Method for quickly preparing Ag2Se block thermoelectric material through self-homogenization

A technology of thermoelectric materials and blocks, which is applied in the field of self-homogenization and rapid preparation of Ag2Se block thermoelectric materials, can solve problems such as lack, strict reaction conditions, and environmental pollution, and achieve significant self-homogenization effects and uniform distribution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

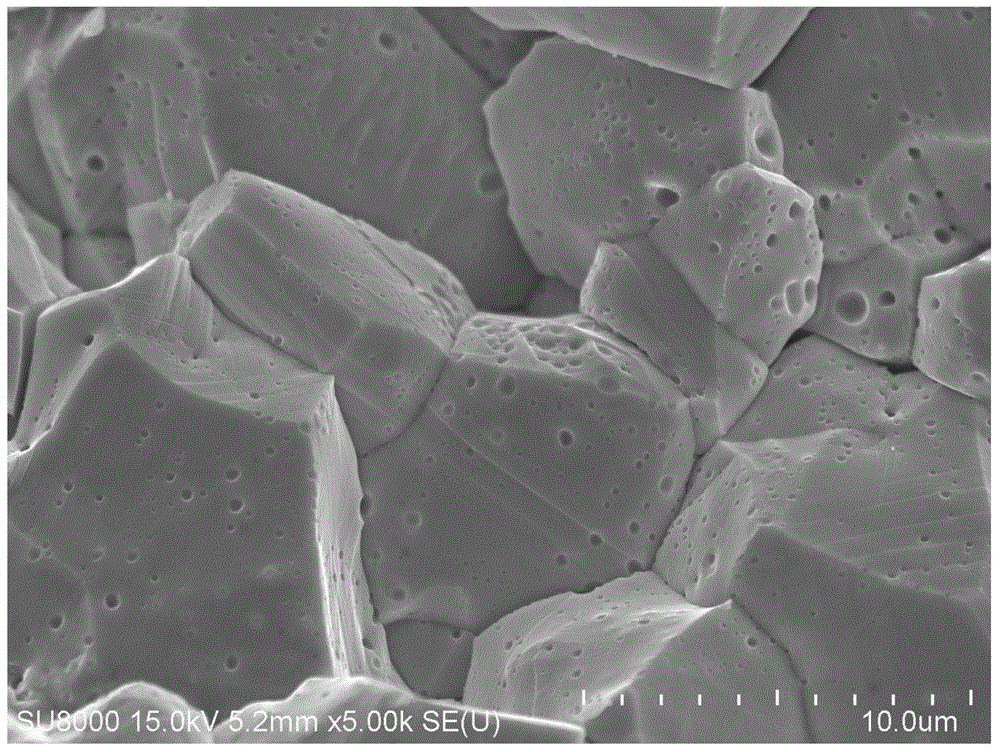

Image

Examples

Embodiment 1

[0034] A self-homogenization rapid preparation of Ag 2 The method of Se bulk thermoelectric material (sintering temperature is 400 ℃, 440 ℃ and 480 ℃ respectively), the specific steps are as follows:

[0035] 1) Using Ag powder and Se powder as raw materials, weigh Ag powder and Se powder at a molar ratio of 2:1, a total of 3 parts, 5g each, numbered A, B, and C respectively;

[0036] 2) Put each raw material in an agate mortar and pre-mix it with a medicine spoon for 7 minutes to obtain a mixed powder (mixed raw material);

[0037] 3) Put the mixed powder into a Φ16mm graphite mold for compaction, then put the graphite mold into the plasma activation sintering (PAS) equipment, and sinter under the vacuum condition below 10Pa, the axial pressure is 40MPa, after 2min to reach The target sintering temperature is 400°C for A, 440°C for B, and 480°C for C, and the holding time is 3 minutes. After the sintering is completed, it is cooled to room temperature with the furnace, and t...

Embodiment 2

[0040] A self-homogenization rapid preparation of Ag 2 The method of Se block thermoelectric material, concrete steps are as follows:

[0041] 1) Using Ag powder and Se powder as raw materials, Ag powder and Se powder are weighed in a molar ratio of 2:1, a total of 5g;

[0042] 2) Put the raw materials in an agate mortar and pre-mix them with a medicine spoon for 1 min. It can be clearly seen that the Ag powder and Se powder are enriched, and a mixed powder (mixed raw material) is obtained;

[0043]3) Put the mixed powder into a Φ16mm graphite mold for compaction, then put the graphite mold into the plasma activation sintering (PAS) equipment, and sinter under the vacuum condition below 10Pa, the axial pressure is 40MPa, and it reaches 440℃ after 2min (Target sintering temperature), the holding time is 3min, and after sintering, it is cooled to room temperature with the furnace to obtain Ag 2 Se bulk thermoelectric materials.

[0044] The product obtained in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com