Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

218results about How to "Reduce softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

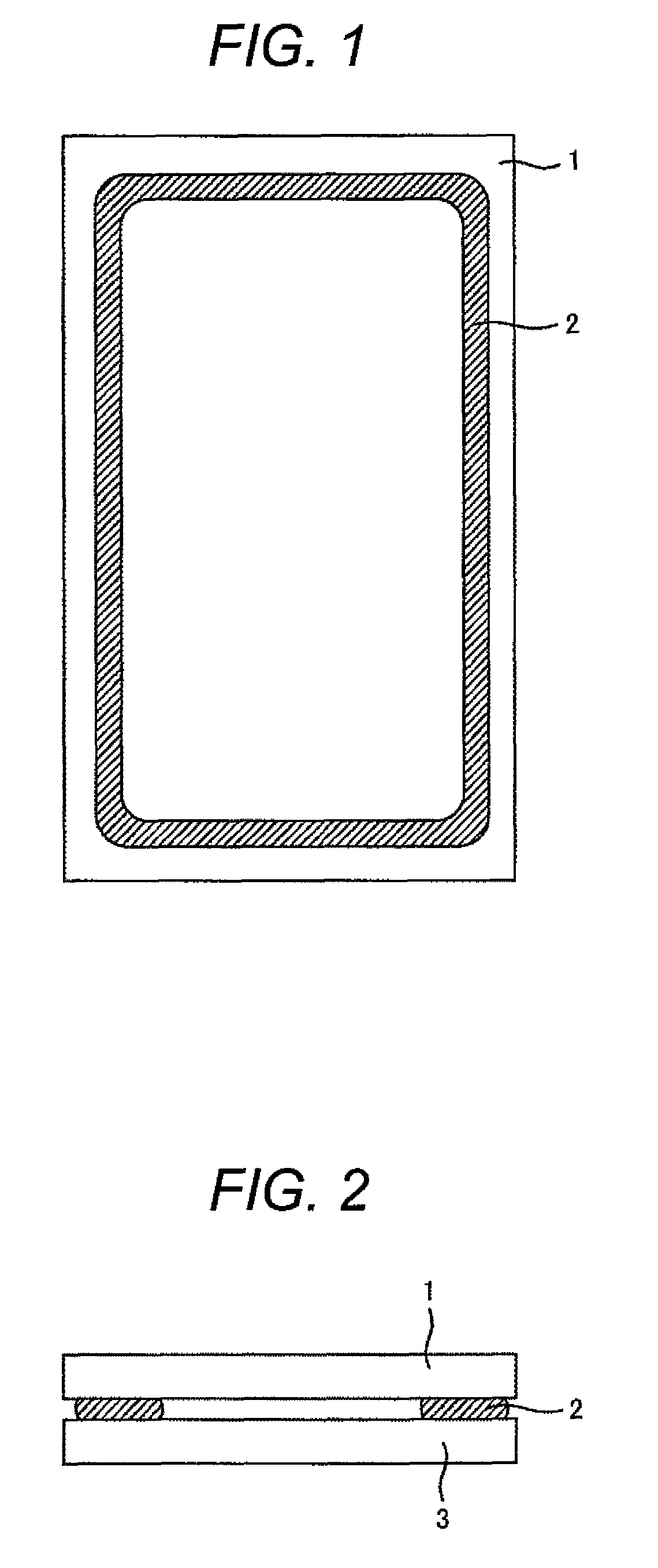

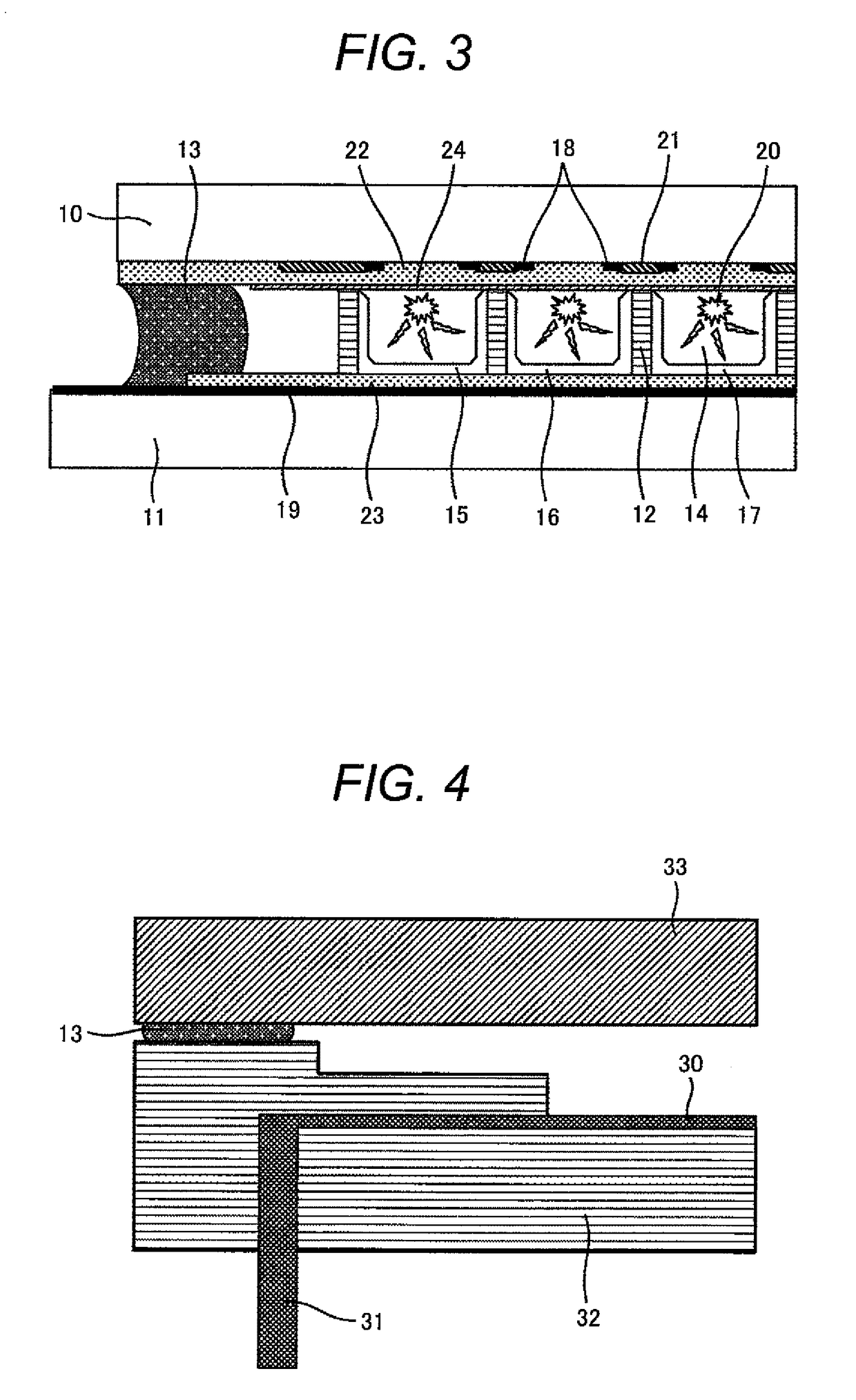

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS20100180934A1Flow on effectReduce softeningAddress electrodesConductive layers on insulating-supportsTe elementAntimony

Owner:RESONAC CORP

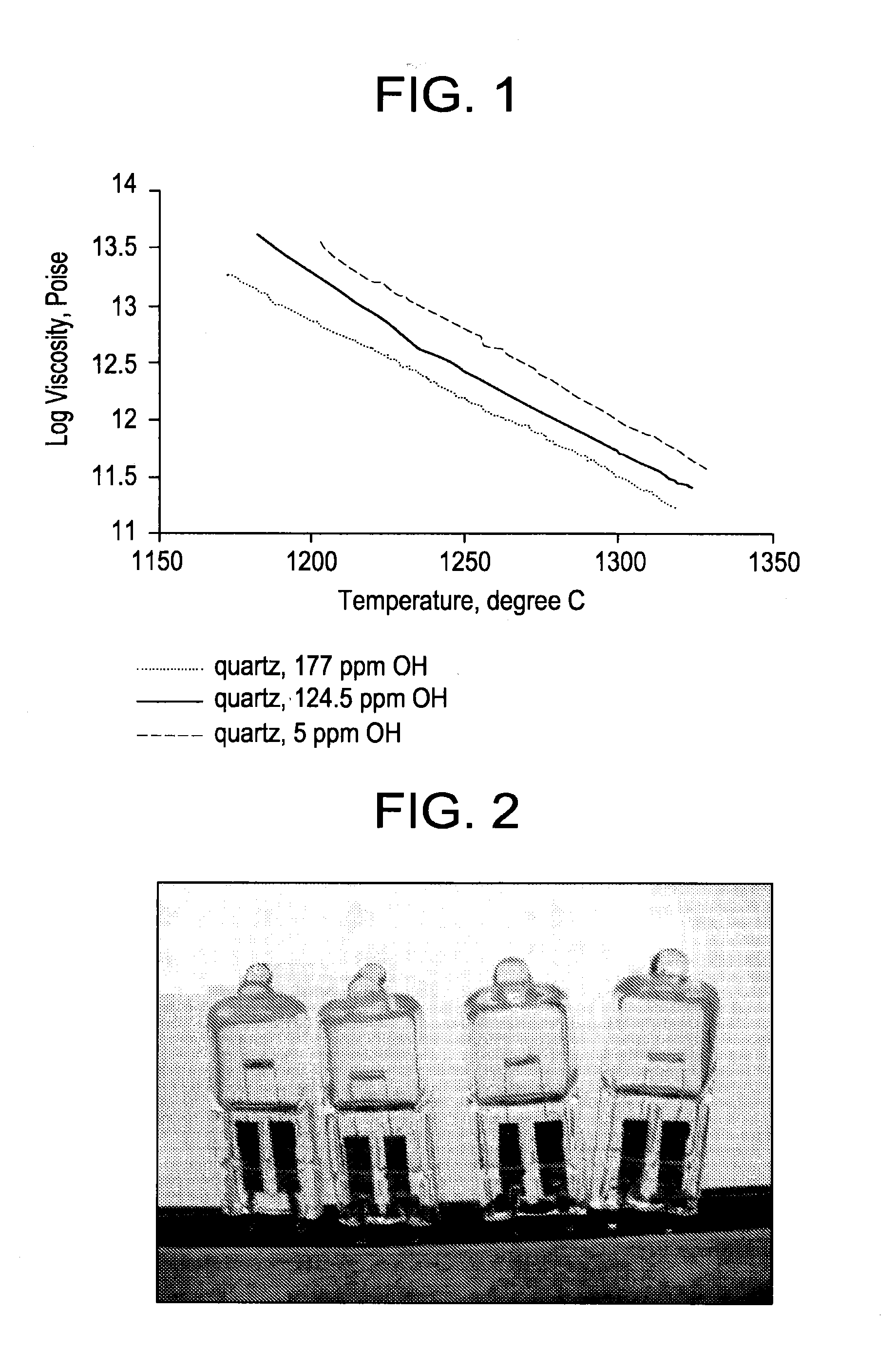

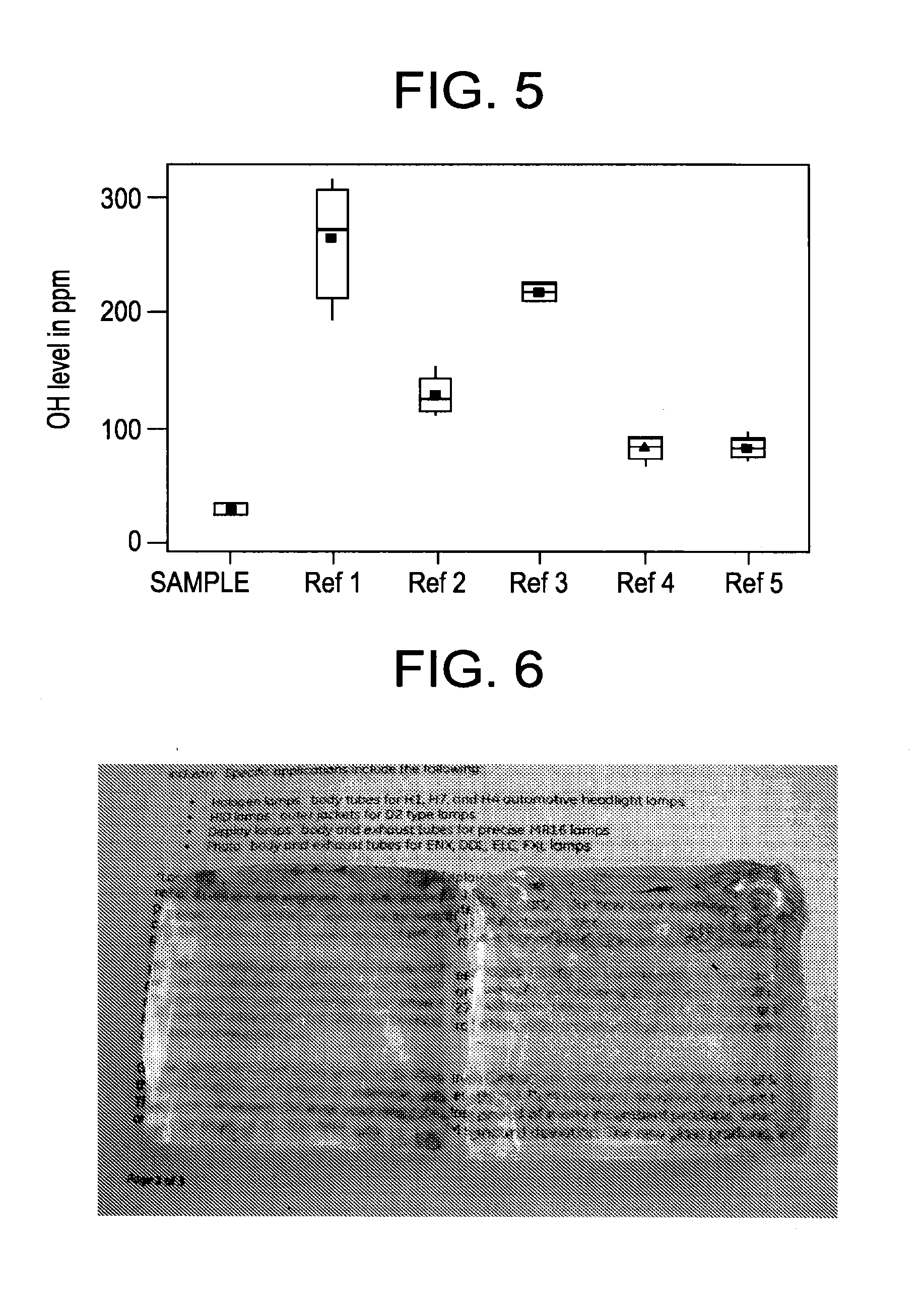

Fused quartz tubing for pharmaceutical packaging

InactiveUS20120148770A1Reduce softeningLow working point temperatureLayered productsPharmaceutical containersRare earthWorking temperature

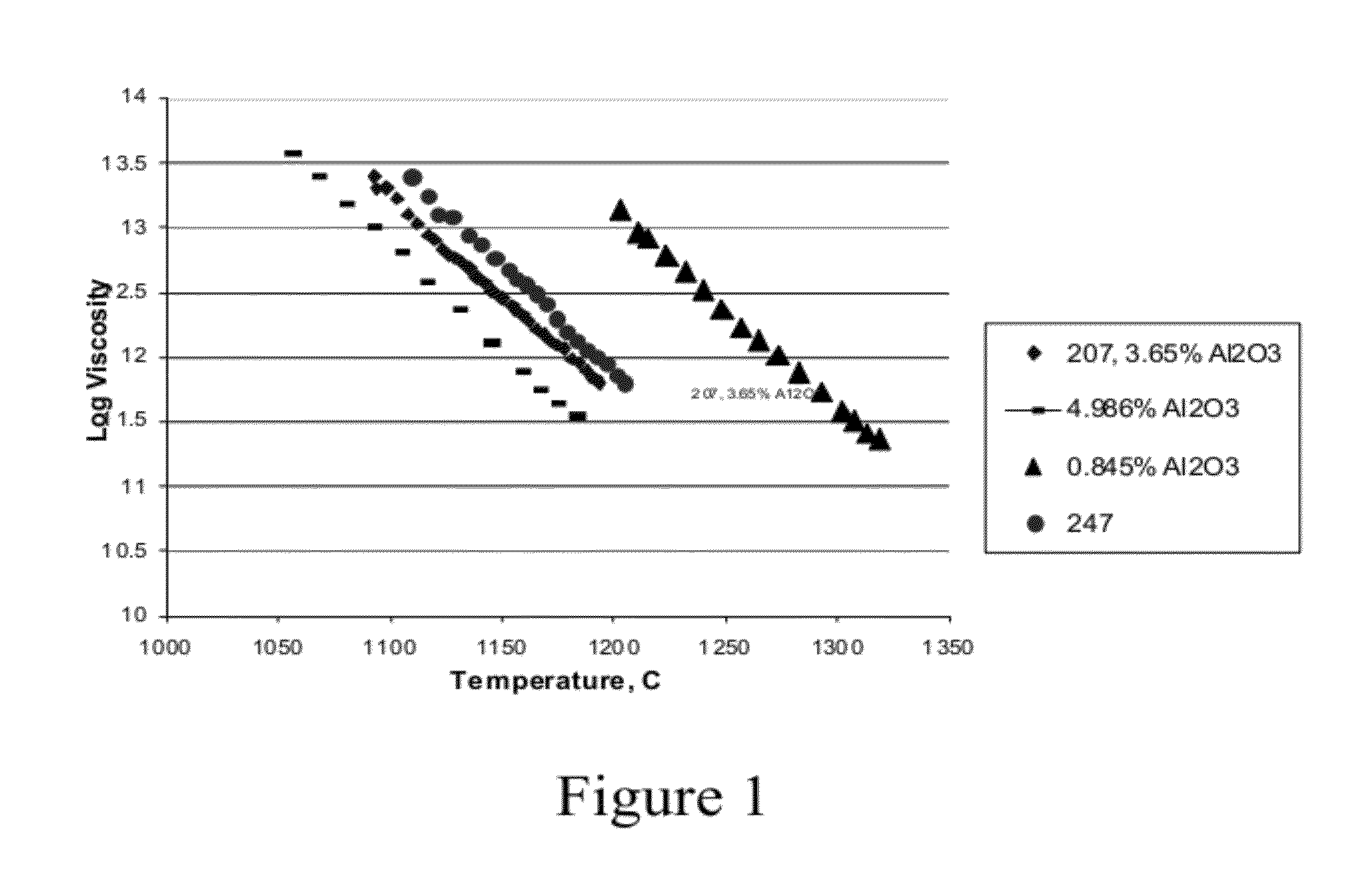

A high silica glass composition comprising about 82 to about 99.9999 wt. % SiO2 and from about 0.0001 to about 18 wt. % of at least one dopant selected from Al2O3, CeO2, TiO2, La2O3, Y2O3, Nd2O3, other rare earth oxides, and mixtures of two or more thereof. The glass composition has a working point temperature ranging from 600 to 2,000° C. These compositions exhibit stability similar to pure fused quartz, but have a moderate working temperature to enable cost effective fabrication of pharmaceutical packages. The glass is particularly useful as a packaging material for pharmaceutical applications, such as, for example pre-filled syringes, ampoules and vials.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Fused quartz tubing for pharmaceutical packaging

ActiveUS20130095261A1Low working point temperatureHigh wt % contentDiagnosticsLayered productsDopantWorking temperature

A high silica glass composition comprising about 92 to about 99.9999 wt. % SiO2 and from about 0.0001 to about 8 wt. % of at least one dopant selected from Al2O3, CeO2, TiO2, La2O3, Y2O3, Nd2O3, other rare earth oxides, and mixtures of two or more thereof. The glass composition has a working point temperature ranging from 600 to 2,000° C. These compositions exhibit stability similar to pure fused quartz, but have a moderate working temperature to enable cost effective fabrication of pharmaceutical packages. The glass is particularly useful as a packaging material for pharmaceutical applications, such as, for example pre-filled syringes, ampoules and vials.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

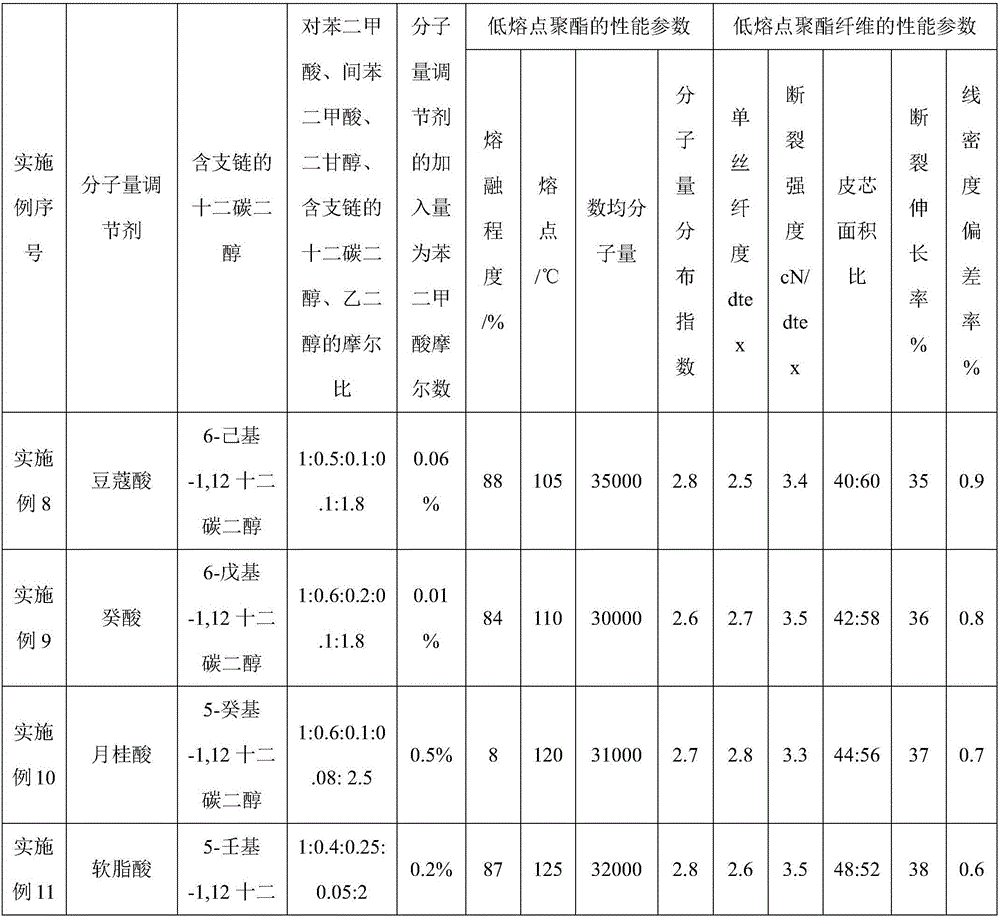

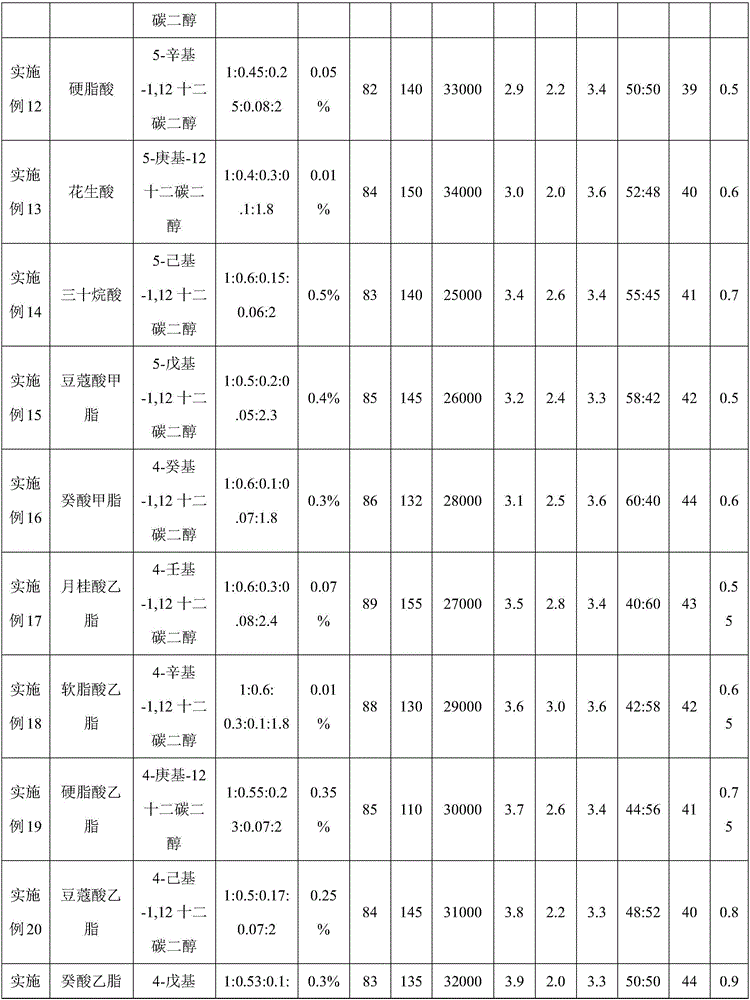

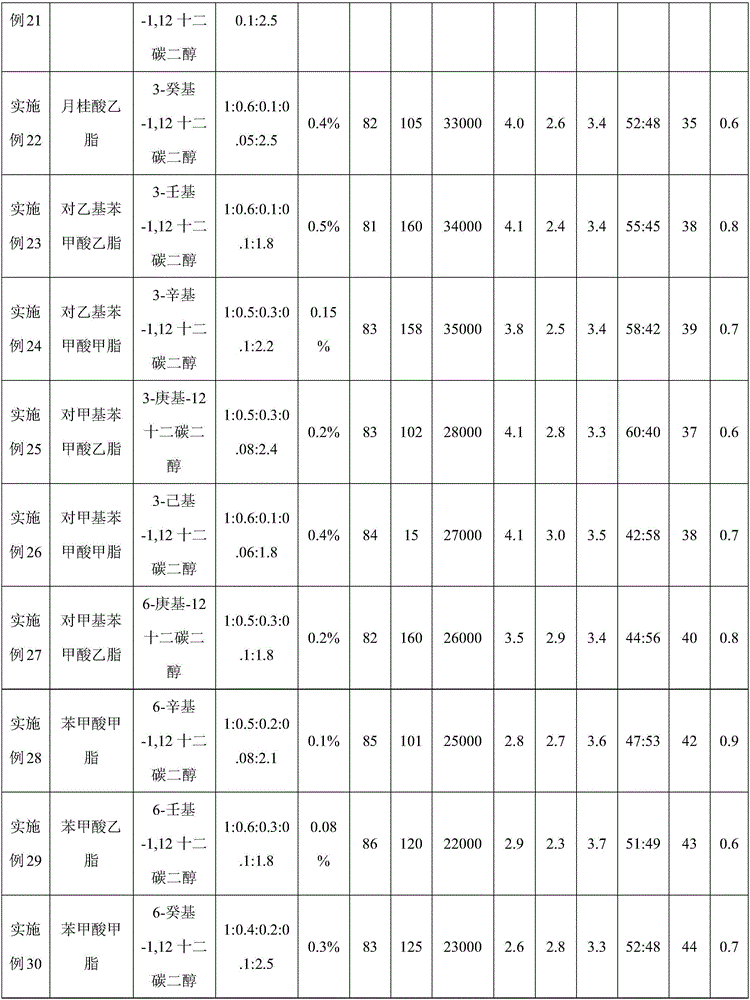

Filament low-melting-point polyester fiber and preparation method thereof

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

Method for preparing absorbing layer of thin film solar cell

InactiveCN101728461AReduce the temperatureReduce softeningFinal product manufactureSemiconductor devicesIndiumNew energy

The invention relates to a method for preparing an absorbing layer of a thin film solar cell, belonging to the technical fields of photoelectric functional material and new energy. The method is characterized in that a Cu-In-Se absorbing layer, a Cu-In-Ga-Se absorbing layer or a Cu-In-Al-Se absorbing layer is prepared by a vacuum magnetron sputtering method; a Cu-In-Se alloy target, a Cu-In-Ga-Se alloy target or a Cu-In-Al-Se alloy target is directly used, and the components of the absorbing layer are controlled by the components of the target; and the film formation quality is controlled by the sputtering technology. The absorbing layer prepared by the magnetron sputtering method can be subsequently treated by annealing in the protection atmosphere, so that the crystallization quality is further improved. The absorbing layer prepared by the method is formed by uniform Cu-In-Se phase, Cu-In-Ga-Se phase or Cu-In-Al-Se phase, so that the component distribution is even, and the components of the absorbing layer are consistent with the components of the target. The method is simple and convenient in technique, easy to control and lower in matrix temperature when in deposition, can select multiple substrates, and ids suitable for industrialized production.

Owner:TSINGHUA UNIV +1

Deep-cycle-resistant lead-acid storage battery anode lead paste formula and preparation process thereof

The invention relates to a deep-cycle-resistant lead-acid storage battery anode lead paste formula which comprises the following components by the weight percentage: 70-90% of a lead powder, 3-15% of sulfuric acid, 3.9-10% of water, 0.05-2% of short fibers, 0.1-0.4% of colloidal graphite, 0.1-0.5% of tetra-basic lead sulfate, 0.1-1.5% of a silica emulsion, and 0.1-5% of a polytetrafluoroethylene emulsion, wherein the particle size of tetra-basic lead sulfate particles is 10-120 nm. A structure of active substances in charge and discharge processes is ensured by adding the polytetrafluoroethylene emulsion; through adding the silica emulsion in a lead paste, silica forms a network structure on the surface of the lead paste, so that lead paste crystals are protected, and the active substance softening and shedding caused by volume expansion and contraction in the charge and discharge processes are reduced; and through adding 4BS in the lead paste, 4BS plays a seed crystal role in the lead paste, and at the same time, with use of the processes of high temperature and paste, a large amount of 4BS crystals are promoted to exist in the lead paste, so as to increase the battery cycle service life.

Owner:CHAOWEI POWER CO LTD

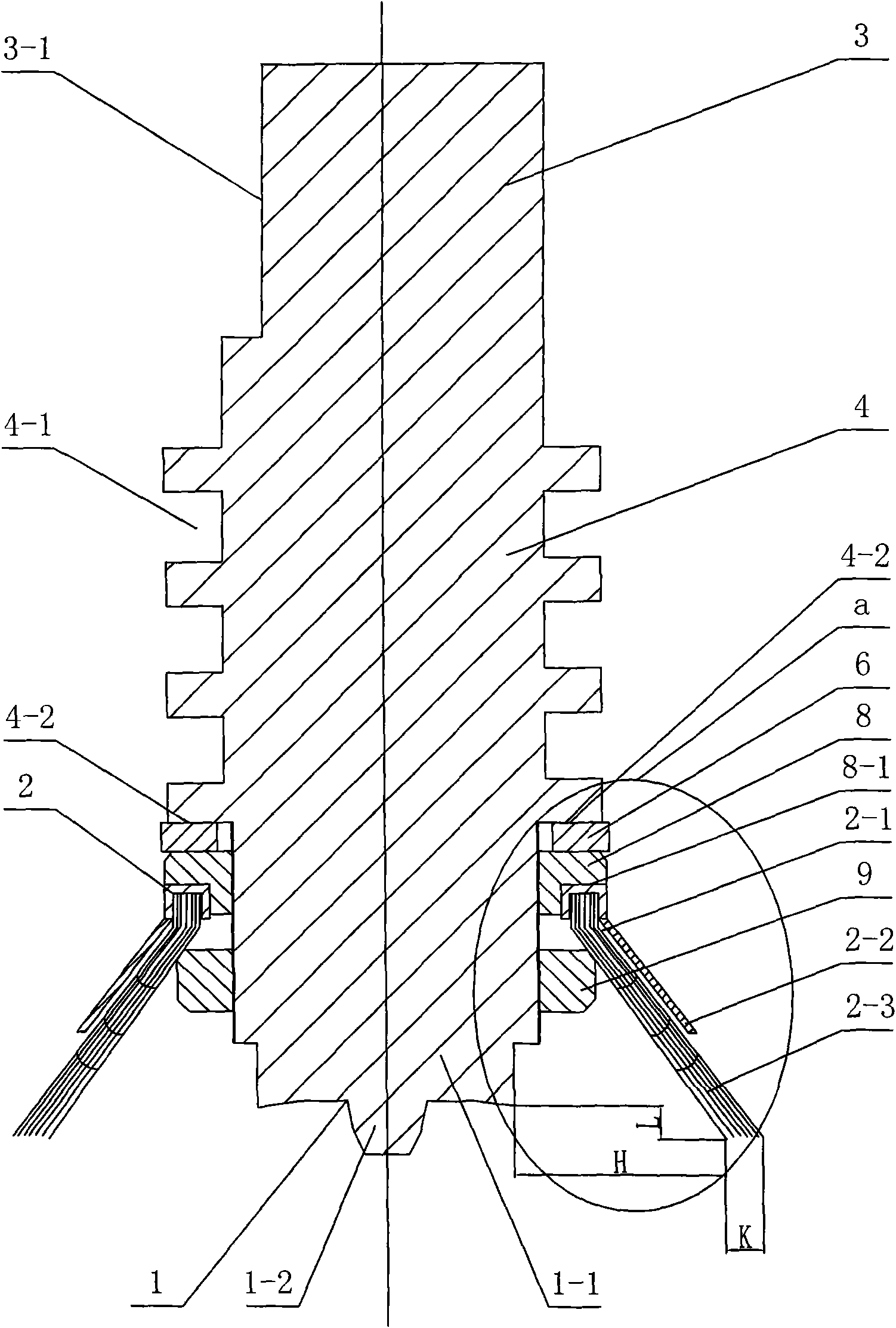

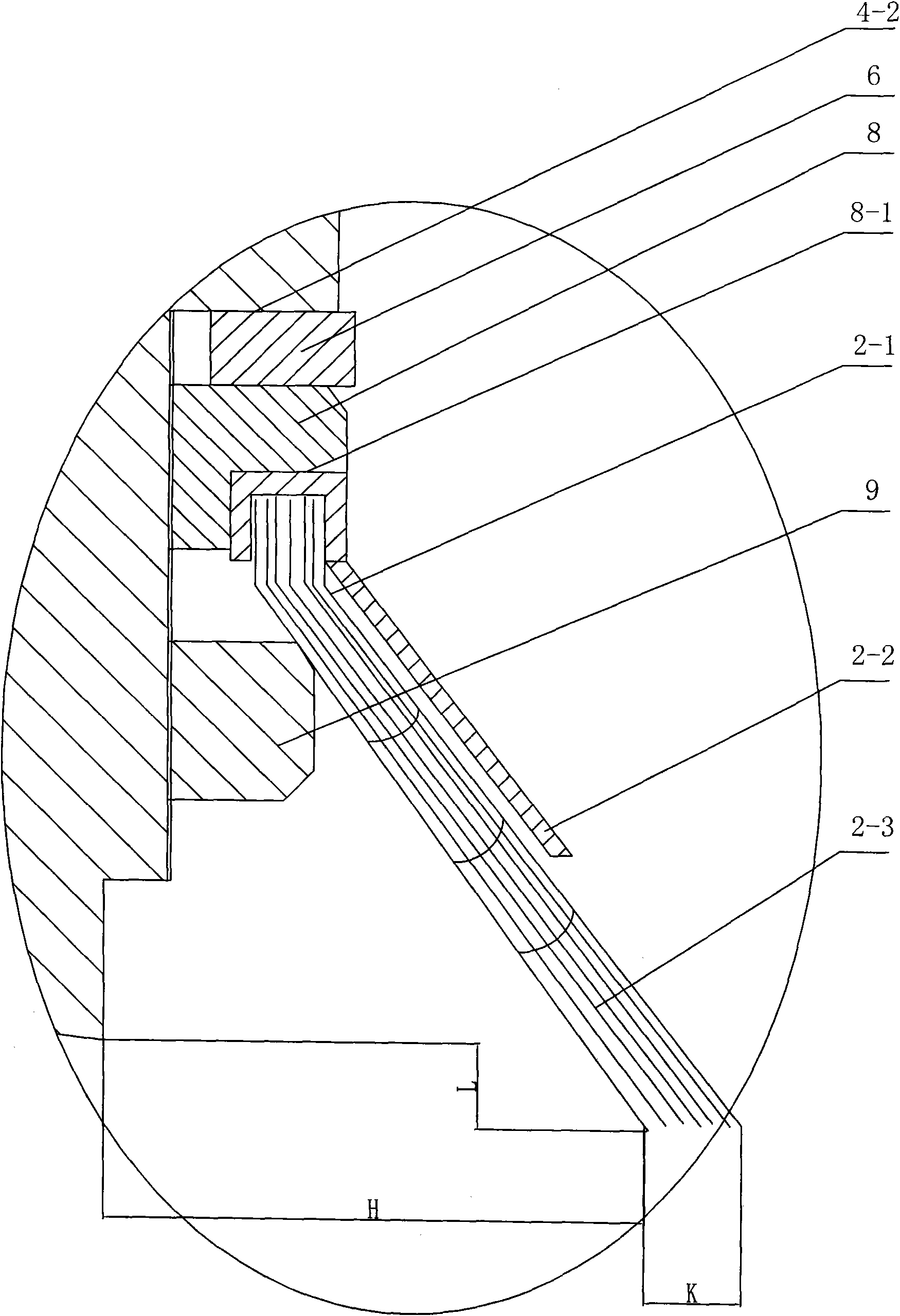

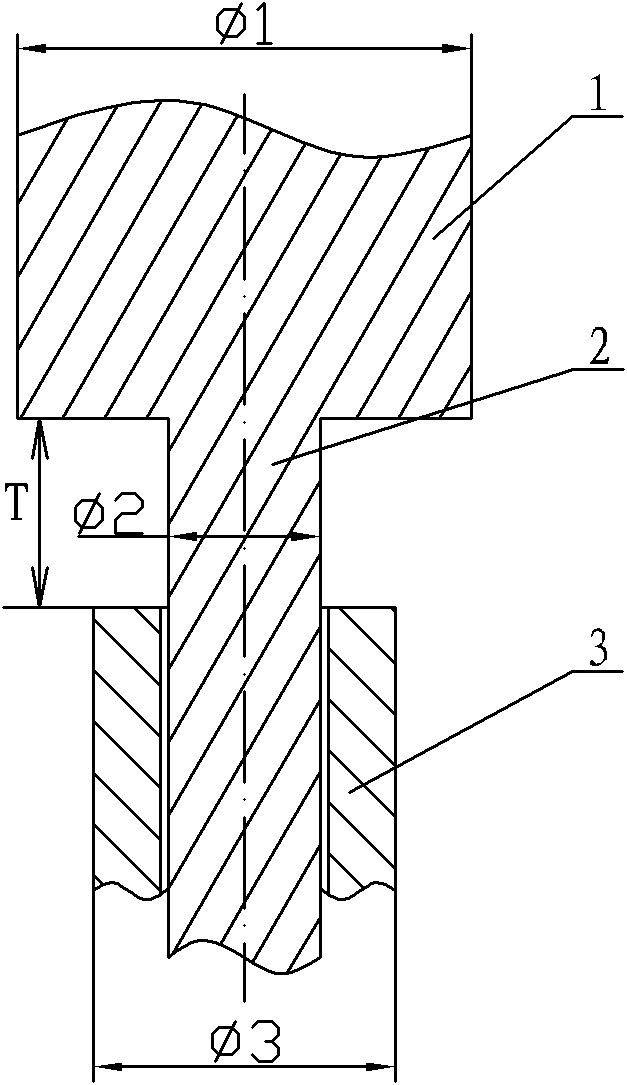

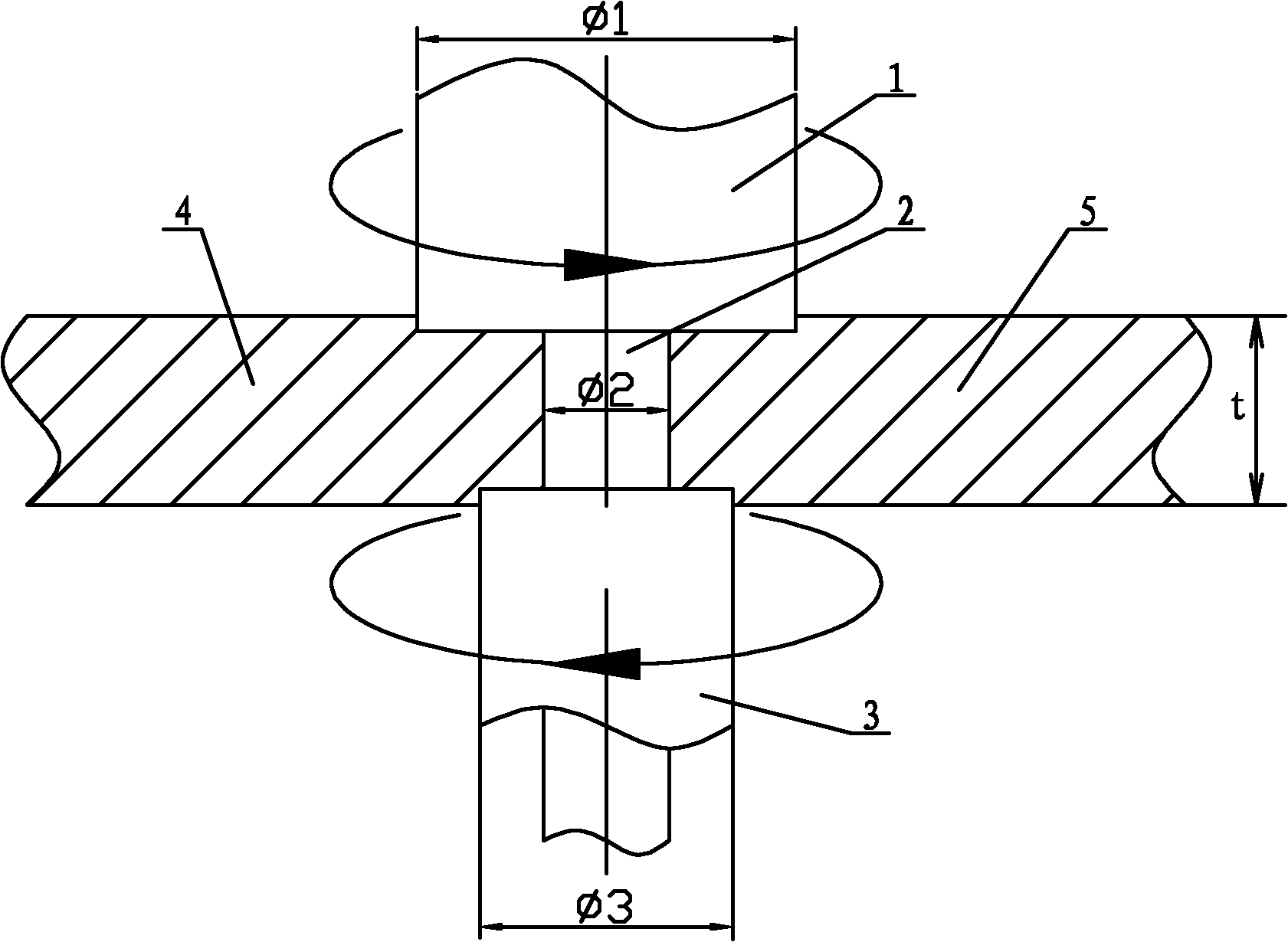

Pin tool suitable for local dry-type friction stir welding in water environment

InactiveCN101554681AAvoid enteringEntry will not happenNon-electric welding apparatusFriction weldingDecomposition

A pin tool suitable for local dry-type friction stir welding in water environment relates to a pin tool of friction stir welding. The invention solves the problems that the existing pin tool of friction stir welding is not applicable to the local dry-type welding in water environment; as underwater welding needs complicated supporting equipment and technical conditions, the difficulty of implementation is comparatively large; and the stability of an electric arc and drop transfer is poor and the decomposition of water at the high temperature of the electric arc can lead to seam hydrogenation so as to cause the deterioration of joint performance. A fitting nut is connected with the upper thread of a shaft shoulder and a positioning backing ring is arranged between the upper end face of the fitting nut and the end face of a shoulder. A U-shaped steel wire brush holder is fixedly installed on the shoulder. The upper ends of a plurality of stainless steel tendons are fixedly installed in the U-shaped steel wire bush holder and an inverted funnel-shaped shade covers the outside of the steel wire brush. The pin tool overcomes the defects of the existing pin tool of friction stir welding in welding under water environment, satisfies the requirements of local dry-type welding under water environment and also boosts the performance of joints.

Owner:HARBIN INST OF TECH

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS8470723B2Reduce softeningAddress electrodesConductive layers on insulating-supportsBismuthAntimony

Owner:RESONAC CORP

Preparation method of lead crystal carbon storage battery

InactiveCN106207279AImprove cycle lifeLower internal resistanceCell electrodesFinal product manufactureIonStrong acids

The invention relates to a preparation method of a lead crystal carbon storage battery. A composite carbon material with high specific surface area is added to a negative plate of the battery, so that the battery provided by the invention has long cycle life and excellent high current charge-discharge capability. A weak acid electrolyte is introduced into the assembled battery, so that, compared with the battery employing a strong acid electrolyte in the prior art, the battery provided by the invention is low in internal resistance; the hydrogen evolution over-potential is improved; the hydrogen evolution problem is effectively solved. Due to the characteristic that the formed electrolyte is in a crystalline state, active materials can be firmly fixed; an enough space is provided for motion of ions; the disadvantages of sulfation of a negative electrode of the lead-acid storage battery, corrosion of a positive grid, active material dropping and the like are effectively overcome; the service lifetime of the battery is greatly prolonged; meanwhile, the formed electrolyte in the crystalline state does not generate acid vapor in the charging process, does not generate a leakage phenomenon and is environment-friendly and safe; and the battery has excellent low temperature resistance.

Owner:宁波中科孚奇能源科技有限公司

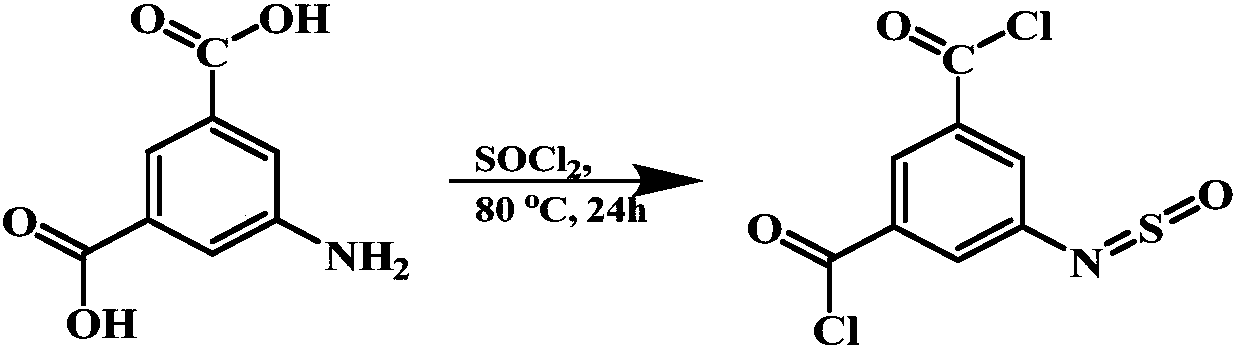

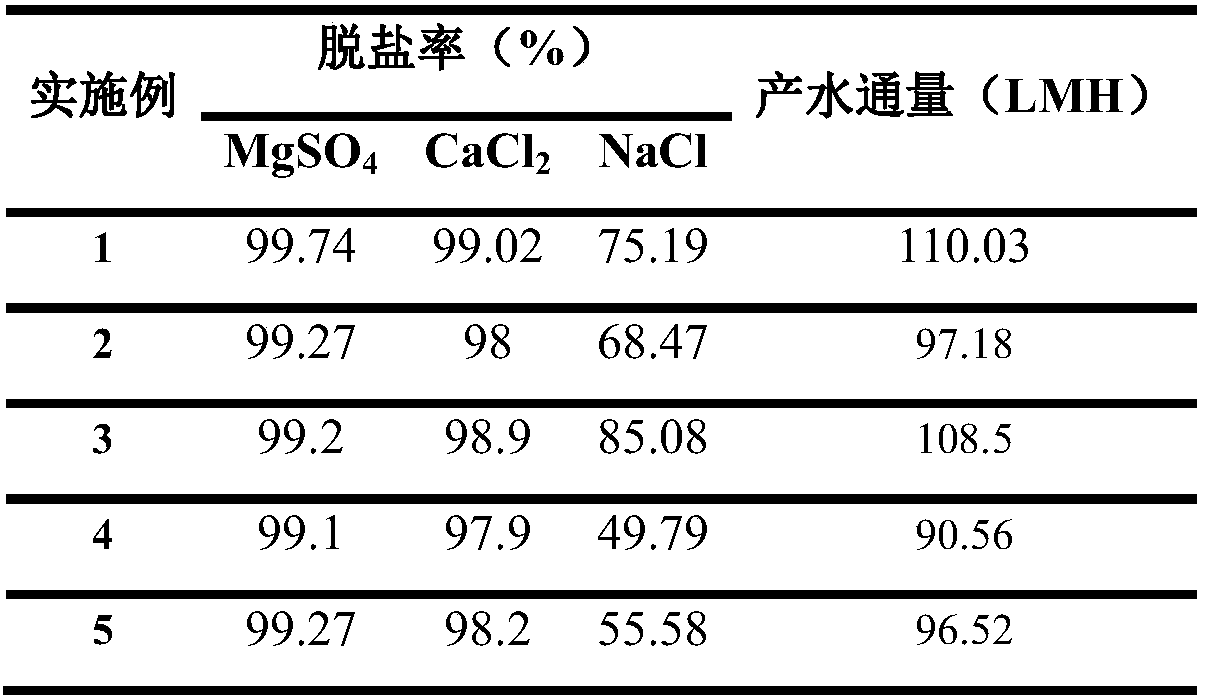

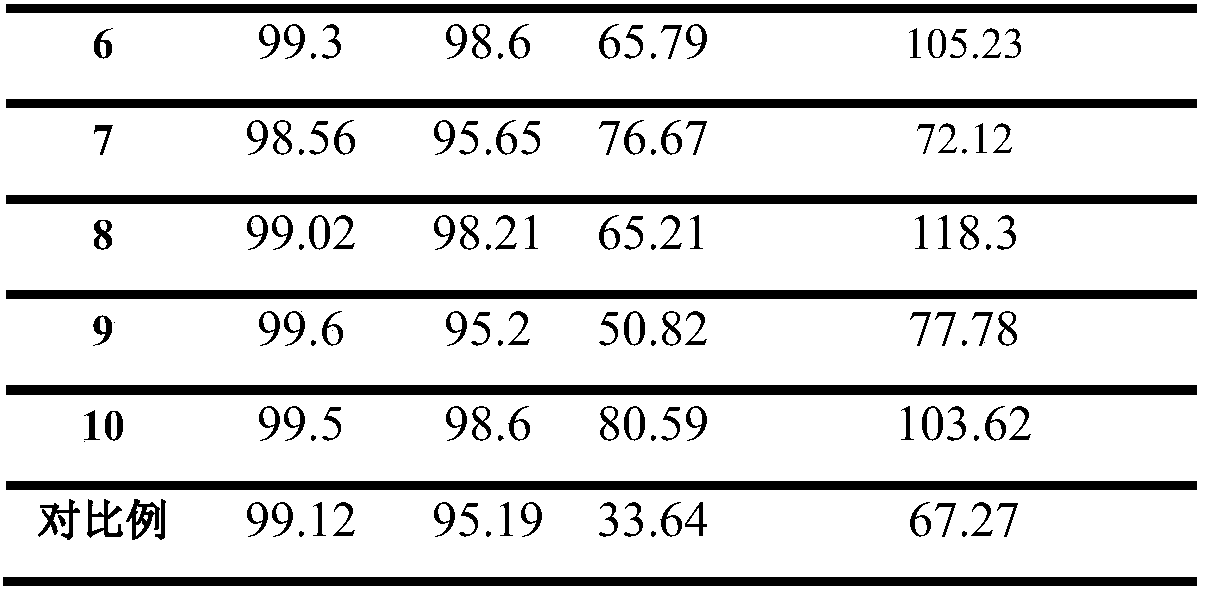

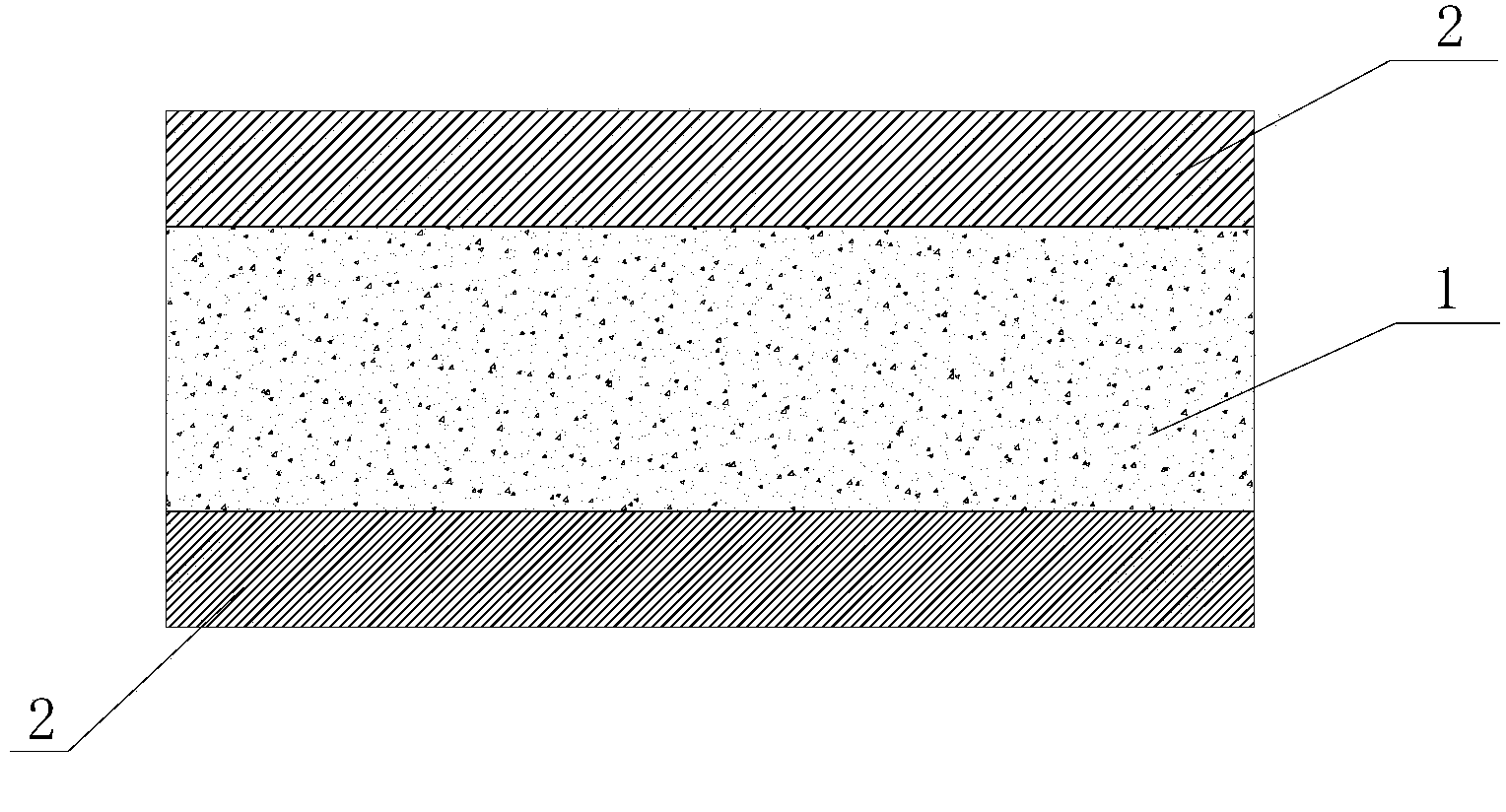

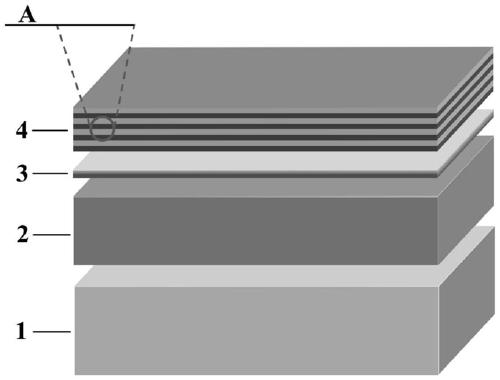

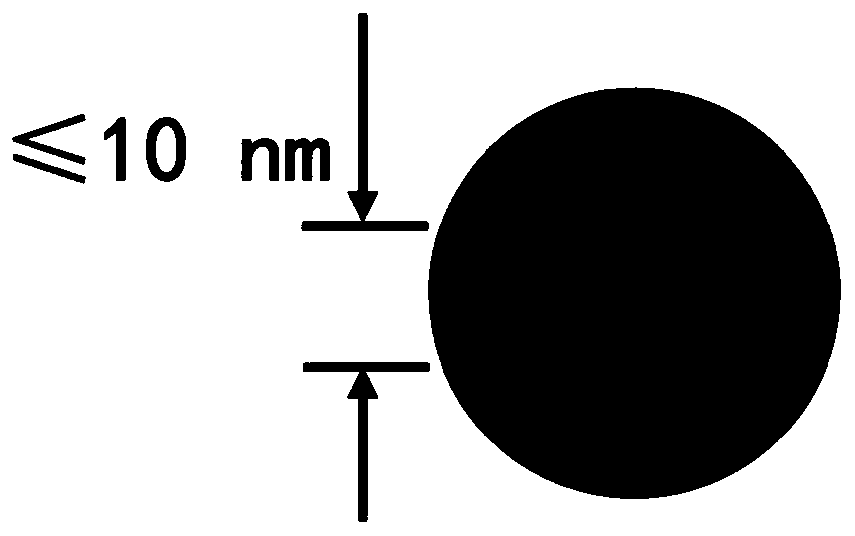

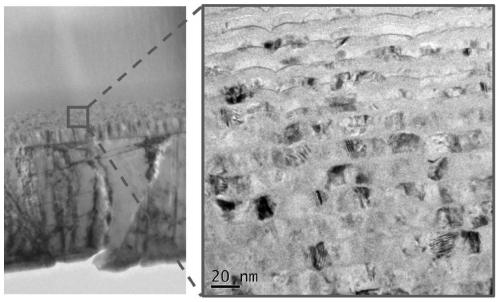

High-throughput polyamide nanofiltration composite membrane and preparation method thereof

InactiveCN108187512ALow operating pressureImprove throughputSemi-permeable membranesWater desalinationChemical oxygen demand

The invention discloses a high-throughput polyamide nanofiltration composite membrane and a preparation method thereof, which belong to the field of polymeric membrane materials. The composite membrane is prepared by the interfacial polymerization reaction between 5-(N-sulfonamido)isophthaloyl dichloride or a mixture of 5-(N-sulfonamido)isophthaloyl dichloride and 1,3,5-trimesoyl chloride and piperazine monomer, and can be widely used in a water softening process for removing bivalent cations such as Ca<2+> and Mg<2+>. The high-throughput polyamide nanofiltration composite membrane is structurally provided with an ultrathin (10nm) release layer, surface charge are low in electronegativity, the membrane surface property is smooth and hydrophilic, high throughput is shown in terms of properties, the high-throughput polyamide nanofiltration composite membrane has an excellent trapping effect on bivalent and polyvalent cations and good pollution resistance, and the high-throughput polyamide nanofiltration composite membrane can be widely applied in high-throughput domestic water purifiers, sea water desalination, brackish water pretreatment, removal of COD (chemical oxygen demand) suchas dye molecules and phenol molecules in wastewater, separation of dye / salt and material separation and concentration processes in pharmaceutical and food industries.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Aluminium alloy composite foil and preparation method thereof

The invention discloses an aluminium alloy composite foil and a preparation method thereof. The foil comprises a core material and a peel material coating the core material, wherein the core material of the peel material is 3003 aluminium alloy. The peel material comprises the following components in percentage by weight: 8.0-9.0% of Si, 1-2% of Cu, 1-2% of Sn, 0.2-0.5% of Ce, and the balance being Al and inevitable impurities. The aluminium alloy composite foil has the beneficial effects that a composite strip external peel designed by the aluminium alloy composite foil can replace conventional alloy type external peel. The aluminium alloy composite foil is excellent in brazing performance, thus ensuring the processing performance of composite brazing filler metal for brazing under low temperatures and solving the problem that the brazing filler metal is difficult to braze under the low temperatures.

Owner:NANTONG HENGJIN COMPOSITE MATERIALS

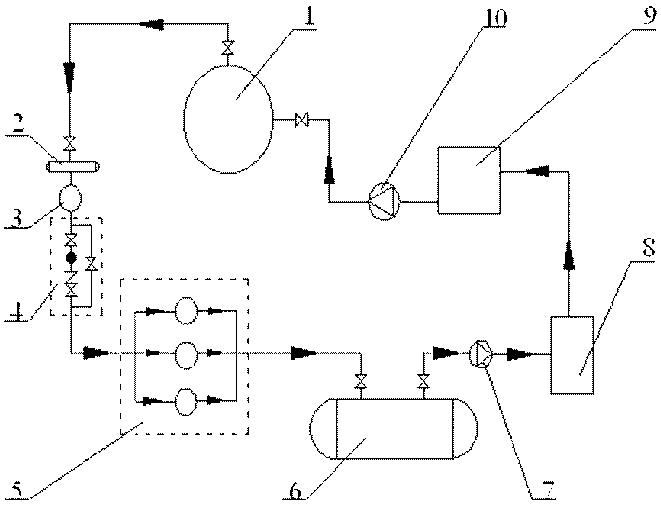

Method for recovering condensation water in production process of gas concrete and recovery system thereof

InactiveCN101700675AScientific and reasonable way of using energyMake full use of waste heatCeramic shaping apparatusRecovery methodUser device

The invention discloses a method for recovering condensation water in the production process of gas concrete. The method comprises the following steps of: firstly, sending the saturated steam produced by a boiler to a still kettle in which gas concrete slabs or blocks are placed, and heating the gas concrete product, wherein the saturated steam is cooled to form the condensation water through the heat exchange; secondly, sending the condensation water drained from the still kettle to a plurality of secondary heating user devices filled with materials, and pre-heating the materials by using the afterheat of the condensation water, wherein the saturated steam is cooled to form the secondary condensation water through the heat exchange; and thirdly, after the secondary condensation water drained from the secondary heating user device satisfies the requirement of boiler water feeding through the purification treatment, sending the secondary condensation water to the boiler of the first step for recycle. By adopting the method, the afterheat resources and water resources discharged from the production process are sufficiently, reasonably and gradually utilized, and the energy and resource consumptions and the production cost of product per unit are reduced.

Owner:TIANJIN UNIV

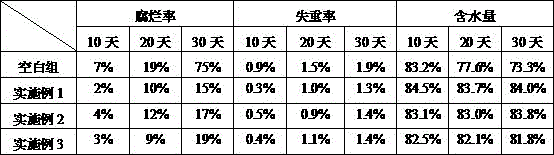

A grape preservative and preparation method thereof

InactiveCN106259873AGuaranteed freshInhibition of respirationAcidic food ingredientsInorganic compound food ingredientsSucroseVitamin C

The invention provides a grape preservative and a preparation method thereof, which belongs to the fruit preservation field. The mentioned grape preservative includes the following ingredients with parts by weight: 0.5-3 parts of cinnamon essential oil, 0.5-2 parts of zanthoxylum bungeanum volatile oil, 0.5-2 parts of sodium alginate, 6-8 parts of sucrose fatty acid ester, 4-6 parts of polysorbate 80, 1-5 parts of propionic acid, 1-4 parts of calcium chloride, 2-4 parts of vitamin C, 2-4 parts of potassium sorbate, 10-20 parts of chitosan citrate solution and 10-20 parts of water. The preparation method comprises the steps of mixing the sodium alginate, sucrose fatty acid ester, polysorbate 80, propionic acid and water and fully dissolving them; then adding the essential oil to get composite essential oils; adding the composite essential oils into the chitosan citrate solution and blending. After picking of grapes, the diseased fruit and bad fruit are removed, the grapes are soaked in the mentioned preservation liquid for 3- 8 min. After taking out the grapes and draining them, the grapes are stored. The grape preservative mentioned in the invention can greatly reduce or delay decrease of quality and decay during storage process of grapes, which has outstanding grape preservation effect.

Owner:滁州嘉实农业科技有限公司

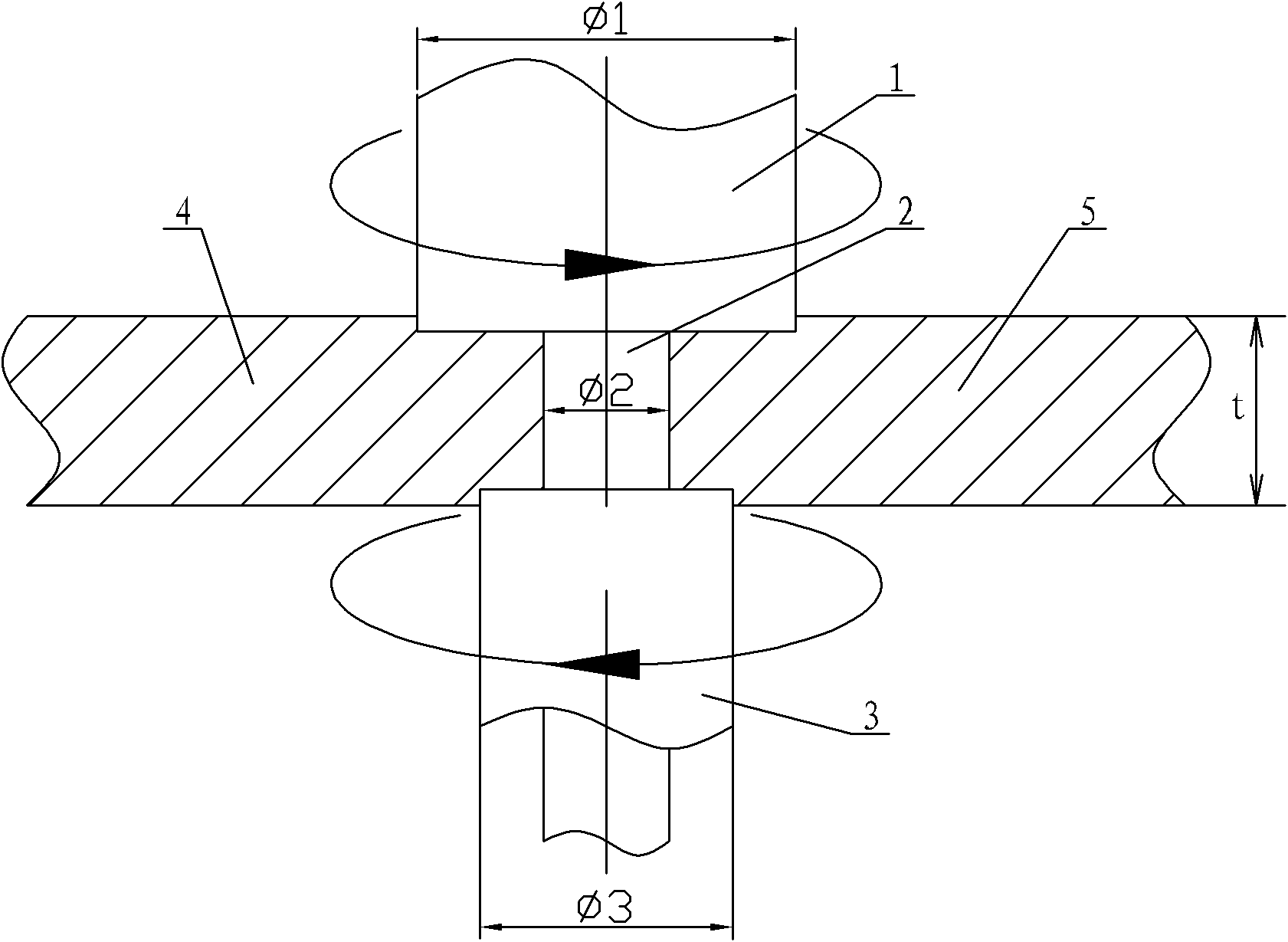

Self-maintained friction stir welding method with reversely rotating upper and lower shaft shoulders

InactiveCN101979209AReduced fracture tendencyReduce torque actionNon-electric welding apparatusEngineeringMechanical engineering

The invention discloses a self-maintained friction stir welding method with reversely rotating upper and lower shaft shoulders, and relates to a self-maintained friction stir welding method to solve the problems that: the upper and lower shaft shoulders have unequal diameters but rotate in the same direction with equal speed, and in the welding process, the weld heat input is large, a workpiece is easy to deform, a mixing needle is inclined to fracture, and the distribution of a weld zone temperature field, a joint structure and residual stress are asymmetric, so that the joint performance is asymmetric, and the bearing capacity of a welding structure is reduced. The method comprises the following steps of: 1, determining the size of a stirring head, namely determining the diameter of the upper shaft shoulder, the stirring needle and the lower shaft shoulder according to the thickness of a first welded workpiece and a second welded workpiece; 2, determining the use length of the stirring needle; 3, fixing the first welded workpiece and the second welded workpiece; 4, positioning the stirring head; and 5, performing friction stir welding on the first welded workpiece and the second welded workpiece, namely integrally forming the upper shaft shoulder and the stirring needle, and allowing the lower shaft shoulder and the upper shaft shoulder to rotate in opposite directions. The self-maintained friction stir welding method is used for self-maintained friction stir welding.

Owner:HARBIN INST OF TECH

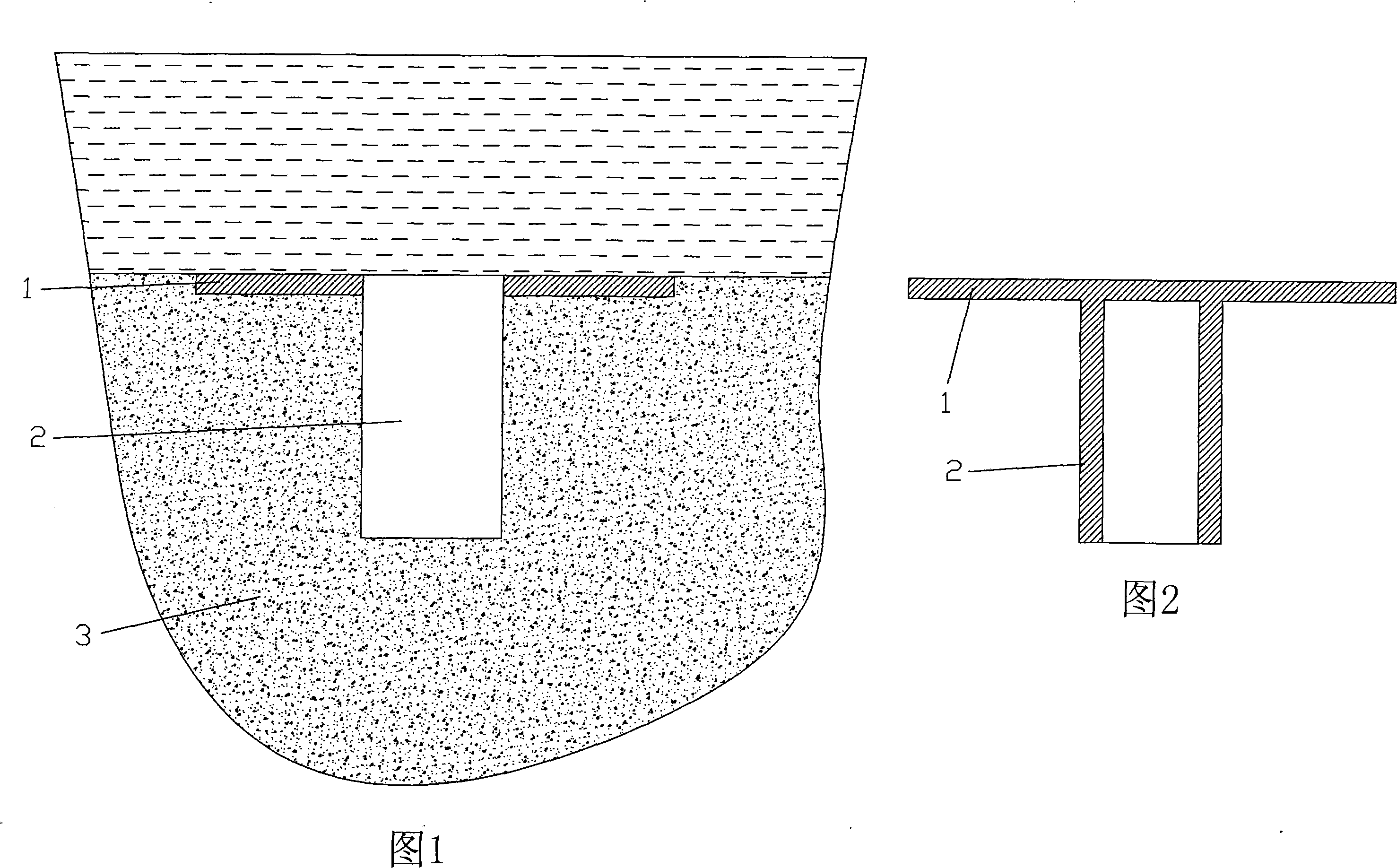

Suction type foundation used on sea-bottom

InactiveCN101158164AReduce softeningGuaranteed stabilityArtificial islandsUnderwater structuresBarrel ShapedStructural engineering

The invention discloses a submarine suction foundation which comprises a barrel shape body. The lateral of the upper end of the barrel shape body is provided with a circular stable disk which is formed into an integrated 'T'-shaped structure together with the barrel shape body. The invention arranges the circular stable disk at the barrel shape body of the suction foundation and presses the stable disk directly onto a soil body surface surrounding the foundation when anchoring the foundation so as to ensure part of the soil body to form an integration more closely with the foundation and to connectively move together with the foundation when the foundation is movably loaded by a horizontal ice force and so on. Therefore, the problems that formerly, as the soil surrounding the barrel foundation gets closer to the barrel foundation, the soil receives bigger disturbance and the softening degree and the liquefaction degree become more and more serious are eliminated; the disturbance brought by the barrel foundation can be more evenly and extensively distributed into the soil surrounding the barrel foundation; the softening degree of the soil body is reduced; the liquefaction of soil mass is eliminated; and thereby the stability of the foundation and the reliability of the anchorage in the submarine soil are guaranteed.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

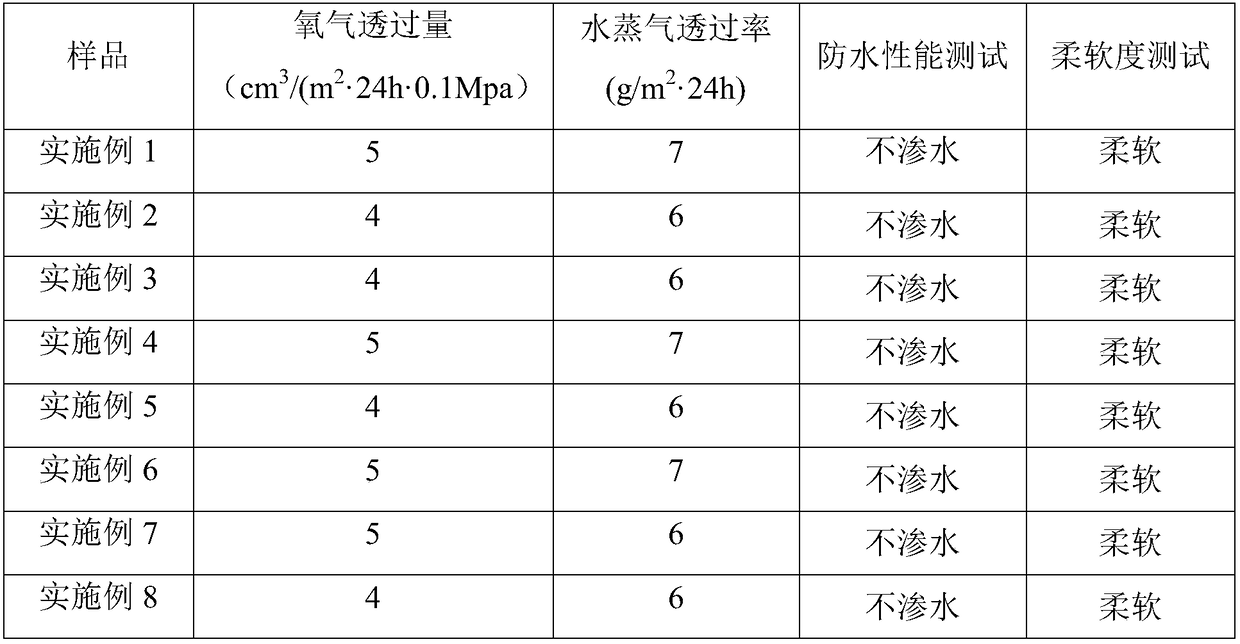

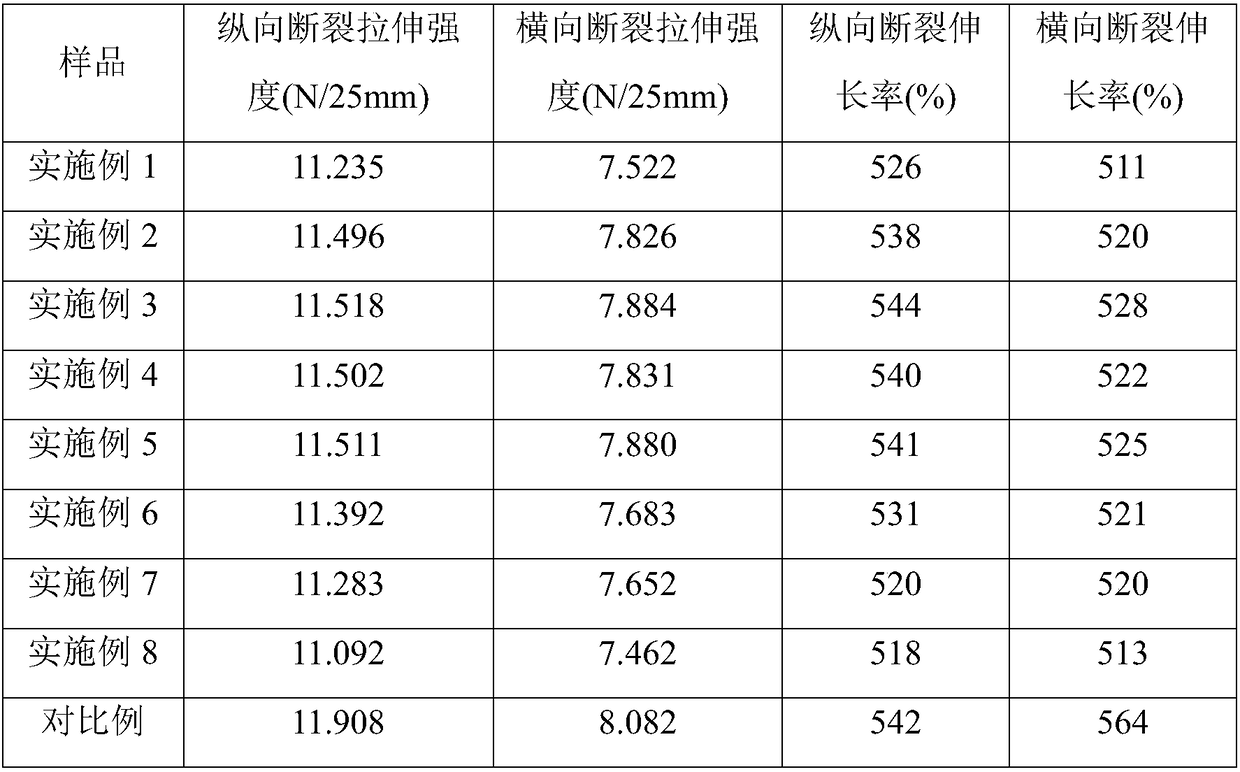

Ultrathin cast film as well as preparation method thereof and application thereof

InactiveCN108129735AImprove water barrier effectEasily brokenFlexible coversWrappersCast filmsMaterials science

The invention discloses an ultrathin cast film. According to the technical scheme, the key point isThe ultrathin cast film is characterized that the ultrathin cast filmby comprises comprising the following components: 7-12 parts of LDPE, 20-25 parts of LLDPE, 30-55 parts of HDPE, 3-5 parts of MLLDPE, 1-3 parts of PP and 5-8 parts of color master batch. The invention further discloses a preparation method for the ultrathin cast film, and the preparation method comprises the following steps: adding materials; performing extrusion plastifying; , extrusion casting, calendaring, setting and cooling; performing corona treatment; and trimming and rolling, wherein during calendaring, setting and cooling, the temperature of a rubber roller is set to be 50-55 DEG C, the temperature of an embossed steel stick is set to be 60-65 DEG C and pulling speed is 60-80 m / min. On the premise of keeping barrier properties, waterproof properties, softness, tensile properties and breakage properties of the cast film, the thickness of the cast film is reduced, the unit weight yield is increased, and the cost is reduced.

Owner:天津市德利塑料制品有限公司

Aluminum matrix composite plate rolling method

ActiveCN106424196AImprove performanceImprove billet structureTemperature control deviceMetal rolling arrangementsHigh intensityLarge deformation

The invention discloses an aluminum matrix composite plate rolling method and belongs to the field of metal matrix composite molding machining. According to the method, on the basis that the density of a composite billet used for rolling is regulated, a plate blank is manufactured through multidirectional free forging and extruding, and the thickness of a rolled plate is 1-150 mm; sectional temperature rolling is adopted, cogging and reversing rolling are both conducted in a recrystallization temperature region so as to avoid detects generated in subsequent rolling, the rest of passes are subjected to large deformation rolling at a dynamic recovery temperature, and the rolling efficiency is improved; the regions of the rolling temperature and the rolling speed are narrowed so that organization can be precisely controlled and detects can be avoided; and medium and low temperature finish rolling is adopted so as to ensure the plate performance. In this way, the manufactured aluminum matrix composite plate has high strength and good corrosion resistance and fatigue resistance, and efficient rolling of large-size plates can be achieved.

Owner:中科复材(滨州)新材料有限公司

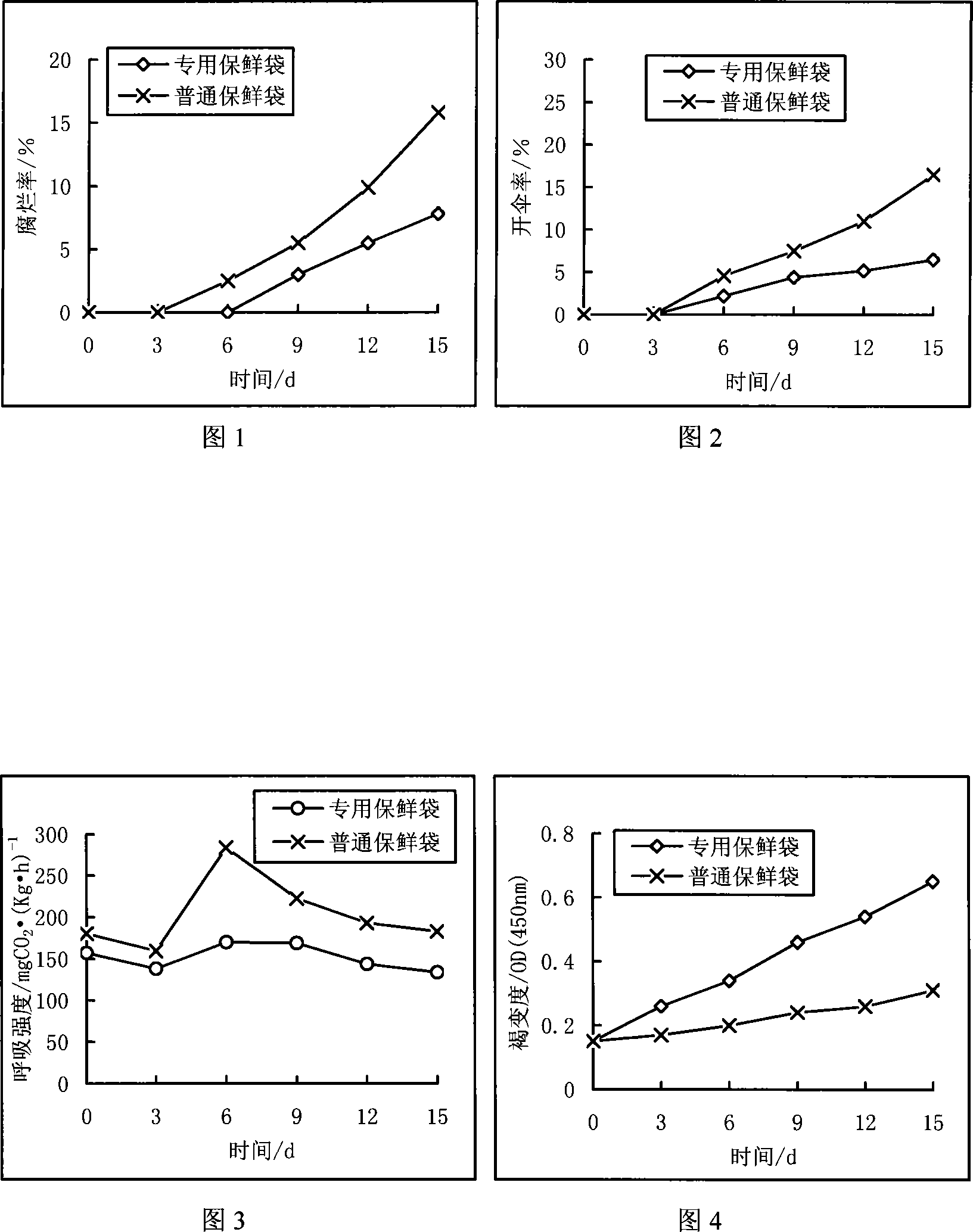

Fresh-keeping bag specially for white mushroom

InactiveCN101228900AInhibition of respirationReduce concentrationFruits/vegetable preservation by coatingMicro environmentBletting

The invention discloses a specialized membrane bag for white mushroom, which belongs to a field of fruit and vegetable preserving technology. The components and the weight proportion of each component are as follows: 100 shares of LDPE, 2-4 shares of SiO2, 8-12 shares of SBS, 13-15 shares of EVA, 0.6-0.8 shares of polyethylene glycol, 0.4-0.7 shares of glycerin monostearate, 1.2-1.6 shares of calcium phosphate, 1.5-2.5 shares of zeolite and 0.4-0.6 shares of paraffin. The bag is characterized in that the bag has good gas-selective permeability, can create a gaseous micro-environment suitable for white mushroom storage, and at the same time avoids the condensation phenomenon in the membrane bag , timely absorbs the ethylene, etc., ripening gas produced in the process of white mushroom storage, thus effectively inhibiting the respiration of the white mushroom, reducing the occurrence of browning, bletting and spoilage etc., so as to prolonging the white mushroom storage period and keep the good quality thereof. The bag can be popularized for application in the field of white mushroom storage and preservation.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

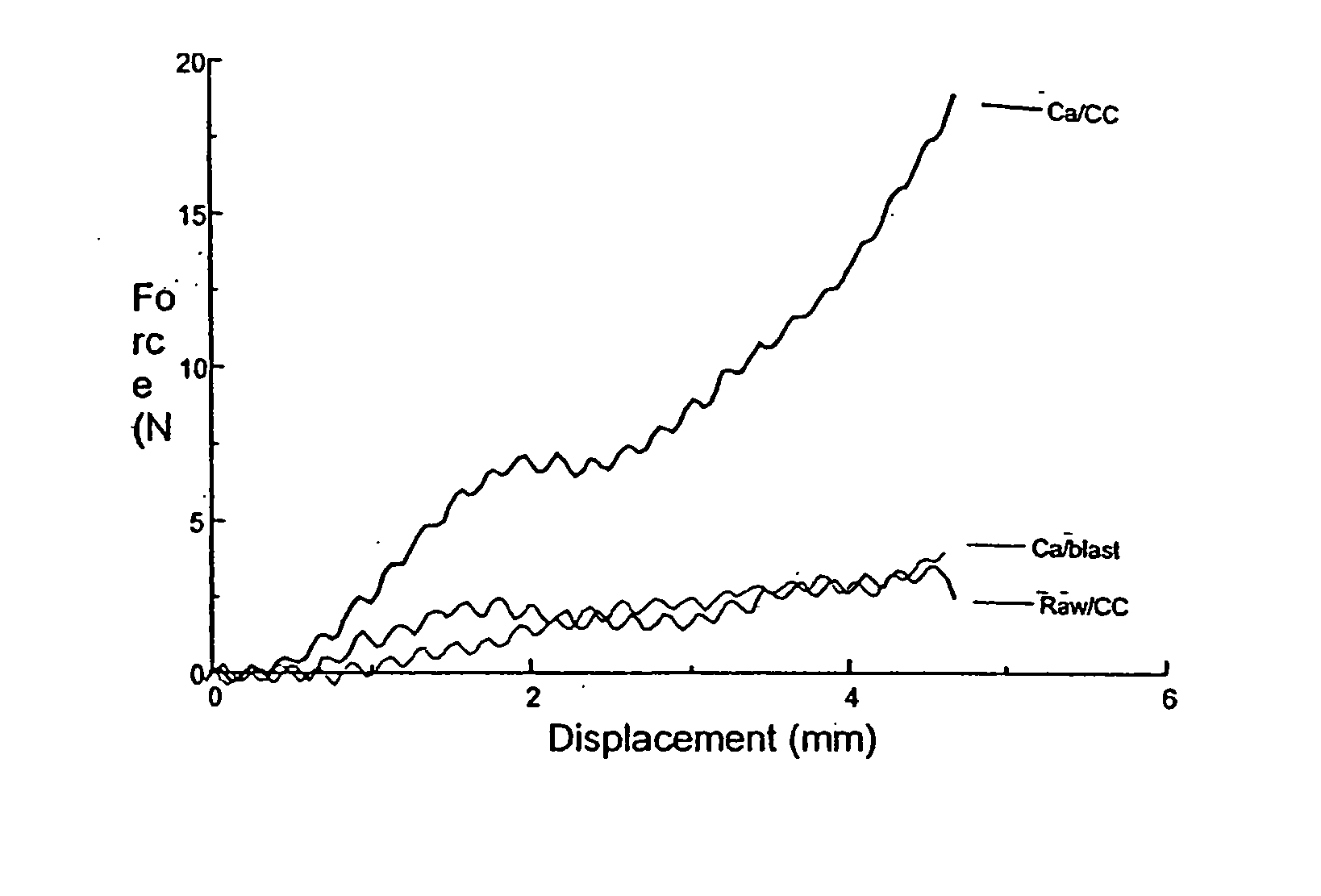

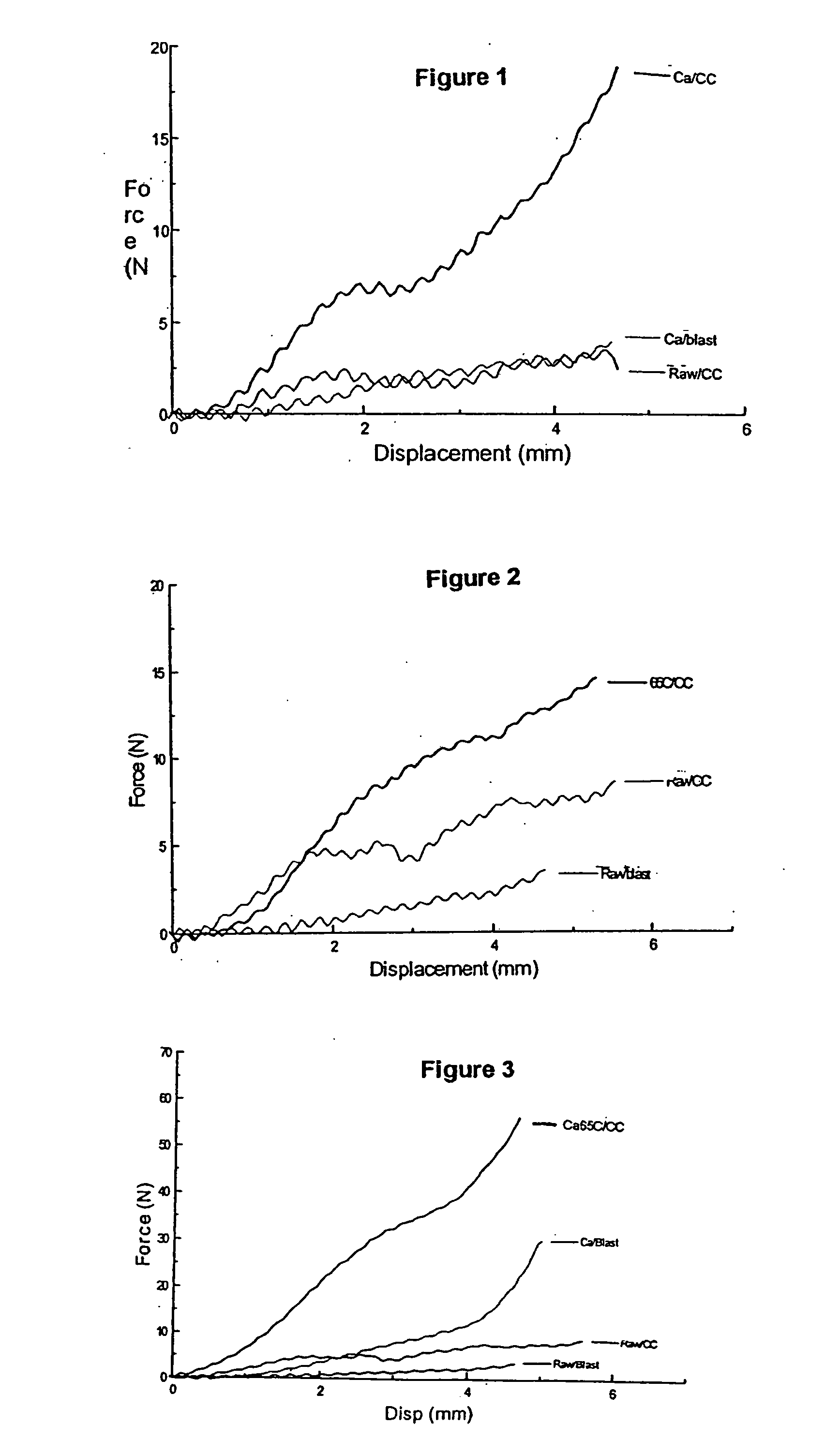

Freezing vegetables

InactiveUS20040065094A1Limit softeningQuality improvementLighting and heating apparatusCooling fluid circulationCore temperatureFrozen vegetables

A process for the production of a frozen vegetable or part thereof, wherein said process comprises the steps: (i) subjecting a vegetable or part thereof to a firming treatment selected from: a) immersing the vegetable or part thereof in a solution of a calcium salt. b) heating the vegetable or part thereof to a temperature in the range 50 to 70° C., and c) a combination of a) and b); (ii) under-cooling to a core temperature of less than or equal to -5° C.; (iii) reducing the temperature to less than or equal to -18° C. The frozen vegetables, when thawed, possess a texture and appearance which closely resembles that of fresh vegetables.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

Image forming apparatus and image forming method

InactiveUS20130044170A1Reduce softeningSuppress rippleDuplicating/marking methodsOther printing apparatusEngineeringMechanical engineering

The image forming apparatus of the present invention includes an image forming member that jets liquid droplets onto a recording medium and forms an image on a front face of the recording medium, a tension imparting member that induces tension of 100N / m to 1000N / m in the recording medium image-formed on the recording medium front face by the image forming member, and a drying member that dries the image formed on the front face of the recording medium when tension induced in the recording medium by the tension imparting member to a residual moisture level of 3 g / m2 or less in the recording medium.

Owner:FUJIFILM CORP

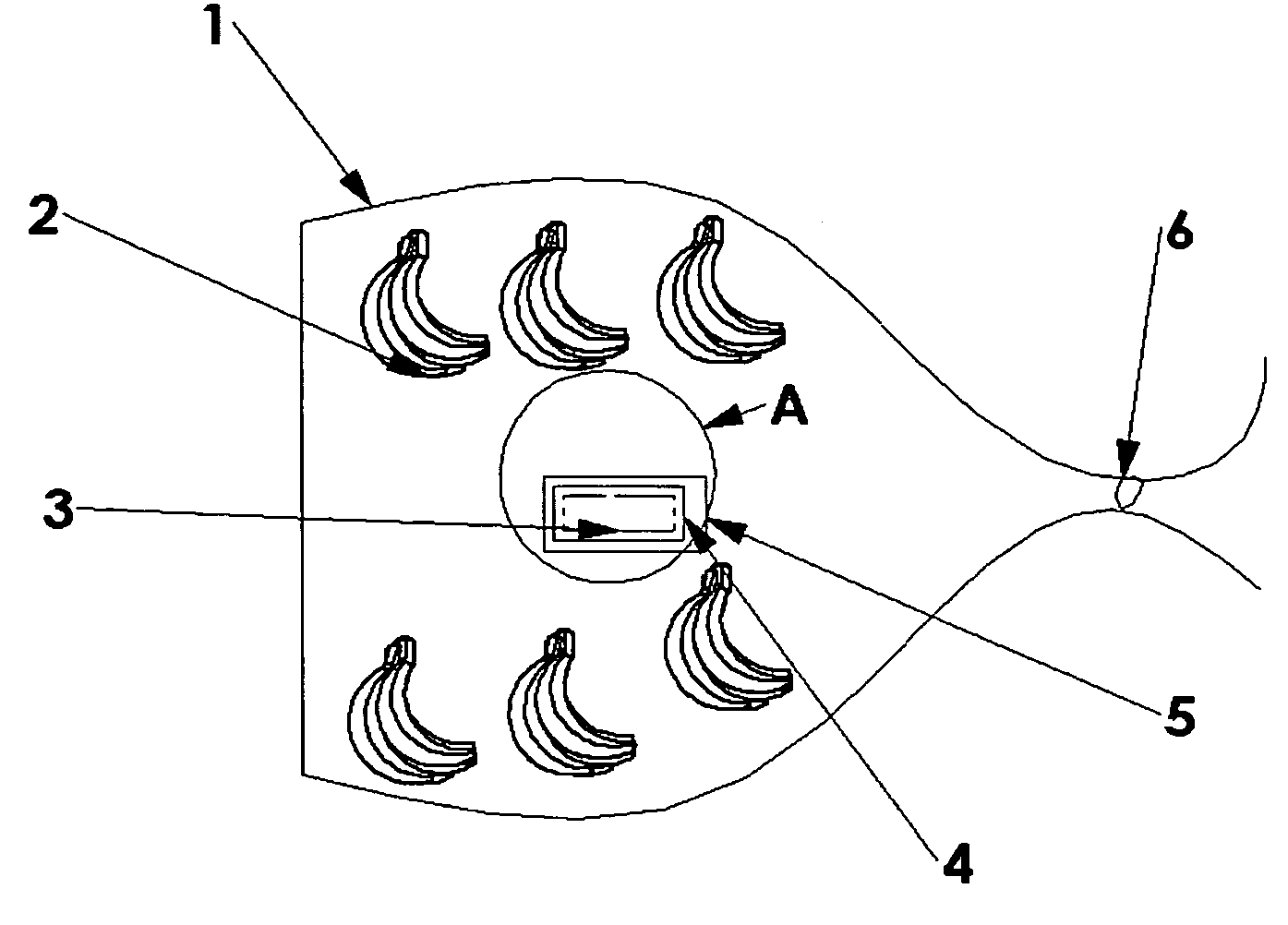

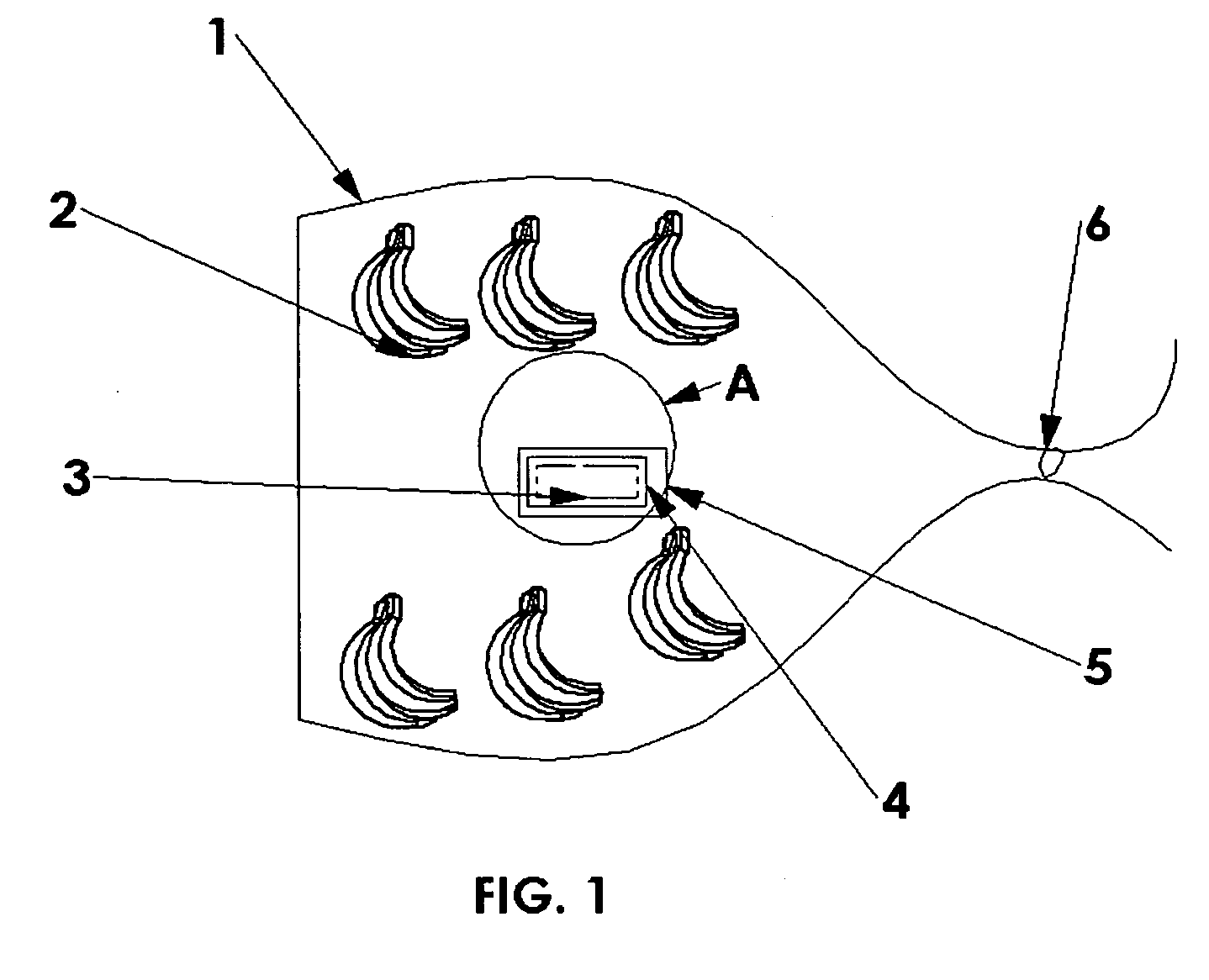

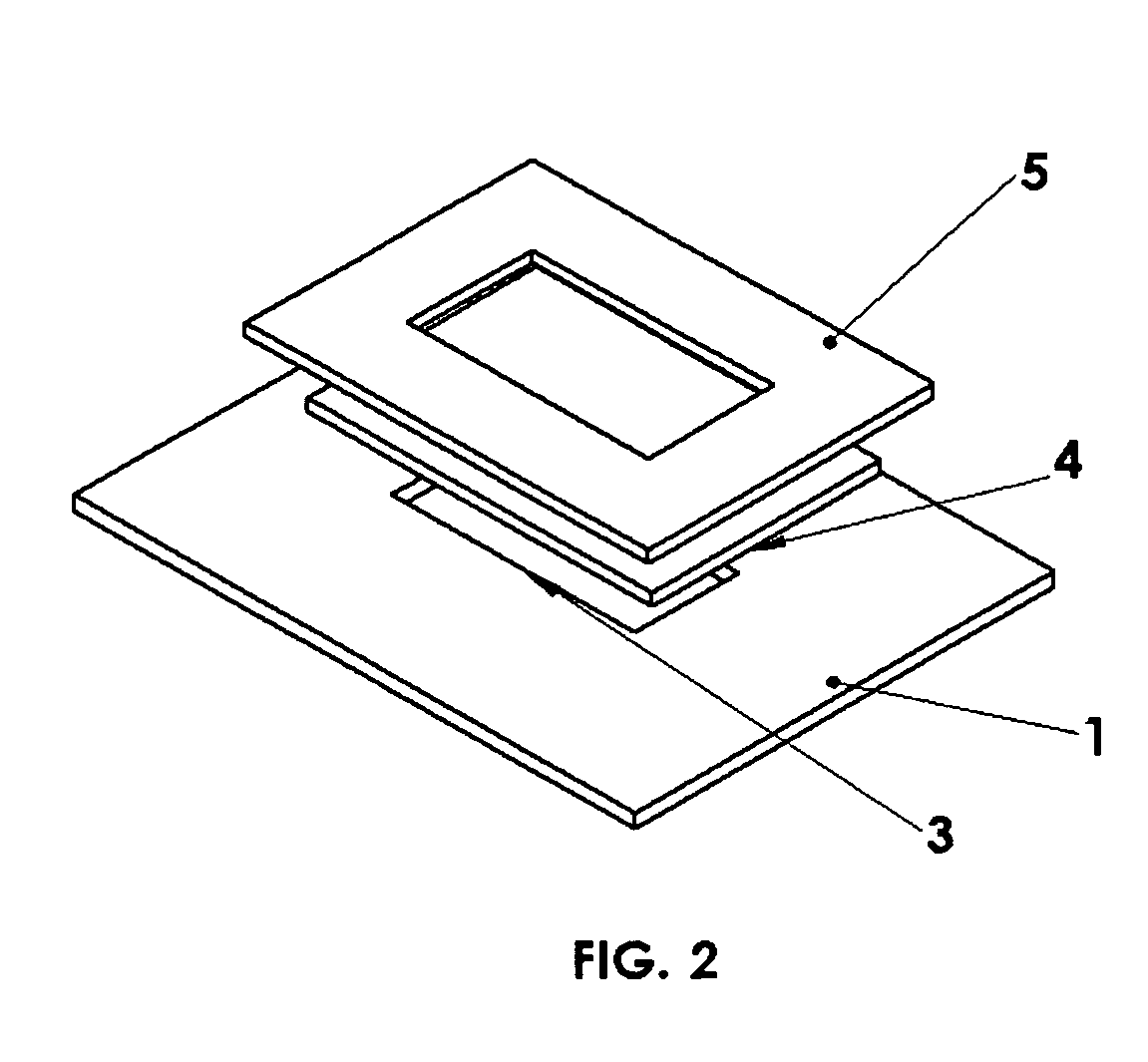

Gas permeable non-woven fabric based film for extending the shelf life of fresh fruits & vegetables and vase life of fresh cut flowers

ActiveUS20090239432A1Extends its shelf/vase lifeHigh permeable polymerSynthetic resin layered productsBagsEngineeringMetabolic heat

Packaging using Gas Permeable Non-Woven Fabric based Film extends the shelf life of various fresh fruits and vegetables and vase life of fresh cut flowers by changing the atmosphere in which these living products are stored and respires. The high oxygen and carbon dioxide permeability of the Gas Permeable Non-Woven Fabric based Film establishes an ideal atmosphere for the specific perishable item, and therefore extends its shelf life. The establishment of lower oxygen and carbon dioxide atmospheres inside packages using Gas Permeable Non-Woven Fabric based film, also leads to reduction in the respiration rate of the perishable items. The reduction in the respiration rate prevents loss of moisture, production of metabolic heat, and yellowing, browning, reduction in production levels of ethylene. Thus the created atmosphere is able to extend shelf life, maintain high quality and preserve nutrients of fresh produce items by naturally regulating respiration of said produce / flower.

Owner:CHANDRA SHUBHAM

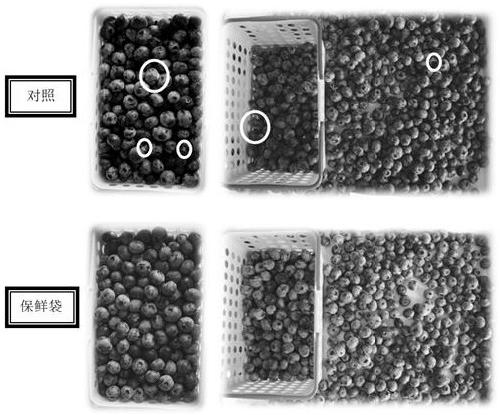

Preservation method for picking, storage, transportation and sales of fruits and vegetables and application of preservation method

PendingCN111387275AExtended picking timePrevent malfunctionHorticulture methodsFood ingredient for microbe protectionCold chainPreservation methods

The present invention discloses a preservation method for picking, storage, transportation and sales of high-value fruits and vegetables. The method is as follows: when fruits and vegetables reach a physiological maturity period, a pre-picking spraying-type 1-methylcyclopropene preservation agent is sprayed on trees, timely picking or delayed picking is conducted, after sorting, the fruits and vegetables are put into a microenvironmental controlled atmosphere preservation box, after fully pre-cooled in an origin place, the fruits and vegetables are put in a physiological and disease-double-controlling 1-methylcyclopropene preservation bag, and cover locking and storing are conducted. Storage, transportation and sales links have the following three modes: (1) a fresh sales mode: the fruitsand vegetables are directly transported to consumers in a cold chain manner and the fresh sales mode is suitable for e-commerce; (2) a storage mode: the fruits and vegetables are transported to cold storages of a storage and sales place for storage in a whole cold chain manner and the storage mode is suitable for fruit and vegetable storage and sales enterprises; and (3) a sales model: the fruitsand vegetables are divided into full box sales and single basket sales and the sales model is suitable for different consumer groups. The treatment method can delay picking time of the fruits and vegetables, delays occurrence of senescence and decay of the fruits and vegetables, and increases commerciality and sales prices of the fruits and vegetables in the storage, transportation and sales links.

Owner:天津市林业果树研究所

Browning preventing broad spectrum fruit preservative and its prepn process

InactiveCN101019571AImprove stabilityExpand the range of acid-base actionFruit and vegetables preservationAdditive ingredientPreservative

The browning preventing broad spectrum fruit preservative is compounded with ascorbic acid 3.0-4.0 weight portions, citric acid 0.5-1.0 weight portions, lactic acid 3.0-4.0 weight portions, calcium chloride 0-1.0 weight portions, ammonium propionate 12.0-13.0 weight portions, sodium chloride 1.5-2.0 weight portions, glycerin 14.0-15.0 weight portions, and water 100 weight portions, and through the steps of mixing all the materials and regulating the pH to 2.5-4.0. The present invention has the advantages of multifunctions of the preservative including sterilizing, preserving, synergizing and antioxidizing; simple compounding and simple use, and low cost.

Owner:NANCHANG UNIV

Optical glass suitable for mold forming

Owner:SUMITA OPTICAL GLASS

Lead-free low softening point glass

InactiveUS6989340B2Improve the overall coefficientIncrease resistanceThermal expansionMaterials science

Disclosed is a lead-free low softening point glass whose composition lies within the system SnO—P2O5 and containing over 5 to 30 mol % of MnO. The addition of MnO allows the water resistance and coefficient of thermal expansion of the glass to be improved without spoiling its feature of a low softening point. The lead-free low softening point glass can be prepared through a simplified production process.

Owner:TOKAN MATERIAL TECH

Curing process of polar plate used for lead-acid battery pack

InactiveCN103137947AHigh speedIncreasing the thicknessLead-acid accumulator electrodesMoistureHot Temperature

The invention discloses a curing process of polar plate used for a lead-acid battery pack, which comprises two steps of curing and drying, and is characterized in that curing is carried out by employing high temperature, and high wet and compression. The curing process has the advantages that the step of curing is carried out with one step, the process is simplified, the curing time is shortened, the curing effect is increased, and free lead and moisture of the cured polar plate are less than 1% through detection.

Owner:江苏海宝电池科技有限公司

Production method for waterproof and flame-retardant shoe upper leather

ActiveCN107881269AImprove compactnessReduce usageTanning treatmentLeather/skins/hides/pelt chemical treatment apparatusManufacturing technologyAcrylic resin

The invention relates to the technical field of leather manufacturing technologies and provides a production method for waterproof and flame-retardant shoe upper leather. Chromium-zirconium-aluminum and zirconium-aluminum-titanium which have the flame-retardant property serve as a tanning agent and a retanning agent to conduct tanning and retanning; the retanning agent, a neutralizing agent and afatting agent which have the waterproof property are selected to enable the leather to have the waterproof property; an environment-friendly-type flame retardant is selected to enable the leather to have the flame-retardant property; and modified graphene-based acrylic resin and modified graphene-based polyurethane are added in filling and coating materials to serve as waterproof and flame-retardant enhancers to enable the leather to have the good waterproof and flame-retardant effects. According to the production method, under the precondition that natural leather has the excellent quality, the environment-friendly and flame-retardant effects of the leather can be achieved, the dosage of the flame retardant is reduced, the production cost is reduced, and the production method is suitablefor batch production and application.

Owner:XINGYE LEATHER TECH CO LTD

Lead-free low softening point glass

InactiveUS20050255985A1Reduce variation in compositionFacilitated releaseThermal expansionSoftening point

Disclosed is a lead-free low softening point glass whose composition lies within the system, SnO—P2O5 and containing over 5 to 30 mol % of MnO. The addition of MnO allows the water resistance and coefficient of thermal expansion of the glass to be improved without spoiling its feature of a low softening point. The lead-free low softening point glass can be prepared through a simplified production process.

Owner:TOKAN MATERIAL TECH

Abrasion-resistant composite protective coating for hard sealing surface of ball valve and preparation method of abrasion-resistant composite protective coating

ActiveCN111218638AReduce coefficient of frictionReduce internal stressMolten spray coatingVacuum evaporation coatingSurface engineeringInternal stress

The invention provides an abrasion-resistant composite protective coating for a hard sealing surface of a ball valve and a preparation method of the abrasion-resistant composite protective coating, and belongs to the field of surface engineering. The invention provides the abrasion-resistant composite protective coating for the hard sealing surface of the ball valve, a Cr3C2-NiCr coating, a Cr->Cr / C / WC dual-mode transition layer and a WC / a-C nano multilayer film are sequentially prepared on the surface of a metal matrix. According to the abrasion-resistant composite protective coating, the abrasion-resistant composite protective coating has a lower friction coefficient, ultralow internal stress, high bearing capacity and excellent abrasion resistance, is suitable for being used as an abrasion-resistant protective material for the hard sealing surface of the ball valve, and can remarkably improve the abrasion resistance and prolong the service life, so that the purposes of reducing thecost and improving the safety and reliability are achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Brazing method for graphite-copper composite commutator

ActiveCN103915745ASolve the strength problemSolve the problem of easy falling offCommutators manufactureAxial pressureGraphite

The invention discloses a low-temperature brazing method for a graphite-copper composite structure commutator. The low-temperature brazing method includes the following machining steps: (1) preparing SnAgCuTi powder brazing filler metal containing the active element Ti, (2) placing the SnAgCuTi powder brazing filler metal on the surface of a graphite plate, heating the SnAgCuTi powder brazing filler metal and the graphite plate to be at the temperature ranging from 450 DEG C-900 DEG C under the vacuum or inert gas protection condition, keeping the temperature for 0 min-60 min, achieving metallization of the surface of the graphite plate, cooling the SnAgCuTi powder brazing filler metal and the graphite plate to be at the indoor temperature, and taking out the SnAgCuTi powder brazing filler metal and the graphite plate, and (3) assembling metallized graphite and a copper commutation blade, exerting the 0.2 MPa-1.2 MPa axial pressure, placing the assembly into a brazing device to heat the assembly to be at the temperature ranging from 240 DEG C to 450 DEG C, keeping the temperature for 0 min-60 min, and completing low-temperature brazing forming of the graphite-copper composite structure commutator. According to the low-temperature brazing method, the problems that in an existing brazing technology of the graphite-copper composite structure commutator, the combination strength between a metal plating layer and the graphite plate is low, and falling is prone to happening are solved, softening of the copper commutation blade is effectively relieved through the low brazing temperature, the performance of the graphite-copper composite structure commutator is improved, the service life of the graphite-copper composite structure commutator is prolonged, and the brazing method has the advantages of being simple, practical, environmentally friendly, efficient, easy to operate, stable in technology, low in cost and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com