Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Upset welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Upset welding (UW)/resistance butt welding is a welding technique that produces coalescence simultaneously over the entire area of abutting surfaces or progressively along a joint, by the heat obtained from resistance to electric current through the area where those surfaces are in contact. . Pressure is applied before heating is started and is maintained throughout the heating period. The equipment used for upset welding is very similar to that used for flash welding. It can be used only if the parts to be welded are equal in cross-sectional area. The abutting surfaces must be very carefully prepared to provide for proper heating. The difference from flash welding is that the parts are clamped in the welding machine and force is applied bringing them tightly together. High-amperage current is then passed through the joint, which heats the abutting surfaces. When they have been heated to a suitable forging temperature an upsetting force is applied and the current is stopped. The high temperature of the work at the abutting surfaces plus the high pressure causes coalescence to take place. After cooling, the force is released and the weld is completed.

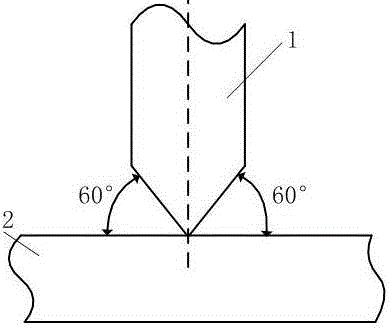

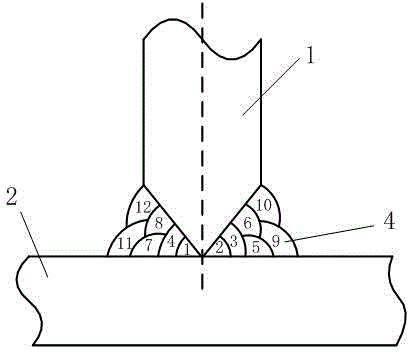

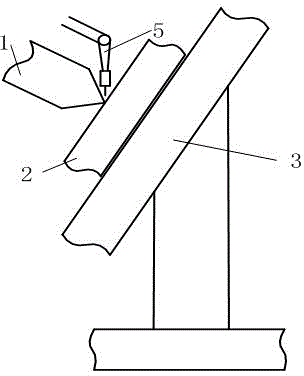

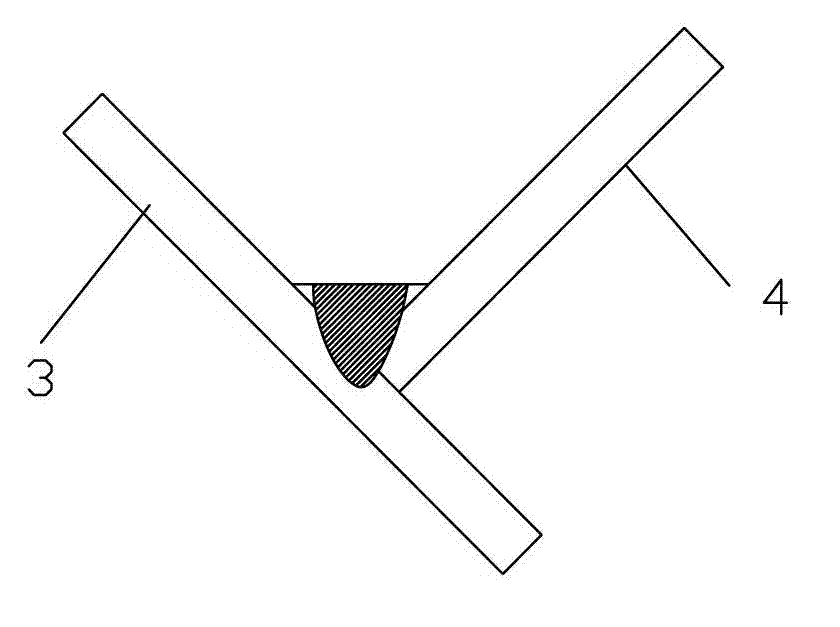

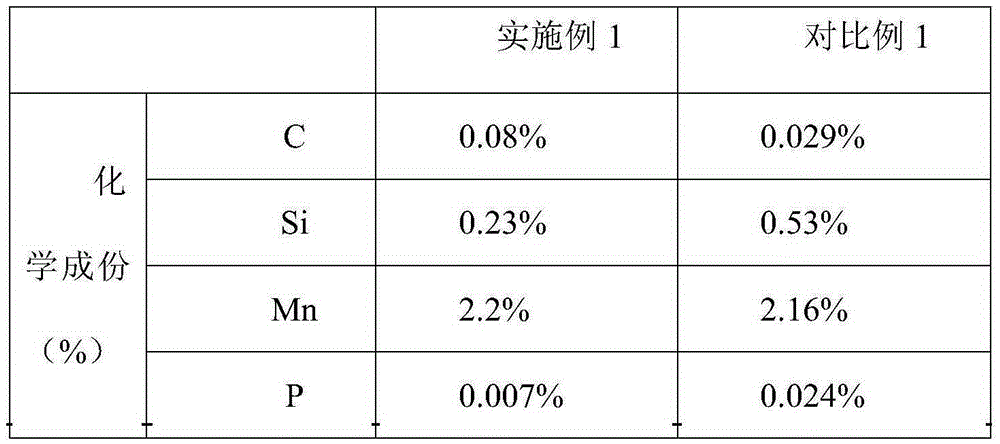

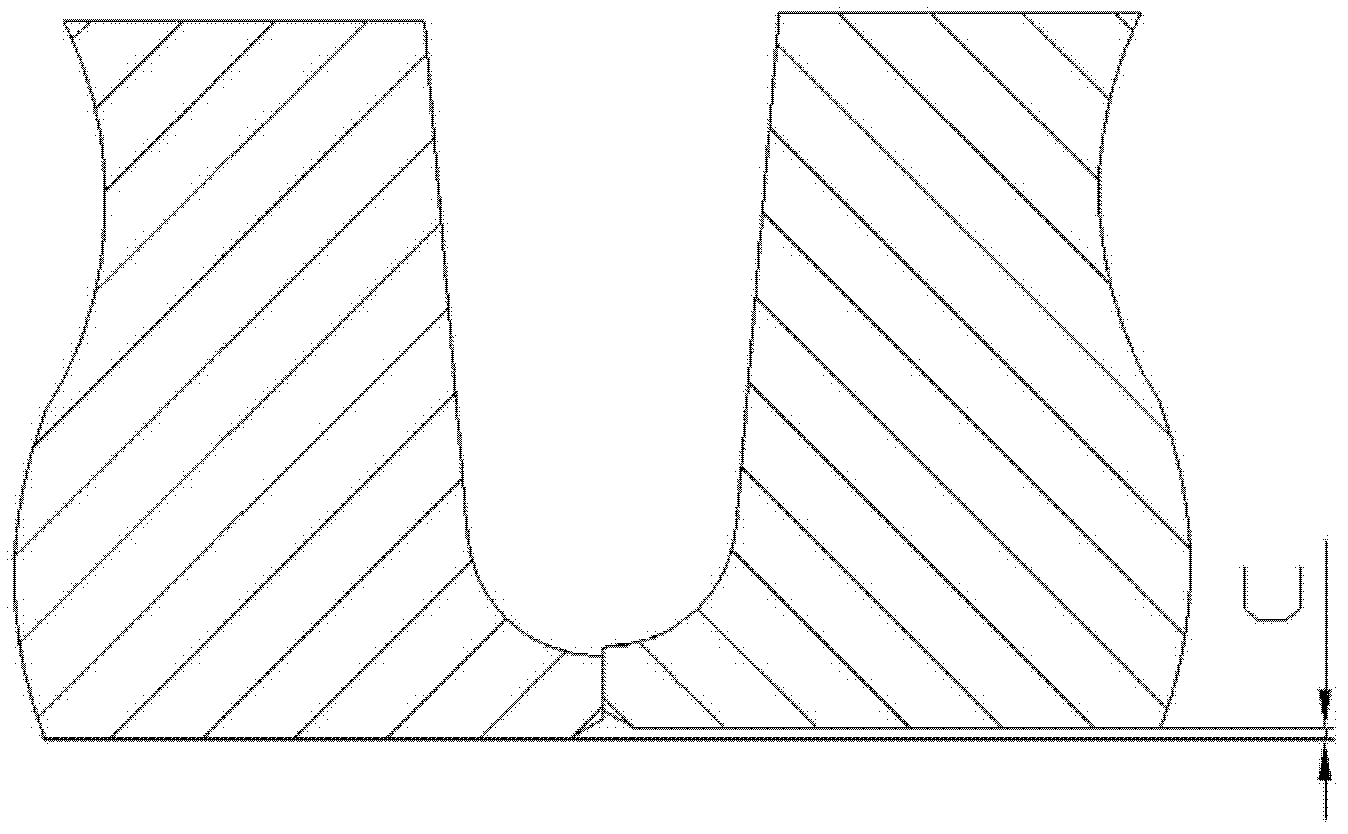

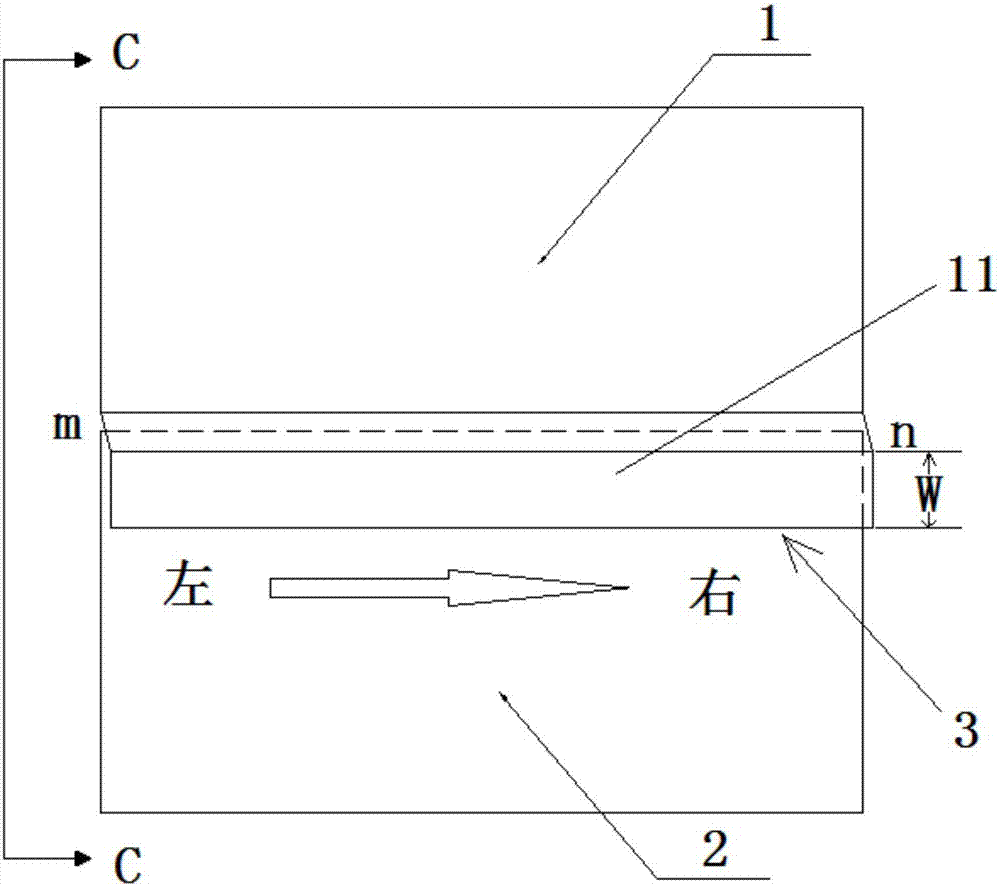

Fillet weld welding structure for K-type grooves of moderately-thick plate without back chipping and welding technology of fillet weld welding structure

InactiveCN105081595AFull penetration ensuresImprove the construction environmentArc welding apparatusWelding/soldering/cutting articlesFillet weldThick plate

The invention relates to a fillet weld welding structure for K-type grooves of a moderately-thick plate without back chipping and a welding technology of the fillet weld welding structure. The fillet weld welding structure is characterized in that symmetric grooves are formed in the two sides of a web plate, the web plate and a bottom plate are tightly attached when assembled in welding, and no gap is reserved when the web plate and the bottom plate are assembled; the grooves of the web plate are machined through a milling machine, no truncated edge is reserved, and the length parts between the two ends in the grooves are fixed at equal diversion points and polished; a welding robot is used for stably welding a welding bead at the position of ship-type welding, welding is carried out alternatively on the two sides in a multi-layer and multi-run manner, back chipping is not carried out on the back face, and slag is not removed in the bead; and the backward deformation theory is utilized in the assembling process, and double-face alternating welding is adopted in the welding process to restrain deformation. By means of the technology, full penetration of the fillet weld below the K-type grooves of the moderately-thick plate is ensured, and the welding quality is improved; and meanwhile, the welding automation degree and the production efficiency are obviously improved, and the welding construction environment is improved.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

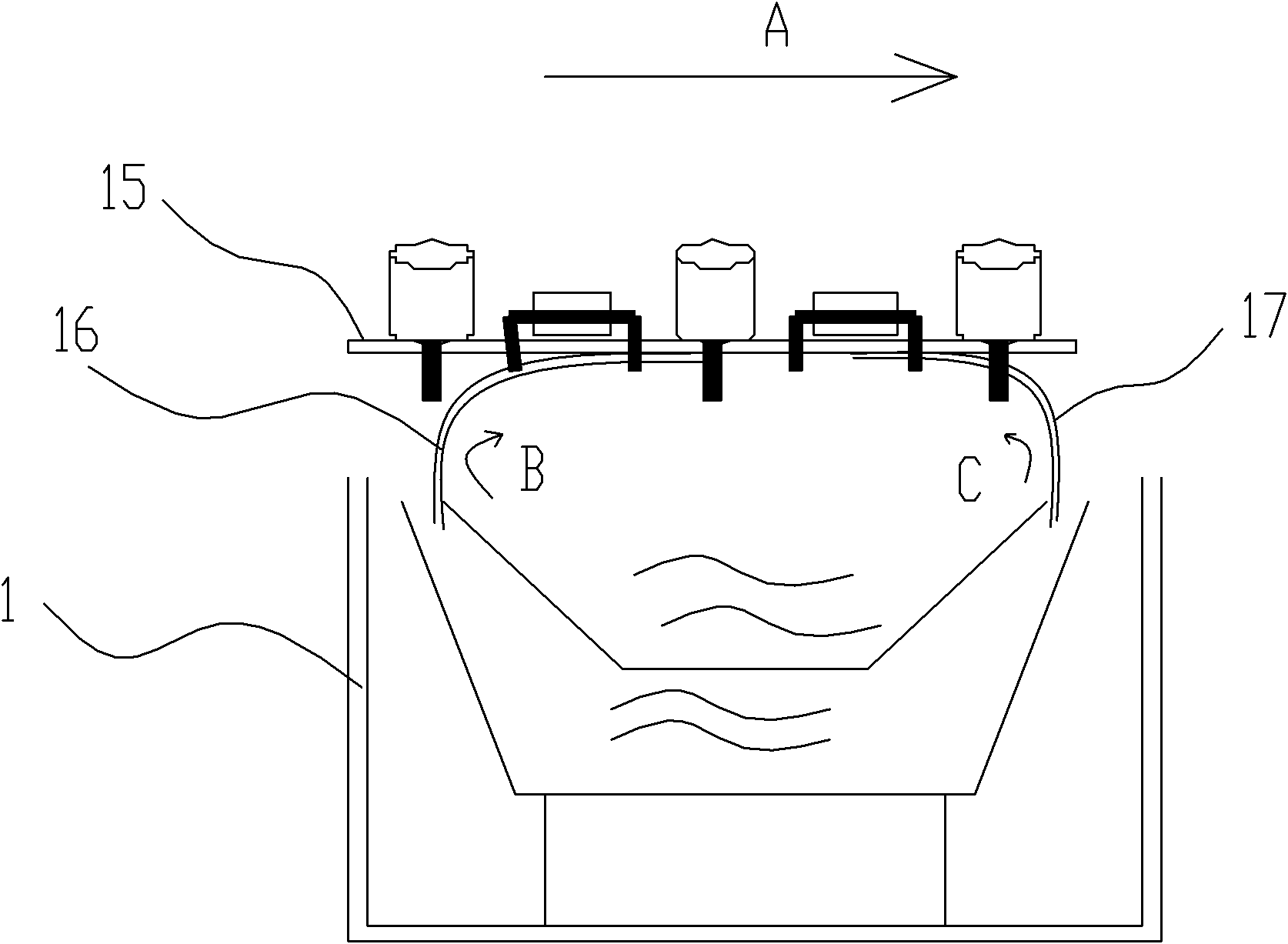

Jet welding method and jet welding groove

InactiveCN102581409ASolve the phenomenon of continuous weldingCompact designPrinted circuit assemblingSolder feeding devicesElectromagnetic pumpPrinted circuit board

The invention relates to a welding process for a PCB (printed circuit board), and discloses a jet welding method, which includes the process steps of flux spraying, preheating and welding. The process step of welding adopts a jet welding process, which is characterized in that melted welding flux is sprayed out of two opposite elongated nozzles parallelly arranged on two sides of a welding groove by the aid of a mechanical pump or an electromagnetic pump, and forms two obliquely upward opposite parabolic liquid surfaces contacting with the surface of the PCB in a parabolic manner. The invention further discloses a jet welding groove using the jet welding method. The jet welding method and the jet welding groove have the advantages that automation of a through hole welding process and through hole welding quality can be effectively improved, electric power resources and tin resources are saved, and production cost can be reduced for electronic manufacturers.

Owner:SHENZHEN KUNQI XINHUA

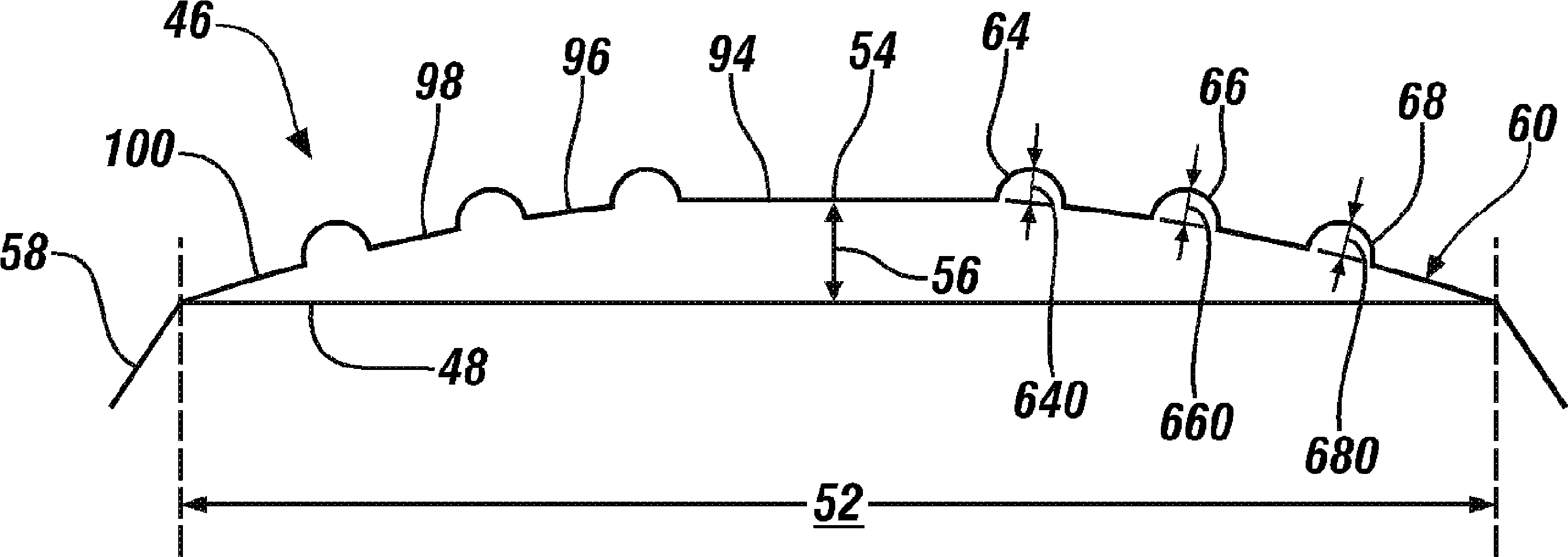

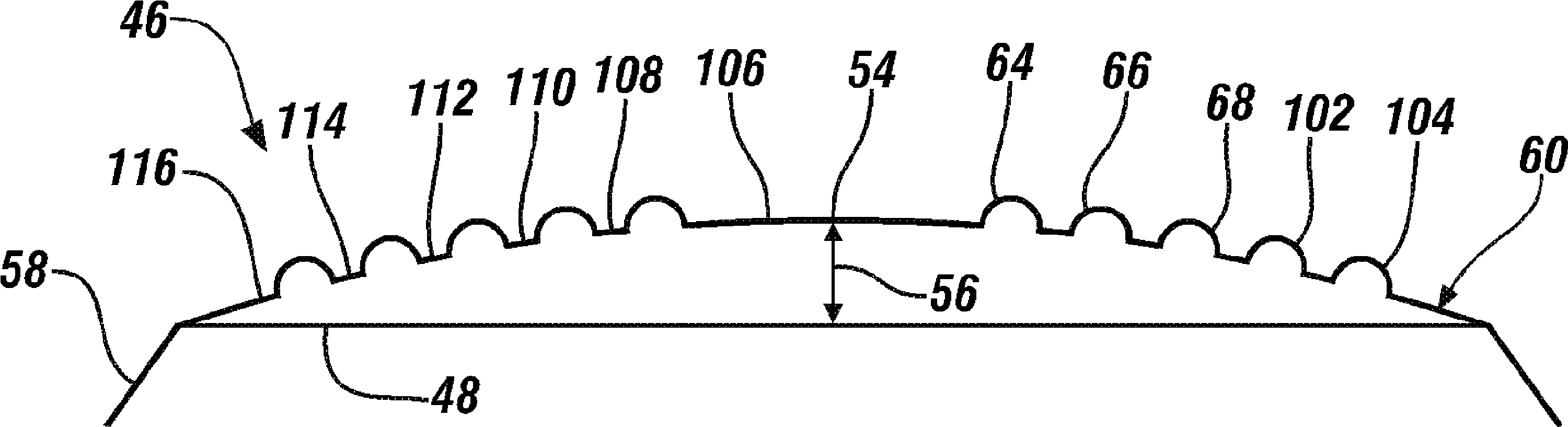

Welding surface design of spot welding

The invention relates to the welding surface design of spot welding. Specifically, a welding electrode for being engaged with an aluminum alloy workpiece during a spot welding process includes a welding surface, the welding surface comprises a base surface and a plurality of circular ridges projecting from the base surface to the outside, the circular ridges are dull and their presence on the welding surface provides some useful abilities for a first welding electrode, including the ability to make a better mechanical and electrical contact with the aluminum alloy workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

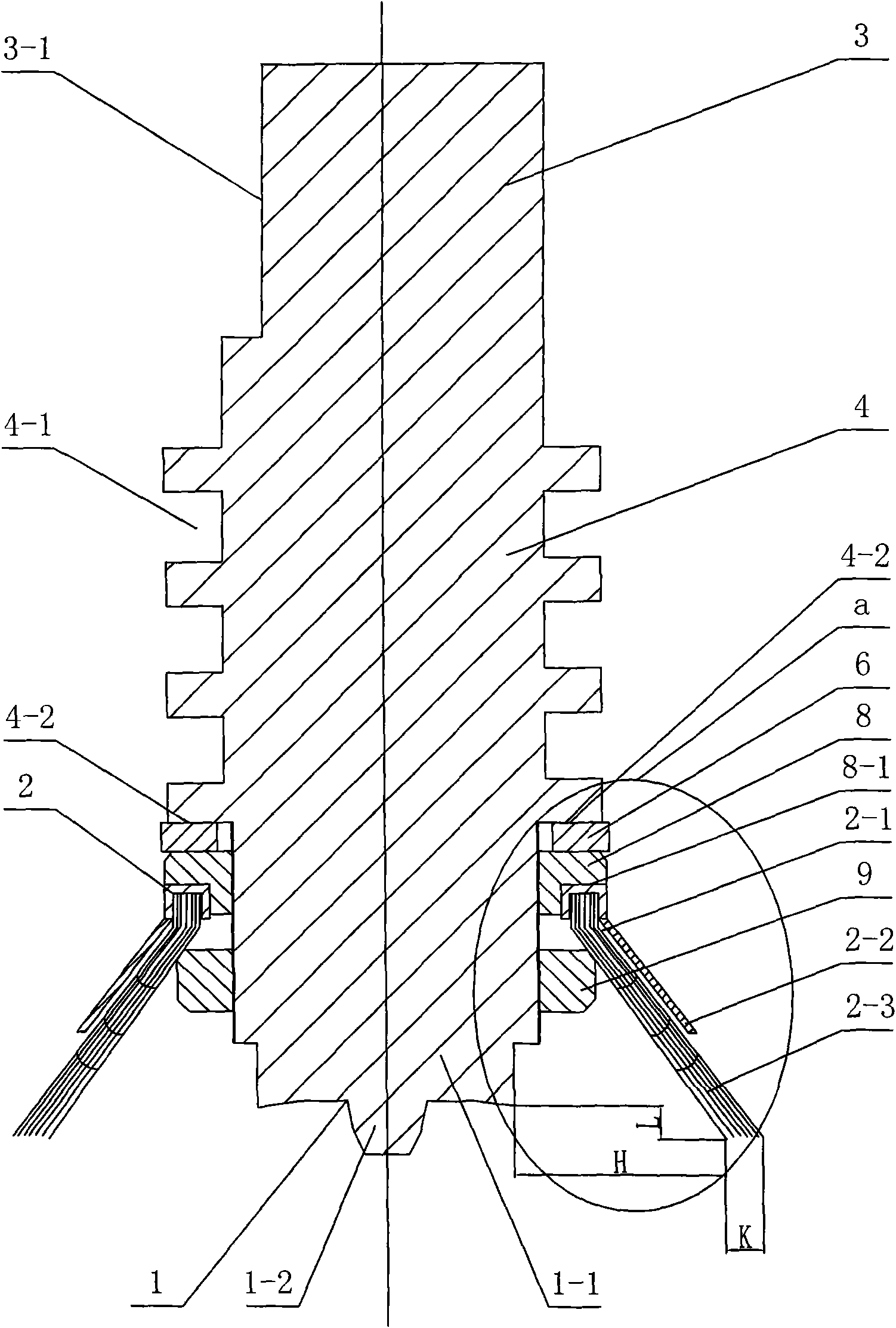

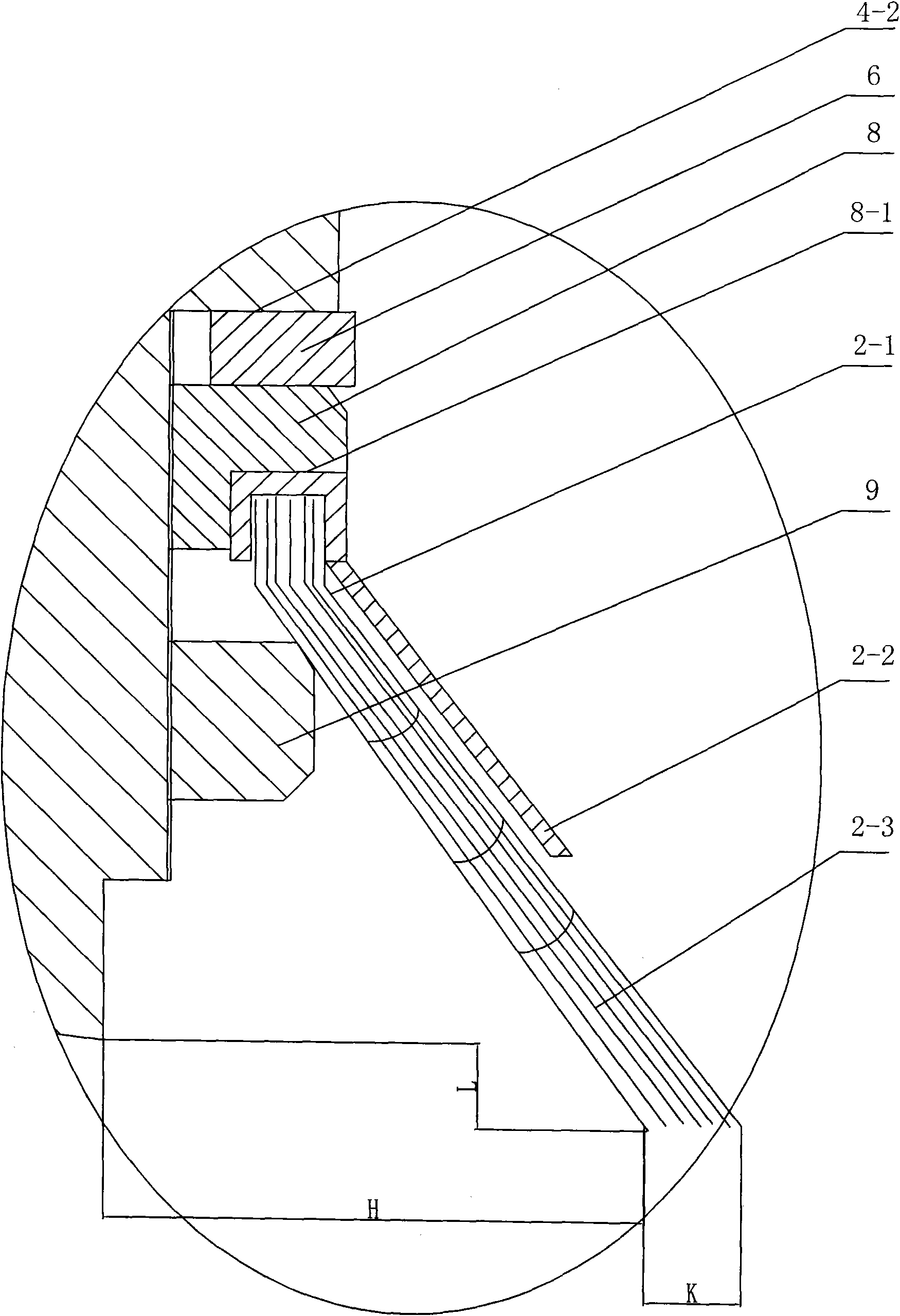

Pin tool suitable for local dry-type friction stir welding in water environment

InactiveCN101554681AAvoid enteringEntry will not happenNon-electric welding apparatusFriction weldingDecomposition

A pin tool suitable for local dry-type friction stir welding in water environment relates to a pin tool of friction stir welding. The invention solves the problems that the existing pin tool of friction stir welding is not applicable to the local dry-type welding in water environment; as underwater welding needs complicated supporting equipment and technical conditions, the difficulty of implementation is comparatively large; and the stability of an electric arc and drop transfer is poor and the decomposition of water at the high temperature of the electric arc can lead to seam hydrogenation so as to cause the deterioration of joint performance. A fitting nut is connected with the upper thread of a shaft shoulder and a positioning backing ring is arranged between the upper end face of the fitting nut and the end face of a shoulder. A U-shaped steel wire brush holder is fixedly installed on the shoulder. The upper ends of a plurality of stainless steel tendons are fixedly installed in the U-shaped steel wire bush holder and an inverted funnel-shaped shade covers the outside of the steel wire brush. The pin tool overcomes the defects of the existing pin tool of friction stir welding in welding under water environment, satisfies the requirements of local dry-type welding under water environment and also boosts the performance of joints.

Owner:HARBIN INST OF TECH

Method and device for welding inside fillet welds of T-shaped joints through infilling-type friction-stir welding

InactiveCN102922125AHigh strengthUnique structureNon-electric welding apparatusFillet weldEngineering

The invention discloses a method and a device for welding inside fillet welds of T-shaped joints through infilling-type friction-stir welding. The method is implemented through the steps that an inside fillet weld of a T-shaped joint is located at a flat-welding position by using a special fixture, and a process auxiliary cushion block made of a material same as that of a parent metal is embedded in the position of the inside fillet weld; a plane required by the friction of a shaft shoulder of a stir-welding head is formed at the inside fillet weld of the T-shaped joint; a weld of the T-shaped joint is heated by using the frictional heat generated by the cushion block and the shaft shoulder of the stir-welding head; and a weld of friction-stir welding is formed under the heat-engine joint action of a stirring pin. The device for implementing the method disclosed by the invention is unique in structure, low in cost and strong in universality. According to the method and the device disclosed by the invention, an effect of welding inside fillet welds of T-shaped joints through friction-stir welding can be achieved; and because the cushion block and the parent metal which are same in material are fused together, the weld reinforcement of welds can be increased, and the strength of joints is improved.

Owner:JIANGSU UNIV OF SCI & TECH

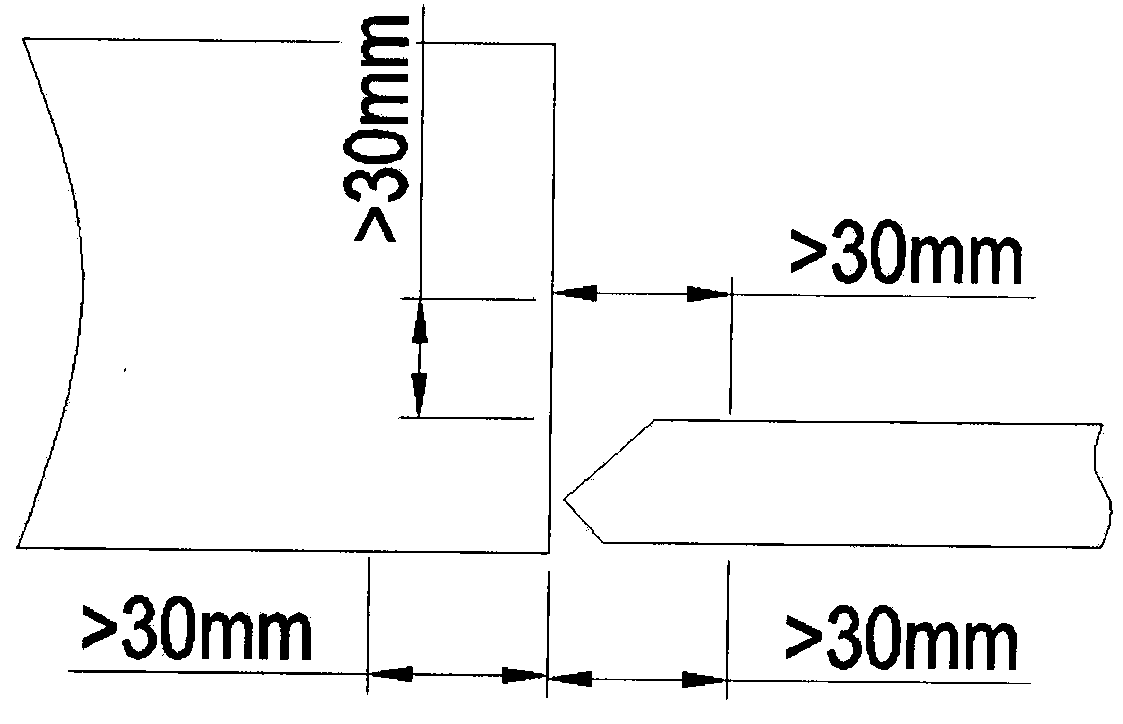

Welding process special for thick dissimilar material plate

ActiveCN104002023AImprove welding efficiencyGuaranteed StrengthArc welding apparatusEngineeringSpot welding

The invention discloses a welding process special for a thick dissimilar material plate. The welding process is characterized by comprising the following steps: a, cutting double-surface and one-side grooves in a welding material; b, grinding the cut grooves and parts within at least 30mm site around a welding area; c, performing spot welding at positions 30mm away from the top ends of two sides of a weld joint, and avoiding any defect in spot welding; d, preheating a base metal at a temperature of at least 150 DEG C; e, welding the weld joint at one side of a large groove, welding a surface covering layer by the method of welding from two sides to the middle, and then performing carbon gouging and back chipping for the other side; f, welding another weld joint at one side of a small groove by the same method as the large groove; g, thermally treating a welding part. The process is high in welding efficiency and small in welding-caused deformation; the weld joints have the characteristics of being high in strength, high in toughness, no defect, and no delayed crack.

Owner:NANTONG COSCO HEAVY IND

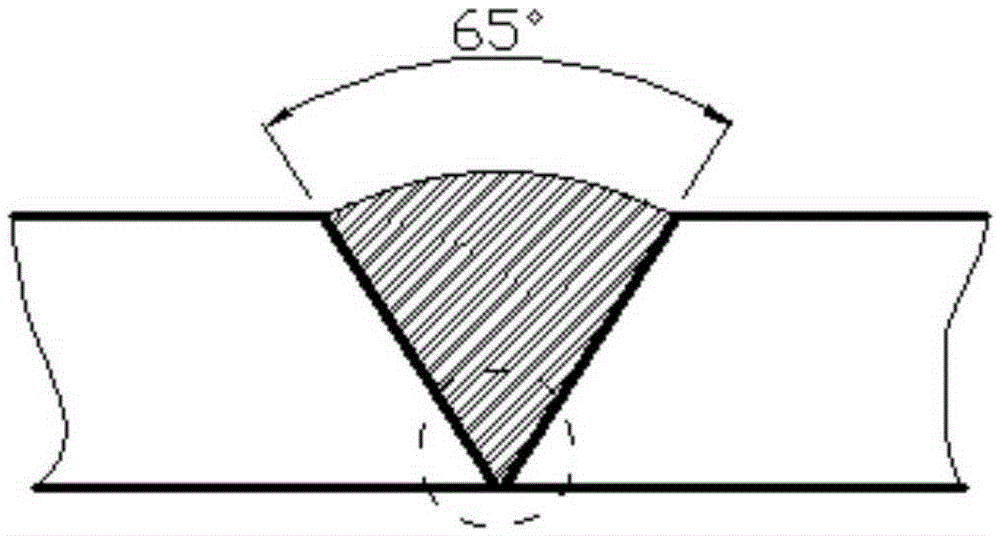

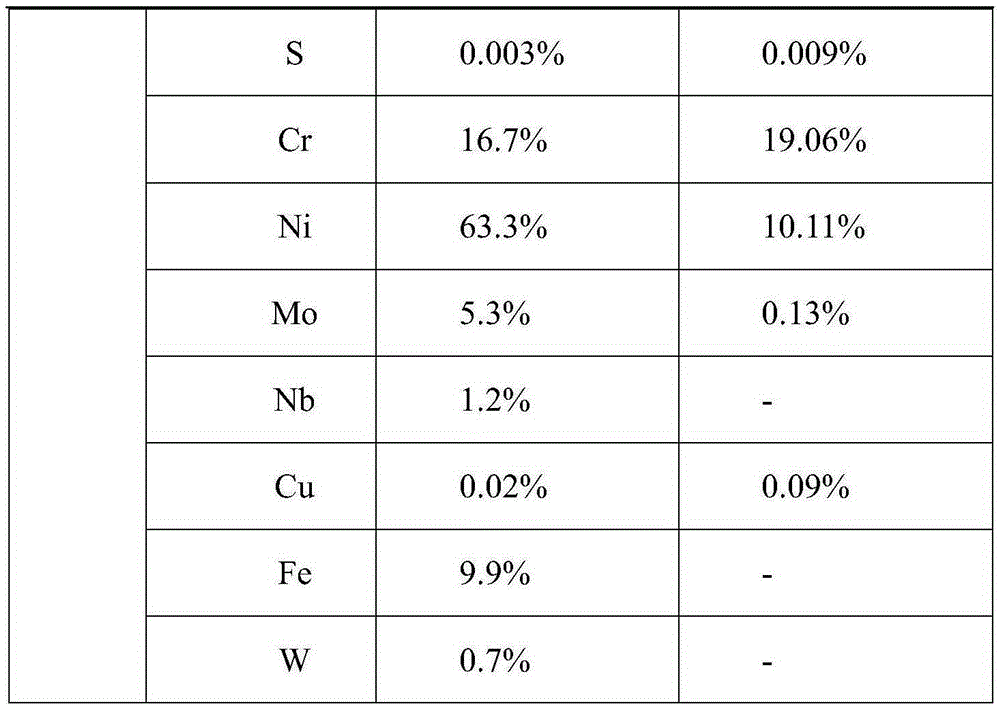

Shielded metal arc welding method used for phase welding of X7Ni9 steel and S30408 steel

ActiveCN105269175AAvoid poor resultsAvoid the problem of excessive concentration of internal stressArc welding apparatusWelding/cutting media/materialsStress reliefAlternating current

The invention provides a shielded metal arc welding method used for phase welding of X7Ni9 steel and S30408 steel. The shielded metal arc welding method comprises the following steps that (1) a V-shaped groove or an asymmetric X-shaped groove is adopted as a shielded metal arc welding groove; (2) the two sides of a weld joint of an X7Ni9 steel plate and an S30408 steel plate is kept in a dry state before welding; (3) an alternating current power source is adopted, and suitable welding process parameters are selected; (4) the interpass temperature is kept to be smaller than 90 DEG C, after first layer of base is welded, the weld joint is polished and cleaned, then fine cracks are detected through permeation and eliminated through a polishing method, and afterwards, filling welding is conducted; and (5) after one side is welded, the reverse side needs to be subjected to back gouging and be polished, and similarly, fine cracks are detected through permeation and eliminated through polishing. According to the shielded metal arc welding method, the properties of the two steel are both taken into account fully, so that the quality of a high-strength dissimilar steel welded joint is effectively ensured. Above all, no stress relief treatment is needed after welding, and the high toughness of the welded joint at the temperature of -196 DEG C can be still ensured.

Owner:WUHAN YIYE STEEL STRUCTURE

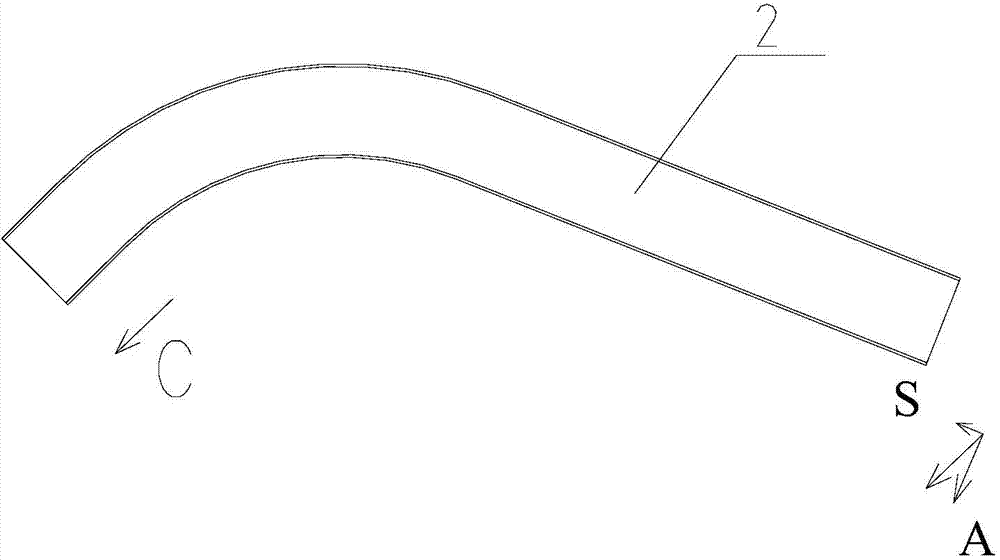

Nuclear island primary coolant circuit main pipe installation method

ActiveCN103769723AShorten the construction periodArc welding apparatusReactor pressure vesselPressurized water reactor

A nuclear island primary coolant circuit main pipe installation method uses a narrow gap automatic argon-welding method which is stable and controllable, through the measurement of a precision measuring instrument and the fitting and matching of modeling, through the adoption of the basic principle that moving track of any points on the rigid body is the same, grooves formed in the two sides of a main pipe is pro-processed. By controlling shrinkage and shrinking direction of the side welding of a main pipe reactor pressure vessel, side welding openings of vapor generators can be qualified fit up and welded with no stress. The nuclear island primary coolant circuit main pipe installation method has the advantages that through the adoption of the narrow gap automatic argon-welding method which is stable and controllable, through the measurement of the precision measuring instrument and the fitting and matching of modeling, through the adoption of the basic principle that moving track of any points on the rigid body is the same, the grooves formed in the two sides of the main pipe is pro-processed, and by controlling the shrinkage and the shrinking direction of the side welding of the main pipe reactor pressure vessel, the side welding openings of vapor generators can be qualified fit up and welded with no stress, compared with the current the third generation million level pressurized water reactor nuclear island main pipe construction scheme, 1-1.5 months of project duration can be saved.

Owner:ZHEJIANG THERMAL POWER CONSTR

III-V family high brilliancy composite coloured or white light luminous diode

This invention discloses LED of III-V group high brightness composite color or white color. The principle of emitting white light is emitting blue and yellow complementary light or bordering upon solar light spectrum. One of the implement uses (aluminium x gallium 1-x)y indium phosphor z nitrogen 1-z. [(Al.sub.xGa.sub.1-x).sub.yIn.sub.1-yP.sub.zN.sub.1-z] as lighting layer material. Said invention also disclose a method for mass production of chip of said LED, which contains bonding epitaxy chip on heat and electric conductive support substrate by chip upset welding technology, stripping grown substrate, stacking up electrode with optimized pattern. Said chip has fine heat conductivity and light taking efficiency.

Owner:金芃

Tungsten inert gas welding method of austenitic heat-resistant steel

InactiveCN108788405AImprove mechanical propertiesReduce brittlenessArc welding apparatusSteel pipelineAustenite

The invention discloses a tungsten inert gas welding method of austenitic heat-resistant steel. According to the tungsten inert gas welding method, for the austenite heat-resistant steel, a 22Cr25NiWCoCu (UNSS31035) seamless steel tube is selected is welded, a welding joint adopts a single-side 30-degree V-shaped groove, and cleaning is carried out; firstly, positions are fixed by using spot welding of tungsten-electrode argon arc welding before welding is carried out, and combined pairing is carried out; and then single-side welding and double-face forming are carried out by using tungsten-electrode argon arc welding, preheating is not carried out before welding, no heat treatment is carried out after welding, and meanwhile full-argon protection is adopted. According to the austenite ic heat-resistant steel pipeline welding process, welding stress and deformation are reduced, the brittleness of the welded joint can be reduced, the occurrence of thermal cracks is inhibited, the improvement of the plasticity and the toughness of the welded joint is realized, and then that the mechanical property of the pipeline after welding is comprehensively improved.

Owner:TIANJIN UNIV

Laser welding method for copper-aluminum welding

InactiveCN108817660AReduce heat buildupImprove welding qualityLaser beam welding apparatusHigh frequency modulationShielding gas

The invention relates to a laser welding method for copper-aluminum welding. The laser welding method for copper-aluminum welding is used for welding a copper part and an aluminum part and comprises the steps that the copper part and the aluminum part are positioned, and a weld seam is formed between the copper part and the aluminum part; the weld seam is welded through high-frequency modulation pulsed spot welding; and by controlling the duty ratio of pulsed spot welding, welding is conducted at the predetermined welding speed, and meanwhile protective gas is blown to the weld seam. Accordingto the laser welding method for copper-aluminum welding, the cooling speed of a molten pool is decreased through preheating of front welding spots to the weld seam and after-heating of rear welding spots to the front welding spots, then, through matching of a high-frequency light emitting mode, the molten pool is always in the environment that the welding seam is preheated by the front welding spots, and the front welding spots are subjected to after-heating by the rear welding spots, the welding quality of a copper-aluminum connecting structure formed by welding the copper part and the aluminum part is ensured, and cracks at the welded position of the copper part and the aluminum part are avoided.

Owner:HANS LASER TECH IND GRP CO LTD

Single-arc twin-wire pipeline all-position welding method

ActiveCN102581432AIncrease filling volumeSimultaneous meltingArc welding apparatusWorkpiece edge portionsEngineeringRobot welding

The invention discloses a single-arc twin-wire pipeline all-position welding method, which belongs to the technical field of oil-gas pipeline welding. The method includes the steps: chamfering ends of two pipelines to be welded, and aligning grooves of the two pipelines through an inner pipeline aligning device; preheating pipe orifices to be welded to reach the temperature higher than 50 DEG C, and setting welding parameters of a single-arc twin-wire pipeline all-position automatic welding machine; and respectively performing root welding, heat welding, filling welding and cosmetic welding for the pipe orifices to be welded from inside to outside by the aid of the single-arc twin-wire pipeline all-position automatic welding machine until the circumferential surface of a welding line is not lower than the outer wall surface of each pipeline. The single-arc twin-wire pipeline all-position welding method can be used for simultaneously melting double welding wires in the same melting area, increasing the filling quantity of the welding wires within unit time, shortening welding time, increasing welding speed and improving the daily welding efficiency for circumferential weld of a unit.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

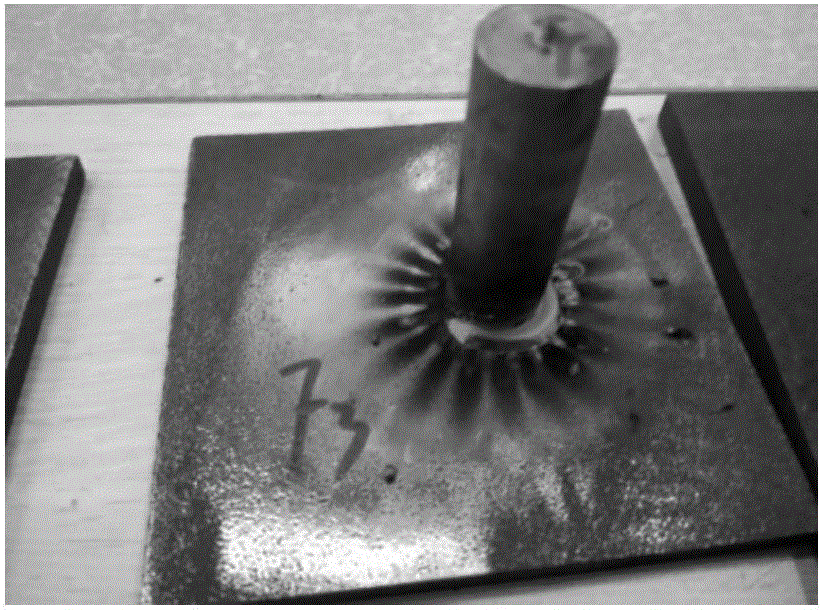

Large-diameter steel stud composite welding method based on arcing-aluminothermy

InactiveCN106181083AReduce usagePlay a protective effectWelding apparatusStud weldingMaterials science

The invention relates to a welding method for a stud and a steel plate, in particular to a large-diameter steel stud composite welding method based on arcing-aluminothermy. The large-diameter steel stud composite welding method is characterized by comprising the following steps that an aluminothermy welding agent containing iron elements is prepared; then the prepared aluminothermy welding agent is put into a ceramic ring, and the ceramic ring is filled with the aluminothermy welding agent; and an inversion type arcing stud welding machine is started, arcing is conducted, and the welding process of the stud welding machine is completed. The aluminothermy welding agent is ignited through arcing, the welding process of a stud is promoted to be continued, the welding melting quantity is increased, and after arcing is completed and the stud is fixed for 10 s-20 s, composite welding is completed. By means of the large-diameter steel stud composite welding method based on arcing-aluminothermy, large-diameter stud welding and steel plate welding can be achieved, the defect problem that stud welding is not fused and the like can be solved; and the advantages of being easy to operate and high in working efficiency are achieved.

Owner:NANJING UNIV OF SCI & TECH

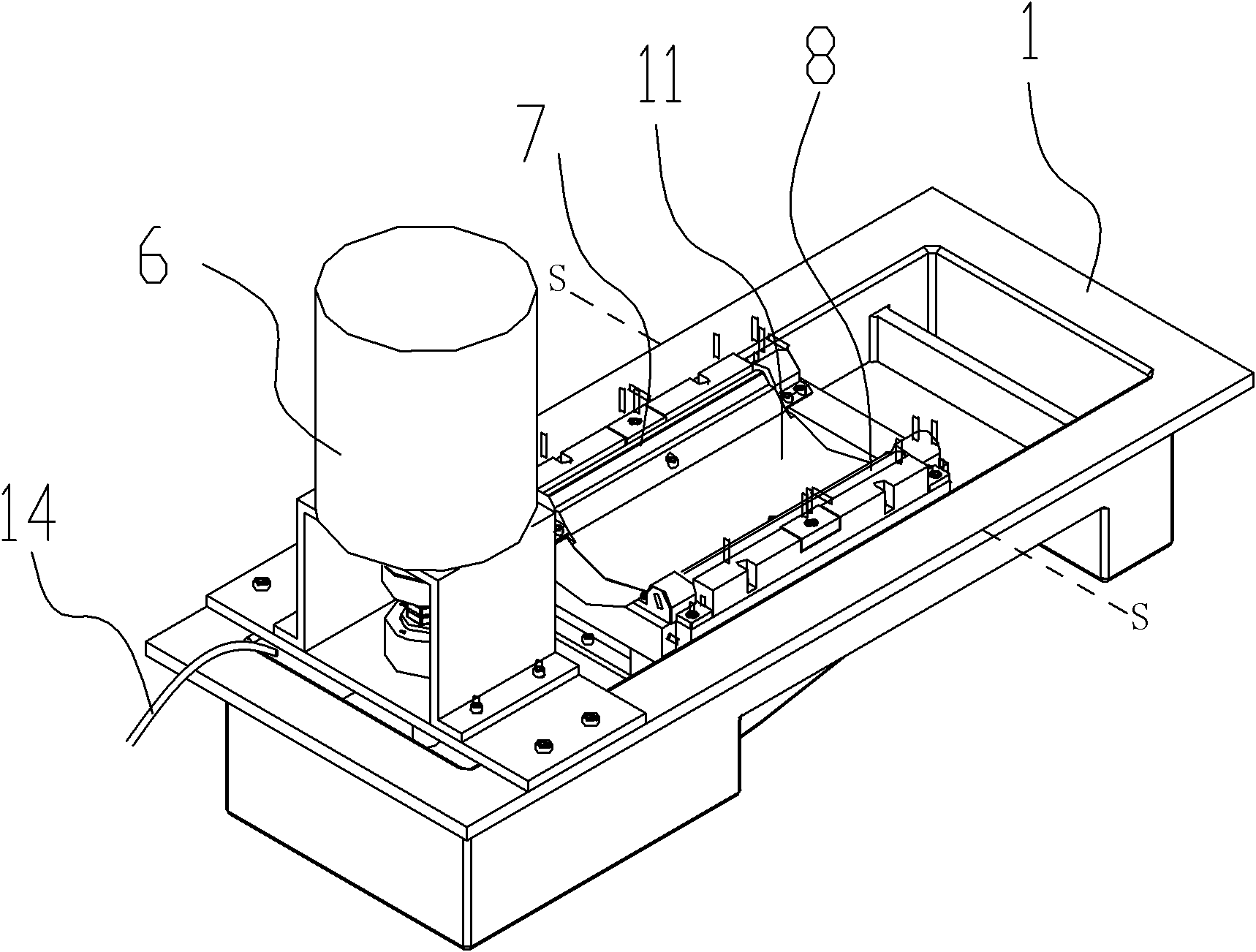

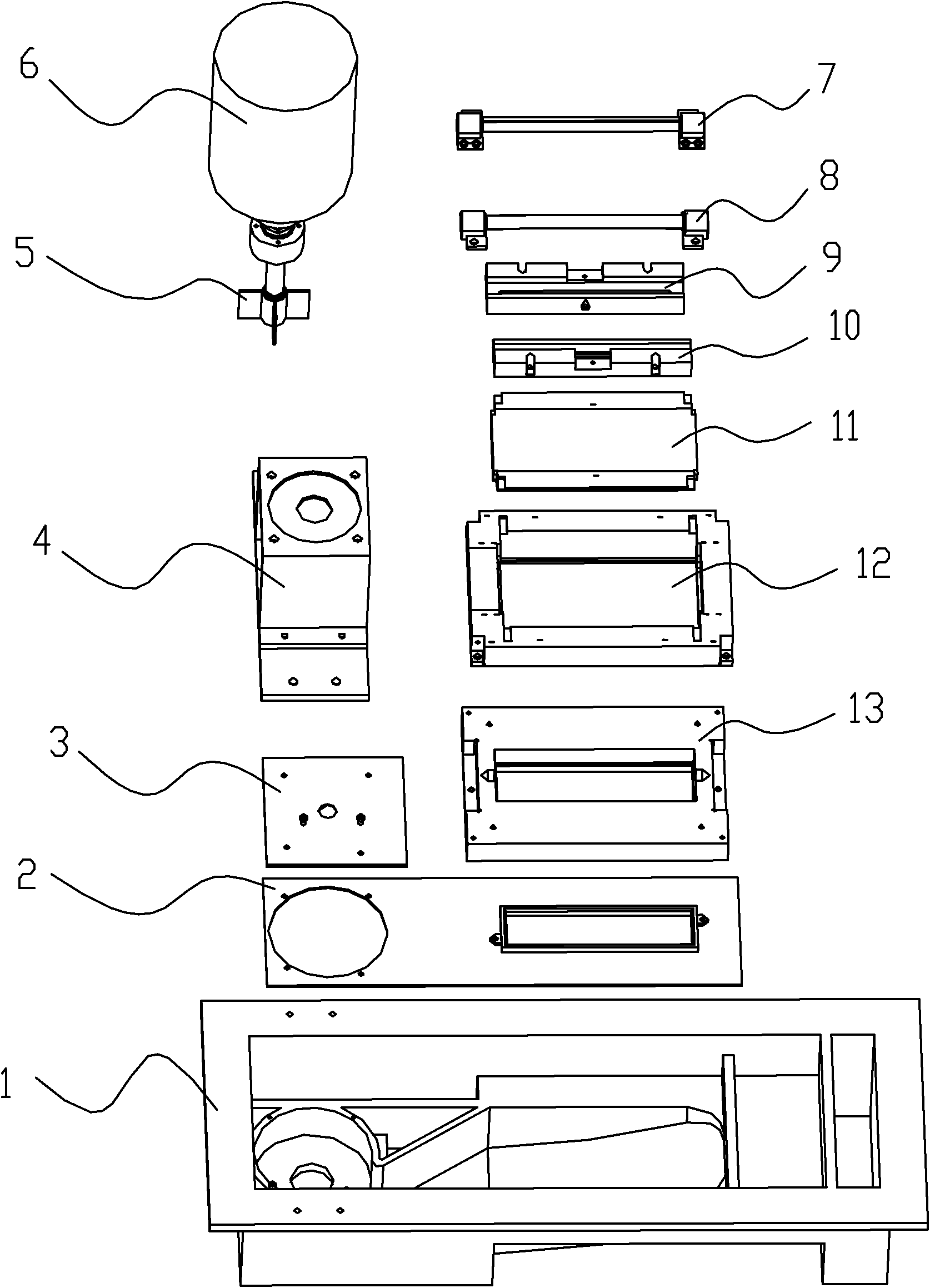

Welding aiding mechanism for solar cell piece series welding machine

ActiveCN104084660AAvoid enteringPrevent volatilizationFinal product manufactureMetal working apparatusLeft halfEngineering

The invention discloses a welding aiding mechanism for a solar cell piece series welding machine. The welding aiding mechanism solves the problems of insufficient welding and infirm welding for cell pieces caused by uneven and incomplete adhesion for welding flux, existing in the prior art. A welding aiding fluid leaching submerging groove (34) and a welding aiding fluid (44) are arranged on the left half part of a welding aiding mechanism transferring platform (33), a welding strip guiding groove (36) is formed in the platform surface of the right half part of the welding aiding mechanism transferring platform (33), a welding strip downward guiding-in arc-shaped block (41) and a welding strip upward guiding-out arc-shaped block (43) are respectively arranged at the groove bottom inside the welding aiding fluid leaching submerging groove (34), a lower pressing welding strip arc-shaped block (42) is arranged on the lower bottom surface of a welding aiding fluid leaching submerging groove cover plate (35), and welding strips (13) from a welding strip delivering mechanism are further arranged between the lower pressing welding strip arc-shaped block (42) and the welding aiding fluid leaching submerging groove (34). The welding strength and reliability are improved, no pseudo welding or over welding occurs, and the welding quality and efficiency are effectively improved.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

Compressing device for single-side spot welding of stainless steel sidewall, spot welding machine and welding process

ActiveCN103567617AHeight adjustableImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesBeam crossingSpot welding

The invention relates to a compressing device for single-side spot welding of a stainless steel sidewall, a spot welding machine and a welding process. The spot welding machine comprises a welder gantry, a welding platform, and spot welding electrodes. The welding platform is used for holding a sidewall to be welded. The compressing device is disposed on the welding platform and comprises two vertical posts arranged on two sides of the welding platform, and a cross beam crossing over the welding platform and connecting the two vertical posts. The cross beam is provided with a plurality of compressing parts used for compressing the sidewall. The vertical posts are movably connected with the welding platform. A frame and a wallboard are integrally compressed with the compressing device, the frame is tightly attached to the outer face of the wallboard and the platform, corrugated deformation of a workpiece is eliminated by pressure of an air cylinder, the wallboard and the frame form a whole after spot welding, and the whole is higher in rigidity; after compressing force is removed, the outer surface can still be even and flatness is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

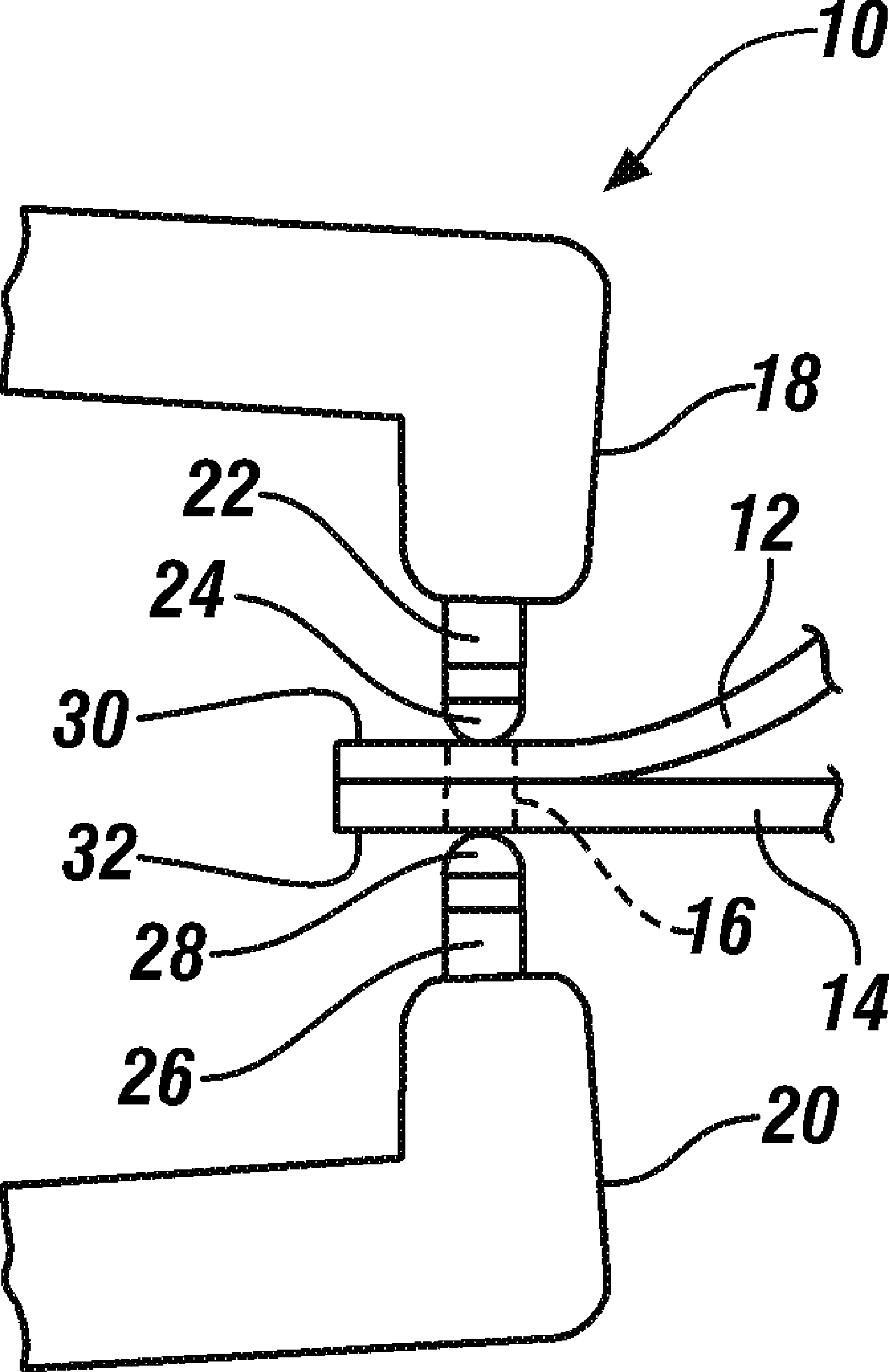

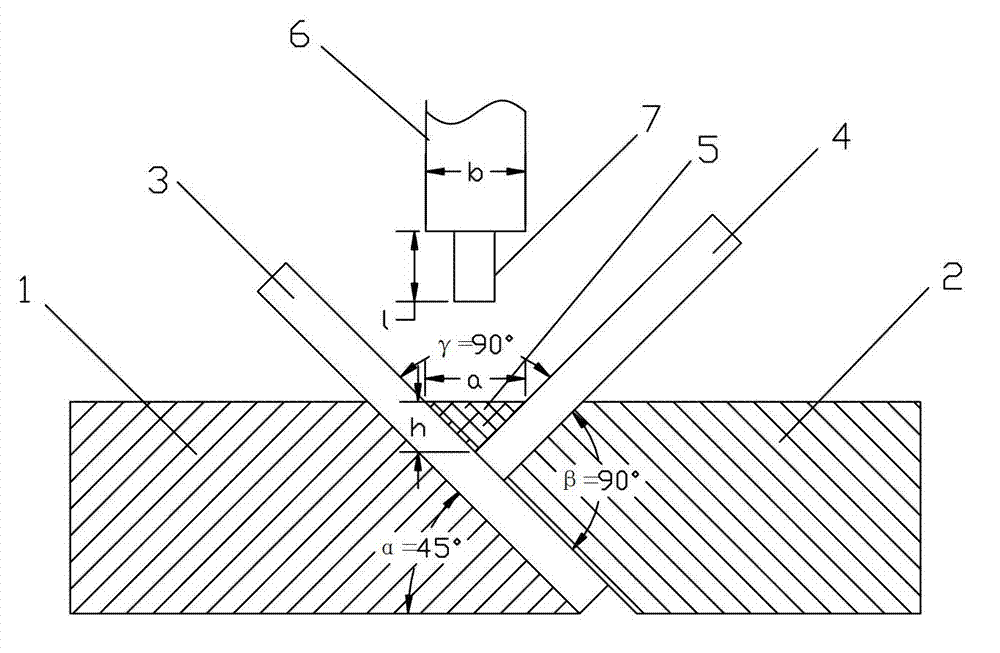

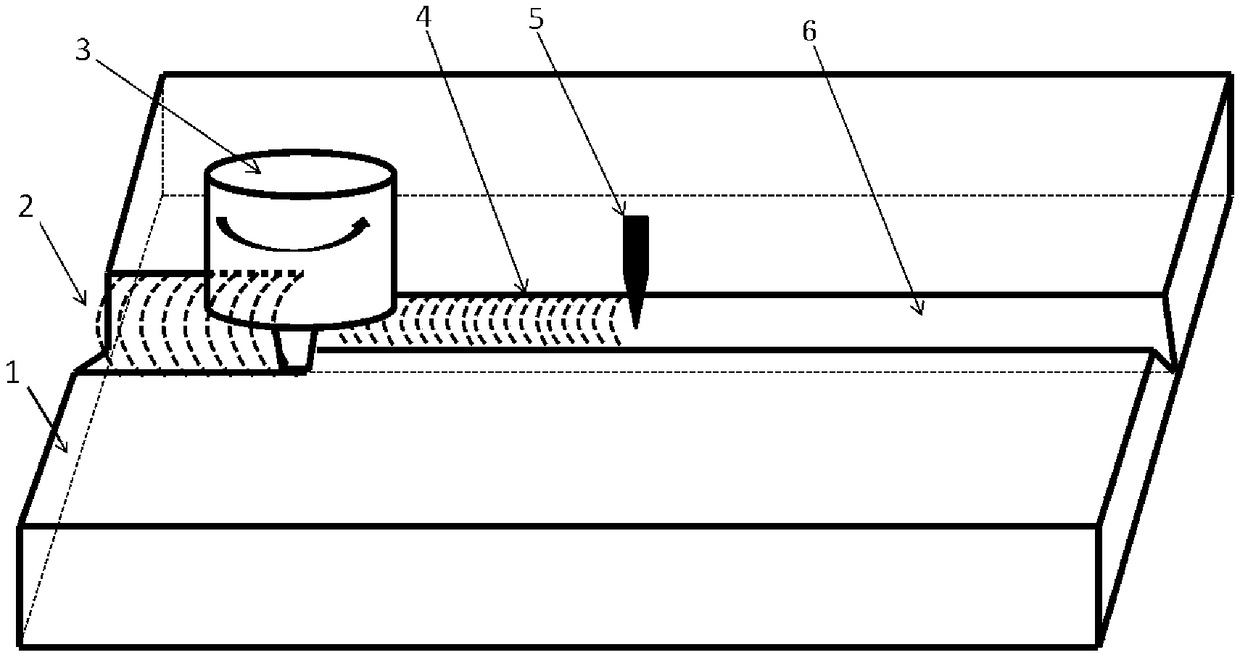

Fusion welding auxiliary heating friction-stir welding method under prefabricated groove situation

InactiveCN108857114AEffective warm-upImprove joint performanceWelding apparatusFriction weldingEngineering

The invention discloses a fusion welding auxiliary heating friction-stir welding method under a prefabricated groove situation. The method comprises the steps of firstly prefabricating grooves (6) with different shapes on a workpiece (1) to be welded, then utilizing fusion welding for accomplishing the welding of the workpiece (1) to be welded, and filling molten liquid metal in the grooves (6) for preheating welded joints, wherein during the welding process, friction-stir welding follows fusion welding, a stirring head (3) is located at the position which is 0 to 300mm away from a fusion welding gun (5), and the welding speed of the friction-stir welding and the welding speed of the fusion welding stay the same during the welding process, so that the distance between the stirring head (3)and the fusion welding gun (5) stays the same. The fusion welding energy is uniform, the workpiece to be welded is effectively preheated, the follow-up friction-stir welding plays a role in improvingthe connector performance, and through the combination of two welding modes, the weaknesses can be greatly avoided, and the welding operation is carried out simply, conveniently and flexibly.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

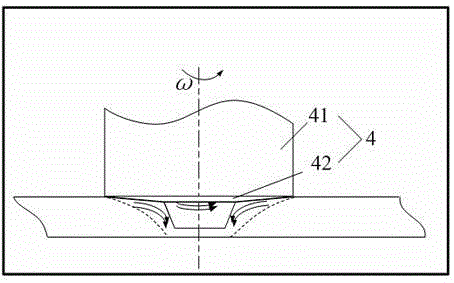

Micro friction stir welding method for small-thickness component and stir shaft shoulder of micro friction stir welding method

InactiveCN105665913AReduce complexityReduce processing difficultyNon-electric welding apparatusUpset weldingEngineering

The invention discloses a micro friction stir welding method for a small-thickness component and a stir shaft shoulder of the micro friction stir welding method. The method comprises the steps that a micro friction stir welding tool with the stir shaft shoulder is installed on an equipment spindle, the stir shaft shoulder is a flat shaft shoulder with cohesive figures or the stir shaft shoulder comprises a shaft shoulder body and a protrusion part protruding outwards from the shaft shoulder body, and the surface of the protrusion part is provided with cohesive figures; and the equipment spindle forms a 0-degree dip angle relative to the normal direction of the surface of a workpiece, the equipment spindle drives the micro friction stir welding tool to rotate at the rotation speed of 5000 rpm or higher, and the micro friction stir welding tool moves along a welding track at the constant welding speed and conducts upsetting welding. A welding process can be completed through only three-axis linkage due to the fact that the equipment spindle forms the 0-degree dip angle relative to the normal direction of the surface of the workpiece. Accordingly, equipment is simple, and stability is ensured through the cohesive figures and the constant-speed welding.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Method for judging residual stress of flash welding junction of mining round-link chain

ActiveCN112355450AEasy to makeSpeed up preparationPreparing sample for investigationMechanical clearance measurementsWeld seamFlash welding

The invention relates to a method for judging the residual stress of a flash welding junction of a mining round-link chain. The method comprises the following steps of: a) sampling: taking a chain ring which just completes port upsetting welding, and removing burrs at a welding seam of the chain ring; b) cooling: performing air cooling on the chain ring of which the burrs are removed after weldingin a dry environment; c) cutting a seam: cutting a seam along the cross section of a to-be-measured chain ring which is cooled to room temperature, wherein the spacing distance between the cutting position and the welding seam is less than 5mm; d) measuring the seam: measuring the width of the cutting seam in the step c), and comparing the width with a theoretical cutting width directly caused bycutting equipment for cutting the seam; e) adjusting process parameters of flash welding according to the measurement result in the step d, wherein the process parameters include but are not limitedto upsetting force and / or upsetting pressure maintaining time or preheating time; and f) repeating the steps a-d until the cutting seam is close to or equal to the theoretical cutting width. Accordingto the judgment method, whether related parameters such as the upsetting force and the pressure maintaining time are in place or not can be found in time and adjusted.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

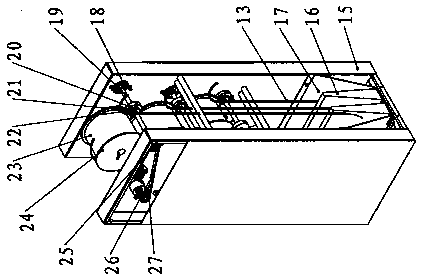

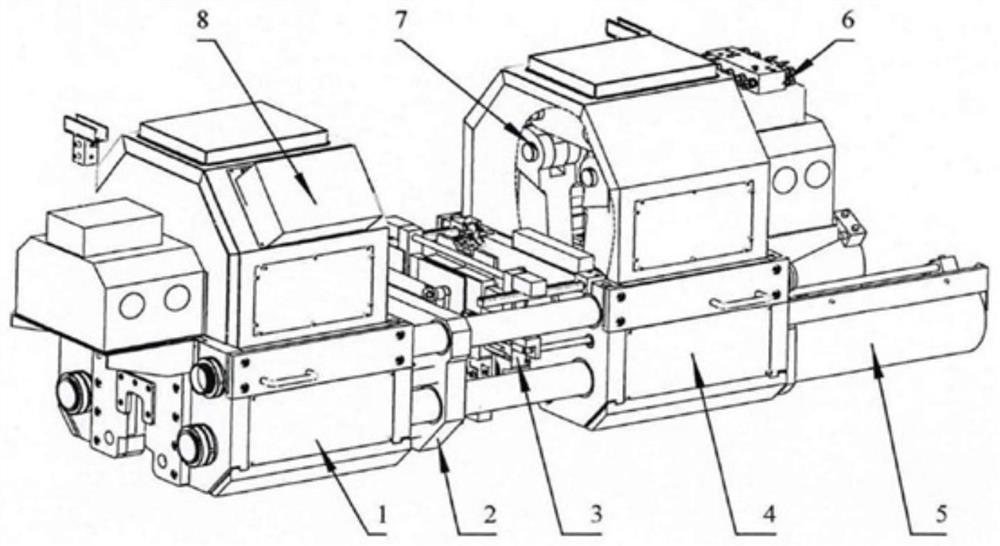

Method for achieving one-time molding of upset welding and wear-resistant welding of oil drill pipe

ActiveCN102837104AQuality improvementReduce contributionWelding accessoriesWear resistantUpset welding

The invention relates to a method for achieving one-time molding of upset welding and wear-resistant welding of an oil drill pipe. The oil drill pipe comprises a drill pipe body, and a male joint and a female joint arranged at both ends of the drill pipe body. The method comprises the steps as follows: firstly, the oil drill pipe is placed on a support device, the female joint extends out of a chuck, and a welding gun on a first welding device is aligned to the female joint to carry out upset welding until the thickness meets the requirement; then the oil drill pipe is turned around, the male joint of the oil drill pipe extends out of the chuck, the welding gun of the first welding device is aligned to the male joint, and the welding gun of the second welding device is aligned to the female joint; and finally, by rotating the oil drill pipe, the first welding device carries out upset welding on a solder wire at the male joint, the second welding device carries out wear-resistant welding on the solder wire at the female joint, and the welding is stopped when the outer diameter of the male joint meets the requirement, thereby finishing one-time molding work of upset welding and wear-resistant welding of the oil drill pipe. A device required by the method has the advantage of simple structure, short operation time, reduction in production cost and improvement on wear-resistant welding quality.

Owner:中曼石油装备集团有限公司

Flash welding forming method for titanium alloy special-shaped-section annular piece

PendingCN112743209AReduce deformation resistanceImprove deformation resistanceResistance welding apparatusHeat-affected zoneButt welding

The invention discloses a flash welding forming method for a titanium alloy special-shaped-section annular piece. The method comprises the following steps that an alloy special-shaped-section annular blank is clamped on a flash butt welding machine, and the distance at an opening of the alloy special-shaped-section annular blank is less than or equal to 8mm, the annular blank is electrified with a current of 160KA, so that the opening of the annular blank flashes and the temperatures of the left end face and the right end face of the opening instantly reach a gasification temperature of 3000 DEG C of alloy, meanwhile, the right end face is fed to the left end face, flashing is stopped after a burning area is formed by burning a distance of 13mm-18mm within 1 minute of flashing, and feeding of the right end face of the annular blank is stopped; and when the temperatures of the left end face and the right end face of the annular blank are reduced from 3000 DEG C to 1000 DEG C, a high-temperature area is formed, the distance between the left end face and the right end face of the annular blank is 10 mm-12 mm, upsetting welding is carried out in the high-temperature area to form the special-shaped-section annular piece, then the temperature of a welding seam is kept being reduced to 960 DEG C under the action of upsetting force, and the technological process is completed, wherein the period of the welding seam temperature from 1000 DEG C to 960 DEG C is called a heat affected zone. The method is mainly used for welding the titanium alloy special-shaped-section annular piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Rail track friction welding method

InactiveCN108568591AFrictional stabilityReduce stickingNon-electric welding apparatusFriction weldingEngineering

The invention discloses a rail track friction welding method. The method comprises the following steps: 1, pre-weld preparation: carrying out pretreatment on the end faces of two sections of rails tobe welded according to the track friction welding requirements, and aligning to form a track friction pair; 2, initial friction: translating the second rail, and enabling the first rail to get close to a track clamp; forming a friction surface after the friction face of the first rail is in contact with the friction face of the second rail, making plastic deformation and mechanical excavation phenomena occur on the friction surface, and gradually increasing the heating power of the friction surface; 3, friction transition: with the progress of a friction process, gradually enlarging the sealing of the friction surface by means of plastic metal with good contact; 4, stable friction: extruding the metal of a high temperature plastic deformation layer from the friction surface to form a flashedge under the action of track motion and friction, and shortening the rails in the axial direction; 5, upset welding: returning the first rail and the second rail for aligning, rapidly applying upset pressure, and using weld zone metal to form rail track friction welding joints.

Owner:SOUTHWEST JIAOTONG UNIV

Single-sided resistance spot-welding welding tool and welding method for railway vehicle

InactiveCN110369847AEasy to processGuaranteed flatnessResistance welding apparatusRelative displacementCompression device

The invention discloses a single-sided resistance spot-welding welding tool and welding method for railway vehicles. The welding tool comprises a copper platform, a compression component and a liftingcomponent, wherein the compression component comprises a transverse beam and a compression device; the transverse beam is located above the copper platform and moves in the longitudinal direction ofthe copper platform; the compression device is used for compressing and gluing a workpiece to the copper platform so as to avoid the relative displacement between the workpiece and the copper platform; the lifting component comprises a lifting and driving component and a lifting rod; one end of the workpiece is upwarped through the lifting component; and a welding point on the curved surface shapeof the workpiece is tangent to the copper platform so as to be matched with the walking track of the curved surface workpiece during spot welding and facilitate the processing of the workpiece. On the one hand, the copper platform is used as the negative pole of single-sided resistance spot welding, and on the other hand, the copper platform is used for ensuring the flatness of the workpiece, sothat no indentation occurs on one side of the workpiece after spot welding, and the processing requirements are met. The welding tool can meet the requirements of seamless processing of flat workpieces and curved surface workpieces, and has a positive promotion effect on the development of the railway vehicle technology in China.

Owner:CRRC SIFANG CO LTD

Shock resisting steel structure welding process

InactiveCN107755854AAvoid the problems of easy mixing of impurities, falling copper slag, and environmental pollutionAvoid stress concentrationWelding electrode featuresCopper platingButt welding

The invention discloses a shock resisting steel structure welding process. The shock resisting steel structure welding process comprises the requirements and steps of (1) material selection, (2) construction conditions and (3) welding parameters and steps; a multi-wire copper-free welding core is selected in the step of material selection; the construction conditions are preheating of a welding rod and the welding core before use; and the welding steps are as follows: the equal-temperature and equal-speed symmetrical welding is performed on two opposite surfaces of two steel columns during butt welding; the first two opposite surfaces are welded firstly when run-on tabs are added; then, the run-on tabs are cut; the surfaces of welding lines are cleaned; then, the second two opposite surfaces are welded; and after the welding is finished, two opposite surfaces are used for continuous welding until the whole welding lines are fully welded. The copper-free welding core is adopted to prevent the problems of copper slag fall and environmental pollution in the welding process of a traditional copper-plated welding core; the multi-wire welding rod is adopted, and the energy of welding electric arc is fully used, so that the welding lines are more reliable, and the problem of brittle rupture caused by air holes and cracks is effectively prevented; and the welding process achieves beneficial effects on the shock resisting aspect in steel structural buildings.

Owner:QINGDAO KEHUA STEEL STRUCTURE

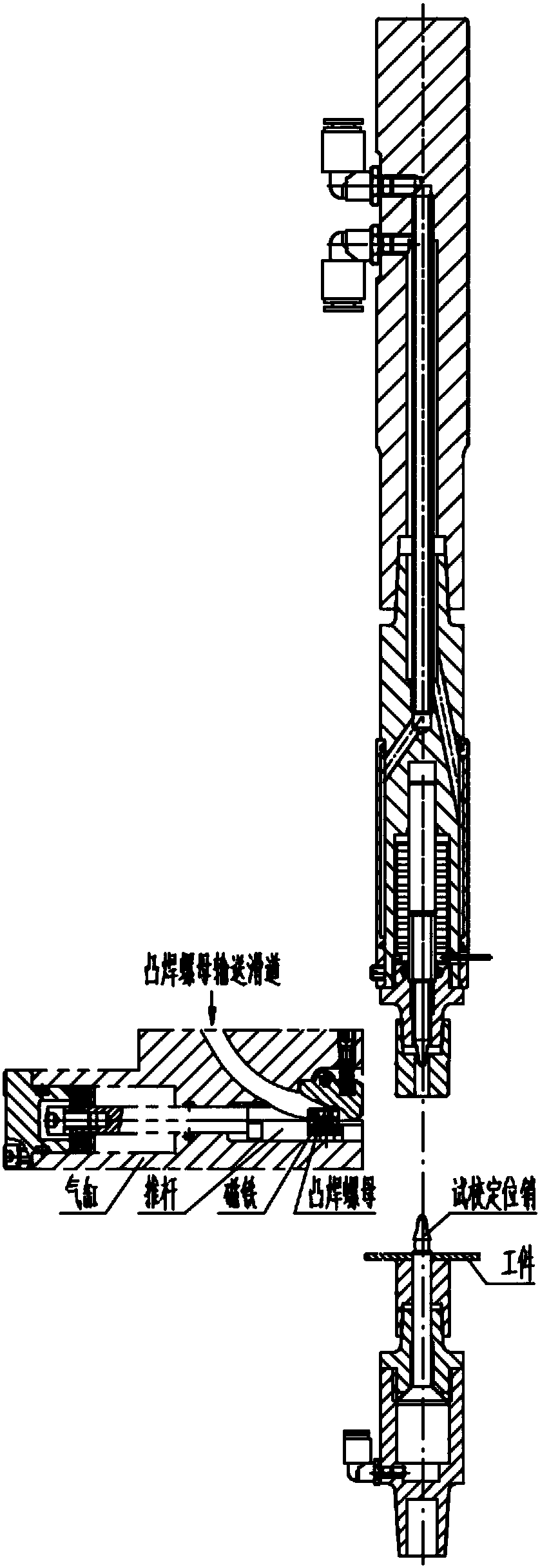

Welding gun automatic projection welding and spot welding structure

InactiveCN108436242AReduce labor intensitySimple structureResistance electrode holdersProduction lineFriction welding

The invention relates to the technical field of novel welding gun automatic projection welding and spot welding structures, in particular to that one welding gun is adopted to complete automatic switching between a projection welding electrode and a spot welding electrode, and therefore a welding manner that one welding gun can compete automatic projection welding and spot welding is achieved. Automatic connection of a fastener becomes a technology trend of current automobile and home appliance application, and the structure solves the problems that according to a past projection welding part,spot welding connection with a large part plate is performed after a nut, a screw and a small part plate are independently subjected to manual projection welding, the welding efficiency is low, and the labor intensity is large. According to the main technical scheme and the technical key points of the structure, due to linkage that projection welding upper and lower electrode heads and spot welding upper and lower electrode cap structures are fast disassembled from and assembled on a side face automatic projection welding nut feeding structure and a welding production line, fast and automaticswitching between projection welding and spot welding is completed.

Owner:上海兰盈智能科技有限公司

Nut welding technology

The invention belongs to the technical field of welding methods, and provides a nut welding process and material preparation; welding raw material pretreatment: use an air gun to blow off impurities on the surface of the welding parts, welding nuts, and welding tooling; Cold heading forming, continuous cold heading 2-3 times, so that the corners of the nut are full and consistent, punch out a through hole in the center of the nut with a cold heading machine; take the center hole of the nut as the positioning reference, use the cold heading machine to make the formed Upsetting multiple welding points with the same height at the edge of one end face of the nut; use a tapping machine to process internal threads in the center hole of the nut to form a welding nut; check welding parameters; feeding; welding; post-heating: welding The final parts are welded at a current of 20000A for 20ms; inspection: inspect the welded products. The purpose of the present invention is to provide a nut welding process, the welding process is simple, easy to operate, and it meets the performance requirements of welding nuts.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Stainless steel plate welding method for radiation environment

InactiveCN106891082AAvoid affecting the welding effectArc welding apparatusWelding/soldering/cutting articlesFillet weldNuclear power

The invention relates to the field of in-service maintenance of nuclear power plants, specifically relates to a welding method for repairing equipment and components in high-radiation areas of a nuclear power plant, and aims at ensuring the personal safety of repairing workers as well as reducing the repairing cost of the nuclear power plant. The stainless steel plate welding method for the radiation environment is applicable to stainless steel plates being 2-5mm in thickness. The method comprises the following steps: pairing and abutting two stainless steel plates, and forming abutting joints being 100+ / -10mm in width; fixing the abutting joints by spot welding; mounting an automatic welding machine for TIG automatic welding in the extending direction of the abutting joints; examining welded fillet welds after the automatic welding machine finishes the welding; and repairing welding gaps in the fillet welds in a manual welding manner. The method is applicable to welding and repairing of the equipment and components in the high-radiation areas of the nuclear power plant, and the injury of radiation on the bodies of the repairing workers can be reduced; the method is fast to weld, small in time consumption, and low in labor cost.

Owner:CHINA NUCLEAR IND 23 CONSTR +1

75 kg/m hypereutectoid steel rail and eutectoid steel rail air pressure welding method and welding part

ActiveCN113618193AReduce internal defectsImprove welding qualityIncreasing energy efficiencyGas flame welding apparatusHeating timeSpray cooling

The invention discloses a 75 kg / m hypereutectoid steel rail and eutectoid steel rail air pressure welding method. The 75 kg / m hypereutectoid steel rail and eutectoid steel rail air pressure welding method comprises the following steps that 1, first-stage heating is conducted, wherein the oxygen flow ranges from 95-105 SLM, the acetylene flow ranges from 105-115 SLM, and the heating time ranges from 250-300 s; 2, second-stage heating is conducted, wherein the oxygen flow is 85-90 SLM, the acetylene flow is 90-95 SLM, the heating time is 80-100 s, and when the surface temperature of to-be-welded parts of steel rails is 1250-1320 DEG C, fuel gas is closed to stop heating; 3, upsetting welding is executed; 4, knot pushing is executed, and pressure maintaining is carried out; 5, air spraying cooling is conducted; and 6, heat treatment is conducted. The method solves the problem that the eutectoid steel rail and the new hypereutectoid steel rail on an existing heavy haul railway are difficult to weld. The invention also discloses a welding part welded by using the method.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Welding process for double-side formation with one-side welding

InactiveCN107649794AImprove welding efficiencyImprove welding qualityArc welding apparatusSurface cleaningEngineering

The invention discloses a welding process for double-side formation with one-side welding. The welding process comprises the steps of a, workpiece surface cleaning; b, welding material selecting and welding process parameter setting; c, welding wire drying, wherein, a welding wire is dried, and the welding wire is kept clean and smooth; d, copper base plate installation, wherein, a submerged arc welding machine is adopted for welding, and a copper base plate is installed on the submerged arc welding machine; e, workpiece placing, wherein, the workpiece is horizontally placed on the lower sideof the submerged arc welding machine, and the center of the longitudinal welding seam of the workpiece is enabled to be kept consistent with the center of the copper base plate; f, run-on plate and run-off plate placing, wherein, a run-on plate and a run-off plate are correspondingly placed on the two ends of the longitudinal welding seam of the workpiece; and g, positioned welding, wherein, fullweld is carried out on the two ends of a workpiece, wherein the length of the workpiece is 100mm, spot welding is carried out, the length is 100mm, spot welding is carried out every 200mm-300 mm, andthe length of spot welding is 30mm-50mm. The welding process has the advantages that a bevelling step is omitted, time and labor are saved, the welding efficiency is improved, and the welding qualityis improved.

Owner:JIANGSU ZHONGXING YONGDA REFRIGERATION MACHINERY MFG

Friction stir welding welding method and tool for non-inclination self-upsetting

ActiveCN104014926BReduce complexityDecrease productivityNon-electric welding apparatusFriction weldingWeld seam

The invention relates to the technical field of welding, in particular to an aclinal self-upsetting, stirring and friction welding method and tool. The tool comprises a stirring head and a stirring needle, the stirring head is of a hollow structure, the stirring needle is rotatably arranged in the hollow structure of the stirring head and can stretch and retract in the stirring head, the axis of the stirring head and the axis of the stirring needle are overlapped, a shaft shoulder of the stirring head is provided with a forging boss, and the height of the forging boss is smaller than the height of the stirring portion left after the stirring needle extends out of the stirring head. In the whole welding process, a dip angle adjusting mechanism does not need to be arranged on equipment, complexity of the welding equipment is reduced, the angle between the shaft shoulder of the stirring head and a plane normal of a material to be welded is 0 degree, and accordingly aclinal stirring friction welding is achieved. When an aclinal stirring friction welding technology is adopted in two-dimensional plane welding, the angle of the stirring head does not need to be adjusted at a welding seam corner, welding procedures are reduced, meanwhile, the dip angle adjusting mechanism does not need to be arranged on the equipment, complexity of the welding equipment is reduced, and welding efficiency is improved.

Owner:BEIJING FSW TECH

Gas-pressure welding method and device for 60 kg/m hypereutectoid steel rail

ActiveCN113618194AReduce internal defectsImprove welding qualityGas flame welding apparatusHeating timeAcetylene

The invention discloses a gas-pressure welding method for a 60 kg / m hypereutectoid steel rail. The method comprises the following steps that firstly, a to-be-welded part of the steel rail is heated through oxy-acetylene flames, wherein a heater of a gas-pressure welding device swings at the amplitude of 3-5 mm, the heating time is 300-350 s, the oxygen flow is 75-90 L / min, and the acetylene flow is 85-95 L / min; when the surface temperature of the to-be-welded part of the steel rail is 1250-1350 DEG C, fuel gas is turned off to stop heating; secondly, upsetting welding is carried out, and primary pressure maintaining is carried out after upsetting welding is completed; thirdly, shearing and secondary pressure maintaining are carried out; and fourthly, heat treatment is carried out on the welding joint of the steel rail. According to the method, the quality of the welding joint of the 60 kg / m hypereutectoid steel rail is effectively improved. The invention also discloses a device for carrying out the method.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com