Thermal mold casting method

A technology of warm mold and mold casting, applied in the field of warm mold casting, which can solve the problems of poor surface finish, quality and performance of billet, inability to use pure metal and eutectic alloy, low production efficiency of directional solidification method, etc., and achieve compact structure , high production efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

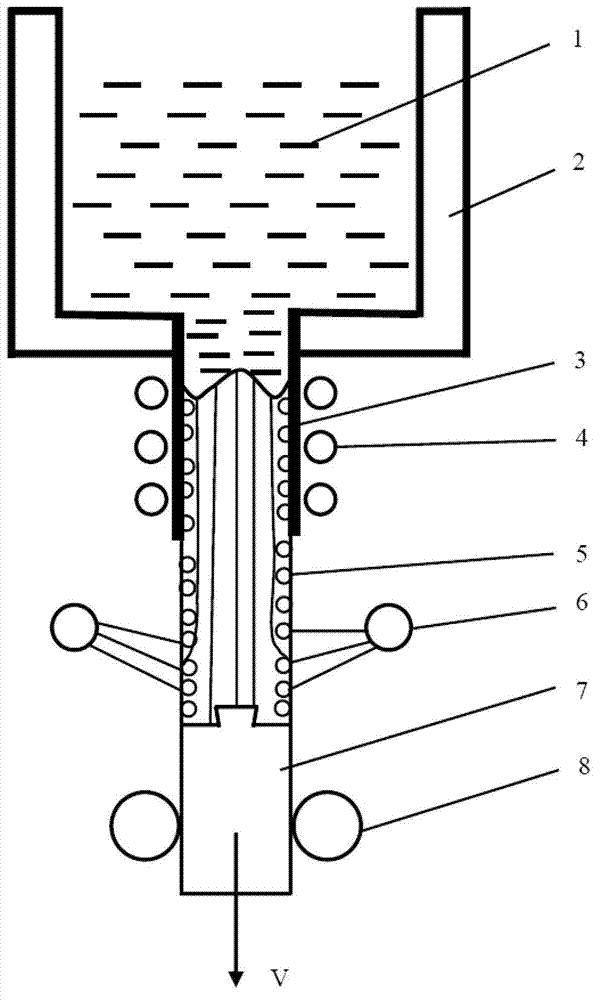

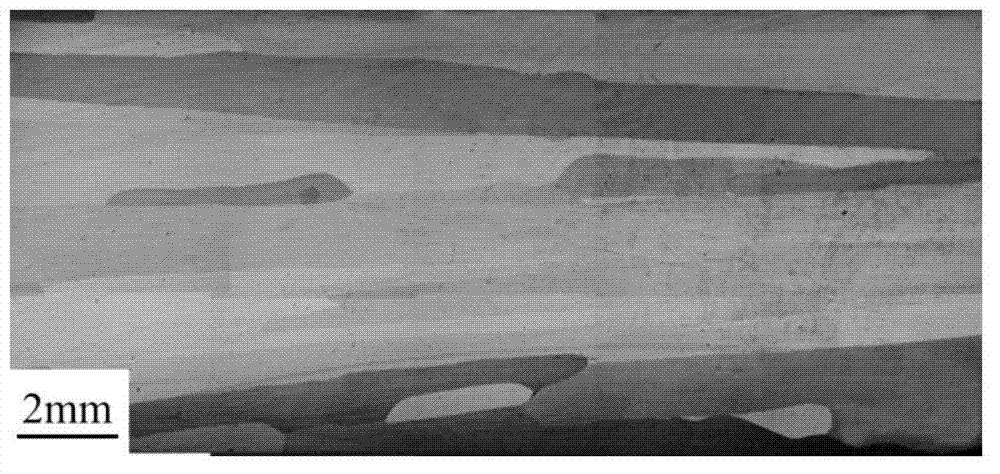

Embodiment 1

[0030] A pure aluminum rod with a diameter of 20mm is formed by warm continuous casting. The pure aluminum melt 1 flows into the low-heat mold 3 from the crucible 2 filled with argon protection; the power of the induction heater 4 is adjusted to control the temperature of the low-heat mold 3 to 550°C; the temperature of the cooler 6 is 15°C, and the flow rate is 1000L / h of cooling water is used to forcibly cool the pure aluminum; the traction mechanism 8 performs continuous drawing at a casting speed of 50mm / min to obtain the pure aluminum rod 5 . The prepared pure aluminum rod has a good surface finish, dense internal structure, and the microstructure mainly consists of columnar crystals inside the pure aluminum rod parallel or approximately parallel to the casting direction and equiaxed crystals on the surface of the pure aluminum rod. Composition, and excellent quality and performance.

Embodiment 2

[0032] The outer square side length is 20mm, and the inner circular hole diameter is 10mm. The pure copper profile is formed by warm casting. The pure copper melt 1 flows into the low-heat mold 3 from the crucible 2 filled with argon protection; the power of the induction heater 4 is adjusted to control the temperature of the low-heat mold 3 to 900°C; the temperature of the cooler 6 is 18°C, and the flow rate is The pure copper is forcibly cooled by 600L / h of cooling water; the drawing mechanism 8 is continuously drawn at a casting speed of 100mm / min to obtain the pure copper profile 5 . The prepared pure copper outer square inner circle profile has good inner and outer surface smoothness, dense internal structure, and the microscopic morphology mainly consists of columnar crystals inside the pure copper profile that are parallel or approximately parallel to the drawing direction and equiaxed crystals on the surface of the pure copper profile. Microstructural composition, and ...

Embodiment 3

[0034] Cu-12wt%Al aluminum-bronze alloy sheet with a width of 25mm and a thickness of 5mm was formed by warm-molding continuous casting. The Cu-12wt%Al aluminum bronze alloy melt 1 flows into the low-heat mold 3 from the crucible 2; the power of the induction heater 4 is adjusted to control the temperature of the low-heat mold 3 to be 850°C; the temperature of the cooler 6 is 20°C, and the flow rate is The Cu-12wt%Al aluminum bronze alloy was forcibly cooled by 800L / h cooling water; the traction mechanism 8 was continuously drawn at a drawing speed of 80mm / min to obtain the Cu-12wt%Al aluminum bronze alloy sheet 5. The prepared Cu-12wt%Al aluminum bronze alloy sheet has good surface finish, relatively uniform chemical composition distribution, dense internal structure, and microscopic morphology mainly composed of columnar crystals and aluminum bronze alloy sheets parallel or approximately parallel to the drawing direction inside the aluminum bronze alloy sheet. The surface la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com