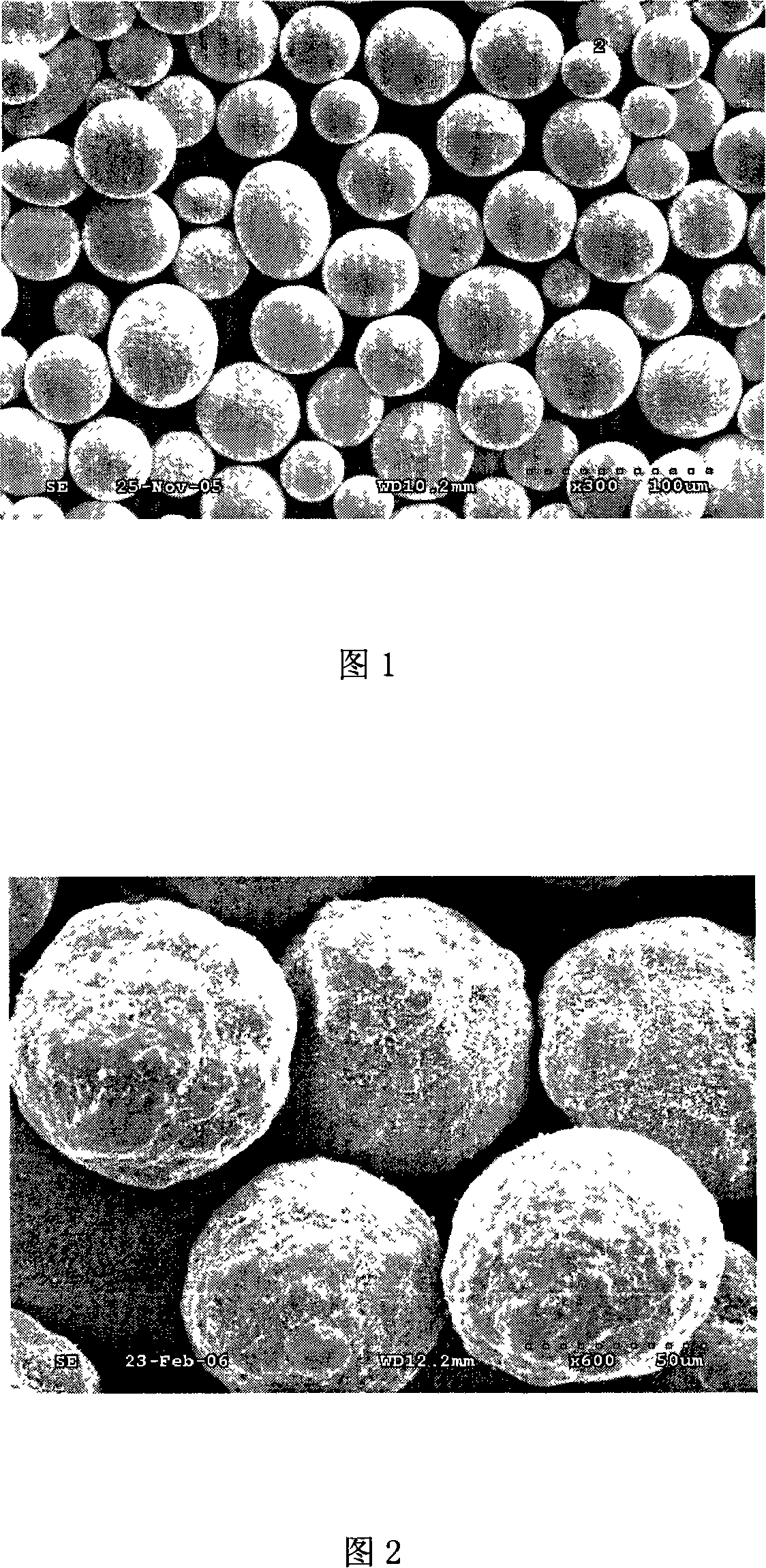

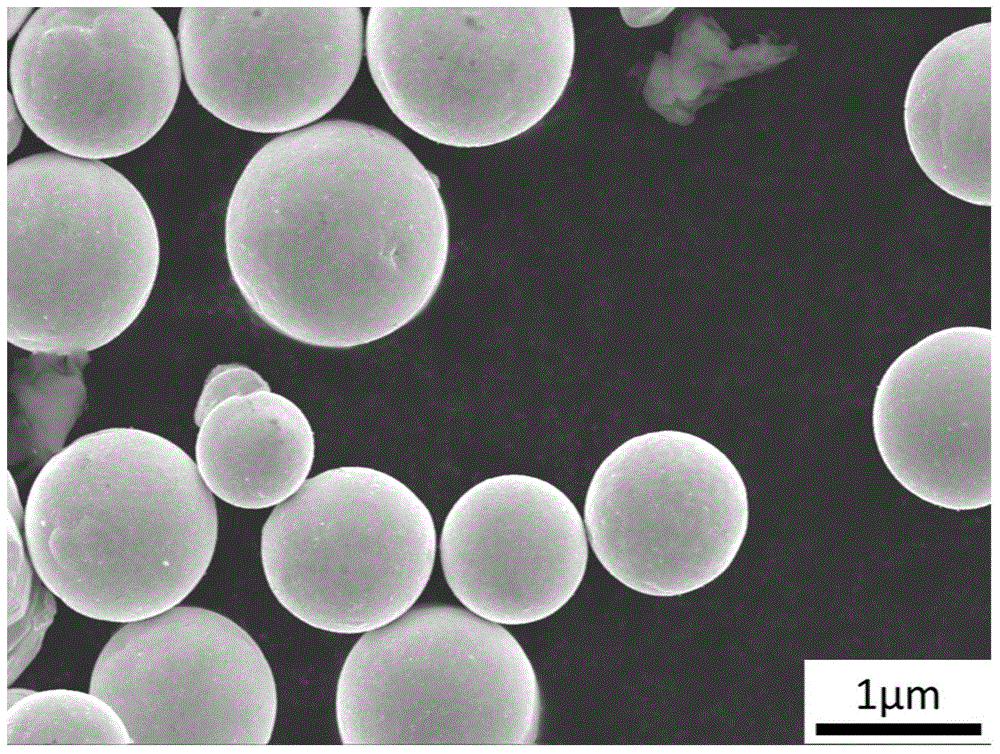

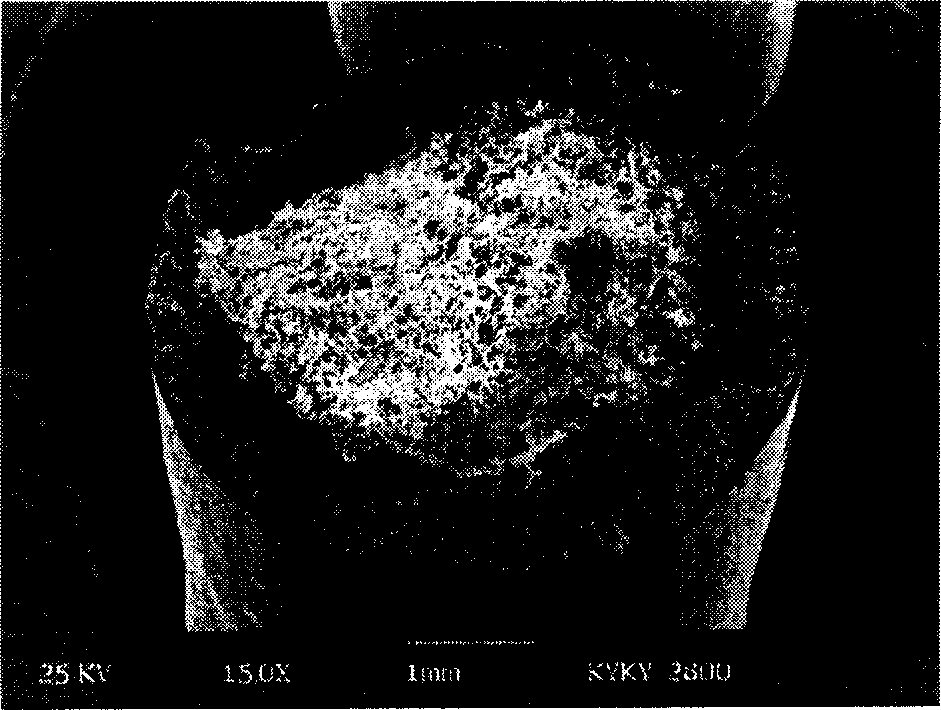

Hot spraying WC/Co powder and coat preparation

The present invention discloses one kind of hot sprayed WC / Co powder and its coating and their preparation. The hot sprayed WC / Co powder consists of Co 5-25 wt%, C 5-6 wt%, and W for the rest, and is in spherical granular structure of size below 150 micron. The powder is prepared through the following steps: 1. sieving, washing and stoving W powder; 2. spheroidizing W powder; 3. carbonizing spheroidized W powder; and 4. coating with Co to form the WC / Co powder. The hot sprayed WC / Co coating is prepared through spraying the WC / Co powder with ultrasonic flame. The WC / Co powder is compact, high in flowability and homogeneous in components; and the hot sprayed WC / Co coating is compact and homogeneous, and has close combination with the base, micro hardness up to 894HV0.2 and wide application.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Preparation of micron/nano-scale high purity tungsten powder

The invention relates to a preparation method of micro / nano-high-purity tungsten powder. Tungstate is dissolved in deionized water, excessive dilute nitric acid or hydrochloric acid is added to allow the mixture to fully generate yellow precipitation, dilute ammonia water is added to fully convert the yellow precipitation to transparent colloid under the stirring condition, a surfactant is added and is evenly dissolved by strong stirring; the hydrothermal reaction is carried out, a product after the hydrothermal reaction uses the deionized water or ethanol for cleaning and filtering, precursor powder is obtained by drying; and the precursor powder is carried out the reduction to obtain the high-purity micro / nano-tungsten powder. The micro / nano-tungsten powder which is prepared by using the invention is characterized by fine particle size, even distribution of the components and high purity, the specific surface particle size and the powder morphology analyzing particle size after the diffusion are less than 80nm, the tungsten particle size of the powder is 20 to 30nm, the powder is spherical or nearly spherical, the oxygen content is lower than 0.18 percent, the tungsten content is more than 99.5 percent, and the powder has good formability and sintering activity.

Owner:CENT SOUTH UNIV

Method for preparing absorbing layer of thin film solar cell

InactiveCN101728461AReduce the temperatureReduce softeningFinal product manufactureSemiconductor devicesIndiumNew energy

The invention relates to a method for preparing an absorbing layer of a thin film solar cell, belonging to the technical fields of photoelectric functional material and new energy. The method is characterized in that a Cu-In-Se absorbing layer, a Cu-In-Ga-Se absorbing layer or a Cu-In-Al-Se absorbing layer is prepared by a vacuum magnetron sputtering method; a Cu-In-Se alloy target, a Cu-In-Ga-Se alloy target or a Cu-In-Al-Se alloy target is directly used, and the components of the absorbing layer are controlled by the components of the target; and the film formation quality is controlled by the sputtering technology. The absorbing layer prepared by the magnetron sputtering method can be subsequently treated by annealing in the protection atmosphere, so that the crystallization quality is further improved. The absorbing layer prepared by the method is formed by uniform Cu-In-Se phase, Cu-In-Ga-Se phase or Cu-In-Al-Se phase, so that the component distribution is even, and the components of the absorbing layer are consistent with the components of the target. The method is simple and convenient in technique, easy to control and lower in matrix temperature when in deposition, can select multiple substrates, and ids suitable for industrialized production.

Owner:TSINGHUA UNIV +1

Preparation method of iron oxide cathode material for lithium ion battery

ActiveCN103227324ASimple preparation processMild reaction conditionsMaterial nanotechnologyCell electrodesElectric devicesSol-gel

The invention discloses a preparation method of an iron oxide cathode material for lithium ion battery, which belongs to the fields of new material and electrochemistry. The invention employs a sol-gel method and normal pressure drying technology for preparing an iron oxide precursor with xerogel or aerogel structure, and after a heat treatment technology, the iron oxide cathode material is parpared. The invention also employs a carbon cladding technology for preparing iron oxide / carbon composite material. The invention has the advantages that the prepared material is fine and uniform particle powder, and the preparation technology process is simple with mild condition and low cost, and is convenient for large scale preparation. The iron oxide cathode material and iron oxide / carbon composite cathode material has higher circulating ratio capacity and good circulating stability, and is used as an ideal lithium ion battery cathode material, and has latent application prospects in the fields of portable electronic equipment, electric automobile and aviation spaceflight, etc.

Owner:UNIV OF SCI & TECH BEIJING

Spherical copper coating tungsten composite powder, preparation method and application thereof

The invention relates to a spherical copper coating tungsten composite powder, a preparation method and an application thereof. The copper coating tungsten composite powder is in a core-shell structure, the shell is a copper plating layer, the core is tungsten powder, and the weight ratio of the tungsten elements and copper elements of the copper coating tungsten composite powder ranges from 5 to 95 : 95 to 5; the spherical copper coating tungsten composite powder has the advantages of fine dispersion performance, high liquidity, even ingredients and high purity. The preparation method includes processing ordinary tungsten powder by a plasma spheroidizing technology, allowing the copper to deposit on the surface of the tungsten powder evenly by the intermittent copper electroplating process, and cleaning and drying the composite powder coated with copper. The spherical copper coating tungsten composite powder is prepared by combining the plasma spheroidizing and intermittent copper electroplating, the method is simple, reliable and easy to operate, the electroplating speed, the electroplated layer thickness and copper content range can be adjusted effectively, the copper-tungsten composite material comprehensive performances can be improved effectively, the expanded application prospect is provided, and the method can be applied to industrialized mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

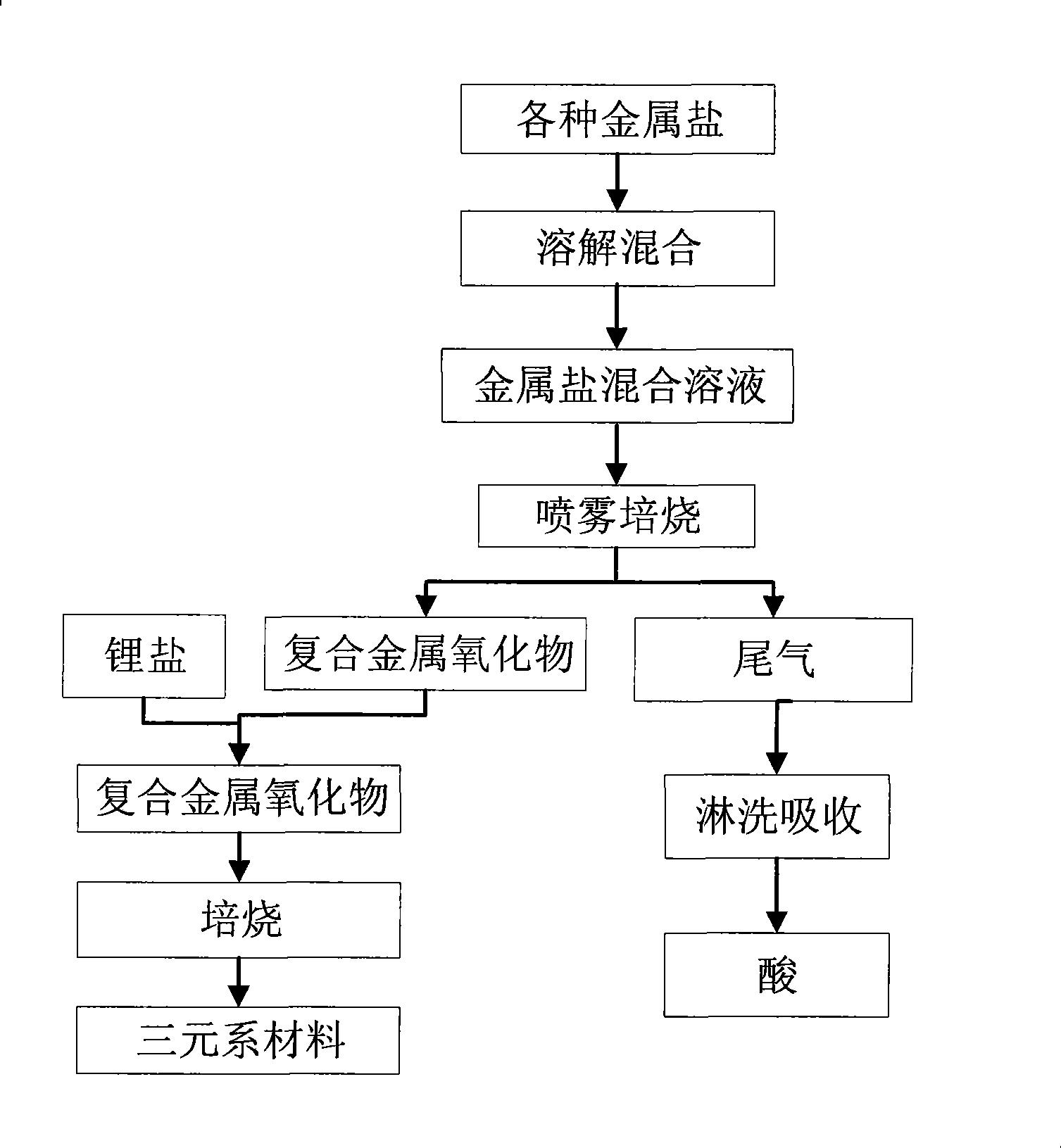

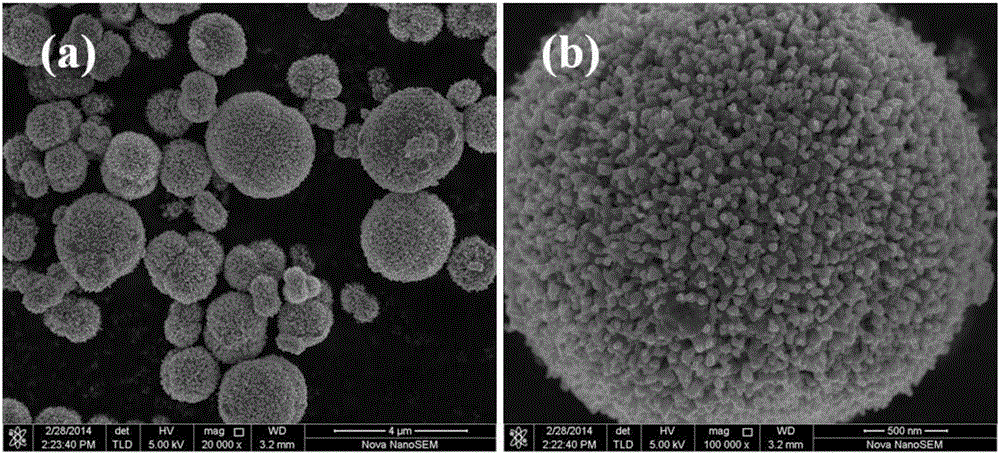

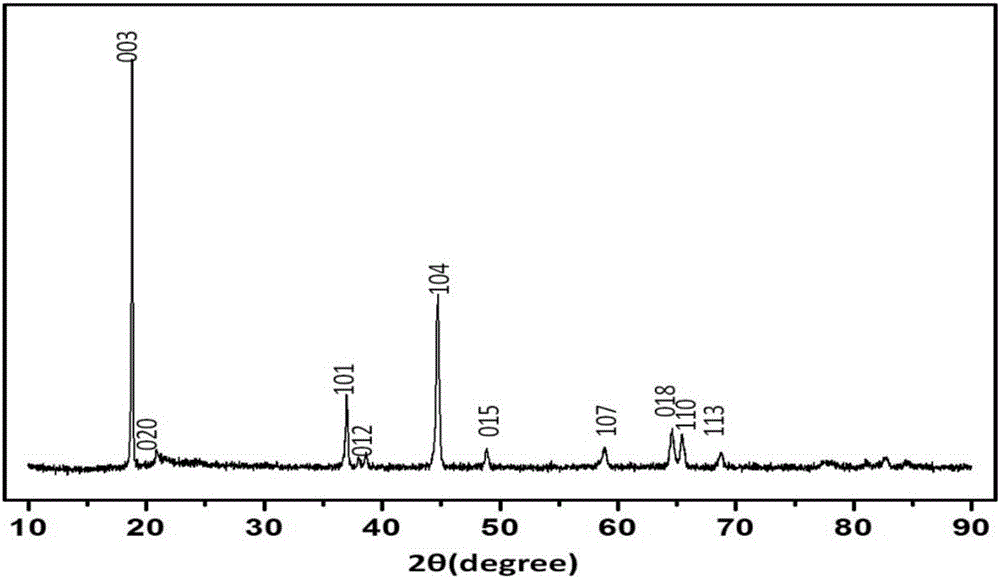

Novel method for preparing lithium ion battery anode ternary material LiCoxNiyMn2O2

InactiveCN101369651AGood fluidity of powderUniform particle sizeElectrode manufacturing processesCrystallinityManganese oxide

The invention relates to a preparation method of ternary system material, in particular to a preparation method of lithium cobalt nickel manganese oxide ternary system material for lithium ion batteries. The invention applies ensured ternary system material salt as raw material. After needed matching weight, by means of eve dissolving and mixing, a composite metal oxide prepared by a spray-roasting method is used as a fore body. The fore body is mixed with a lithium-source compound according to the substance amount of 1:1-1.5, and then roasting is carried out at the temperature of 700 to 1000 degrees centigrade to obtain the ternary system material. The tail gases, such as vapor, acidic gas, generated in the spray-roasting process are absorbed by a washing tower to obtain acid. The invention has the advantages of advanced technique, stable production, low cost, no waste water discharge, environmental protection, high product purity, even granularity, high crystallinity, etc.

Owner:ZHEJIANG HUAYOU COBALT

Method for preparing multi-arc ion plating aluminium titanium chrome silicon yttrium nitride multi-component ultra-hard reaction film

InactiveCN101230448AQuality improvementGuaranteed repeatabilityVacuum evaporation coatingSputtering coatingAlloyTitanium

The invention relates to a method of preparing a multi-component super-hard reaction film for a multiple-arc ion-plated nitride of titanium, aluminum, chrome, silicon and yttrium. The method includes the following steps in sequence: the confirmation of the deposition technique and the design of the components of the target material (1); the preparation of a alloy target (2); the selection and pre-processing of a workpiece sample (3); the confirmation of the quantity of the electric arc source (4); the confirmation of the deposition technique (5); the acquirement of a transition layer (6); the processing of vacuum heating (7) and the rotation of the workpiece sample. The method confirms the variation range of the components of the Ti, Al, Cr, Si, Y elements in the complex Ti-Al-Cr-Si-Y alloy target and causes the super-hard reaction film of the (TiAlCrSiY)N to have the advantages of strong adhesive power (larger than or equal to 180 N) and high hardness (larger than or equal to HV3200).

Owner:SHENYANG UNIV

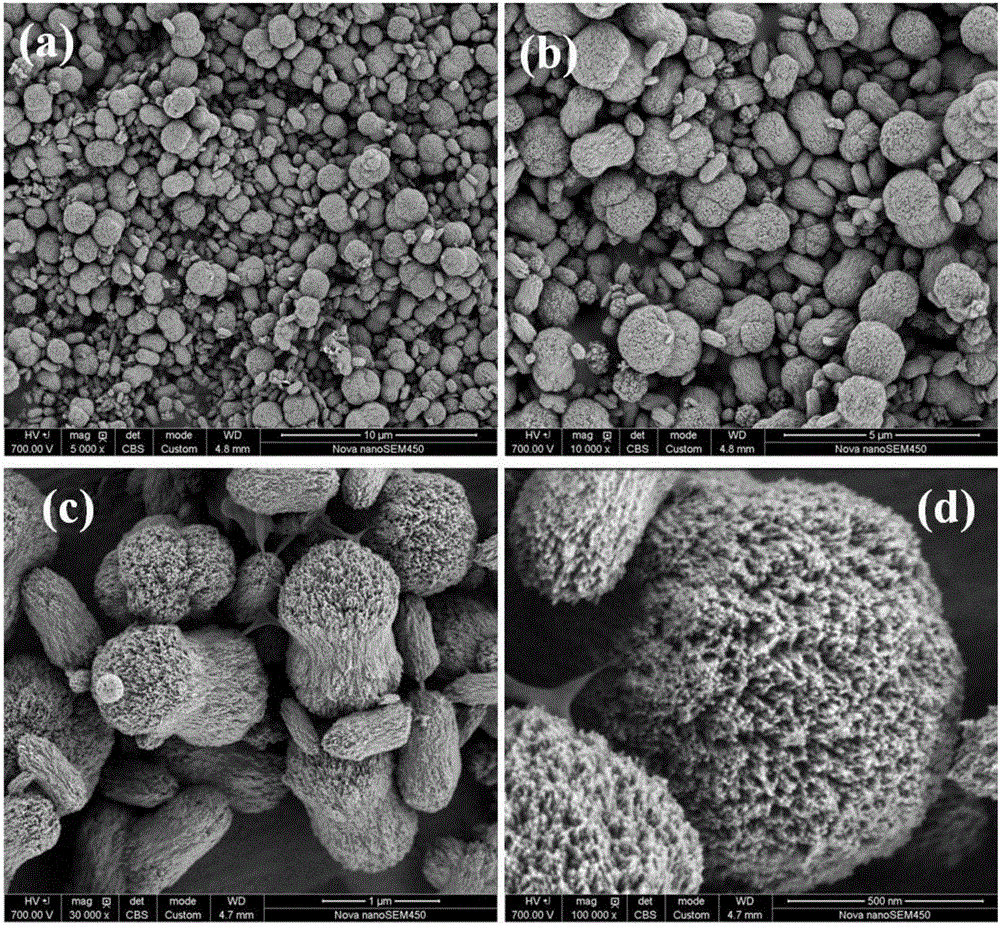

Lithium-rich manganese-based cathode material precursor, cathode material and preparation method thereof

ActiveCN106564967AAccelerates and intensifies the mass transfer processWell mixedMaterial nanotechnologyCell electrodesNickel saltManganese

The invention belongs to the field of electrode material preparation and relates to a lithium-rich manganese-based cathode material precursor, a cathode material and a preparation method thereof. The preparation method comprises the following steps: mixing metal salts (manganese salt, cobalt salt and nickel salt) and a surfactant and water, and dissolving to obtain a metal salt solution; putting a precipitant in water, stirring and dissolving to obtain a precipitant solution; carrying out liquid-liquid coprecipitation reaction on the metal salt solution and the precipitant solution in a hypergravity field reactor, filtering, cleaning, and carrying out vacuum drying so as to obtain a precursor; mixing the precursor and lithium salt and then calcining so as to obtain the lithium-rich manganese-based cathode material. By the coprecipitation method based on the hypergravity technology, the lithium-rich manganese-based cathode material precursor with primary particle being below 100 nm and secondary particle being 1-10 microns is rapidly prepared, and furthermore the prepared cathode material has advantages of uniform component distribution and particle size distribution, small granularity and high activity. Initial irreversible capacity can be reduced, and cycle performance of a lithium ion secondary battery can be enhanced.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

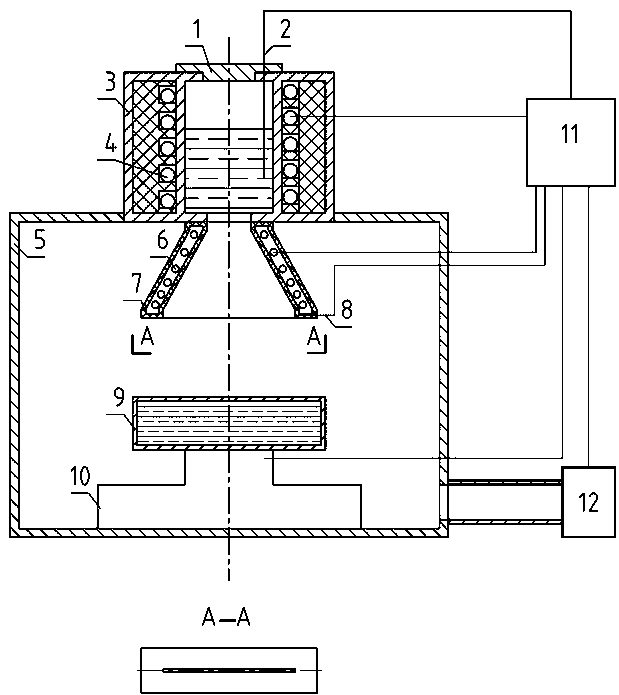

Thin layer fast solidification forming device and method

The invention relates to a thin layer fast solidification forming device and method. According to the device, a narrow-seam-shaped spraying nozzle is placed in a working cavity, and liquid metal thin layers continuously flow out of the spraying nozzle and fast solidified on a moving platform which continuously moves and performs forced cooling till parts of needed sizes are obtained. The device and method are high in production efficiency, relatively low in cost and suitable for production of large cast ingots.

Owner:SHANGHAI UNIV

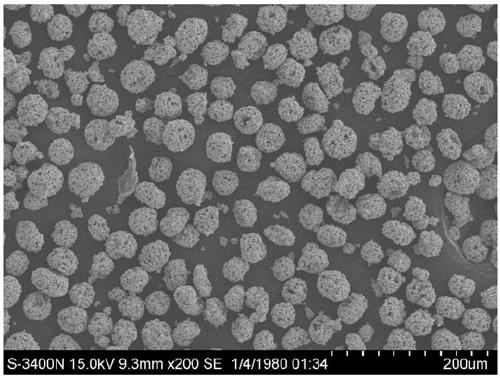

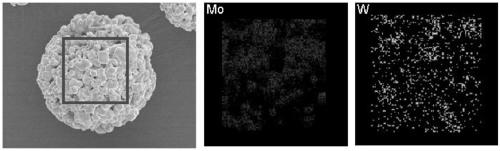

Preparation method of spherical tungsten-molybdenum alloy powder for 3D printing

InactiveCN109692965AEasy to shapeImprove liquidityAdditive manufacturing apparatusTransportation and packagingSpray GranulationSpherical shaped

The invention provides a preparation method of spherical tungsten-molybdenum alloy powder for 3D printing and belongs to the field of refractory metal 3D printing. The preparation method comprises thefollowing steps of (1) mechanically mixign tungsten powder and molybdenum powder in proportion; (2) preparing the mechanically mixed powder into spherical precursor powder through the spray granulation technology; (3) conducting sintering on the precursor powder; and (4) conducting spheroidizing treatment on the sintered powder through the plasma spheroidization technology. The spherical tungsten-molybdenum alloy powder prepared through the method is excellent in sphericity degree and fluidity and narrow in particle size distribution and has excellent formability through 3D printing verification.

Owner:BEIJING UNIV OF TECH

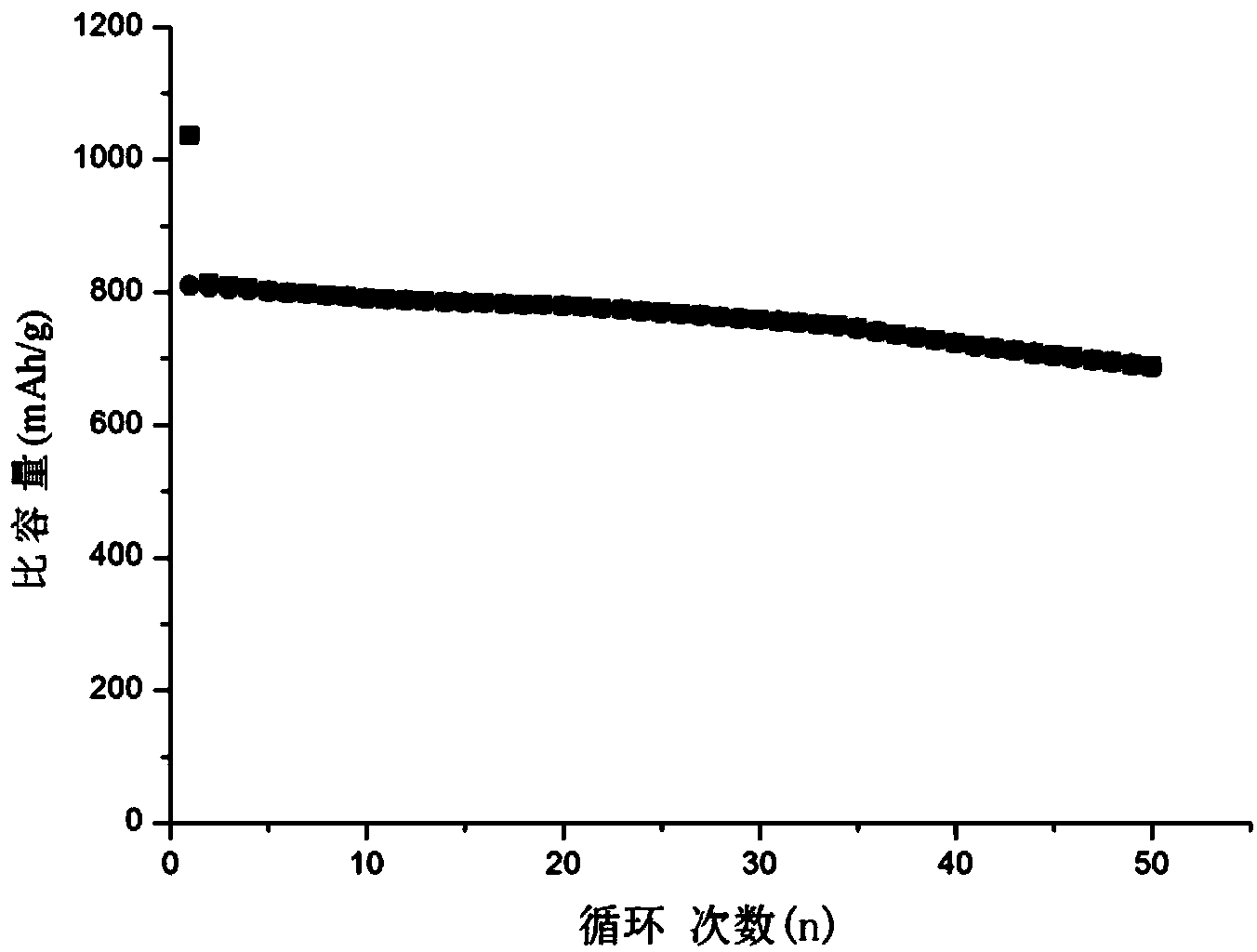

Preparation method of lithium ion battery silicon-carbon composite cathode material

InactiveCN103515582AUniform particle sizeEvenly distributed ingredientsCell electrodesSecondary cellsCarbon compositesNitrogen gas

The invention discloses a preparation method of a lithium ion battery silicon-carbon composite cathode material. The preparation method is characterized by comprising the following steps: 1), dissolving ethyl orthosilicate in a mixed solution of absolute ethyl alcohol and deionized water, adding organic acid in the solution, regulating the pH value of the solution to 3-5, and marking the solution as a solution A; 2), adding graphite particles in the solution A, stirring the mixture, and marking the mixture as a mixture B; 3), slowly adding ammonia water in the mixture B while stirring by high speed magnetic force, wherein the concentration of the ammonia water is 10-20%, adding a basic catalyst until forming gel; 4), drying gel prepared in the step 3 at 90-110 DEG C; 5), introducing hydrocarbon gas and nitrogen or the mixed gas of nitrogen and argon to the gel material prepared in the step 4 at 600-800 DEG C for 2-6 h, and then introducing high-pure nitrogen or high-pure argon, raising the temperature to 900-1200 DEG C, keeping the temperature for 1-6 h, cooling the mixture, and at last obtaining the silicon-carbon composite cathode material.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Gamma-type high-entropy rare earth disilicate with ultrahigh-temperature stability and preparation method thereof

ActiveCN111056826AIncrease configuration entropyHas ultra-high temperature stabilityRare-earth elementHigh density

The invention relates to the field of ceramic materials for thermal barrier / environmental barrier integrated coating layers of advanced aero-engines, and in particular, relates to gamma-type high-entropy rare earth disilicate with ultrahigh-temperature stability and a preparation method thereof. The chemical formula of the gamma-type high-entropy rare earth disilicate ceramic material is defined in the specification, wherein n is more than or equal to 5, and REn is one of rare earth elements Y, Sc, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu respectively. The preparation method specifically comprises the preparation processes: by taking corresponding rare earth oxide powder and silicon oxide powder as raw materials, performing wet mixing, and performing pressureless sintering synthesis in an air atmosphere, and thus obtaining the gamma-type high-entropy rare earth disilicate ceramic powder material; and further hot-pressing and sintering in a hot-pressing furnace witha protective atmosphere to obtain the gamma-type high-entropy rare earth disilicate ceramic block material with excellent high-temperature phase stability. According to the invention, the gamma-typehigh-entropy ceramic material with high purity, high density and excellent high-temperature phase stability can be prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for quickly preparing Ag2Se block thermoelectric material through self-homogenization

ActiveCN104878234AAchieve densificationSignificant self-homogenizing effectThermoelectric device manufacture/treatmentThermoelectric materialsRoom temperature

The invention discloses a method for quickly preparing an Ag2Se block thermoelectric material through self-homogenization for the first time. Ag powder and Se powder are used as raw materials; firstly the raw materials are easily mixed, and then the mixed raw materials are directly subjected to plasma activated sintering (PAS), so compact Ag2Se block thermoelectric material can be prepared in several minutes. The process dissolved by the method is super easy, the preparation time is super short, the obtained product is uniform in component distribution, and an obvious effect of self-homogenization is shown. The prepared Ag2Se block thermoelectric material is superior in performance, the room temperature ZT exceeds 0.6, and a good foundation is laid for large-scale preparation and large-scale application of the Ag2Se compound.

Owner:WUHAN UNIV OF TECH

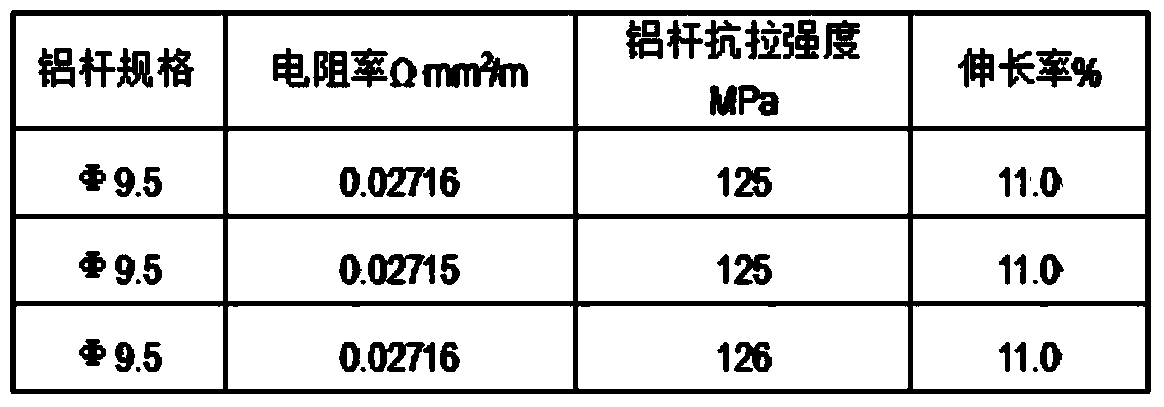

High-conductivity hard aluminum wire and preparing technology thereof

ActiveCN103854807AGuaranteed tensile strengthImprove conductivityNon-insulated conductorsCable/conductor manufactureCarrying capacityAtmospheric pressure

The invention discloses a high-conductivity (63 percent IACS) hard aluminum wire and a preparing technology thereof. The preparing technology of the high-conductivity hard aluminum wire comprises the following steps that firstly, a high-conductivity aluminum rod is prepared in a continuous casting and rolling mode; secondly, the high-conductivity aluminum rod is drawn into high-conductivity aluminum wires which are drawn through various dies, wherein the coefficient of elongation of the last die is controlled within 1.35-1.50, and the coefficients of elongation of the other dies are controlled within 1.30-1.40; thirdly, a plurality of high-conductivity aluminum wires are twisted, the pay-off tension is controlled in the twisting process, the control air pressure is smaller than or equal to 3 kilograms, the tensile strength of the manufactured single hard aluminum wire is larger than or equal to 160 MPa, and the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C. The tensile strength of the manufactured single hard aluminum wire in an overhead conductor is larger than or equal to 160 MPa, the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C, the tensile strength of the hard aluminum wire is kept, the conductivity of the hard aluminum wire is increased to 63 percent IACS, and the conductivity is increased by 3.28 percent compared with the stipulated conductivity of a hard aluminum wire in common GB / T17937-2009. The high-conductivity hard aluminum wire is used in the overhead conductor, the loss of the circuit electric energy can be greatly reduced, the circuit operation cost is reduced, and the carrying capacity of the wire can be obviously improved.

Owner:FAR EAST CABLE +2

Electroslag remelting process of nickel-based superalloy

InactiveCN110724826ASmooth surface qualityHigh yieldIncreasing energy efficiencyFurnace typesSlagSuperalloy

Owner:JINGYE STEEL CO LTD

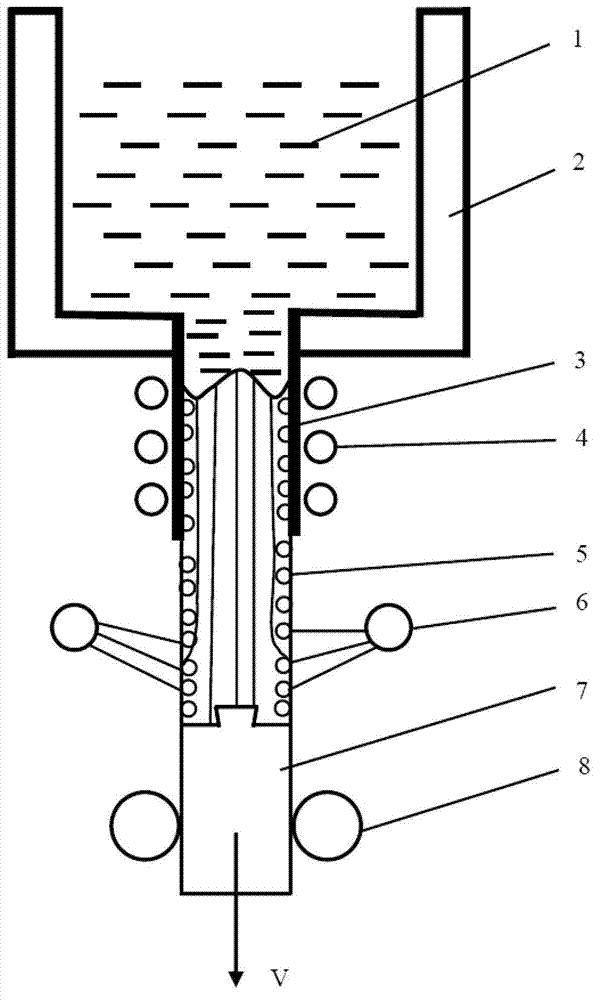

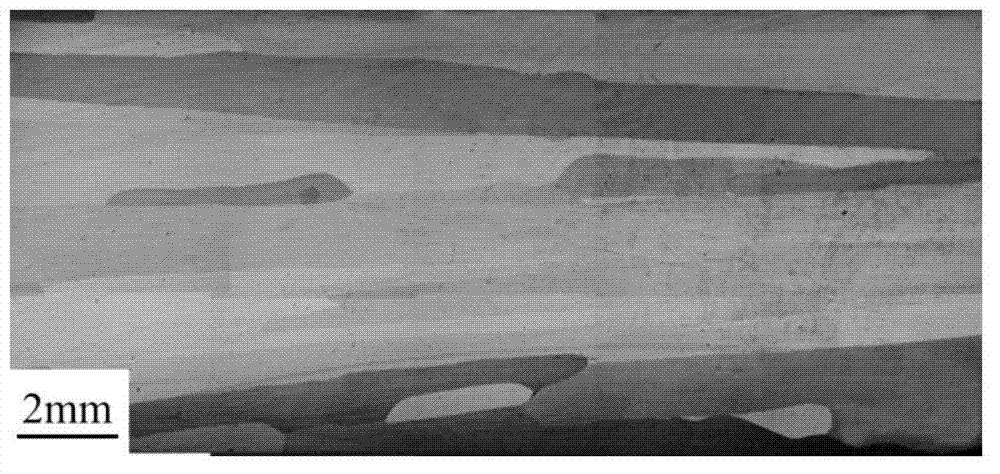

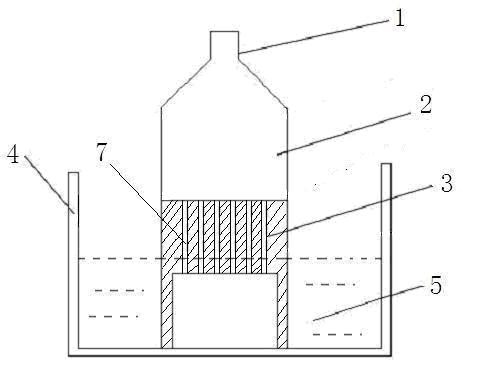

Thermal mold casting method

The invention provides a thermal mold casting method. The thermal mold casting method is characterized by comprising the following steps of: heating a casting mold by a heater, or heating the casting mold by utilizing heat conducted by a metal melt before entering the casting mold so as to maintain the temperature of the casting mold to be in the range lower than the temperature of a solid phase line of metal and higher than the cooling temperature of the casting mold; carrying out forced cooling on the metal by a cooler arranged near an outlet of the casting mold; and drawing a metal casting blank by using a traction mechanism. The thermal mold casting method provided by the invention has the advantages that the application range is wide, the promotion value is very large, high-quality metal casting blanks with excellent performance, good surface smoothness, high size accuracy, high compactness, more uniform components, columnar crystal parallel or approximately parallel to the jiggering direction in the metal and isometric crystal concurrent microstructures on the surface layer of the metal can be produced with low energy consumption and high efficiency, and the subsequent plastic processing with a large screw-down rate can be carried out according to the need.

Owner:UNIV OF SCI & TECH BEIJING

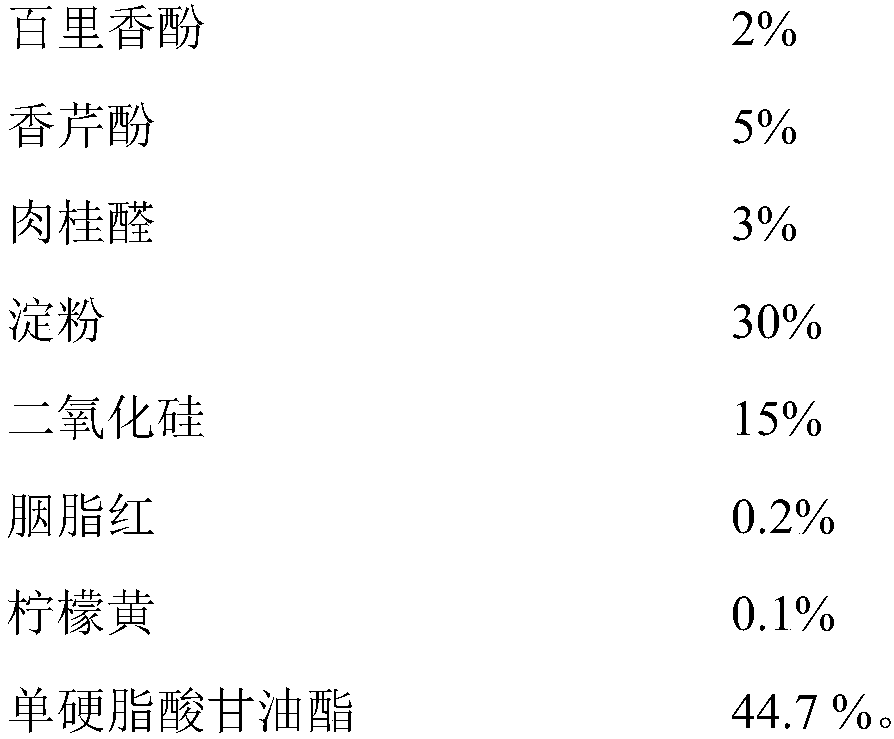

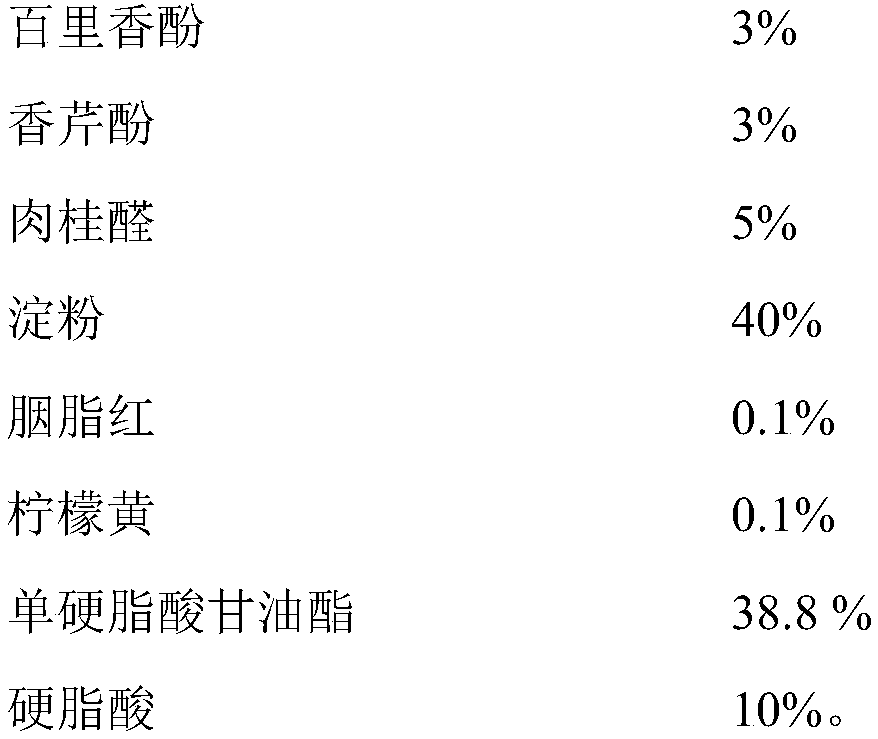

Compound plant essential oil micro-capsule preparation and preparation method thereof

InactiveCN108260719ASmooth microcapsule surfaceUniform colorAccessory food factorsWorking-up animal fodderAdditive ingredientPigment

The invention discloses a compound plant essential oil micro-capsule preparation and a preparation method thereof, and belongs to the field of animal feed additives. The compound plant essential oil micro-capsule preparation comprises the following ingredients in percentage by mass: 5-30% of plant essential oil, 30-60% of auxiliary materials, 0-1% of pigments, and the balance of a carrier material; and the plant essential oil is a compound composed three essential oils, including carvacrol, thymol and cinnamaldehyde, at random proportions. The compound plant essential oil micro-capsule preparation disclosed by the invention is light red to red round smooth solid particles, wherein the micro-capsules are smooth at surface, uniform in color and luster, and 200-800 microns in particle size; and thus, the compound plant essential oil micro-capsule preparation has relatively good fluidity and dispersibility so that uniform mixing of feeds is facilitated so as to avoid sticking of the feedson walls when the feeds are used for feeding. And thus, the compound plant essential oil micro-capsule preparation is capable of reducing consumption loss, and increasing breeding benefits.

Owner:FOSHAN STANDARD BIO TECH

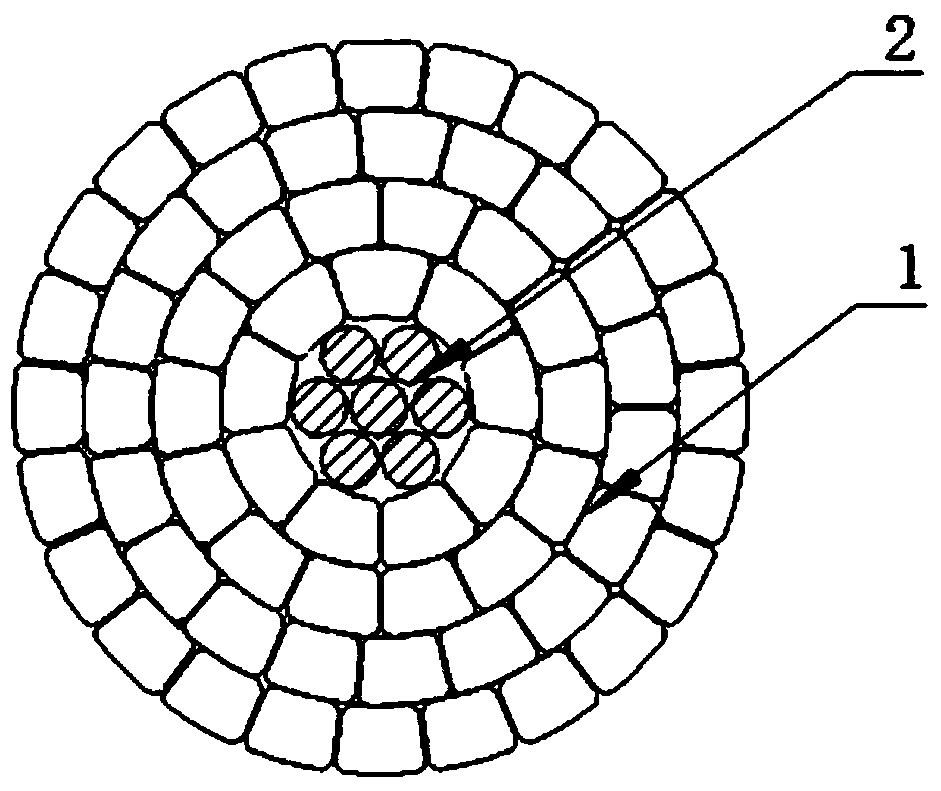

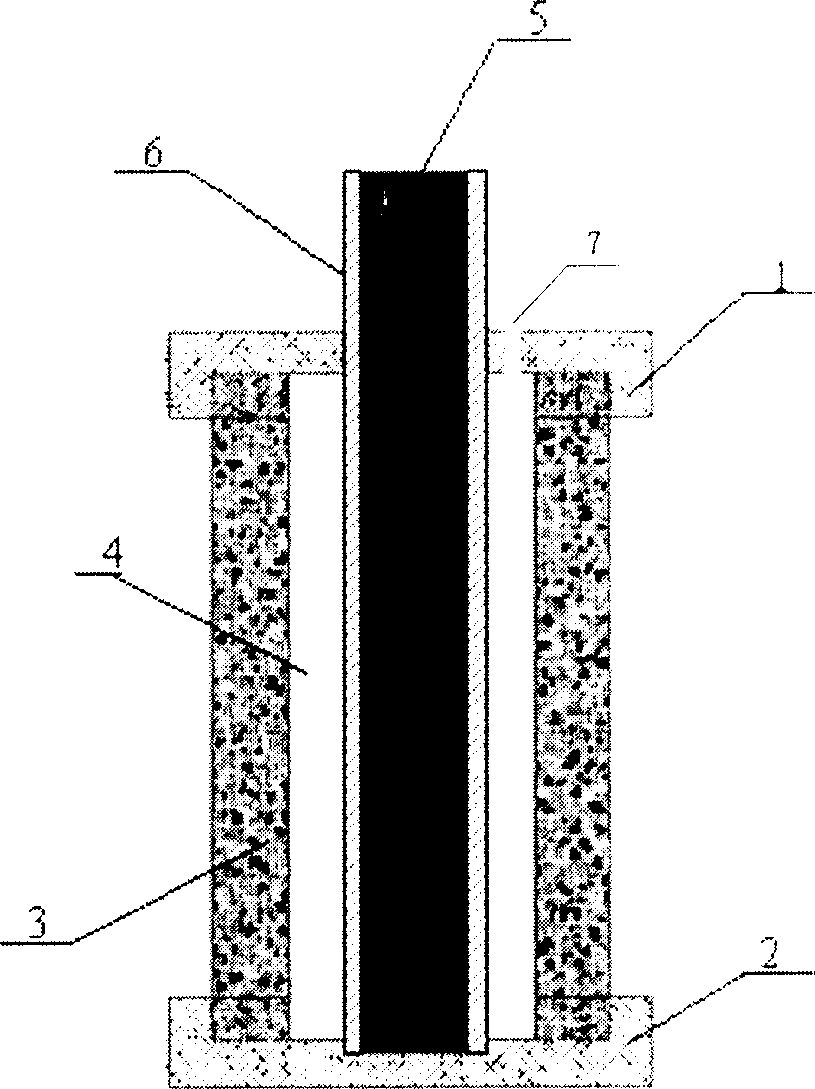

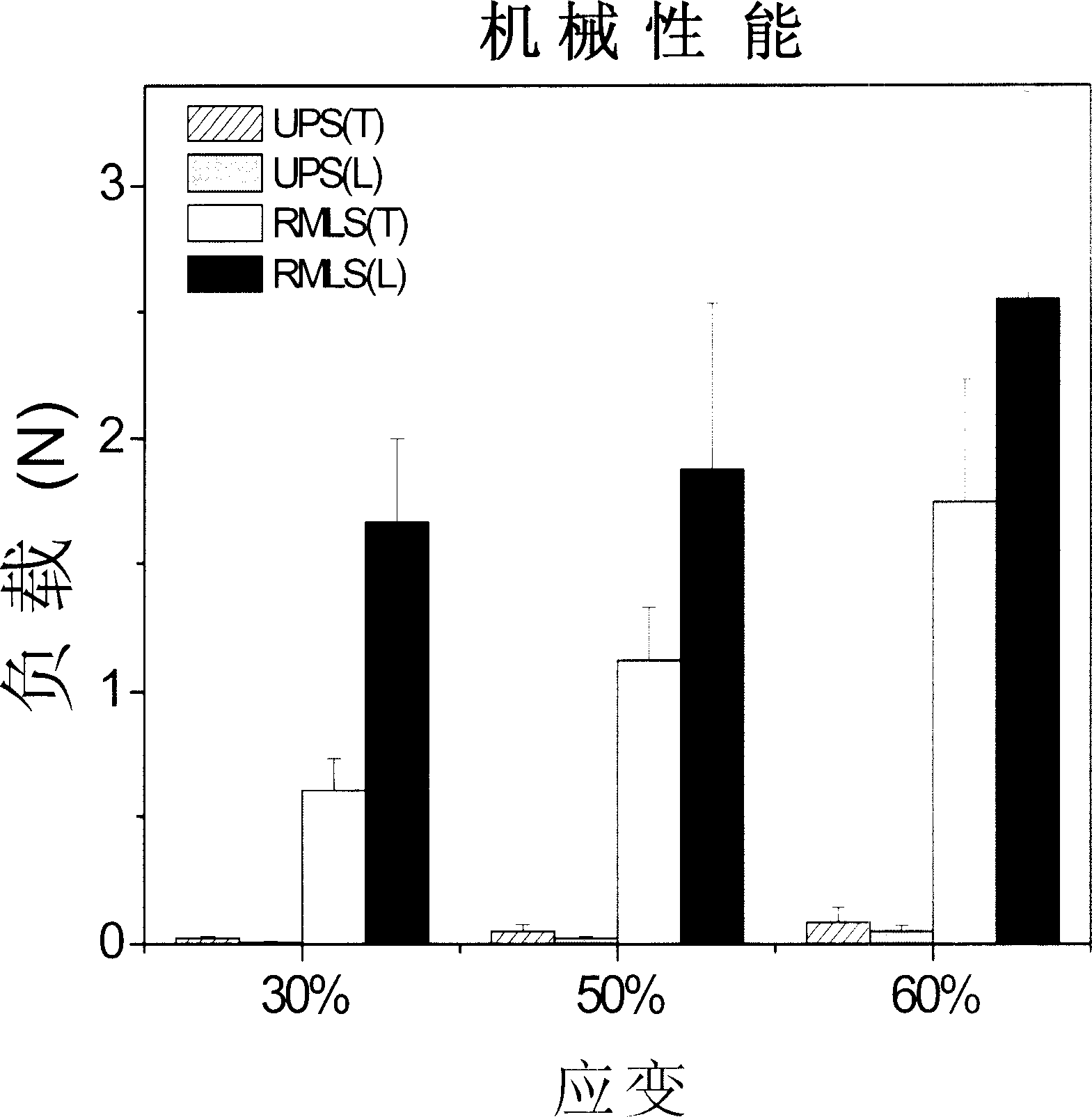

Biotic bone tissue engineering stent and its preparation method

InactiveCN1911456AGood biocompatibilityGood bone conductionProsthesisBiocompatibility TestingBiological materials

A tissue-engineered bionic bone scaffold with high biocompatibility, bioactivity, degradability and osteoplastic induction has a three-layer structure composed of external degradable compact biofilm layer, central porous layer with less pore diameter for high mechanical strength, and internal porous layer with big pore diameter for transferring nutrients. Said central and internal layers are a composition consisting of in-situ formed nano-phase Ca-P salt and degradable biologic material.

Owner:TSINGHUA UNIV

Solar heat-absorbing paint

InactiveCN106010241AImprove stabilityGood weather resistanceFireproof paintsAntifouling/underwater paintsPolyethylene glycolSolvent

The invention discloses solar heat-absorbing paint which is prepared from the following components in parts by weight: 25-35 parts of an acrylate-modified composite emulsion, 2-6 parts of a fluorocarbon surfactant, 35-55 parts of a nano carbon powder and manganese dioxide mixture, 7-12 parts of a curing agent, 50-35 parts of a film forming agent, 1-3 parts of an absorption enhancer, 10-20 parts of a solvent, 5-10 parts of dispersants, and 0.5 to 0.7 part of a thickening agent, wherein the dispersants are sodium dodecyl sulfate and polyethylene glycol / polyvinyl pyrrolidone; the film forming agent is modified fibroin-gelatin; nano carbon powder is 10-20 nm in particle size, 150-180 m<2> / g in specific surface area and 90-95% in carbon content. The prepared solar heat-absorbing paint has excellent weather resistance and water resistance under the outdoor condition, the preparation process is simple and easy to understand, and the heat absorption efficiency of the heat-absorbing paint is further ensured.

Owner:NANNING KEYU ENERGY TECH CO LTD

Casting equipment and method using solid-liquid two-phase region temperature as casting mold temperature

The invention discloses casting equipment and a casting method using solid-liquid two-phase region temperature as casting mold temperature, and belongs to the technical field of metal casting. The casting equipment is characterized by consisting of a crucible, two-phase region casting molds, a heater, a cooler and a traction mechanism, wherein one or more two phase region casting molds are arranged below, above or beside the crucible; the casting mold is insulated and heated through the heater or heated by using the heat which is conducted by the cast metal melt before entering the casting mold so as to keep the casting mold temperature between the solidus temperature and the liquidus temperature of the cast metal; the cast metal is forcibly cooled through the cooler which is arranged close to the outlet of the casting mold or a cooling device which is arranged at the outlet of the casting mold and can move along the casting direction; and the traction mechanism is used for drawing a metal casting blank. The equipment of the invention has the advantages of simple structure, convenient operation and repair, high production efficiency and wide application range and can industrially produce the high-quality metal casting blank with high strength, high plasticity, high surface finish, high dimensional accuracy, high compactness and low or no segregation in batches.

Owner:UNIV OF SCI & TECH BEIJING

Preparing method for aluminum base silicon carbide

ActiveCN105400977AEvenly distributed ingredientsReduce porosityTransportation and packagingMetal-working apparatusPorosityAluminium powder

A preparing method for an aluminum base silicon carbide comprises the steps that firstly, SiC / Al slurry is prepared, SiC slurry is obtained through preparing of SiC micro powder, and aluminum powder and magnesium powder are added in proportion and are evenly mixed; secondly, tape casting is carried out, the SiC / Al slurry is subjected to defoaming, an initiating agent with the weight accounting for 1% to 3% of the total weight of the SiC / Al slurry and monomer with the weight accounting for 2% to 4% of the total weight of the SiC / Al slurry are added and are evenly mixed, and tape casting is carried out to obtain an SiC / Al cast film; thirdly, biscuiting is carried out on the cast film, wherein biscuiting is carried out on the casting film obtained in the second step, and an SiC / Al biscuit is obtained; and fourthly, vacuum sintering is carried out, and the SiC / Al biscuit is sintered in the vacuum state to obtain the aluminum base silicon carbide. The aluminum base silicon carbide is prepared through a gel tape casting method, obtained product components are evenly distributed, the porosity is low, the heat conduction rate is high, the magnesium powder is introduced, the sintering performance is improved, and the sintering temperature is reduced. The technology is simple, and energy consumption is low.

Owner:李大海

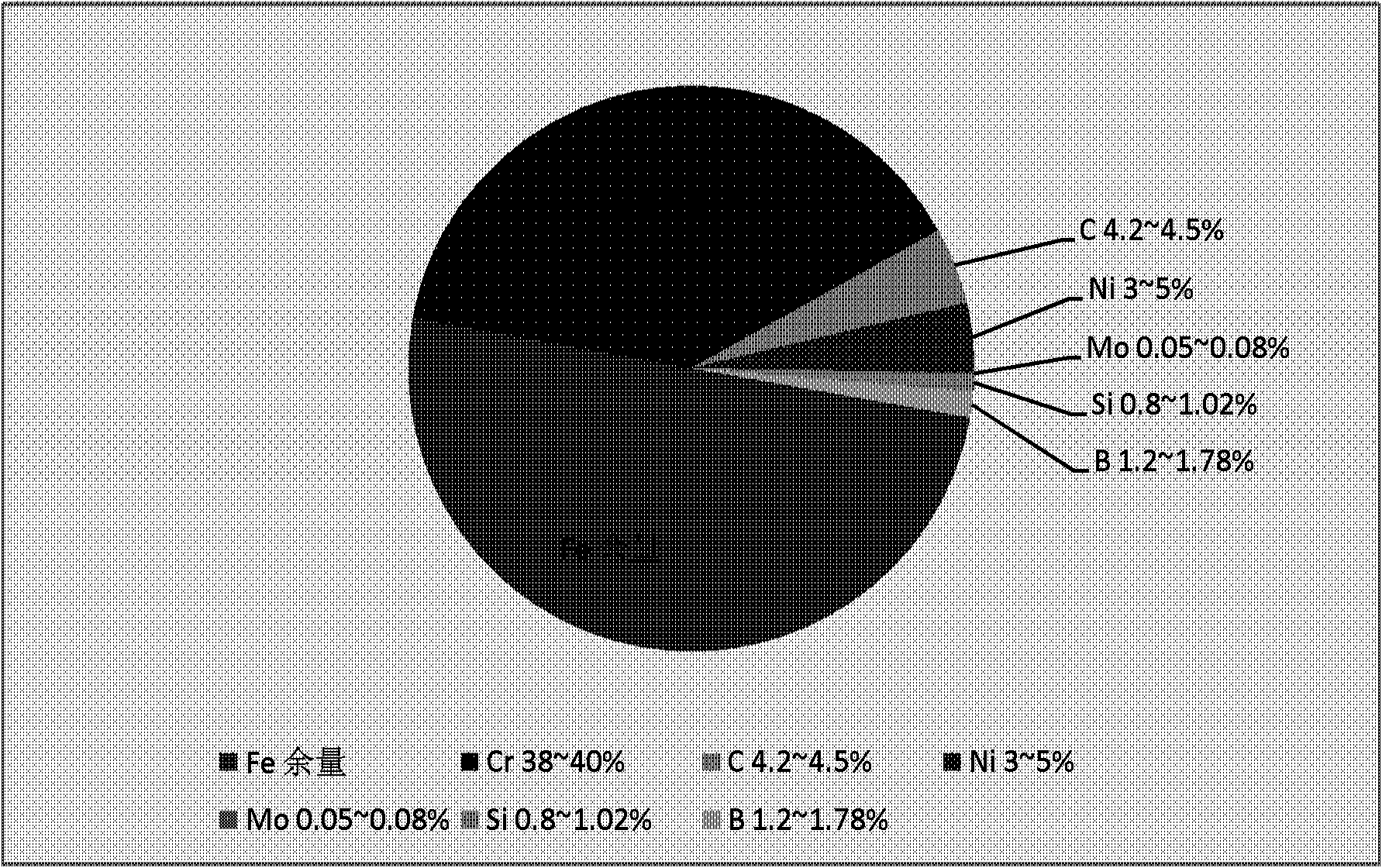

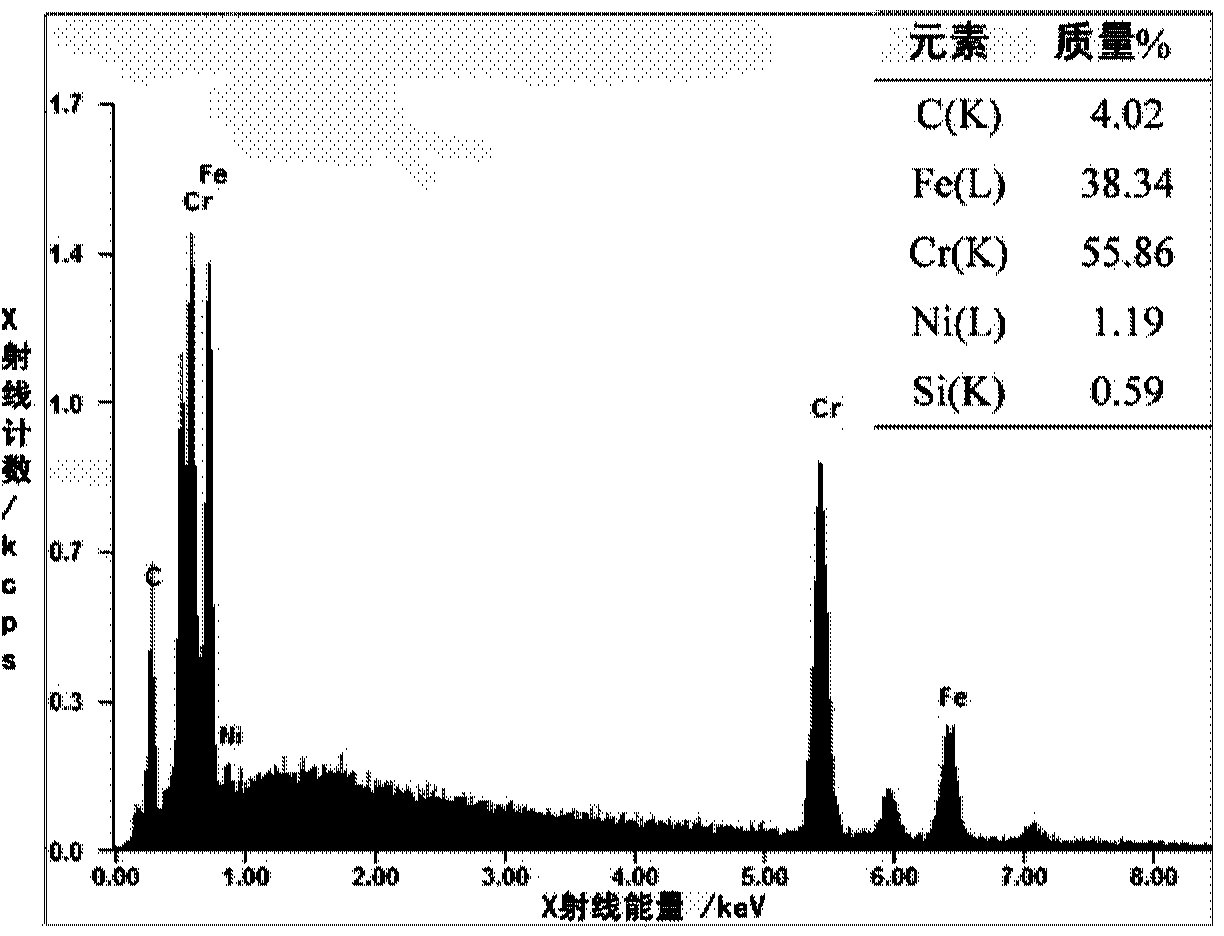

Iron-based composite powder high in chromium content for laser cladding

ActiveCN103752818AHigh hardnessImprove wear resistanceMetallic material coating processesCrack freeHardness

The invention discloses iron-based composite powder high in chromium content for laser cladding. The iron-based composite powder high in chromium content for laser cladding is composed of the chemical compound of Cr3C2, Cr and Fe, Ni, Mo, Si and B. The iron-based composite powder high in chromium content for laser cladding comprises, by mass, 38%-40% of Cr, 4.2%-4.5% of C, 3%-5% of Ni, 0.05%-0.08% of Mo, 0.8%-1.02% of Si, 1.2%-1.78% of B and the balance Fe. The particle size of the iron-based composite powder is between +140 meshes and -325 meshes. The iron-based composite powder is high in carbon content and chromium content, the hardness of a coating can be effectively improved, requirements of the laser cladding technology of iron-based base materials such as carbon steel and stainless steel can be met, a cladding layer of a sample of the iron-based composite powder is free of cracks and macroscopic pores, all the components are distributed evenly, the hardness of the iron-based composite powder can reach HV0.21000 and is five times that of a base body, the corrosion resistance of the iron-based composite powder cladding layer is improved due to the high chromium content, and the iron-based composite powder is suitable for normal temperature, high temperature, abrasion resistance and corrosion resistance working conditions.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for growing yttrium ferrite crystal by guided mold pulling method

InactiveCN101942694AFast growthImprove optical qualityPolycrystalline material growthBy pulling from meltCrucibleCrystal growth rate

The invention relates to a method for growing an yttrium ferrite crystal by a guided mold pulling method, which comprises the following steps: placing a guided mold with internal longitudinal gaps in a crucible, adding polycrystal materials into the crucible, heating the crucible to melt the polycrystal materials, enabling the molten polycrystal materials to rise over the gaps at the bottom of the guided mold so as to enable the molten polycrystal materials to be raised to the top surface of the guided mold along the longitudinal gaps in the guided mold under the capillary effect, then dropping seed crystals, and finally pulling to obtain the yttrium ferrite single crystal. The invention can prepare large-size yttrium ferrite single crystals, simplify the post processing procedure of the crystal and lower the preparation cost of the crystal, and has the advantages of high crystal growing speed and good optical uniformity of the prepared crystal, thereby solving the problem that the pulling method can not be used for preparing large-size single crystals.

Owner:FUZHOU UNIV

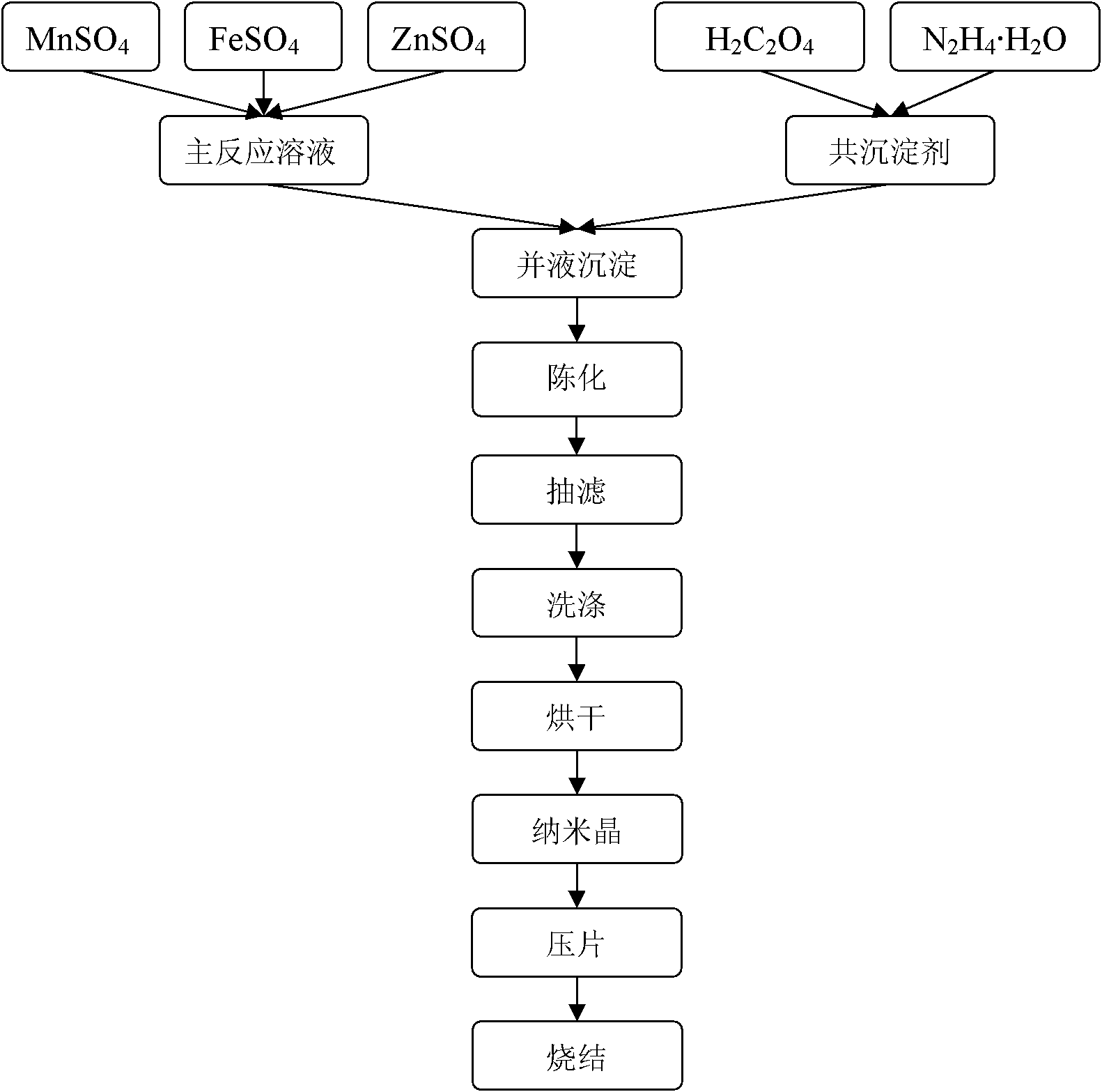

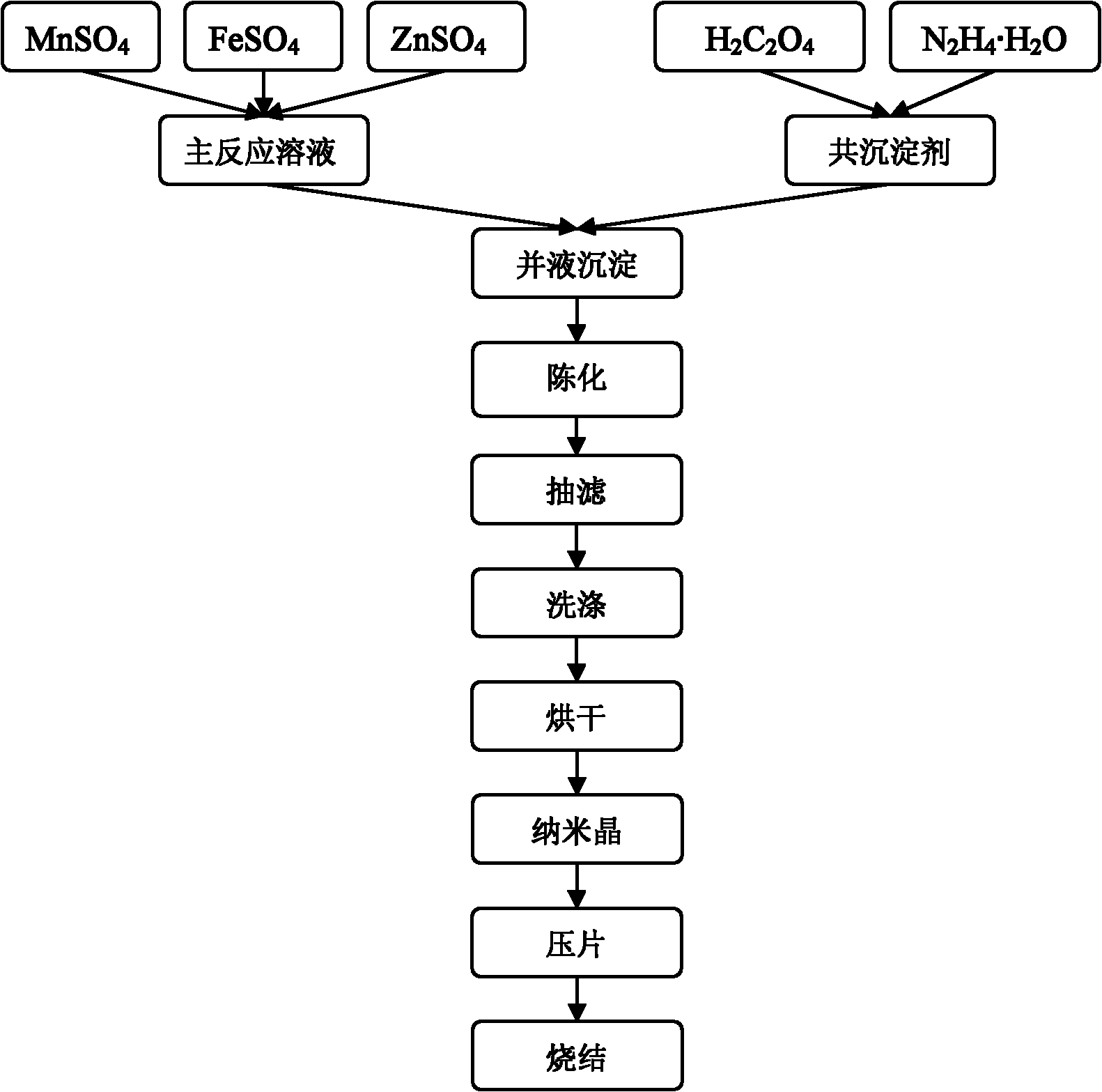

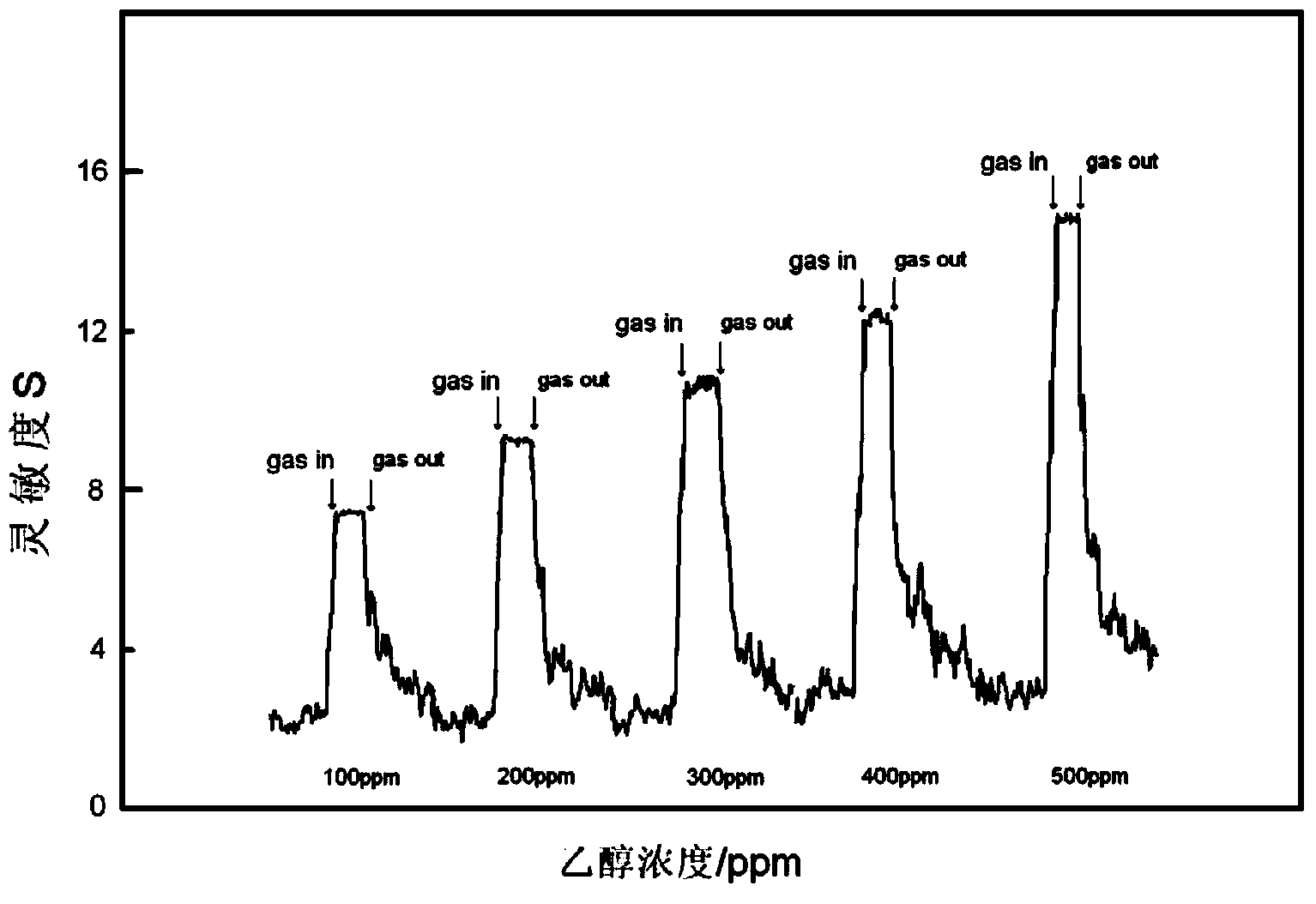

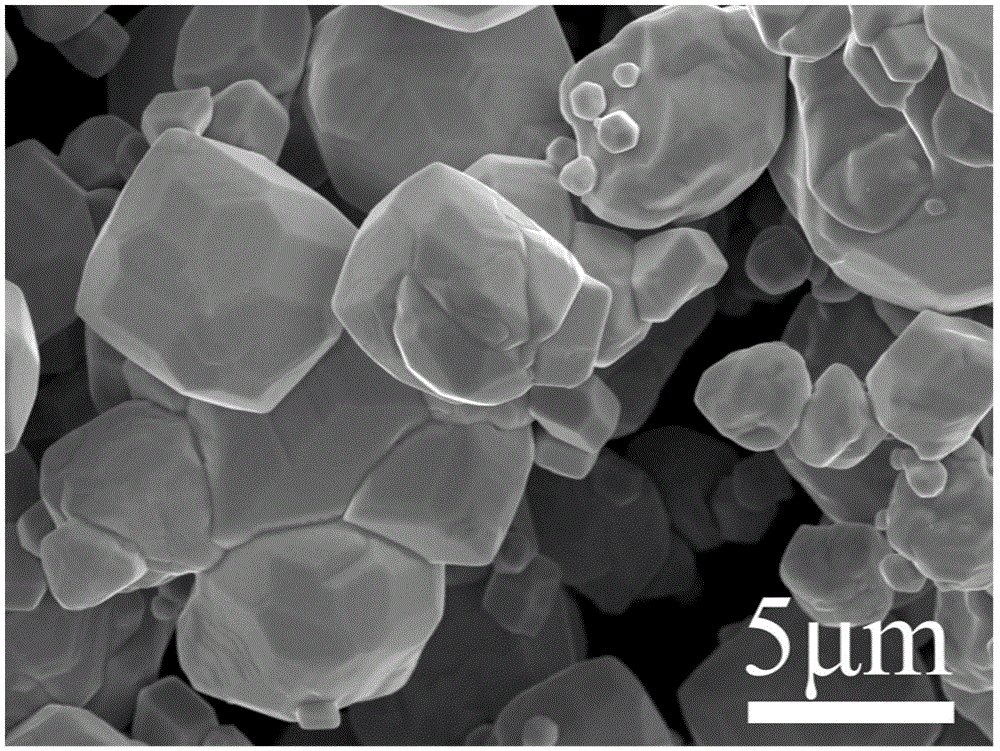

Nano-crystal Mn-Zn ferrite magnetic material with high initial permeability and high thermal-magnetic sensitivity and preparation method of nano-crystal Mn-Zn ferrite magnetic material

The invention relates to a nano-crystal Mn-Zn ferrite magnetic material with high initial permeability and high thermal-magnetic sensitivity and a preparation method of the nano-crystal Mn-Zn ferrite magnetic material. When the Mn-Zn ferrite material is prepared, a raw material is composed of a main reactant and a precipitator, wherein the main reactant comprises the following components in percentage by weight: 68-72% of FeSO4, 8-15% of ZbSO4 and the balance of MnSO4; and the precipitator is hydrazine oxalate (H2C2O4N2H4.H2O). By using the preparation method, the initial permeability of the prepared Mn-Zn ferrite is up to 7500 at 25 DEG C, and the thermal-magnetic sensitivity of the prepared Mn-Zn ferrite is about 1 DEG C. the Mn-Zn ferrite prepared by the method can be widely applied to temperature detection and control systems such as household appliances, industrial machinery and the like.

Owner:苏州天铭磁业有限公司

Nb-Si intermetallic compound bar and preparation method thereof

The invention discloses an Nb-Si intermetallic compound bar. The Nb-Si intermetallic compound bar is prepared from, by atomic percentage, 35%-45% of silicon, and the balance niobium and inevitable impurities. The invention further discloses a preparation method of the Nb-Si intermetallic compound bar. The preparation method includes the steps that 1, silicon powder and niobium powder are ball-milled and dried to obtain mixed powder; 2, a blank is formed after compression molding, the blank is sintered, and then an Nb-Si intermetallic compound sintered body is obtained; 3, an Nb-Si intermetallic compound cast ingot is obtained after electric arc melting, and a semi-finished bar is obtained after cutting; and 4, the Nb-Si intermetallic compound bar is obtained after electron beam zone melting. The Nb-Si intermetallic compound bar has the beneficial effects of being high in quality and purity, low in oxygen mass content and uniform in component distribution, the bar is further crushed into powder to serve as a raw material for preparing a high-temperature oxidation-resistant coating and also serve as a strengthening phase of a super-high-temperature oxidation-resistant material, and broad application prospects are achieved in the aerospace field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of p-n junction type ZnO-CoTiO3 room temperature gas-sensitive film

ActiveCN104020193AEasy to prepareWide range of raw materialsVacuum evaporation coatingSputtering coatingSputteringWorking temperature

A preparation method of a preparation method of a p-n junction ZnO-CoTiO3 room temperature gas-sensitive film. The method is as below: placing a TiO2 target and a Co3O4 target into two radio frequency target positions of a magnetron sputtering instrument, and placing a Zn target into a direct current sputtering target position; then placing a Si substrate on a coating sample stage of the magnetron sputtering instrument, then vacuumizing, introducing Ar gas, then conducting pre-sputtering, introducing O2 gas, and finally conducting sputtering coating on the Si substrate to obtain a precursor film; calcining the precursor film, controlling the calcination temperature at 300-700 DEG C and calcination time at 0.5-3 h, and then cooling to room temperature in the furnace to obtain the p-n junction type ZnO-CoTiO3 room temperature gas-sensitive film. The method can effectively control the composition of the film, has good film forming property, convenient operation and short production cycle; and the prepared p-n junction type ZnO-CoTiO3 gas-sensitive thin has uniform distribution, and excellent room temperature gas-sensitive property and can effectively reduce the working temperature.

Owner:SHAANXI UNIV OF SCI & TECH

Flat plate solar energy heat absorption coating

InactiveCN105482603AReduce hydrophilicityImprove waterproof performanceRadiation-absorbing paintsUltraviolet lightsEngineering

The invention discloses a flat plate solar energy heat absorption coating. A light absorption agent, a film forming agent, a solvent and an addition agent are evenly scattered in a ball milling mode, then a film forming addition agent is added into the mixture to be mixed to be uniform, and therefore the flat plate solar energy heat absorption coating is obtained. The flat plate solar energy heat absorption coating is prepared from, by weight, 50-100 parts of the film forming agent, 10-30 parts of the film forming addition agent, 35-55 parts of the light absorption agent, 20-50 parts of the solvent and 10-30 part of the addition agent. The film forming addition agent is ethylene glycol monobutyl ether, triethylene glycol monomethyl and the like. A preparation method of the film forming agent comprises the steps that casein and gelatin are mixed according to the weight ratio of 5-10:2-3, water is added into the mixture, the mixture is soaked at the temperature of 15-22 DEG C and then transferred to a plate under the normal temperature, a mixture solution with methyl methacrylate and polysiloxane quaternary ammonium sodium with the ratio of parts by weight of 1-2:1-3, the mixture is stirred and then irradiated by ultraviolet light for 10-15 min, and then modified casein-gelatin is obtained. The film forming agent is modified and then used as the important raw material of the coating, so that the prepared coating has the good weather resistance and water resistance under the outdoor conditions, the preparation technology is simple and easy to understand, and the heat absorption efficiency of the heat absorption coating is ensured.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

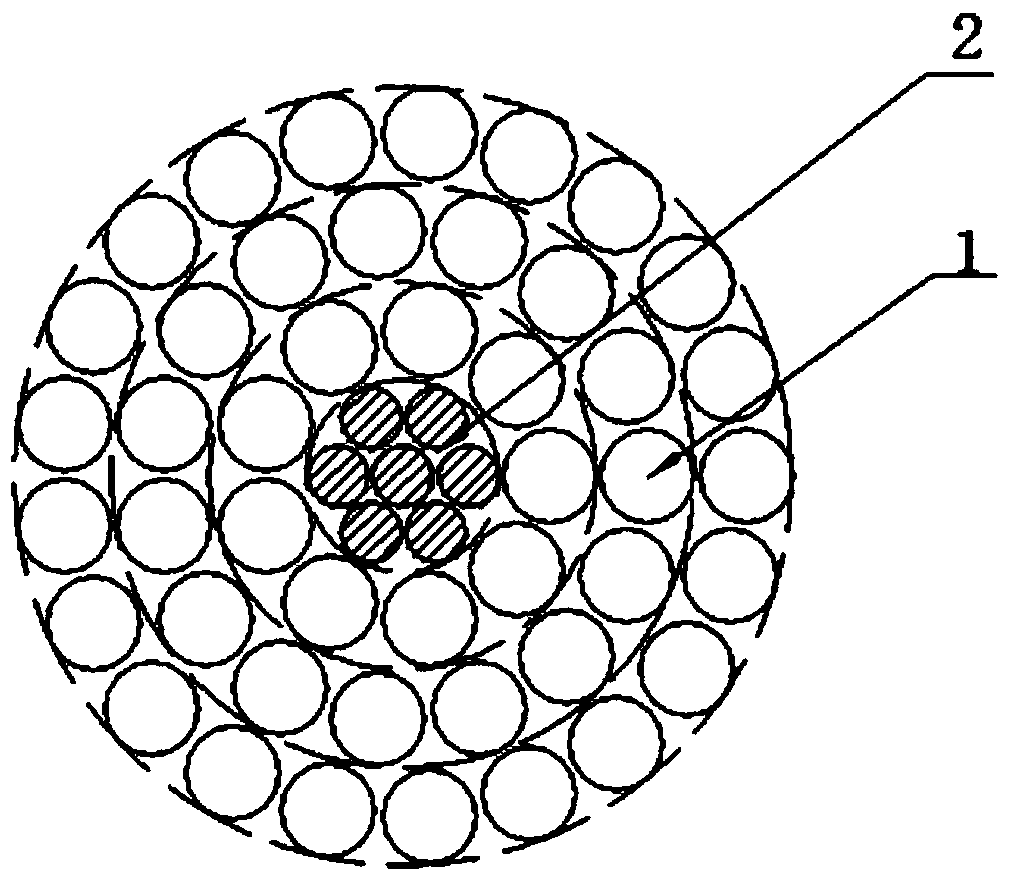

Composite powder for high gravity alloy and preparation method thereof

The invention discloses composite powder for a high gravity alloy and a preparation method thereof. The composite powder particle for the high gravity alloy has an irregular or spherical shape; the composite powder has a core-shell structure, the inner core is tungsten whose grain sizes are uniformly distributed, the shell is a nickel-based alloy with a uniform thickness, and the mass ratio is 85-97 to 15-3; and the composite powder has the advantages of uniform composition and high purity and the like. The preparation method comprises steps: oil removing and acid cleaning are carried out on tungsten powder; intermittent plating technology is then adopted for enabling the nickel-based alloy to be uniformly deposited on the surface of the tungsten powder; and the composite powder after being plated is cleaned and dried. The intermittent plating technology is adopted to prepare the composite powder for the high gravity alloy, the method is simple, reliable and easy to operate, the electroplating speed, the plating layer thickness, and the composition content range can be effectively adjusted, the mechanical performance of the high gravity alloy can be effectively improved, the application prospect is wide, and mass industrialized production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

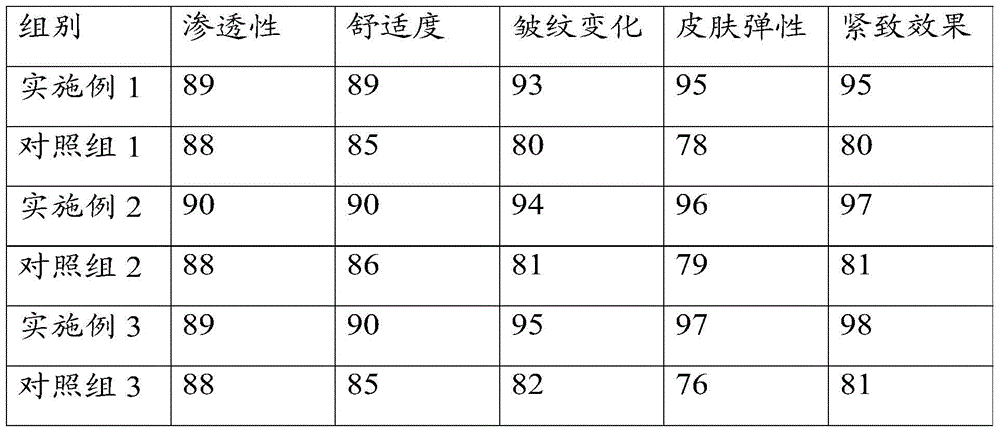

Anti-wrinkle firming eye cream and preparation method thereof

InactiveCN105596262ARestore elasticityHigh transparencyCosmetic preparationsToilet preparationsPalmitatesTetrandrine

The invention relates to the field of cosmetics, and particularly relates to an anti-wrinkle firming eye cream and a preparation method thereof. The anti-wrinkle firming eye cream is prepared from the following raw materials: a phase A including glycerinum, hexylene glycol, hyaluronic acid, oat bran extract, PVM / MA decadiene crosslinked polymer and water, a phase B including shea butter, polydimethylsiloxane and caprylic / capric triglyceride, a phase C including sodium hydroxide and water, a phase D including sodium polyacrylate, vitamin E acetate, vitamin A palmitate and coenzyme Q10, a phase E including D-pantothenyl alcohol and nicotinamide, and a phase F including gingko extract, tetrandrine and phenoxyethanol. The anti-wrinkle firming eye cream is prepared from raw materials which are synergized and enhanced, and can effectively infiltrate into the corium layer of skin to repair the impaired collagen structure, nourish impaired cells, deeply improve skin problems and restore elasticity of periocular skin, so that the periocular skin is white, tender, smooth and elastic; and the anti-wrinkle firming eye cream has strong permeable feeling, so that the remarkable effects of removing wrinkles and firming the periocular skin can be achieved.

Owner:BEIJING 7SHOW TIMES TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com