Pin tool suitable for local dry-type friction stir welding in water environment

A technology of friction stir welding and stirring head, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., and can solve the problem that the stirring head cannot be applied to local dry welding, poor stability of arc and droplet transition, complex supporting equipment and technology Conditions and other issues, to achieve the effect of narrowing the distribution range, reducing the width and softening degree, and accelerating the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

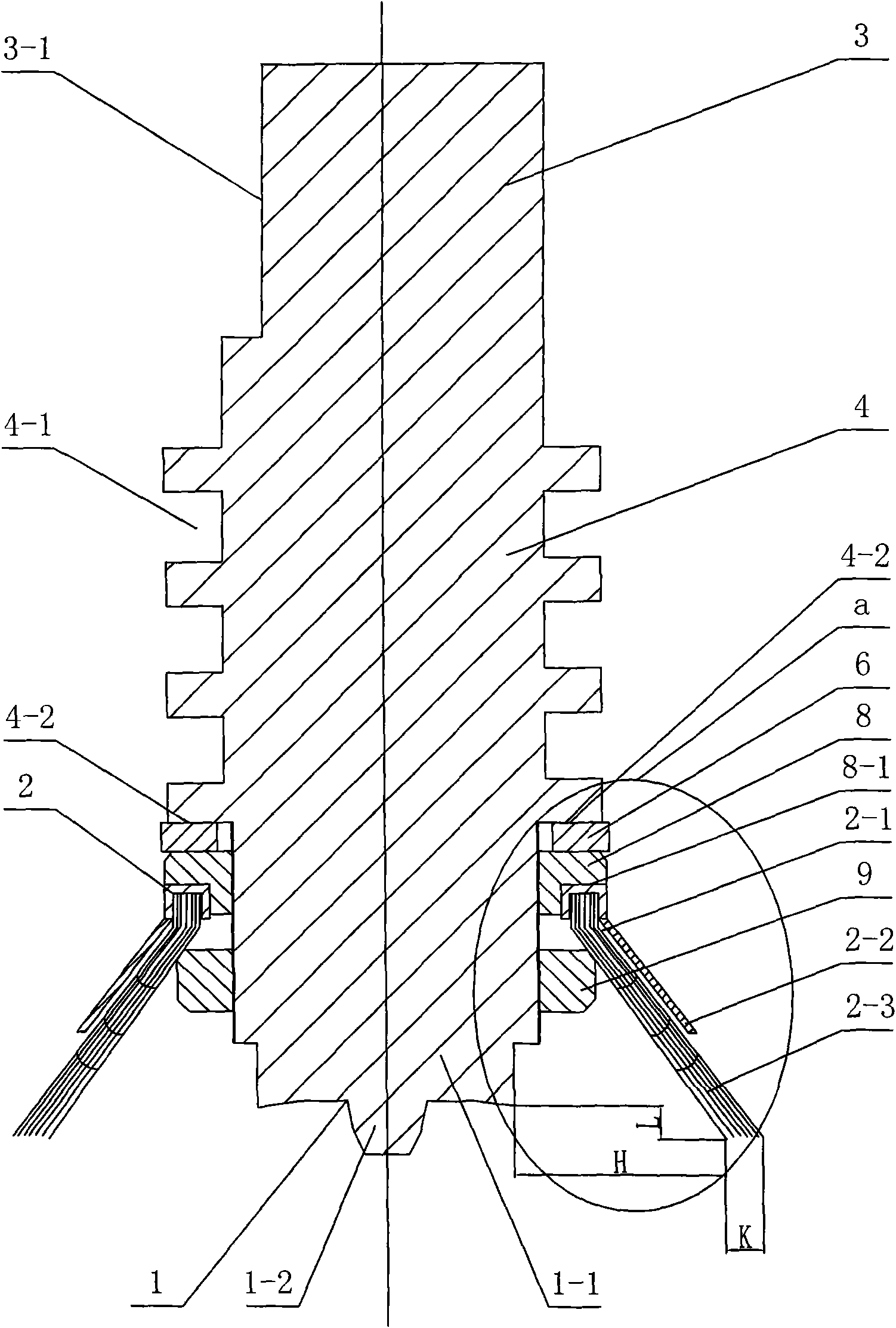

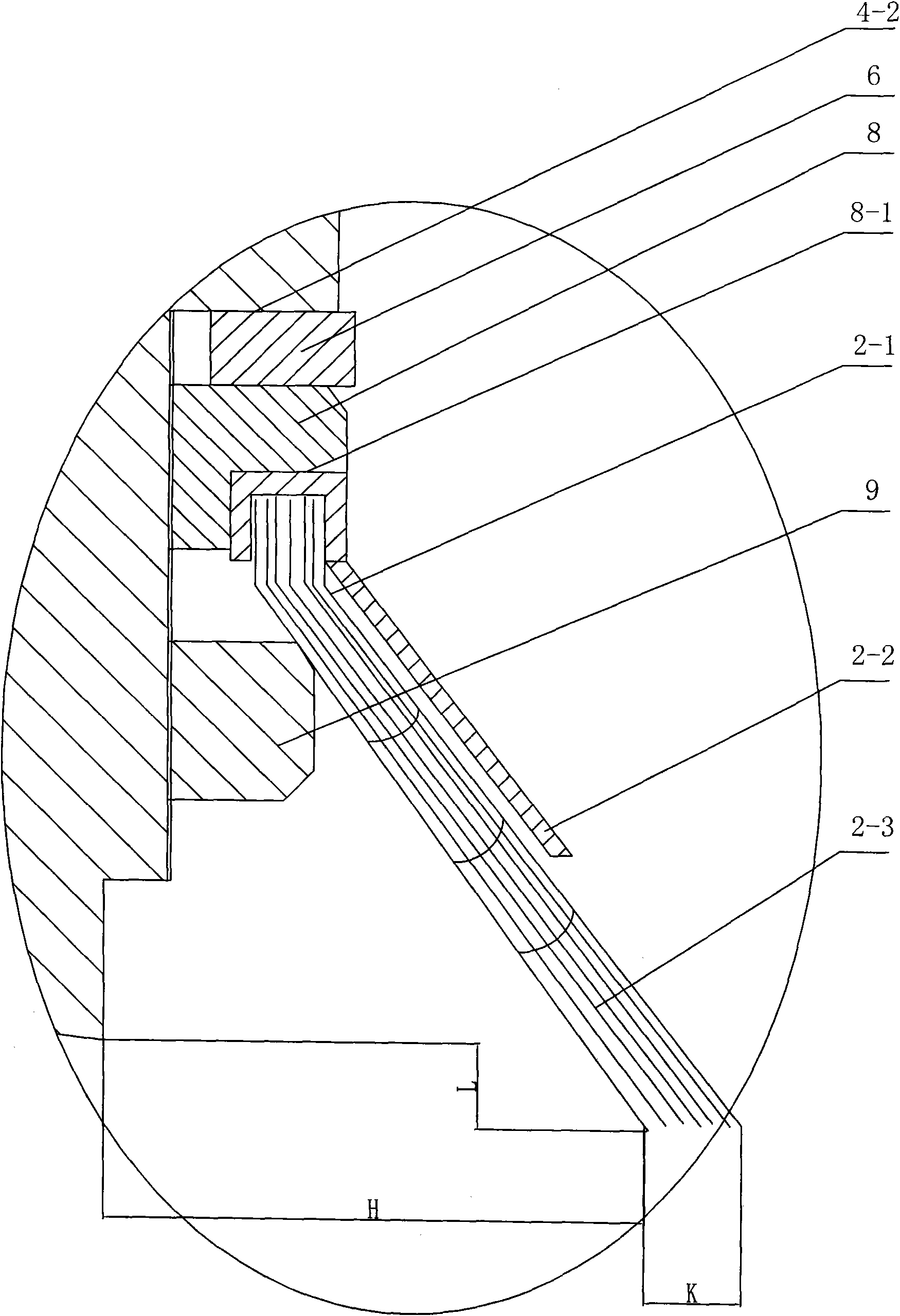

[0008] Embodiment 1: Combining Figure 1 to Figure 2 Illustrating this embodiment, a stirring head suitable for local dry friction stir welding in a water environment includes a stirring head base, which is composed of a cylindrical clamping body 3 , a cylindrical connecting body 4 and a stirring head. The cylindrical clamping body 3, the cylindrical connecting body 4 and the stirring needle 1 are coaxially made into one from top to bottom in sequence, and a positioning table is formed at the junction of the stirring needle 1 and the cylindrical connecting body 4. The shoulder end surface 4-2, the side surface of the cylindrical clamping body 3 is provided with an anti-loose fastening surface 3-1, and the cylindrical connecting body 4 is provided with an annular heat-insulating heat-dissipating groove 4-1; the stirring The needle 1 is composed of a shaft shoulder 1-1 and a needle body 1-2. The shaft shoulder 1-1 and the needle body 1-2 are coaxially made into one body from top...

specific Embodiment approach 2

[0009] Specific implementation mode 2: Combining Figure 1 to Figure 2 Describing the present embodiment, the inverted funnel-shaped cover 2-2 of the present embodiment is made of stainless steel, copper or rubber material. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation three: combination Figure 1 to Figure 2 Describing the present embodiment, the upper ends of the plurality of stainless steel wire bundles 2-3 in the present embodiment are uniformly fixed in the U-shaped wire brush holder 2-1. With this setting, the water is better drained. Other components and connection relationships are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com