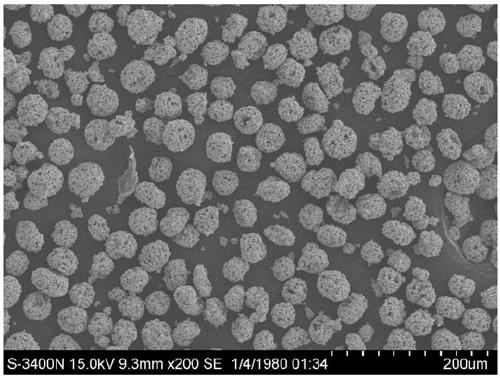

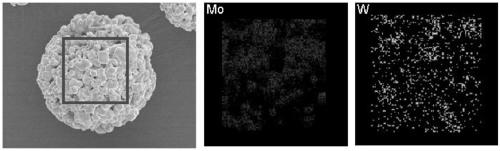

Preparation method of spherical tungsten-molybdenum alloy powder for 3D printing

A tungsten-molybdenum alloy, 3D printing technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problem that the performance cannot meet the performance requirements of 3D printing powder and formed products, and achieves lower production costs, The effect of uniform distribution of ingredients and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Select tungsten and molybdenum primary powders with a particle size range of 0.5-10um, and the proportion of tungsten powder in the tungsten-molybdenum mixed powder is 65.19wt.%;

[0024] 2) Add binder and deionized water to the mixed powder first, the total solid content of tungsten and molybdenum is 70wt.%, of which the binder content is 1wt.%, and the mass added to the mixed powder is 10wt. % of the abrasive material, then ball milling is carried out at 230rpm at a rotating speed, and the ball milling time is 0.5h;

[0025] 3) Add a dispersant to the mixed powder after ball milling, the content of which is 0.5wt.%, and then put it into a ball mill for ball milling at 230rpm, and the ball milling time is 0.5h;

[0026] 4) Spray-dry the mixed powder with an air-flow spray granulator, wherein the feeding rate is 15mL / min, the spray pressure is 0.1MPa, and the drying temperature is 190°C to prepare the precursor powder;

[0027] 5) Use a sintering furnace to sinter t...

Embodiment 2

[0031] 1) Select tungsten and molybdenum primary powders with a particle size range of 0.5-10um, and the proportion of tungsten powder in the tungsten-molybdenum mixed powder is 65.19wt.%;

[0032] 2) Add binder and deionized water to the mixed powder first, the total solid content of tungsten and molybdenum is 80wt.%, of which the binder content is 1wt.%, and the mass added to the mixed powder is 20wt. % of the abrasive material, then ball milling is carried out at 250rpm at a rotating speed, and the ball milling time is 1h;

[0033] 3) Add a dispersant to the mixed powder after ball milling, the content of which is 1wt.%, and then put it into a ball mill for ball milling at 250rpm, and the ball milling time is 1h;

[0034] 4) Spray-dry the mixed powder with an air-flow spray granulator, wherein the feeding rate is 4mL / min, the spray pressure is 0.1MPa, and the drying temperature is 190°C to prepare the precursor powder;

[0035] 5) Use a sintering furnace to sinter the prec...

Embodiment 3

[0039] 1) Select tungsten and molybdenum primary powders with a particle size range of 0.5-10um, and the proportion of tungsten powder in the tungsten-molybdenum mixed powder is 65.19wt.%;

[0040] 2) Add binder and deionized water to the mixed powder first, the total solid content of tungsten and molybdenum is 80wt.%, of which the binder content is 1wt.%, and the mass added to the mixed powder is 10wt. % of the abrasive material, then ball milling is carried out at 230rpm at a rotating speed, and the ball milling time is 1h;

[0041] 3) Add a dispersant to the mixed powder after ball milling, the content of which is 1wt.%, and then put it into a ball mill for ball milling at 230rpm, and the ball milling time is 1h;

[0042] 4) Spray-dry the mixed powder with an air-flow spray granulator, wherein the feeding rate is 15mL / min, the spray pressure is 0.2MPa, and the drying temperature is 190°C to prepare the precursor powder;

[0043] 5) Use a sintering furnace to sinter the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com