Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Effective warm-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

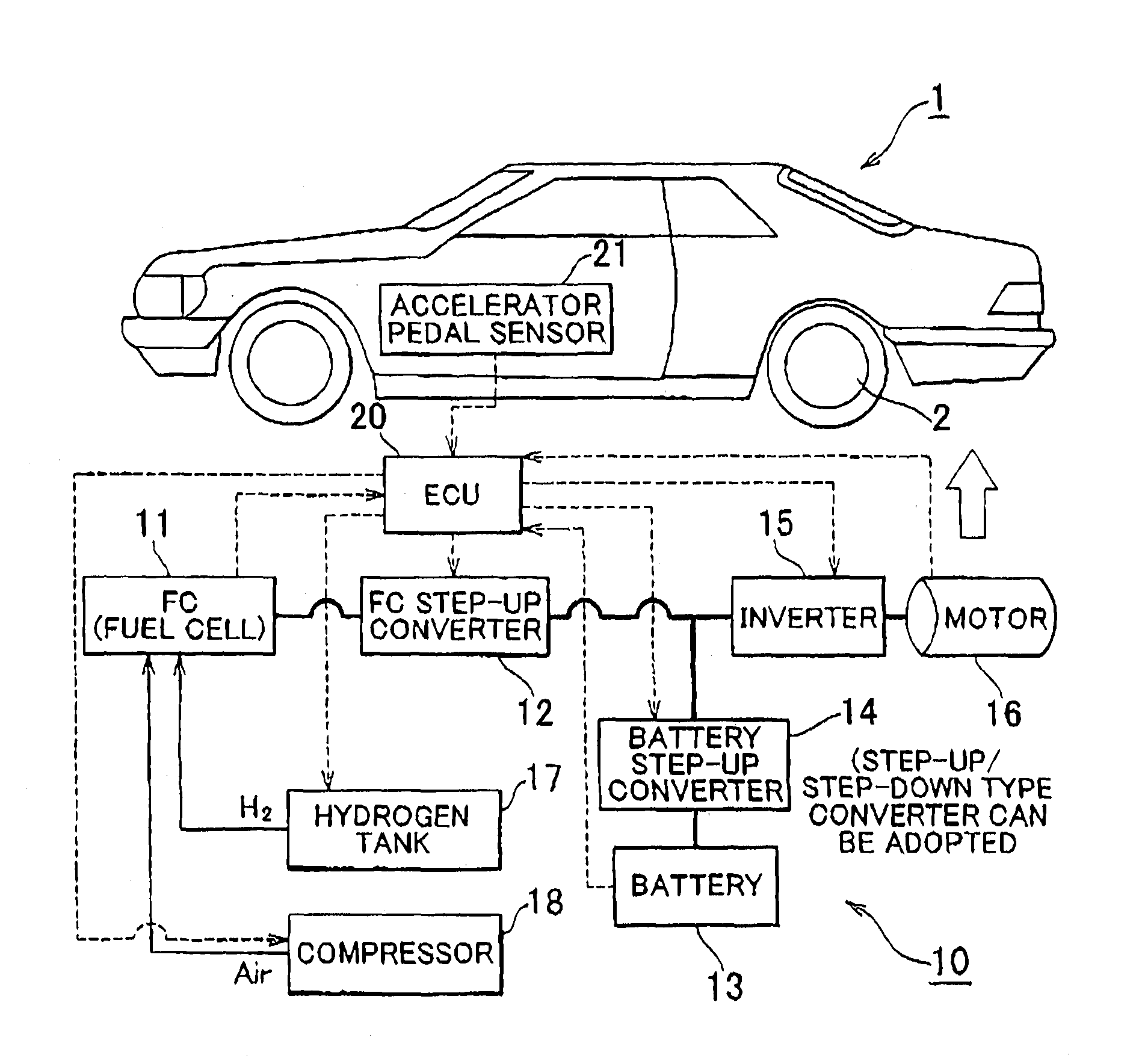

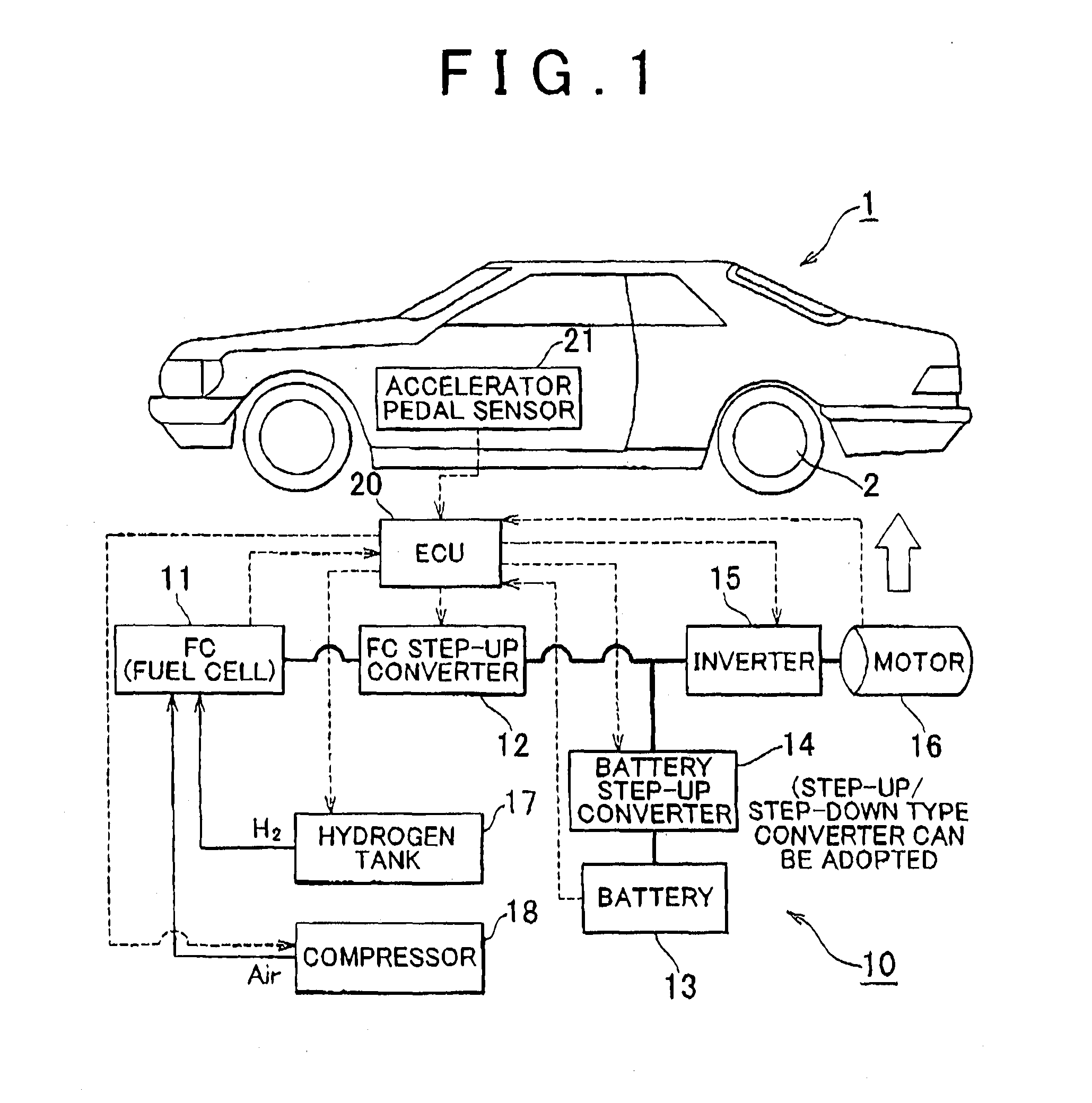

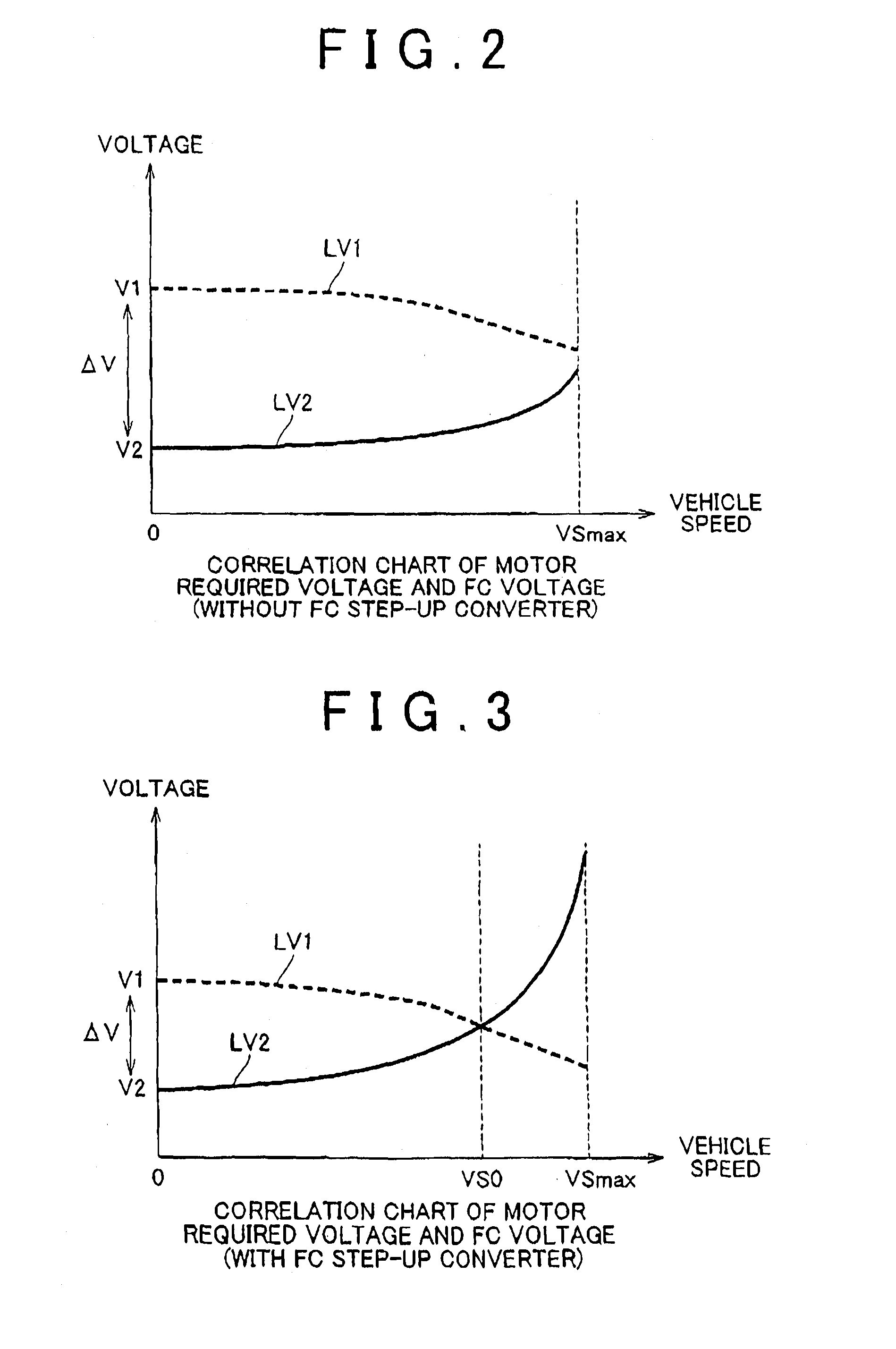

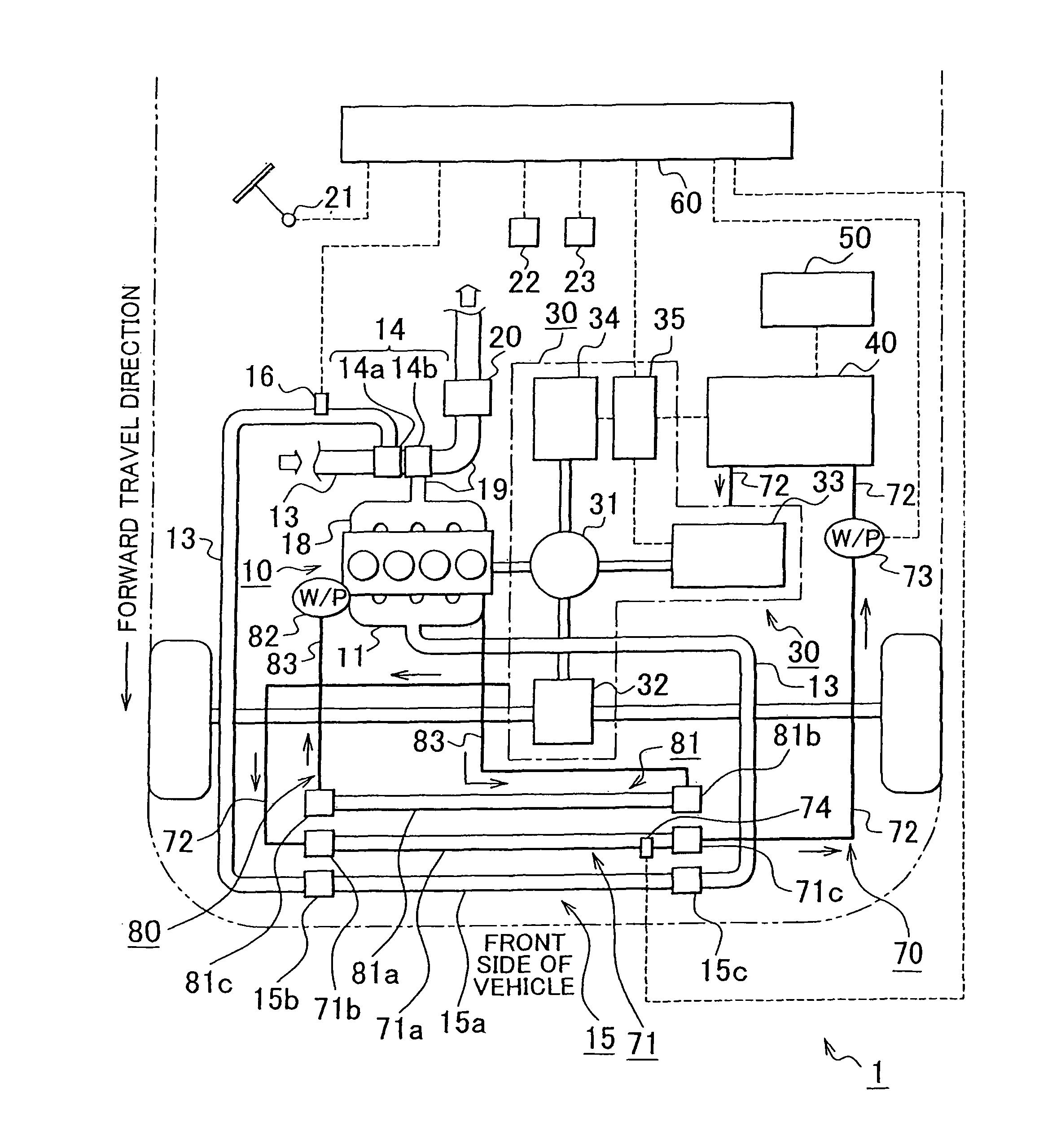

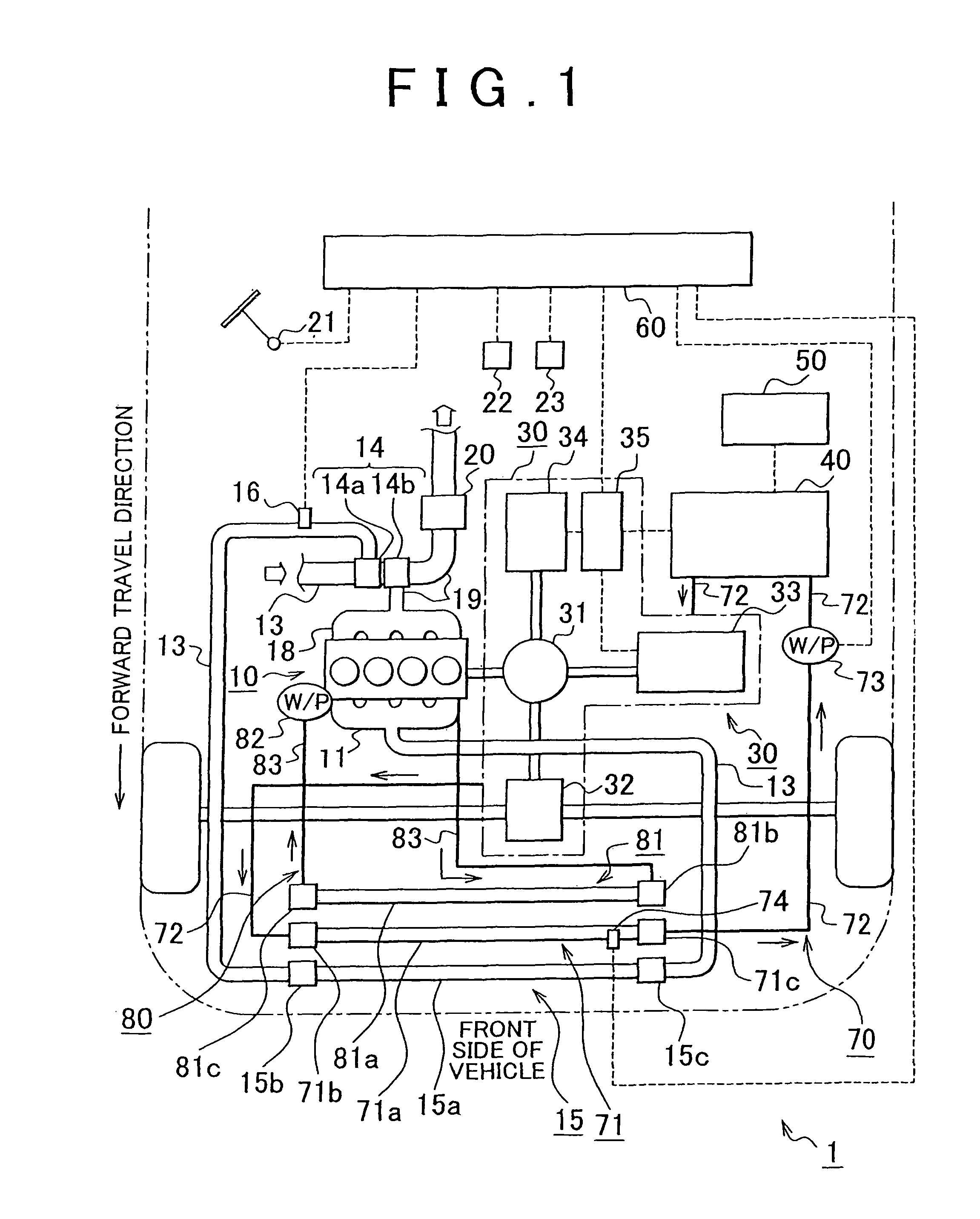

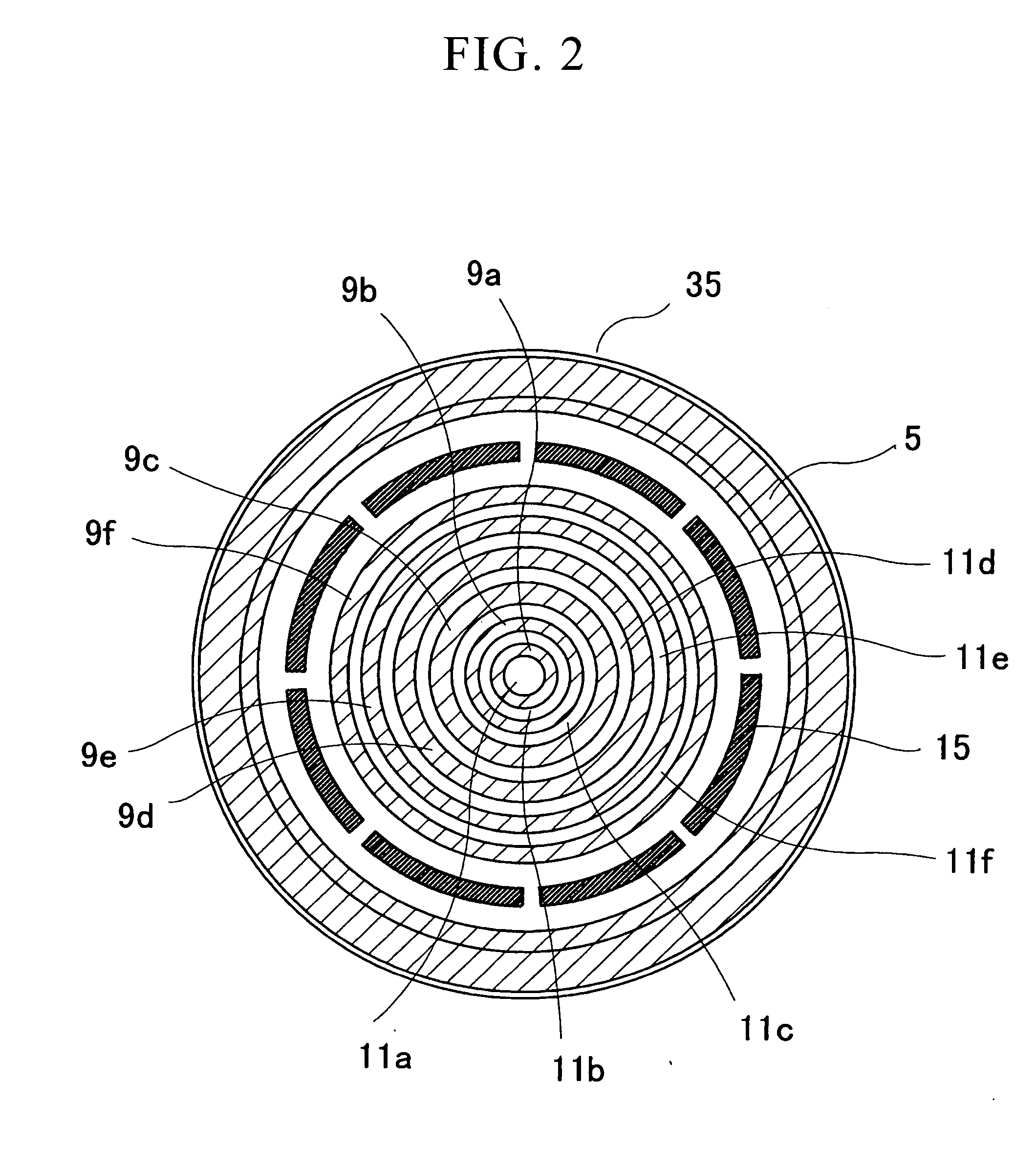

Fuel cell system and method of controlling the same

ActiveUS20110020719A1Effective warm-upFuel cell auxillariesTransportation fuel cell technologyFuel cellsDrive motor

A fuel cell system is equipped with a drive motor, a fuel cell, normal electric power generation means for performing normal electric power generation under a condition that the fuel cell is not warmed up, warm-up electric power generation means for performing warm-up electric power generation with lower electric power generation efficiency than normal electric power generation, and warm-up control means for controlling performance of warm-up electric power generation by the warm-up electric power generation means on a basis of a predetermined index on a necessity to warm up the fuel cell. The warm-up control means controls an operation state of the fuel cell during warm-up electric power generation on a basis of a correlation between the system loss required for warm-up of the fuel cell and a warm-up output required for driving of a load including the drive motor during warm-up of the fuel cell.

Owner:TOYOTA JIDOSHA KK

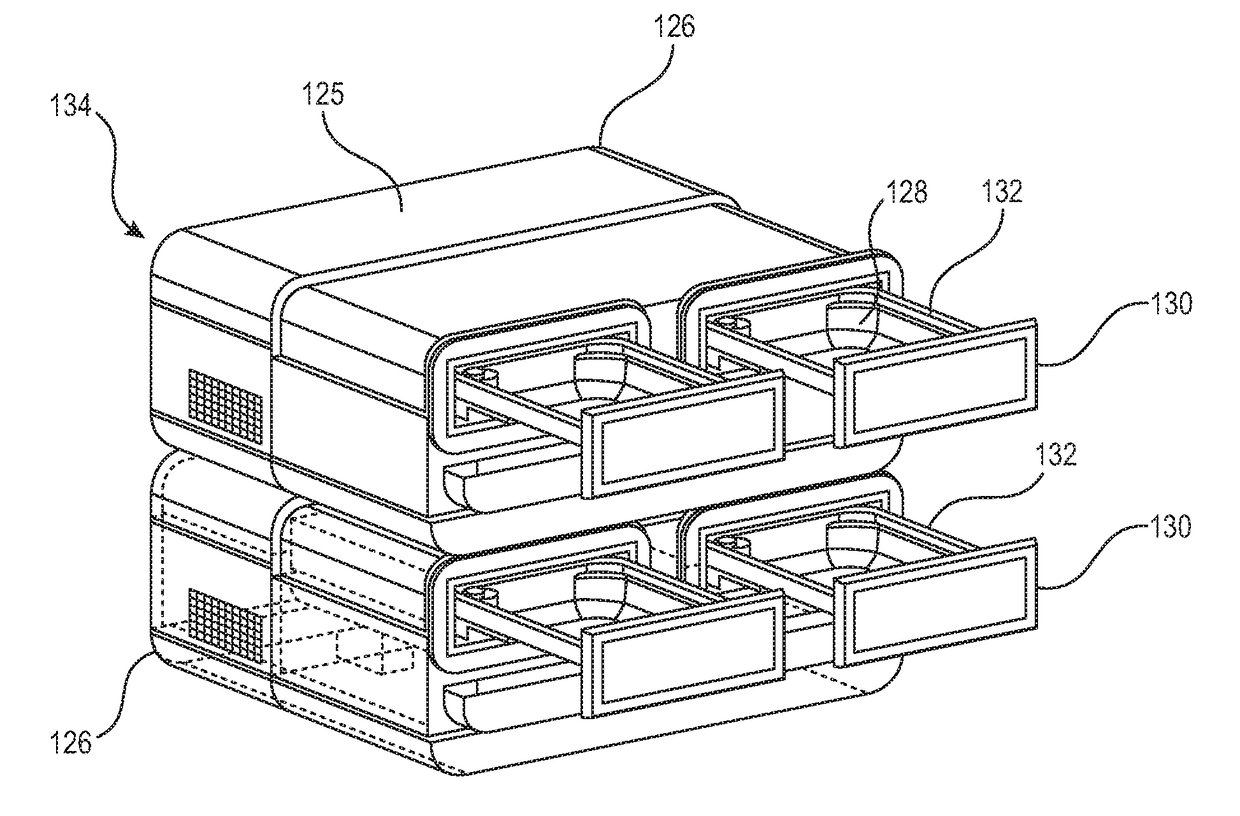

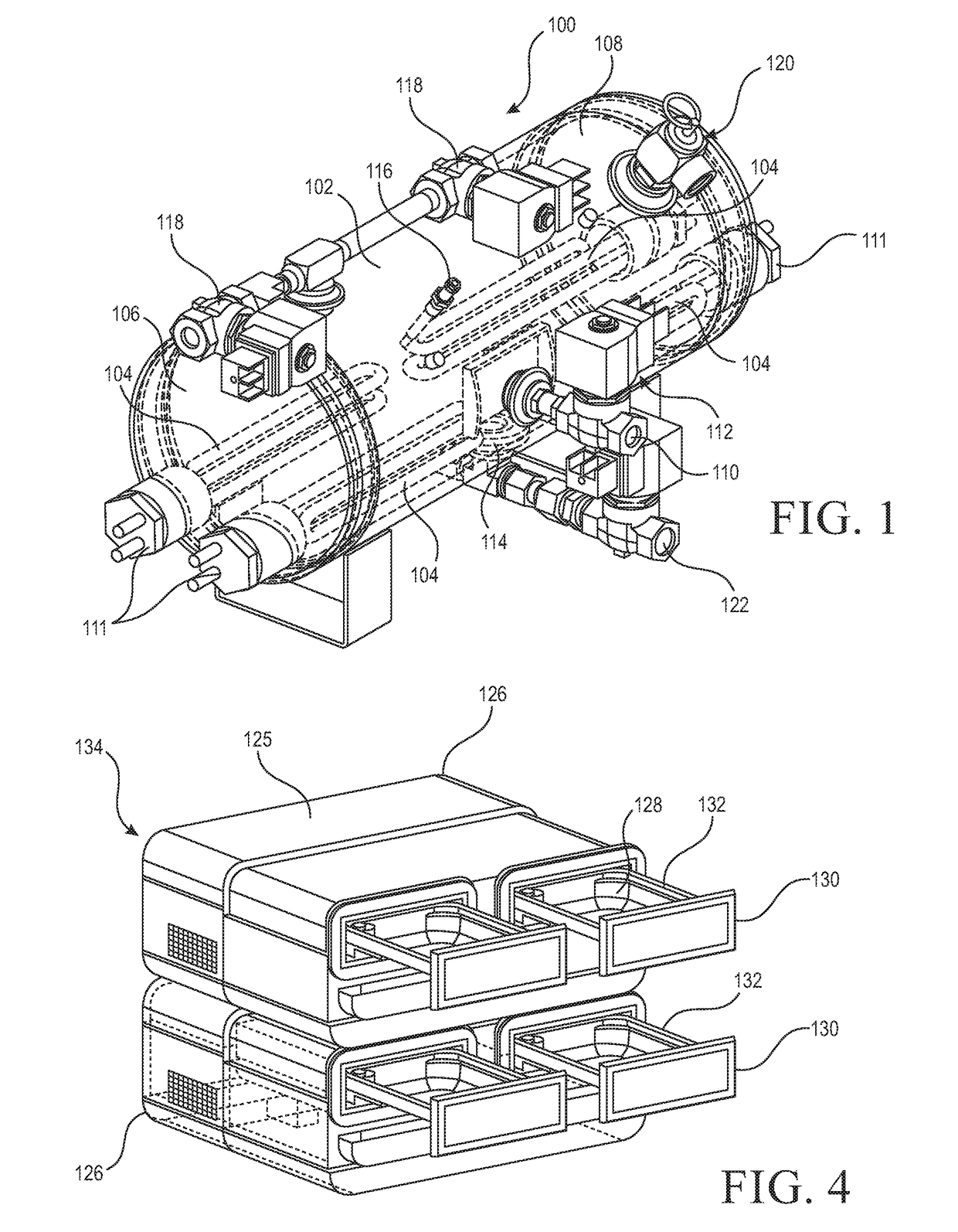

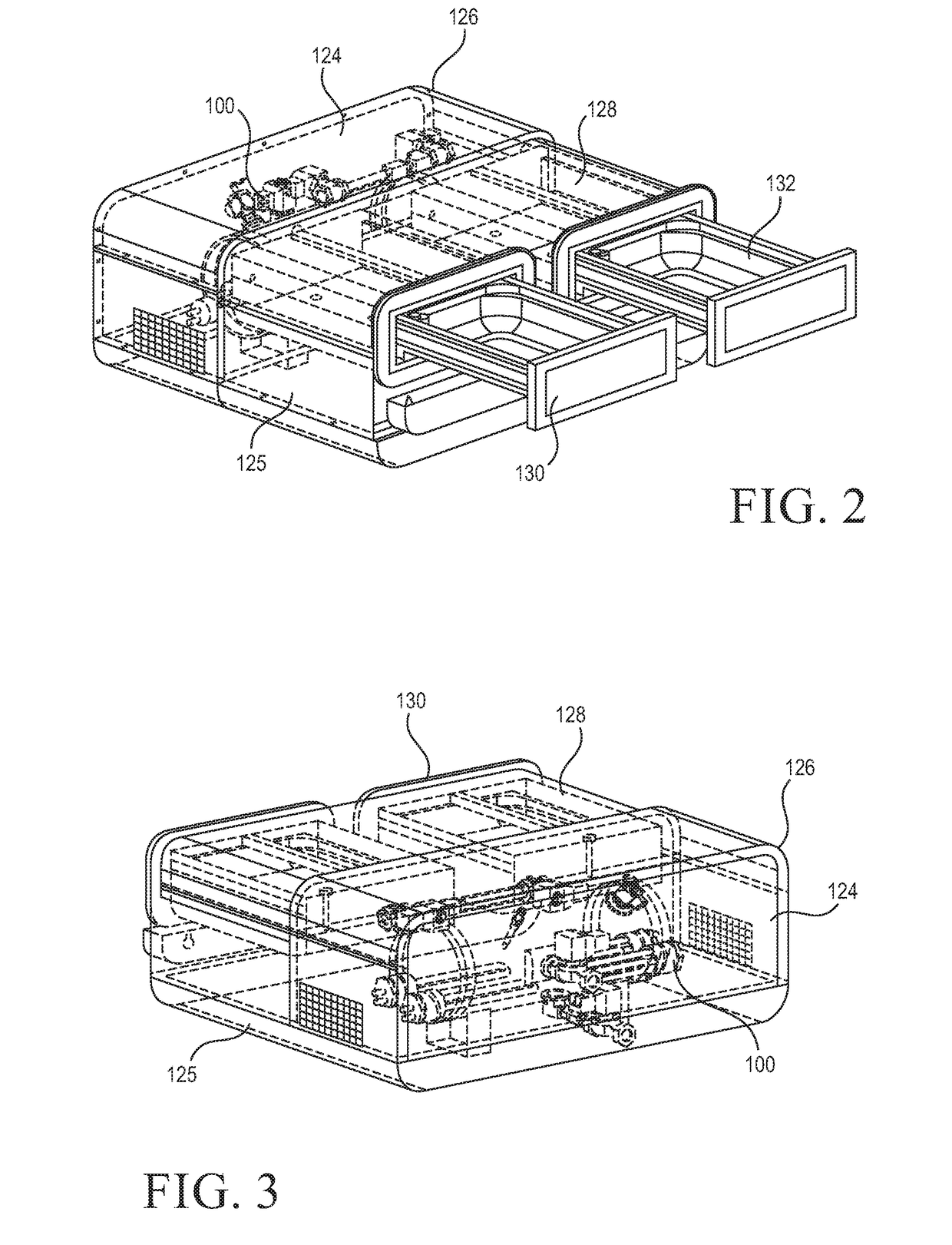

Mini steam generator for cooking food, modular cooking appliance, and modular food preparation station

InactiveUS20170095105A1Effective warm-upEfficient heatingSteam generation heating methodsSteam cooking vesselsEngineeringFood products

A mini steam generator for preparing or cooking various different types of food through means of a steaming process is disclosed. The mini steam generator is compact in size and is fluidically coupled to one or more cooking chambers for preparing or cooking the desired food products. The mini steam generator and the one or more cooking chambers may be disposed within a modular cooking appliance housing, and two or more modular cooking appliance housings may be fixedly connected together so as to effectively form a food preparation assembly or food preparation station.

Owner:A J ANTUNES & CO

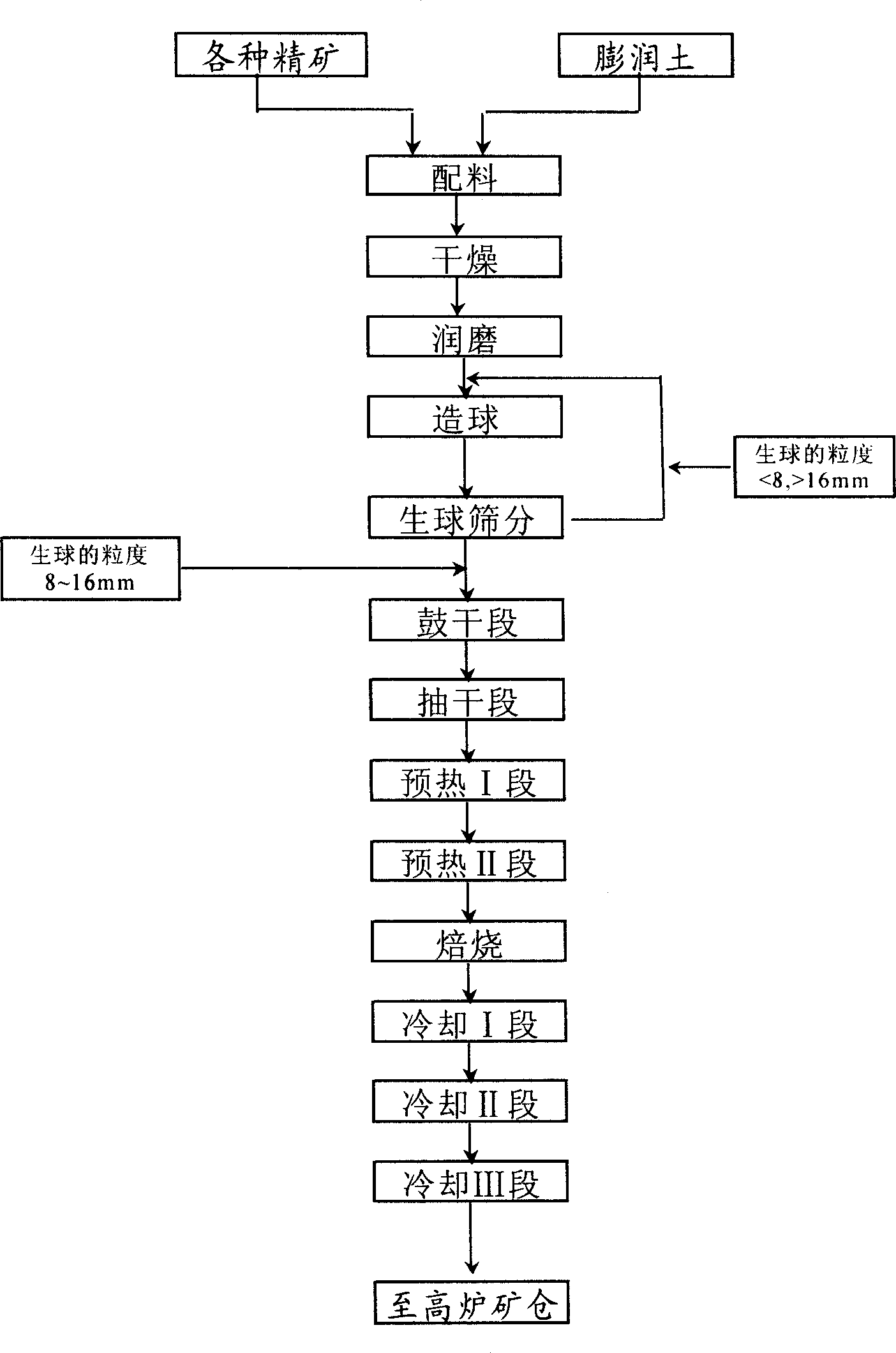

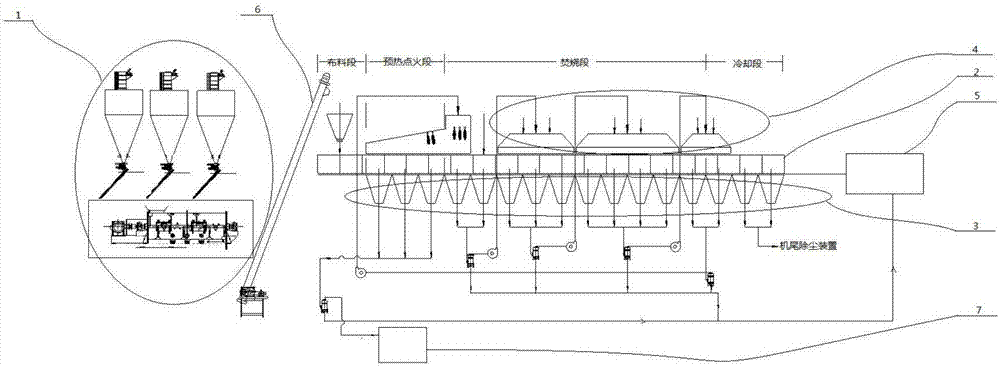

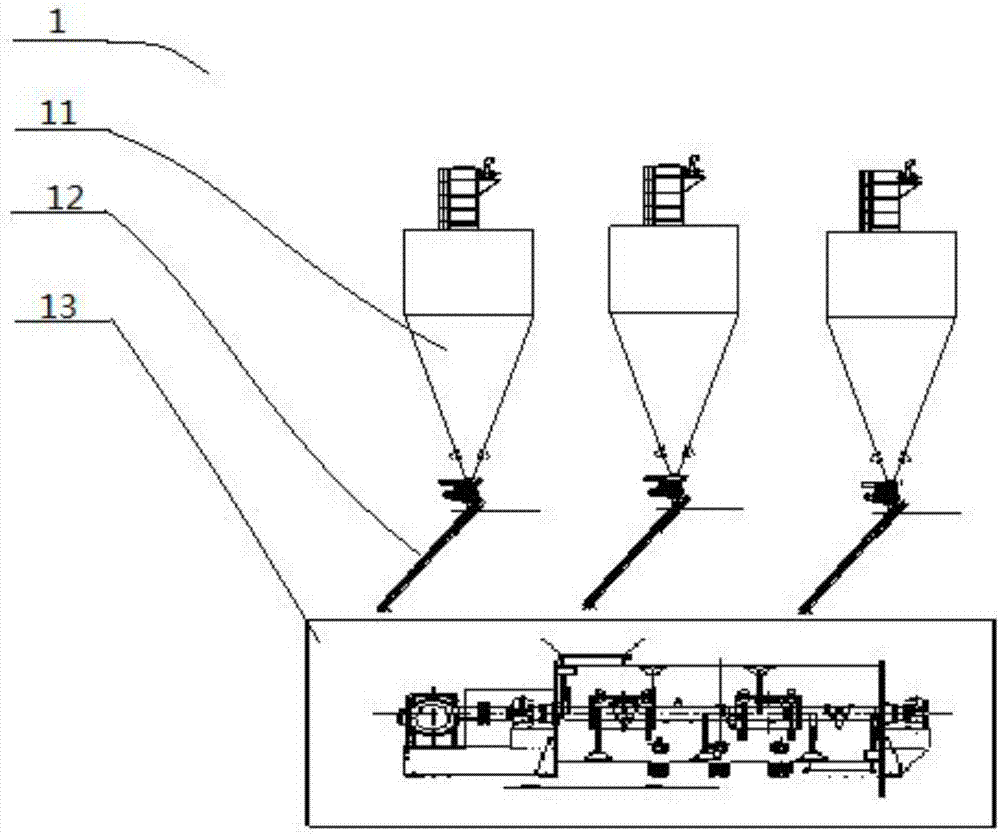

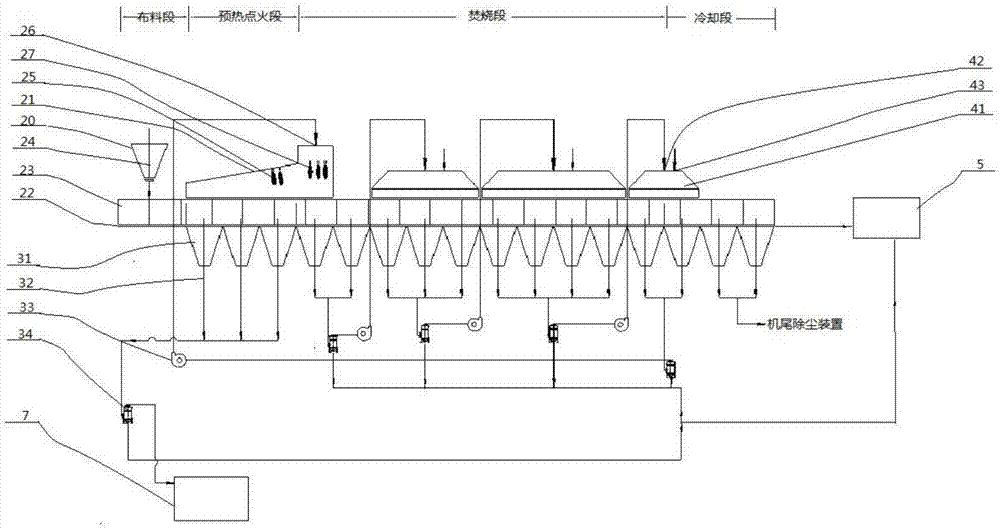

Method for producing high titanium type acid pellet vanadium titanium by chain grate - rotary kiln

This invention discloses a method for producing Ti-rich V-Ti oxidized pellets by chain grate and rotary kiln. The method comprises: mixing vanadic titanomagnetite concentrate with common magnetite concentrate at a weight ratio of 7:3, adding 2.0 wt. % of bentonite, palletizing to obtain 8-16 mm pellets by a disc pelletizer, drying (50-350 deg.C) and pre-heating (500-1000 deg.C) by a chain grate for 12 min, sending dried pellets into a rotary kiln, torrefying at 1150-1300 deg.C and 1.0 r / min for 30-35 min, and cooling torrefied pellets. The obtained Ti-rich V-Ti oxidized pellets have compression strength higher than 1800 N, and TiO2 content of 7.0%, thus can meet the requirement of blast furnace smelting.

Owner:攀枝花钢城集团有限公司球团厂

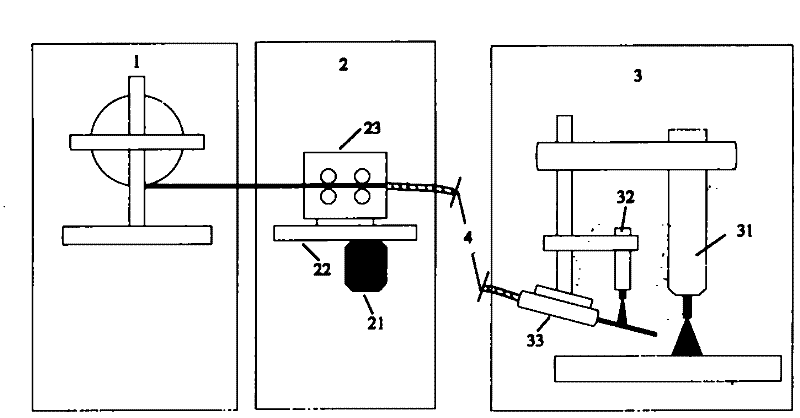

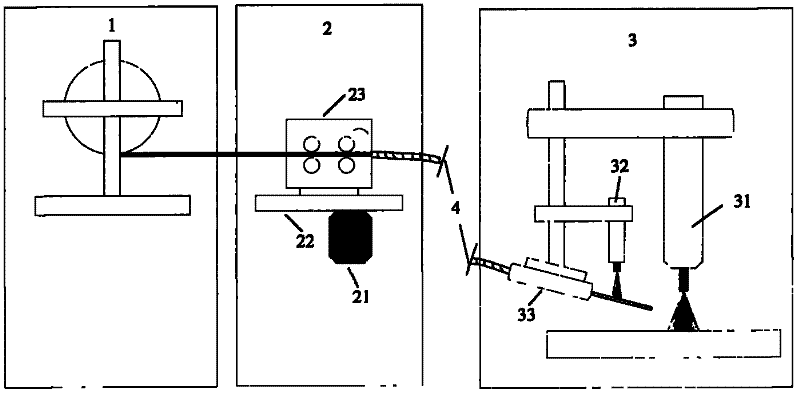

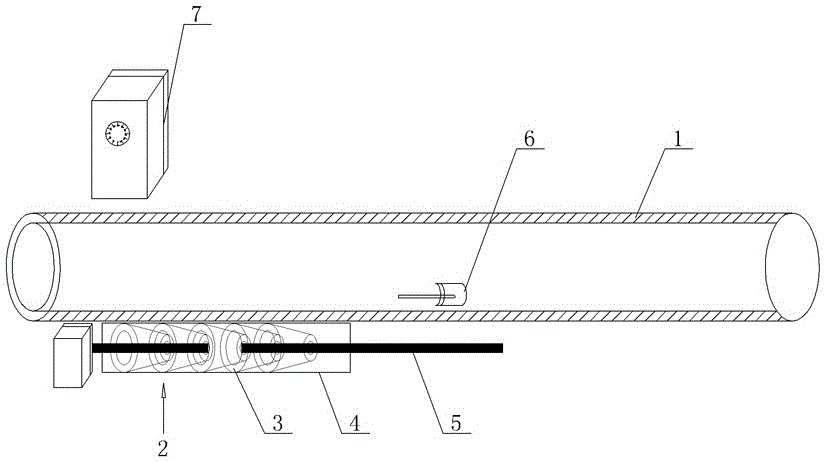

Cold metal transition welding method and device thereof

The invention aims at providing a cold metal transition welding method and a device thereof. The device consists of an MAG (Metal Active Gas) welding wire automatic feeding unit, a vibration wire feeding unit and an argon arc hot wire welding gun unit; the MAG welding wire automatic feeding unit is connected with the vibration wire feeding unit; the vibration wire feeding unit is connected with the argon arc hot wire welding gun unit through a hose; the argon arc hot wire welding gun unit comprises a straightener, an auxiliary arc welding gun and a main TIG (Tungsten Inert Gas) arc welding gun; and the auxiliary arc welding gun and the main TIG arc welding gun compose a heating source of the argon arc hot wire welding gun unit. The welding method comprises the following steps of: switching on a welding main circuit, and initiating a main TIG arc to heat a welding workpiece; and starting the MAG welding wire automatic feeding unit and a vibrating motor after the arcing of an auxiliary arc is stable. According to the cold metal transition welding method and the device thereof, the welding process is stable, the welding quality is even, the wire-feeding speed and the welding current are independently adjusted, the device is simple, and the cost is low. Based on the ordinary MAG welding wire feeding and arc wire-heating equipment, the vibration wire feeding unit is introduced, thewire heating manner is changed, thus, the cold metal transition welding is realized.

Owner:LIAONING SUPOR SHOWER EQUIP

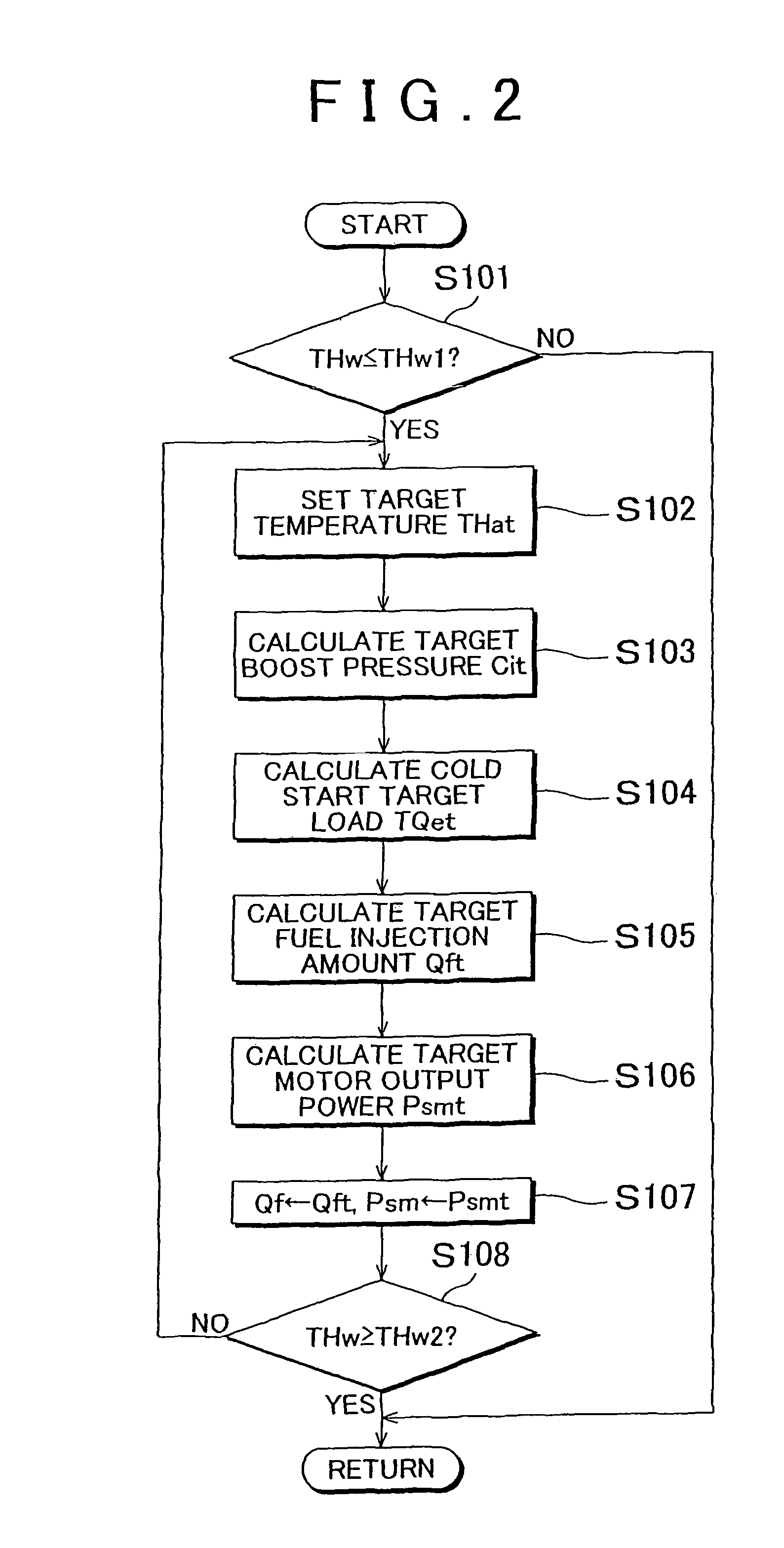

Hybrid system control apparatus and hybrid system control method

ActiveUS8494698B2High viscosityIncrease friction lossHybrid vehiclesInternal combustion piston enginesHybrid systemIntercooler

A hybrid system control apparatus is provided in which an intercooler is disposed upstream of the motor cooling radiator in a flow path of the ambient air flowing in an engine compartment, and / or is disposed such that at least a portion of the intercooler and a portion of the motor cooling radiator contact each other. The hybrid system control apparatus includes a warm-up portion that increases temperature of the boost air by controlling a load of the engine in cold start of a hybrid system such that the boost pressure from the forced air induction device is equal to or higher than a target boost pressure.

Owner:TOYOTA JIDOSHA KK

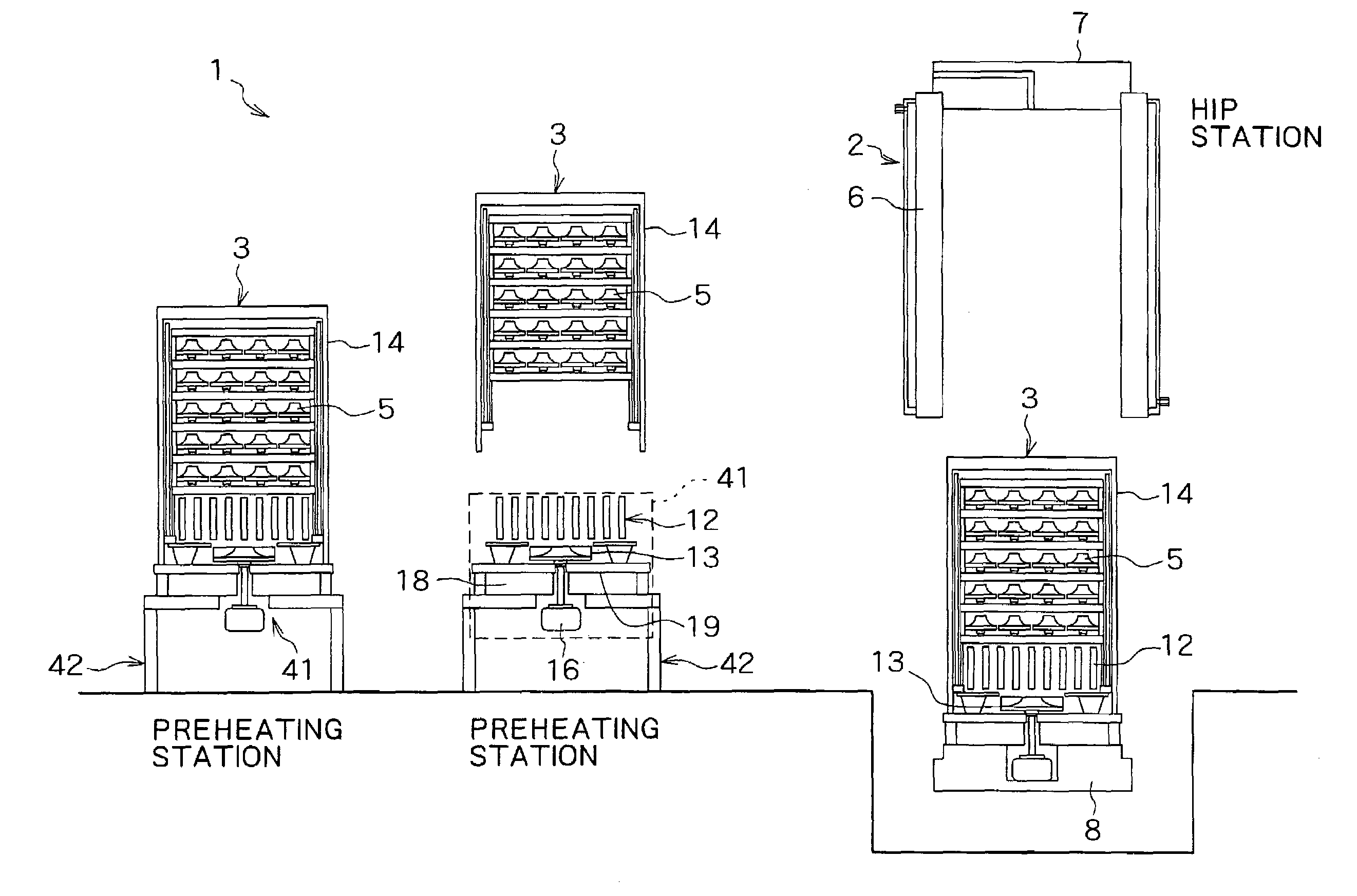

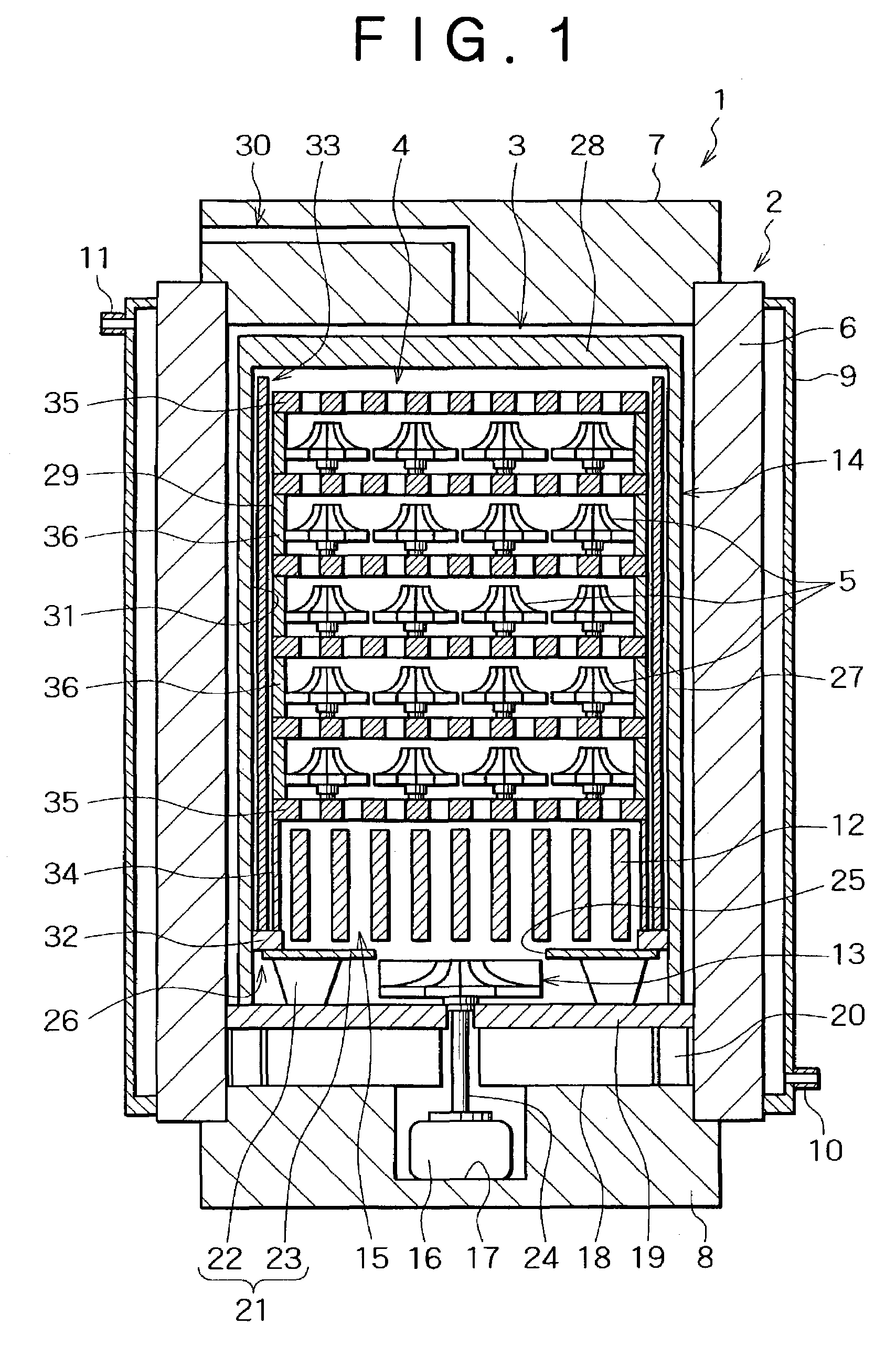

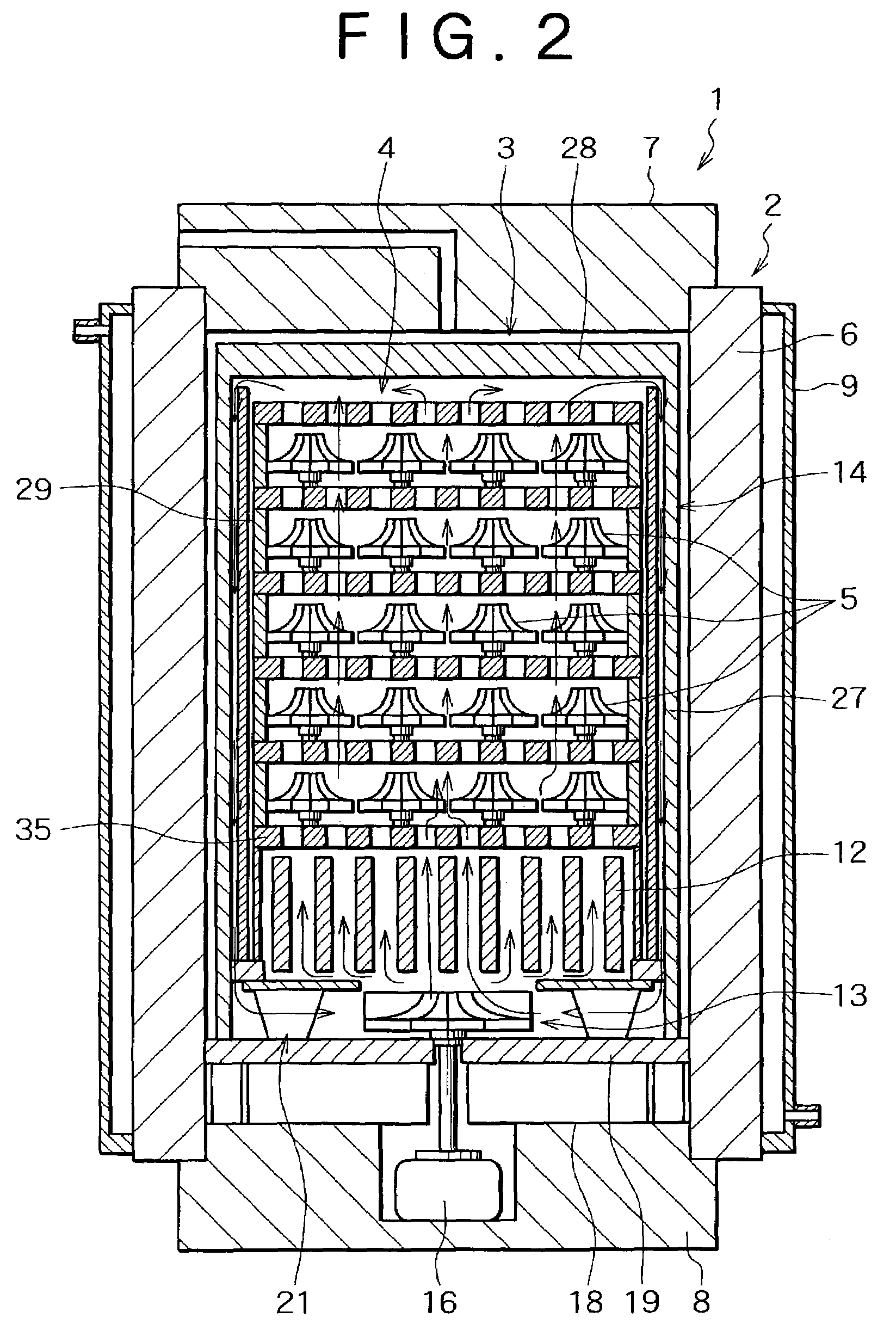

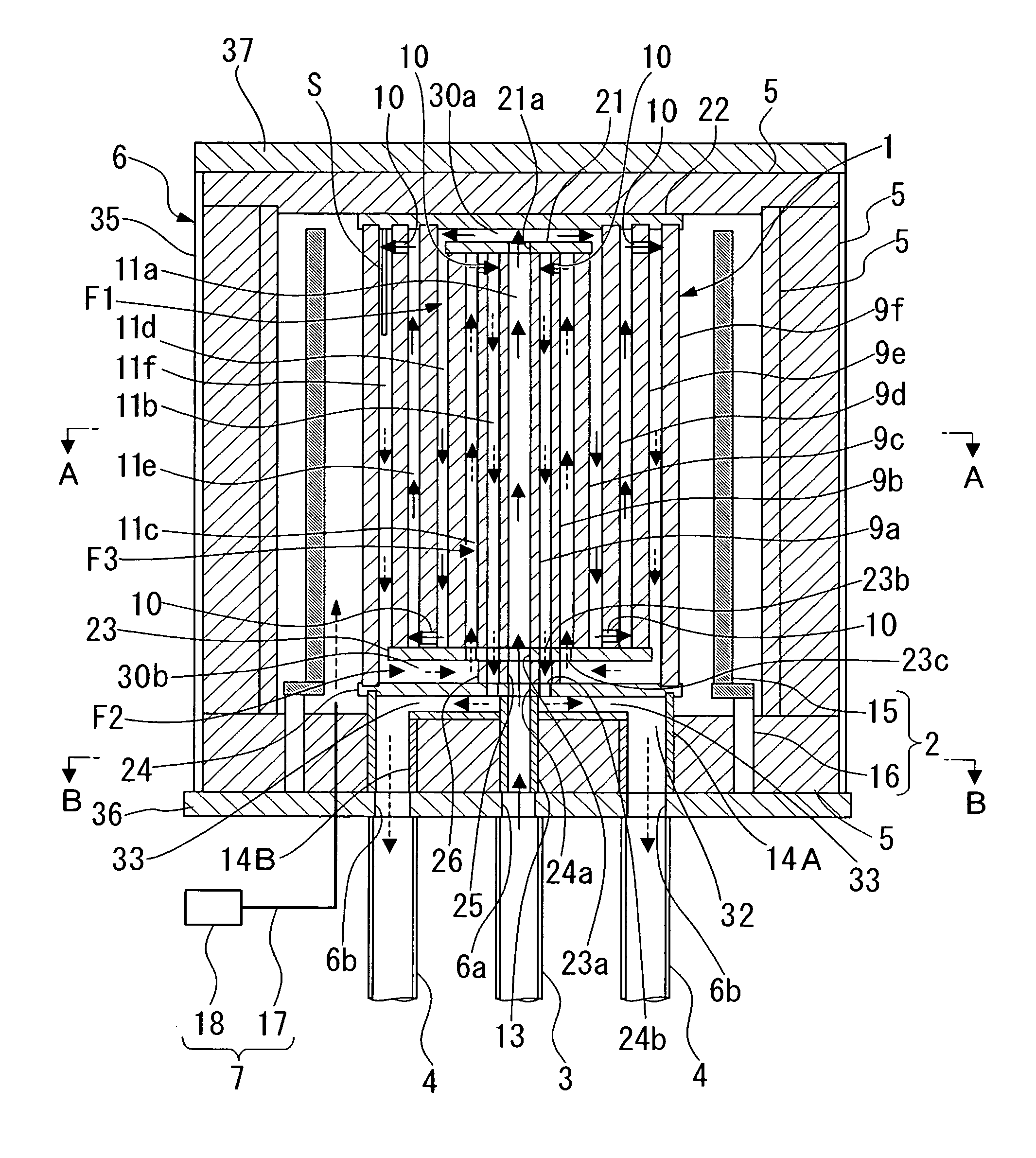

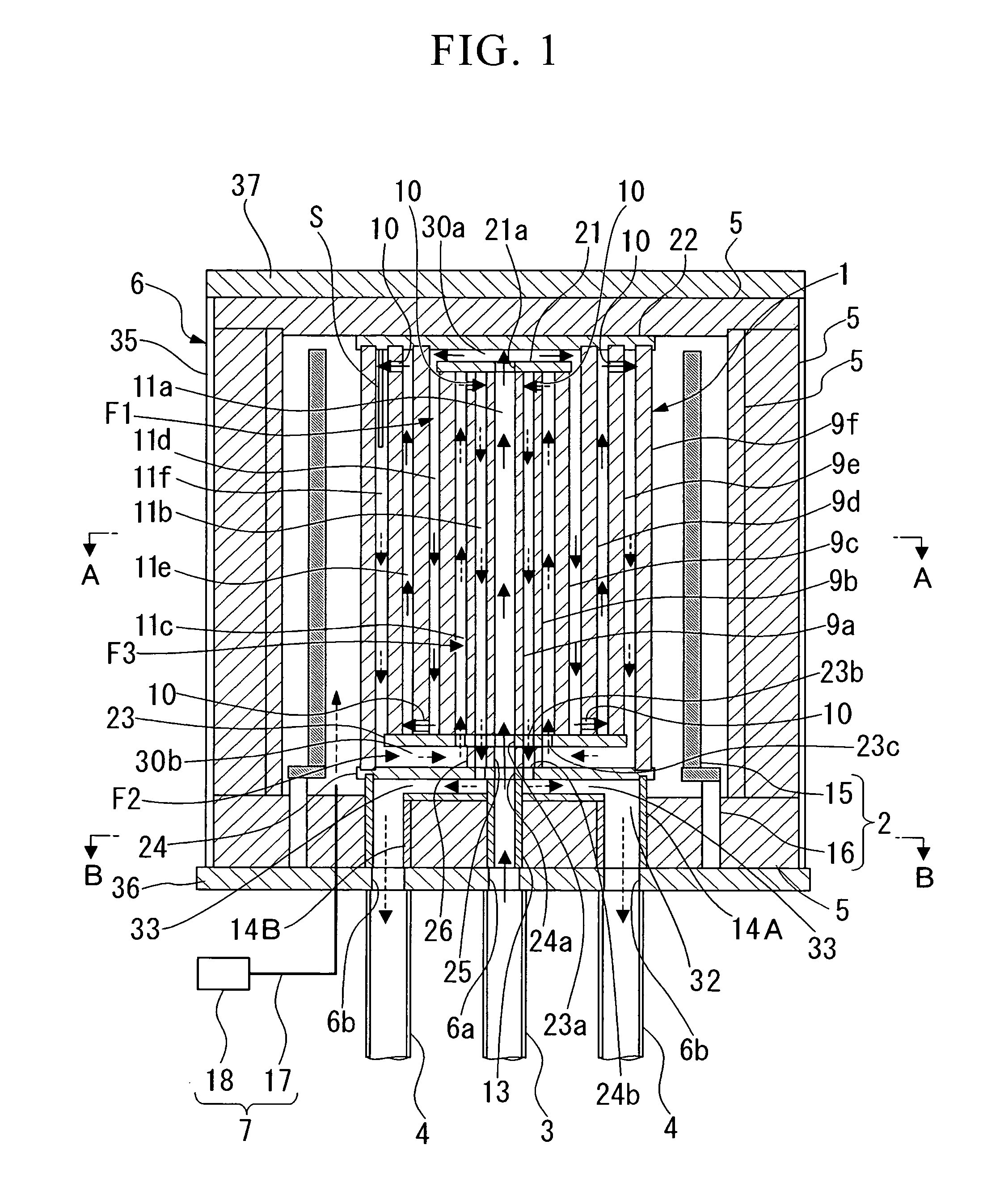

Hot isostatic pressing apparatus

InactiveUS7008210B2Efficient heatingLess expensiveMuffle furnacesConfectioneryEngineeringProduct gas

A treatment chamber for heating and pressing workpieces and a heat insulating structure which covers the treatment chamber sideways and from above are provided within a high-pressure vessel. Below the treatment chamber are disposed a base heater for heating a pressure medium gas and a fan for supplying the pressure medium gas in a heated state into the treatment chamber and stirring the heated gas. The workpieces can be held on the heat insulating structure side, and the heat insulating structure and the workpieces can be taken out from the interior of the high-pressure vessel and can be conveyed together separately from a lower lid of the high-pressure vessel. A hot isostatic pressing apparatus is provided less expensively which can heat and press workpieces at a relatively low temperature of not higher than 600° C. Besides, it is possible to shorten the cycle time in HIP.

Owner:KOBE STEEL LTD

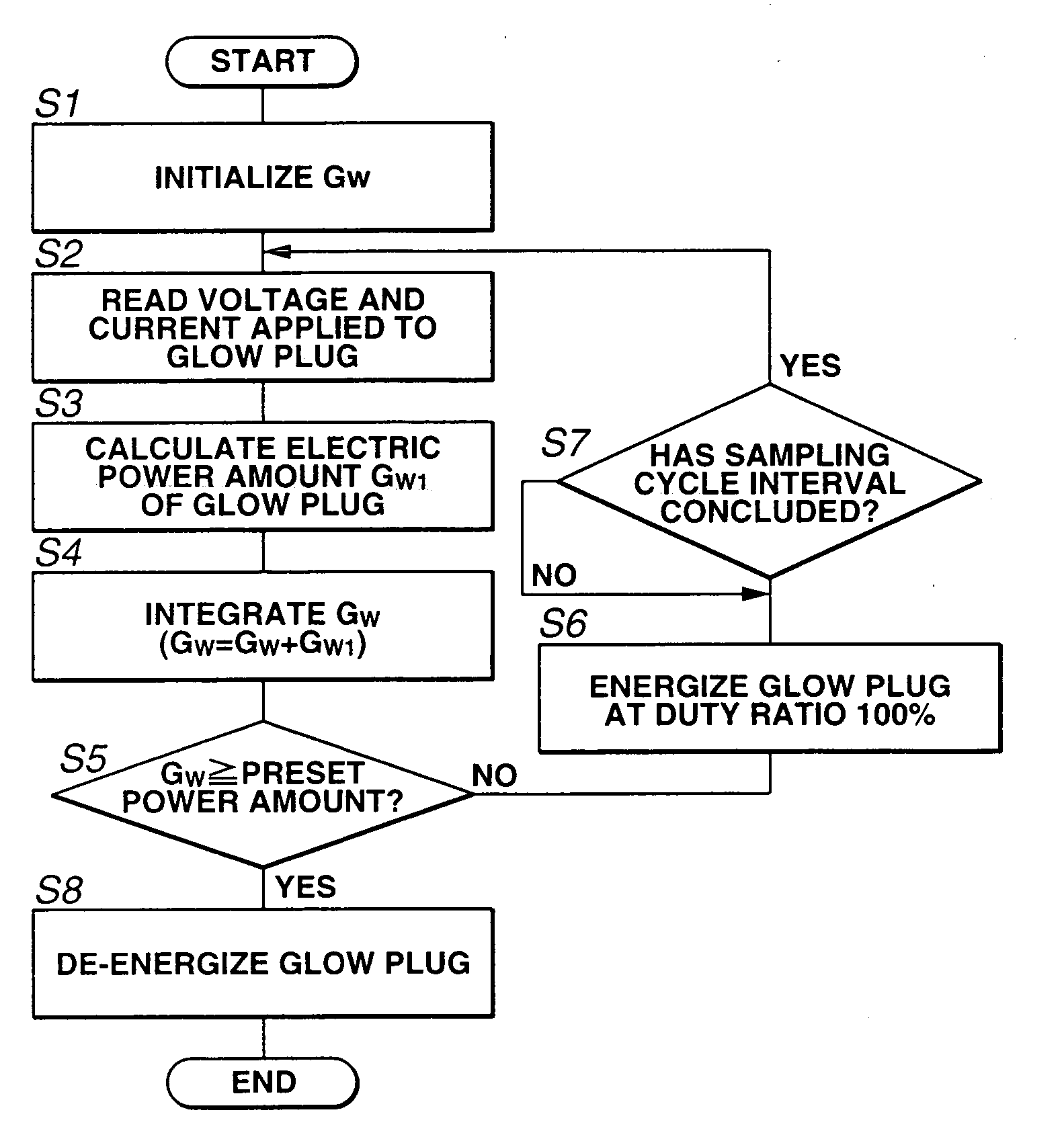

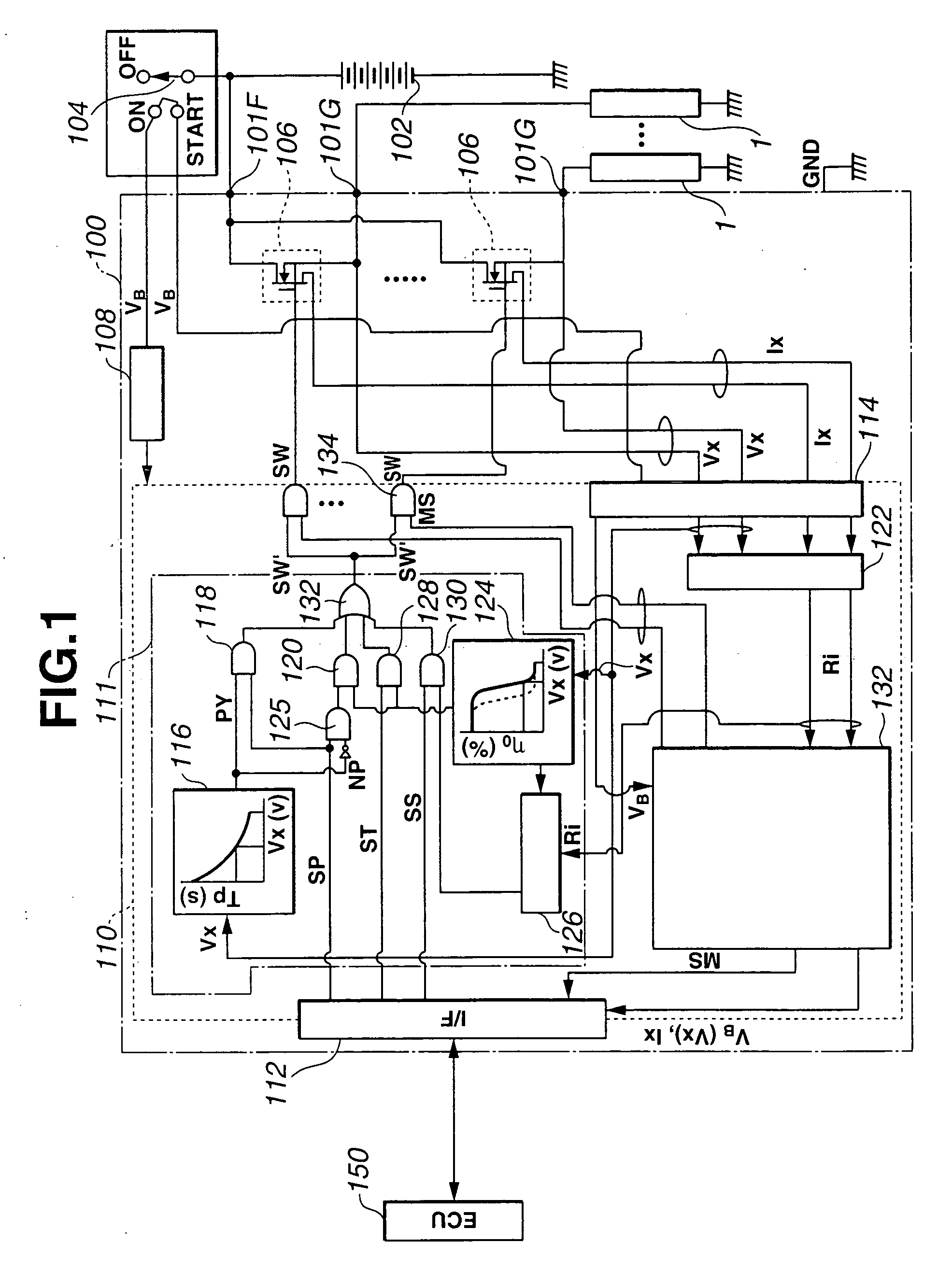

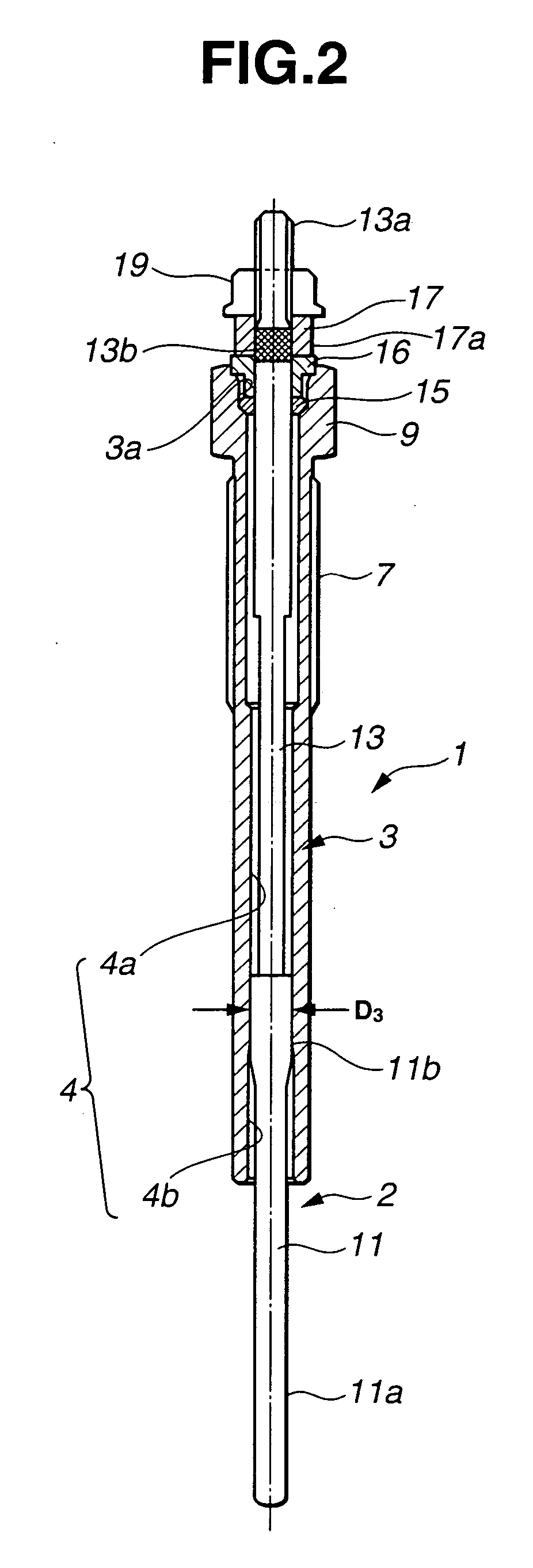

Controller of glow plug and glow plug

InactiveUS20060049163A1Stable maintenanceConvenient ArrangementElectrical controlIncandescent ignitionElectrical resistance and conductanceCombustion chamber

There is provided a control device for a glow plug, capable of controlling the energization of a resistance heater of the glow plug by a resistance control process while attaining good resistance control response under cooling of the heater by fuel injection and combustion gas and thereby stably controlling the amount of heat generated by the heater. The resistance heater includes a resistive heating element having a ratio of electrical resistance R1000 at 1000° C. to electrical resistance R20 at 20° C. of 6 or larger, and the glow plug is mounted with at least part of the resistive heating element being protrudingly located in an engine combustion chamber. Under such a condition, the control device controls energization of the resistance heater in a steady control mode to adjust electrical power supplied to the resistance heater in such a manner as to keep a resistance of the heater within a predetermined range.

Owner:NGK SPARK PLUG CO LTD

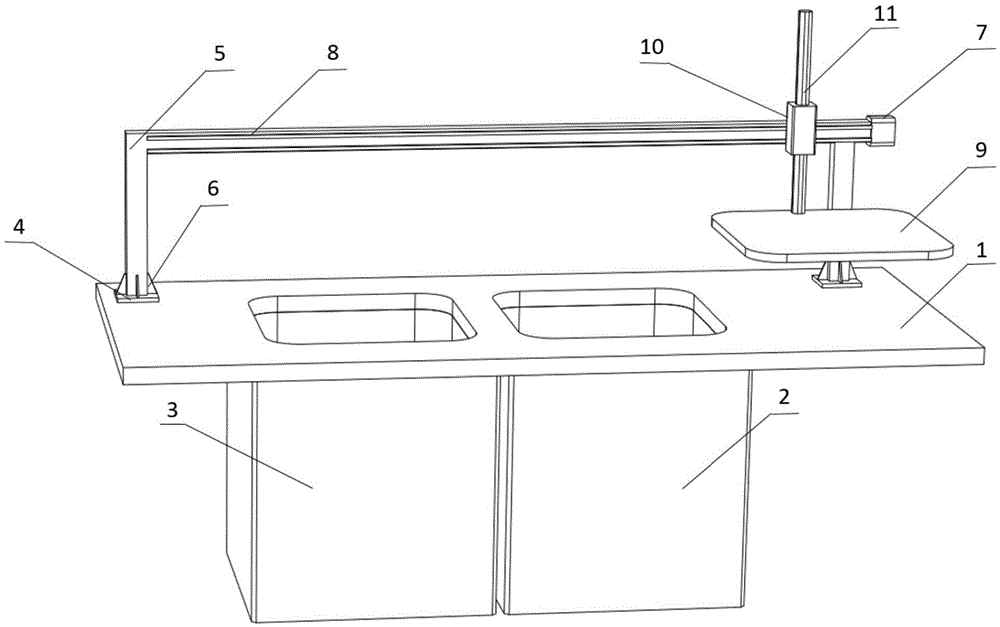

Electrostatic surface laying layer system manufactured through powder bed additive

InactiveCN105642900AImprove part densityAvoid residual stressAdditive manufacturing apparatusIncreasing energy efficiencyElectrostatic attractionResistance wire

The invention provides an electrostatic surface laying layer system manufactured through a powder bed additive. The electrostatic surface laying layer system comprises a formed working table top, a powder supply cylinder and a forming cylinder are arranged below the working table top, a truss mechanism is connected above the working table top through connection plates, the truss mechanism is configured with a sliding rail, the sliding rail is matched with a sliding block, a guide rod is connected to the sliding block, the bottom of the guide rod is connected with an electrode powder pressing plate, the sliding block is controlled by a stepping motor connected to the end of the sliding rail, a ceramic plate and a resistance wire are embedded into an electrode powder pressing plate body of the electrode powder pressing plate, and the ceramic plate is located above the resistance wire. According to the electrostatic surface laying layer system, a mode of electrostatic attraction force is adopted, and charged powder is densely adsorbed to the electrode powder pressing plate, so that the powder is compressed to the surface of a formed piece, and the effect of improving density of parts is achieved; after powder pressing is achieved, the electrode powder pressing plate preheats each layer of powder and the formed piece below the powder, and the phenomena of buckling deformation and the like are avoided; the mobile electrostatic surface laying layer system is high in speed, the powder laying amount is precisely controlled, and production efficiency is improved.

Owner:XI AN JIAOTONG UNIV +1

Preheating starting method for aluminium electrolysis cell

The invention relates to a preheating starting method for an aluminium electrolysis cell, and the preheating starting method comprises the following preheating starting processes: (1) drilling on the upper surface of a carbon or graphite electrode, and pre-embedding a heating element in the electrode; (2) heating a hearth by using a heating assembly according to a roasting curve; (3) after reaching a target temperature, adding a solid or liquid electrolyte until reaching a required electrolyte level, regulating the power of the heating assembly, and primarily building heat balance and inner hearth mold required by the electrolysis cell; (4) introducing direct current for electrolyzing a preheating electrode; and (5) gradually utilizing an electrode which normally operates to replace the preheating electrode carrying the heating element. The method disclosed by the invention can evenly heat; in the preheating process, an anode and the bus do not need flexible connection; a traditional cell of which the cathode is in an abnormal-shape structure can be effectively preheated, and an inert electrode aluminium electrolysis cell can be effectively preheated and started; and a stable electrolysis environment is built, current efficiency is improved, and the service life of the electrode is prolonged. The preheating electrode can be reused to lower electrolysis cell starting cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

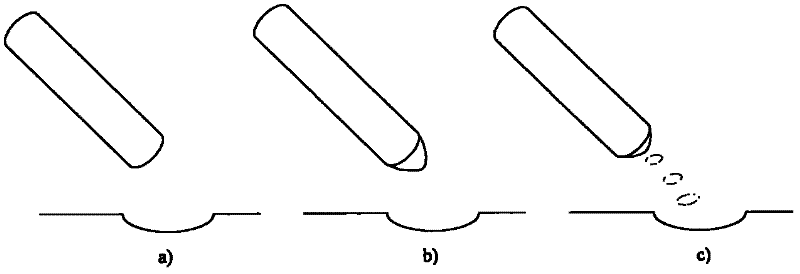

Linear friction welding method

InactiveCN101367156AReduce vibrationExtended service lifeNon-electric welding apparatusPhysicsConstant frequency

The invention discloses a linear friction welding method, which is characterized in that the method comprises the following steps: the amplitude of two weldments is preset as a constant amplitude, and the vibration frequency is increased to higher frequency from lower frequency at the early stage of friction; then a constant-frequency constant-amplitude friction stage is performed, and the vibration frequency and the amplitude are constant at this time; at the final stage of the friction, the amplitude is gradually reduced, and the welding is finished by applying upsetting pressure when the amplitude is gradually reduced to zero to lead the two weldments to return and align; and the friction pressure is constant during the whole welding process. The larger amplitude and the lower frequency at the early stage of the friction can perform effective mechanical cleaning and preheating to the friction interface; at the middle and late stage of the friction, the amplitude is gradually reduced to ensure that a high temperature interval of a joint is wider and evener, deformed metal can be fully restored and recrystallized, thereby eliminating the residual stress of the welding joint and improving the quality of the joint.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

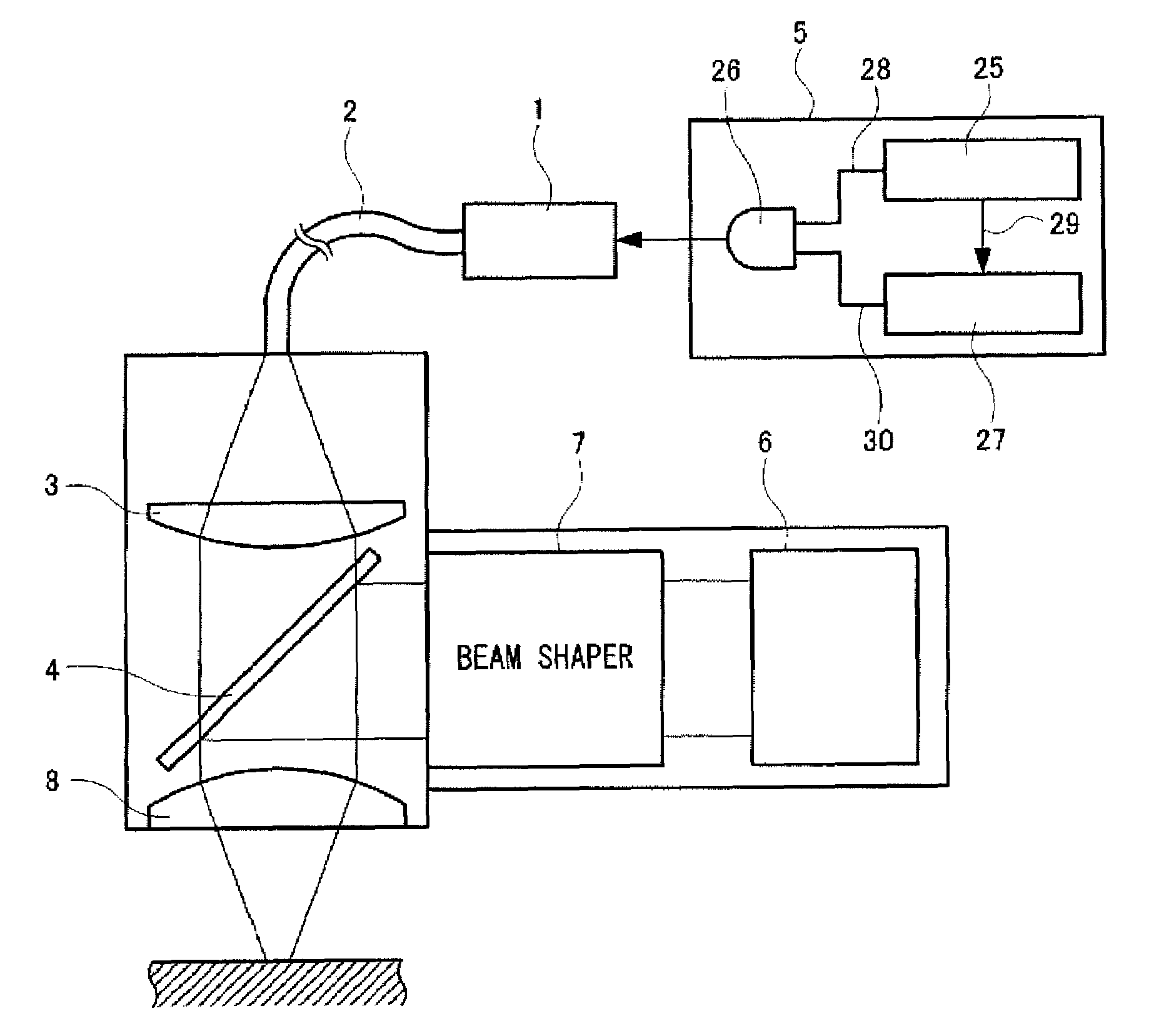

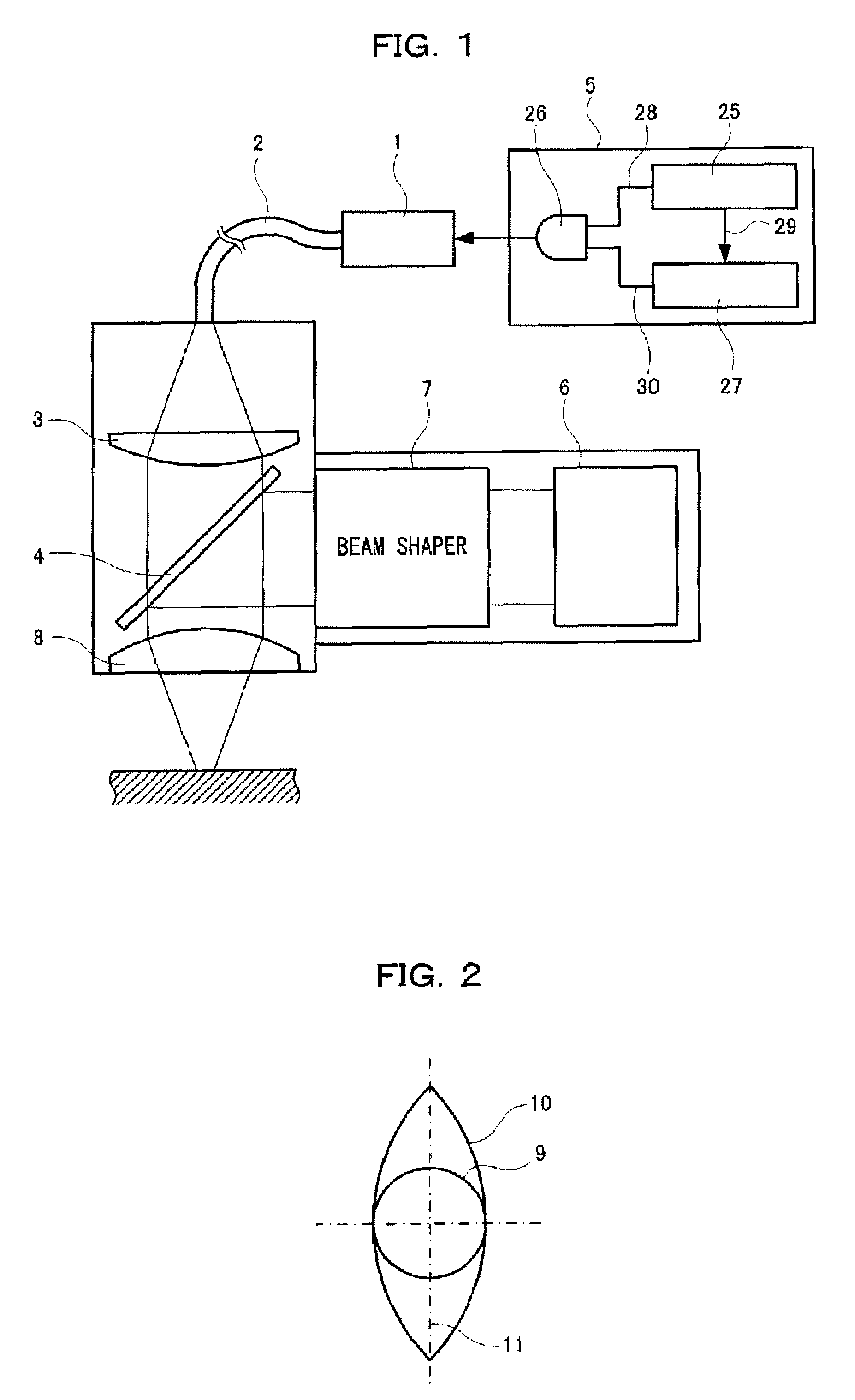

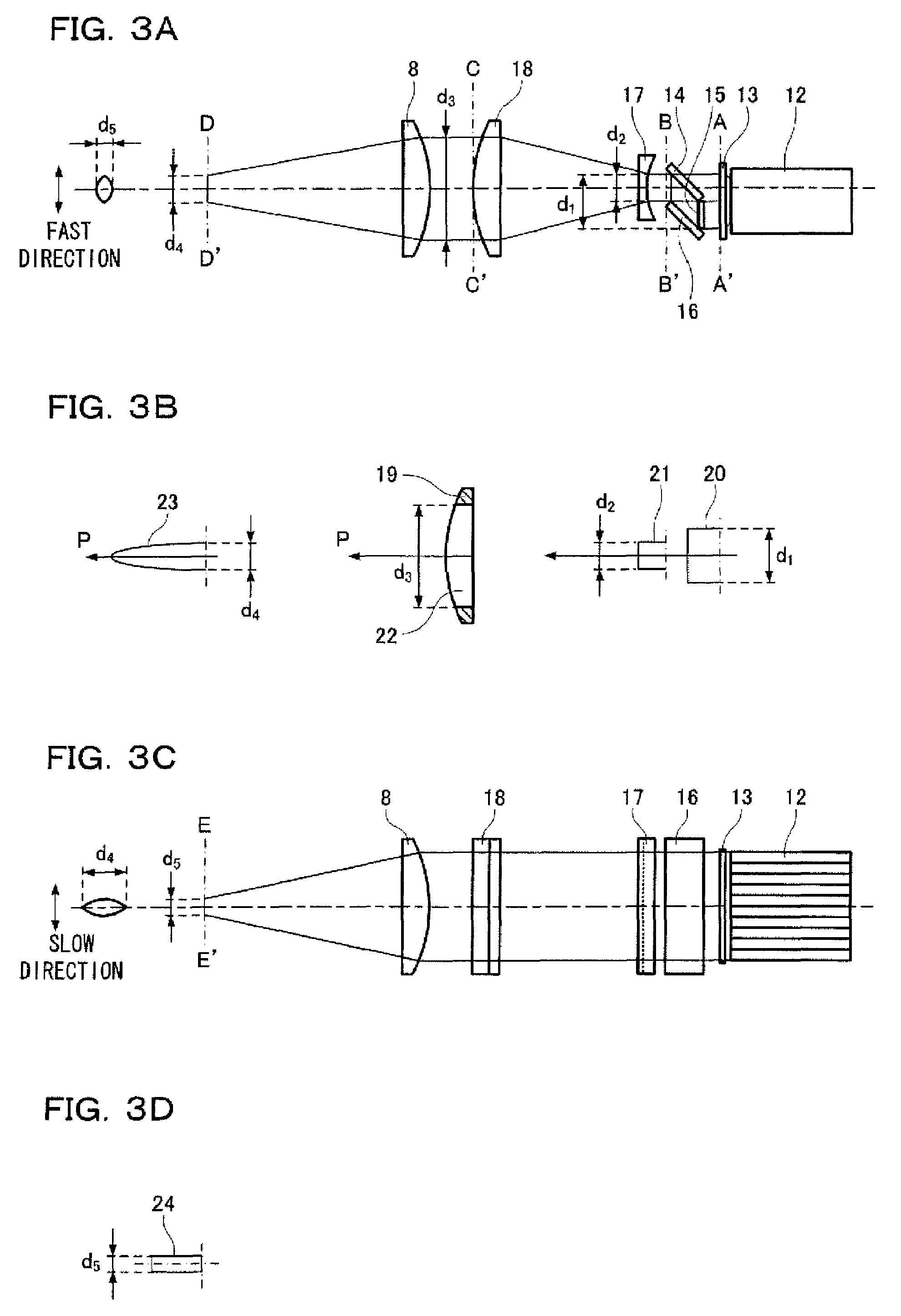

Laser apparatus and manufacturing method of a battery

InactiveUS7646794B2Suppress power fluctuationsShorten speedLaser detailsPrimary cellsMetallic materialsLaser light

A laser apparatus is provided which is capable of achieving deep penetration into an aluminum-like metal material without causing welding defects such as spatters or cracks and performing high-speed pulse seam welding. The laser apparatus includes a pulse power source that generates a current signal and a mask signal for masking a fluctuation component included in the current signal, and which supplies a current signal in which a fluctuation component has been masked by the mask signal to a YAG pulsed laser oscillator. In addition, the laser apparatus sets the spot shape of a CW laser light oscillated by a CW laser oscillator to a rhombic streamlined shape, and causes a focus spot of the CW laser light to include a circular focus spot of a pulsed laser light.

Owner:PANASONIC CORP

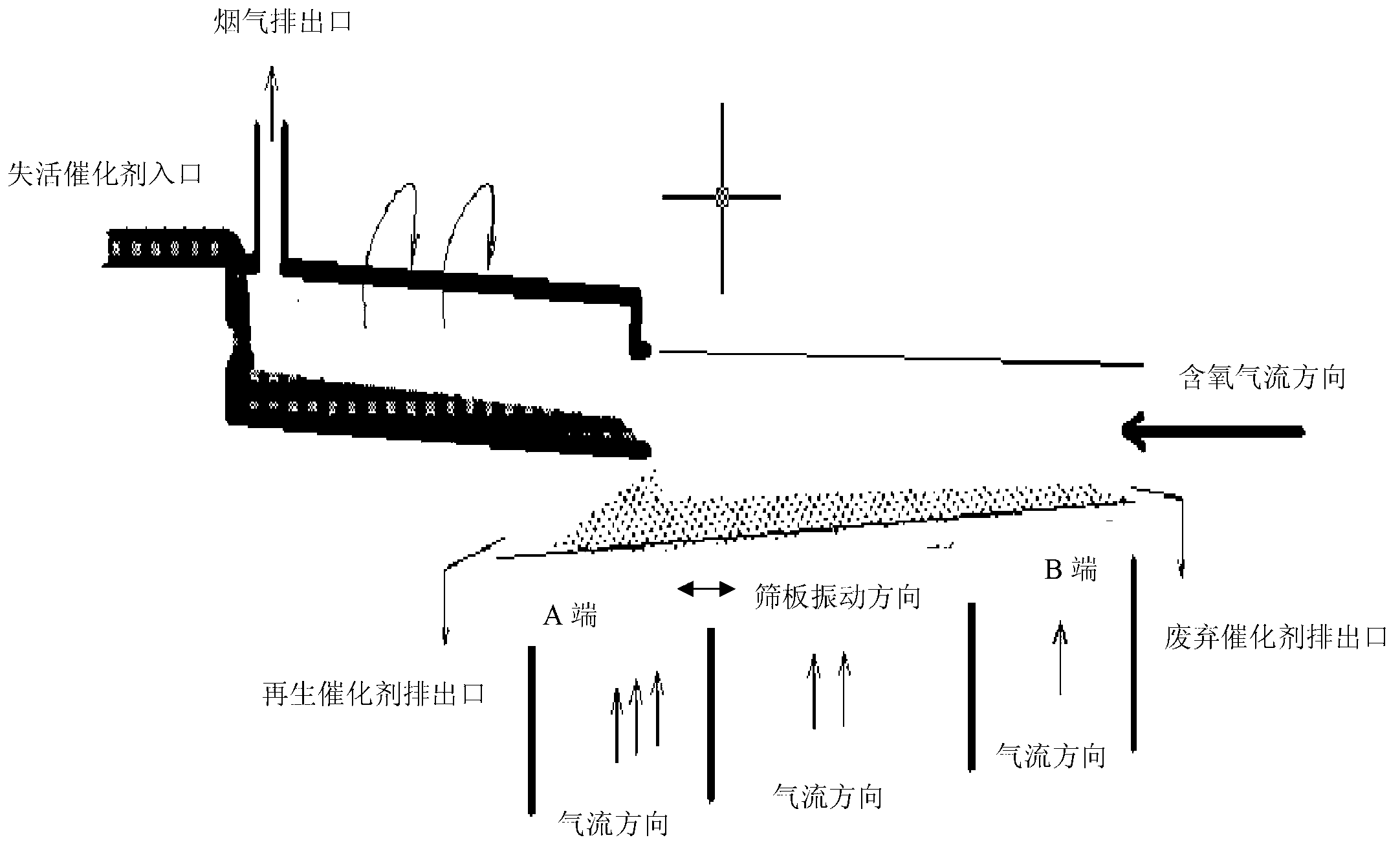

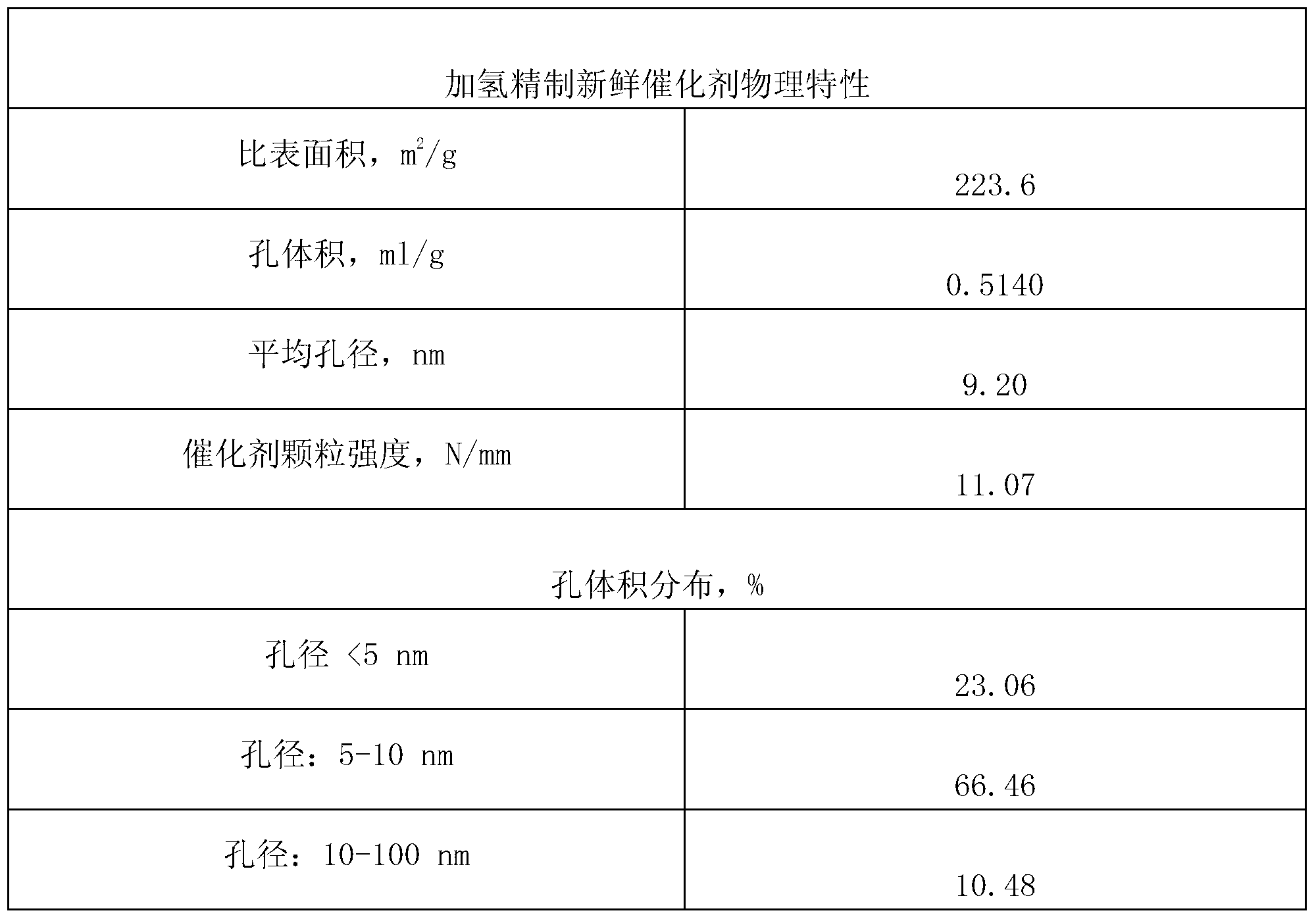

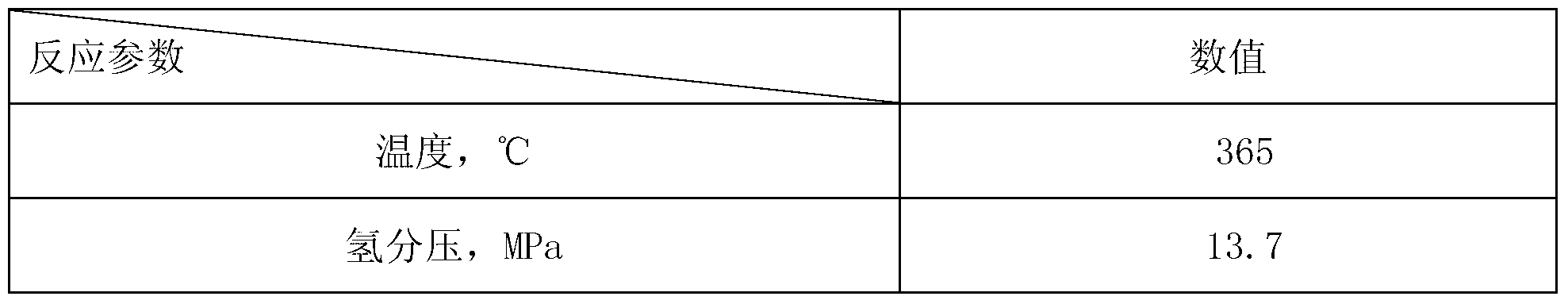

Deactivated catalyst regeneration and density grading system and process thereof

ActiveCN103272653AHigh activityExtended service lifeCatalyst regeneration/reactivationEngineeringJoint action

The invention discloses a deactivated catalyst regeneration and density grading system which comprises a rotary kiln used as a deactivated catalyst regenerator and a vibrating screen used as a density grading device of a regenerated catalyst, wherein the rotary kiln inclines horizontally for 1-3 degrees; the vibrating screen inclines horizontally for 3-5 degrees and vibrates in an inclined direction; a deactivated catalyst is regenerated in the rotary kiln, and regenerated catalyst granuless are fluidified on the vibrating screen by means of air flows penetrating through meshes of the vibrating screen from bottom to top; and under the joint action of gravity, fluidifying force and vibratory force, the regenerated catalyst granules with different densities are separated or graded on the vibrating screen.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

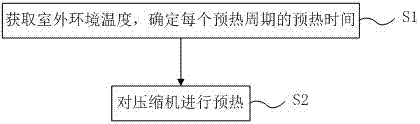

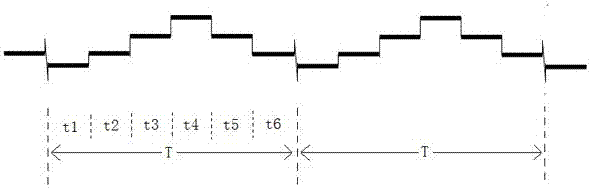

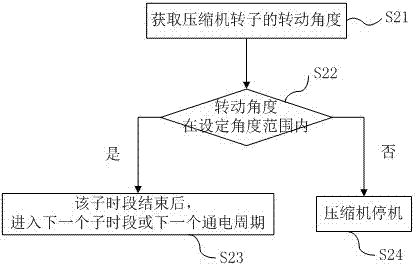

Control method for lowering preheating noise of compressor

ActiveCN107246392AReduced warm-up noiseEffective warm-upRotary/oscillating piston pump componentsLiquid fuel engine componentsPower flowTime-sharing

The invention discloses a control method for lowering preheating noise of a compressor. When the compressor is preheated, a compressor winding U, a compressor winding V and a compressor winding W are electrified in a time sharing manner; two-phase windings are electrified at the same time within each electrification period, current during compressor preheating is reduced, accordingly, noise generated during compressor preheating is lowered, influences on normal life of users are avoided, user complaints due to the noise problem are avoided, and the using experience of the users is improved. Meanwhile, effective preheating of the compressor is guaranteed, and a good preheating effect is achieved. Meanwhile, in each electrification period, electrification current is fluctuated and is not constant, compressor damage due to continuous too high constant current is avoided, and the poor preheating effect caused by continuous too low constant current is avoided; and a good preheating effect is guaranteed, and compressor damage is avoided as well.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

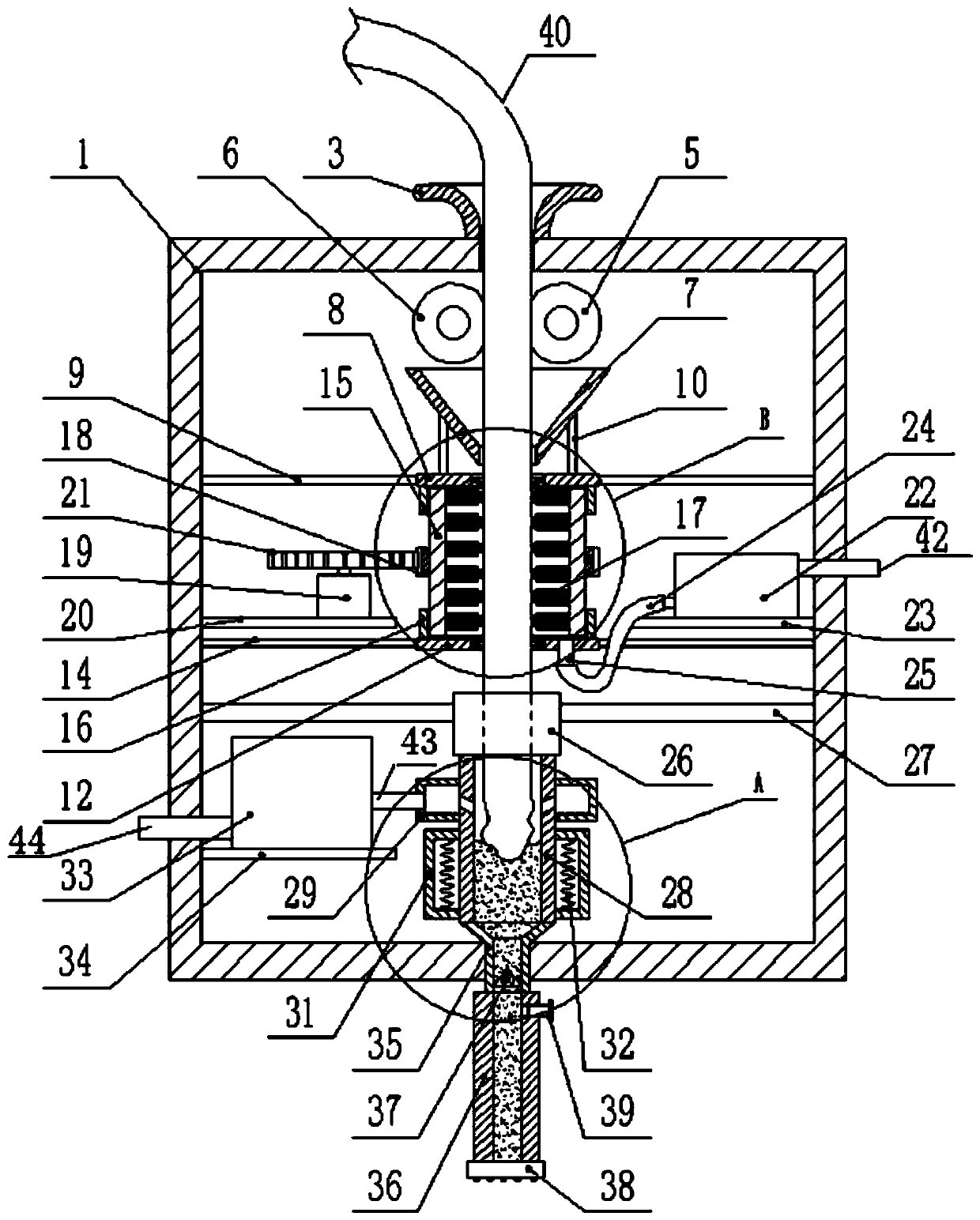

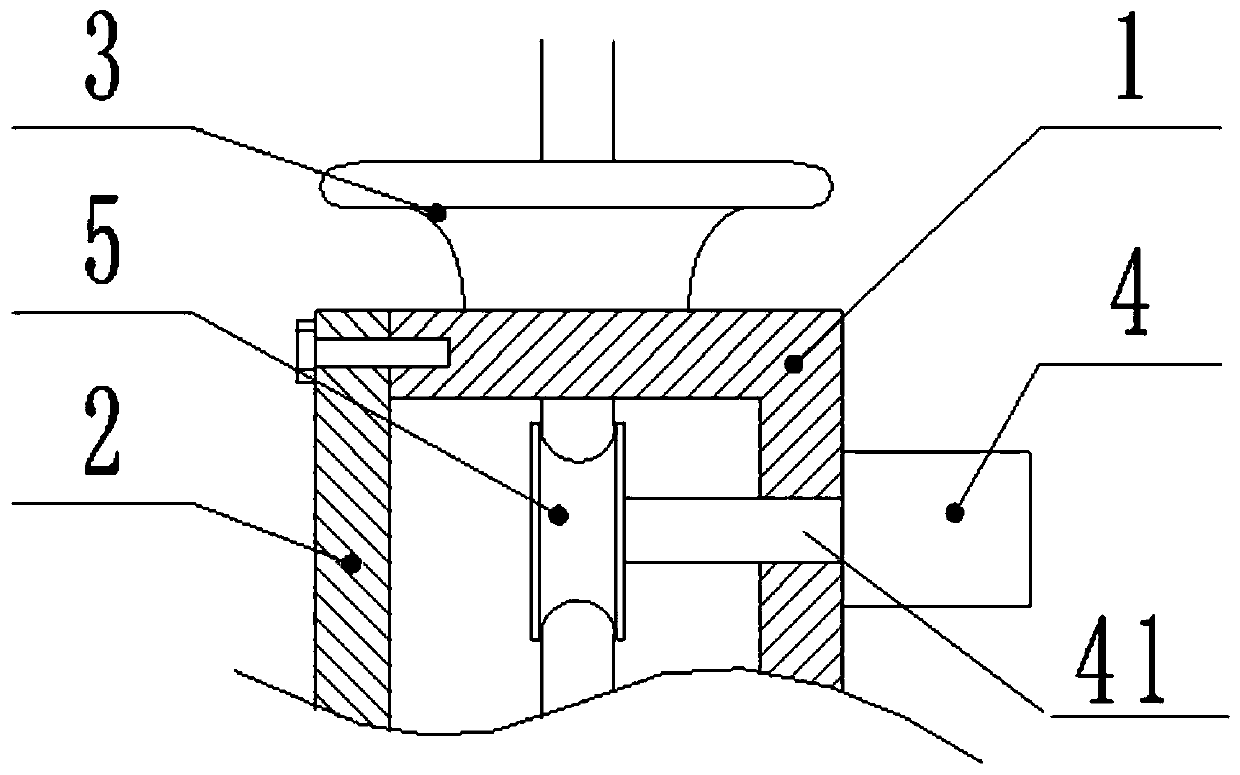

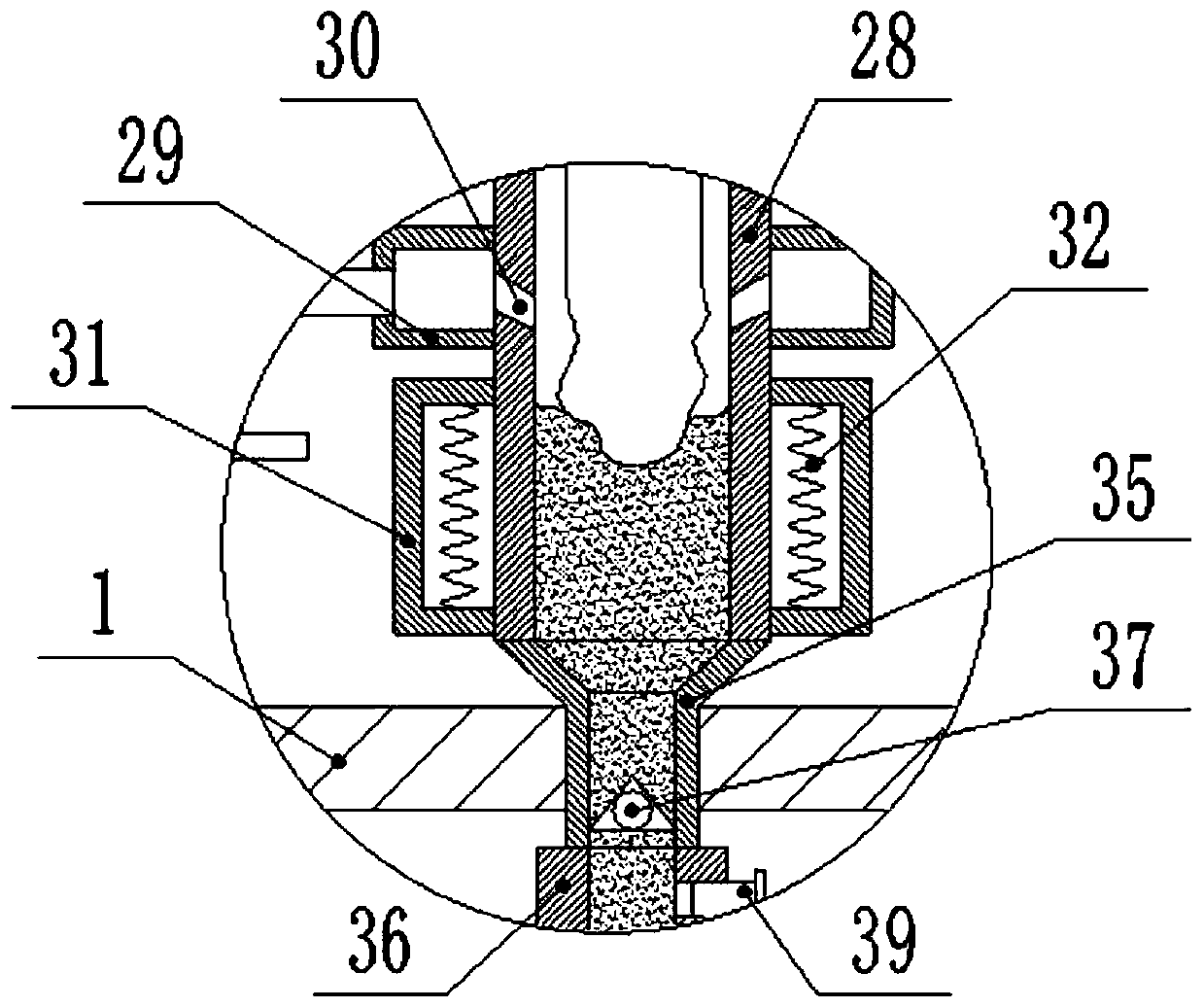

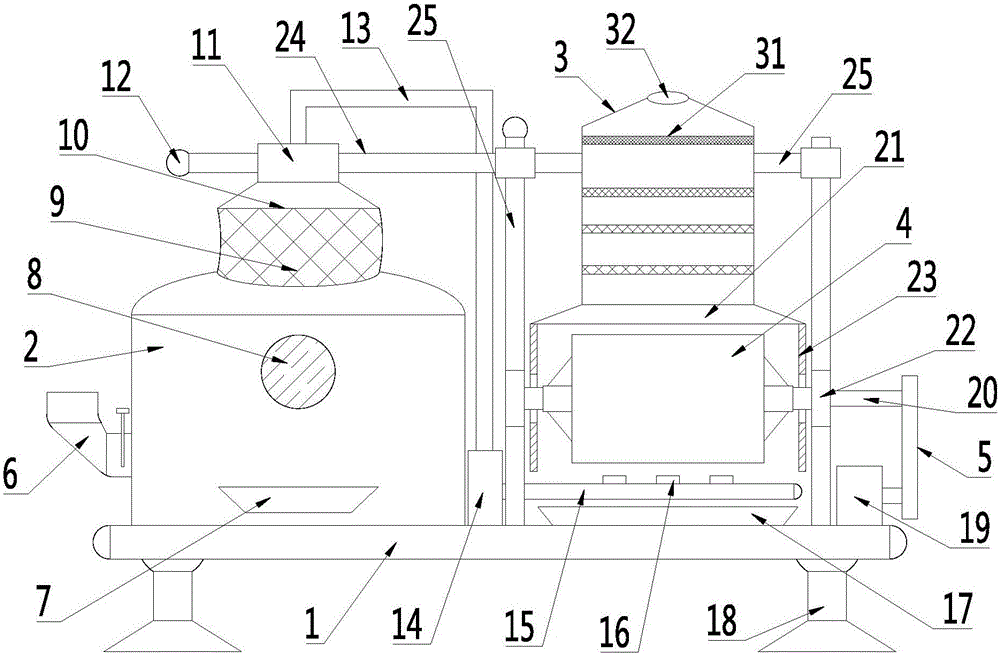

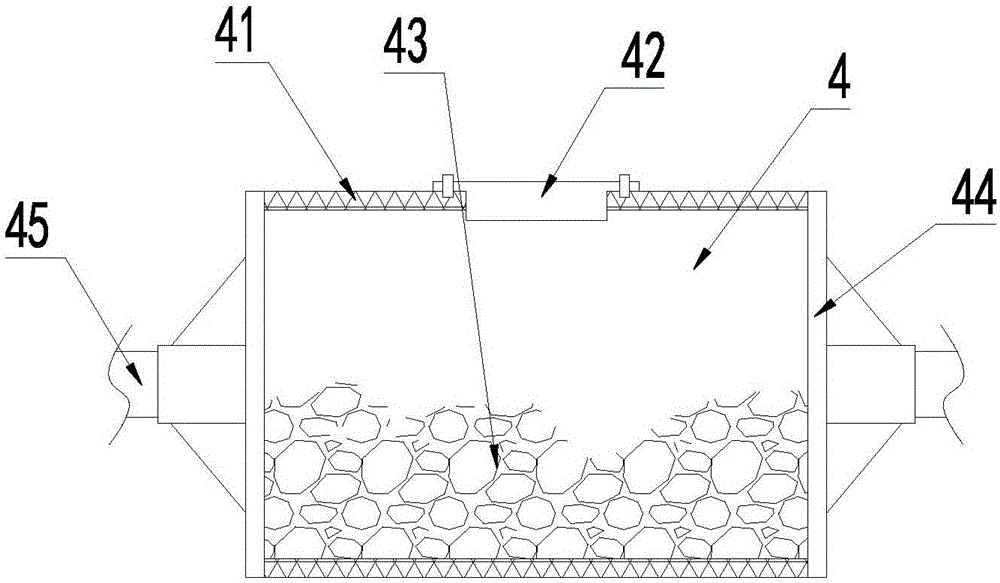

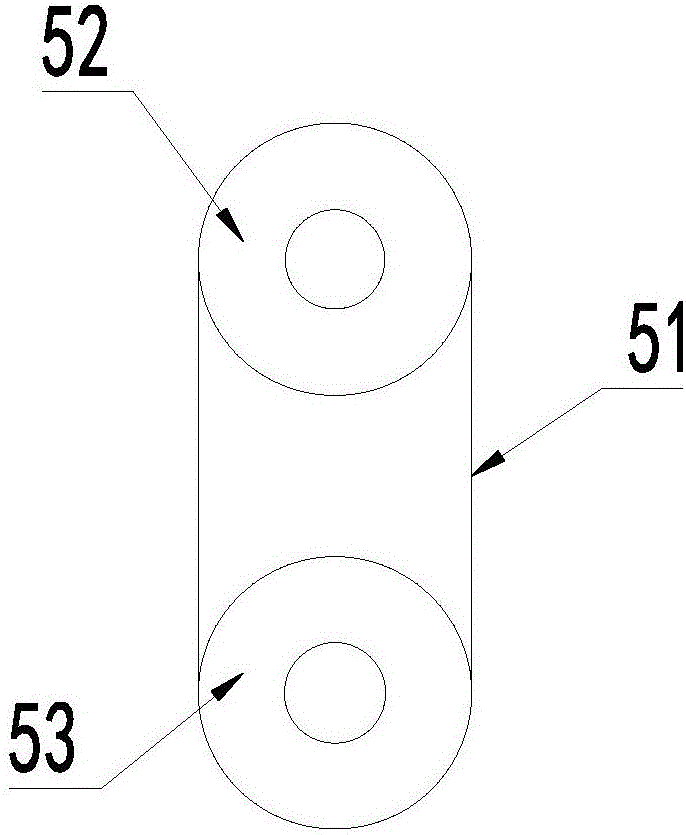

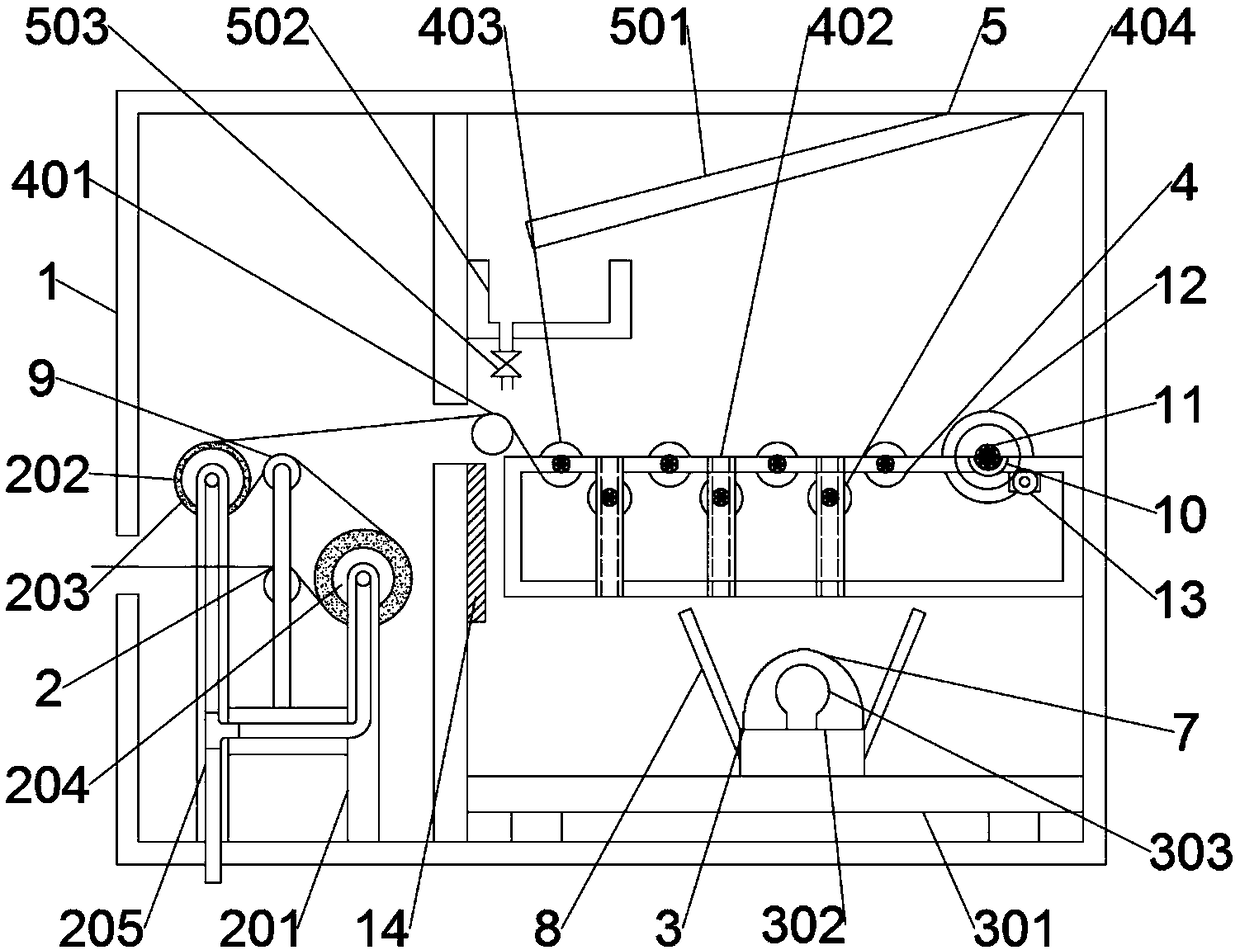

Wire extruding device for 3D printing machine

ActiveCN109927295AEffective straighteningEffective warm-upAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention discloses a wire extruding device for a 3D printing machine. The wire extruding device comprises a shell (1), a guiding mechanism, a cleaning mechanism, a heating mechanism and a discharging mechanism; a cavity is formed in the shell (1); the guiding mechanism, the cleaning mechanism, the heating mechanism and the discharging mechanism are arranged in sequence; a wire channel (40) isformed from the guiding mechanism to at least a part of the heating mechanism; a box door (2) is arranged on the shell; a through hole penetrating to the cavity is formed in the upper surface of theshell; the guiding mechanism comprises a group of pulley units; a gap is formed between each group of pulley units; the cleaning mechanism comprises a roller (15); a plurality of brushes (17) are arranged on the inside wall of the roller; the heating mechanism comprises a passing cylinder (26) and a melting cylinder (28); a preheating unit and a heating unit are sequentially arranged on the outersurface of the melting cylinder in the vertical direction; and the discharging mechanism communicates with the melting cylinder. The wire extruding device achieves the effects that the straightness ofa wire in the extruding process is effectively improved, no impurities exist basically, the melting effect is good, the product quality is effectively improved, and the product cost is reduced.

Owner:WUHU INST OF TECH

Industrial-boiler flue gas waste heat recycling device

ActiveCN106500517AImproved drying and preheatingSimple device structureIncreasing energy efficiencyWaste heat treatmentProcess engineeringCoal

The invention discloses an industrial-boiler flue gas waste heat recycling device which comprises a base, an industrial boiler, a flue gas filter tank, a coal preheating tank and a soot collecting tank. The flue gas filter tank and the coal preheating tank are arranged between stand columns installed on the base separately, a second dust hood is fixedly installed on the lower portion of the flue gas filter tank, the upper portion of the second dust hood communicates with the lower portion of the flue gas filter tank, and the coal preheating tank is rotationally connected with the two stand columns through rolling bearings; and an exhaust pipeline is arranged under the coal preheating tank, the exhaust pipeline communicates with a suction pipeline through a negative pressure fan, the exhaust pipeline is located over the soot collecting tank, the coal preheating tank comprises an enclosing plate, a movable cover, side plates and a rotating rod, and multiple filter screens are fixedly installed in the flue gas filter tank from top to bottom in sequence. The industrial-boiler flue gas waste heat recycling device is simple in structure, reasonable in design, capable of effectively utilizing waste heat of flue gas in the boiler for drying and preheating coal and improving the burning efficiency of the coal and high in practicability.

Owner:BRIGHT THERMAL EQUIP CO LTD

Glass microballoon manufacturing device and preparation method thereof

InactiveCN102417291APrevent molten buildupReduce devitrificationGlass shaping apparatusGlass productionDevitrificationCombustor

The invention discloses a glass microballoon manufacturing device comprising a furnace body (1) and a waste gas treatment device, wherein the furnace body (1) is formed by air-tight connection of an upper part and a lower part, the upper part of the furnace body is of a cubic shape, a waste gas emission port (4) is arranged at the top of the upper part, one or more injection-type burners (2) are horizontally installed on the side of the upper part, a preheating air pipe (14) is arranged in the upper part, the lower part of the furnace body is of a square conical shape, and one or more microballoon collectors (3) are arranged at the bottom of the lower part. According to the glass microballoon manufacturing device and the preparation method thereof provided by the invention, the furnace body which adopts the cubic structure enlarges the cooling space; the horizontally installed injection-type burners and the preheating air pipe arranged in the furnace body can give full play to the heat value of fuel, thus reducing energy source waste, saving energy and reducing emission; TiO2 and Al2O3 with relatively lower costs are adopted, the refractive index of the product is greater than or equal to 1.93; and the glass microballoon manufacturing device and the preparation method thereof have the advantages of reducing devitrification, improving the cooling velocity, having good product quality, improving the utilization ratio of raw material, being capable of large-scale production, and the like.

Owner:SICHUAN ZHONGKE BETTER TECH

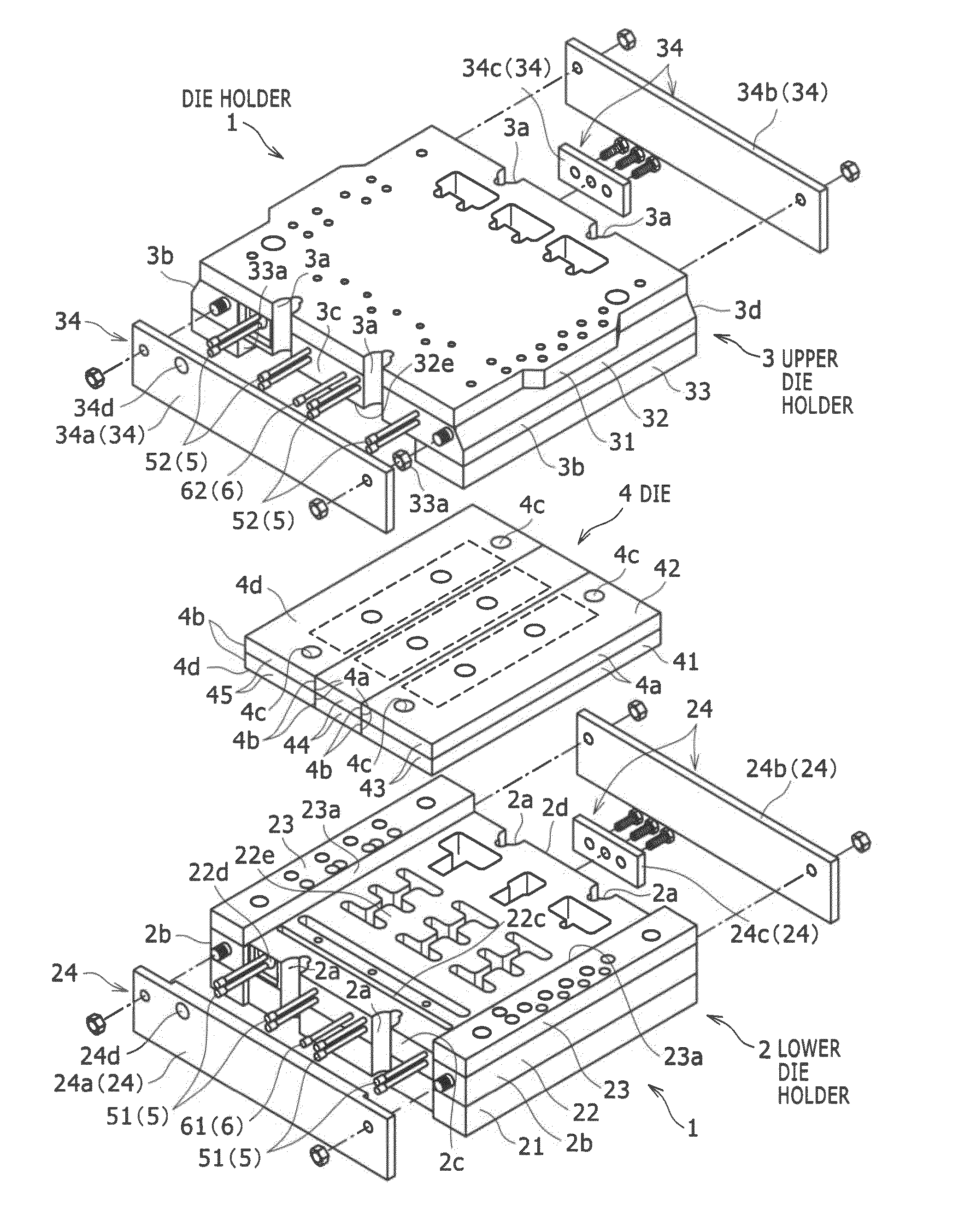

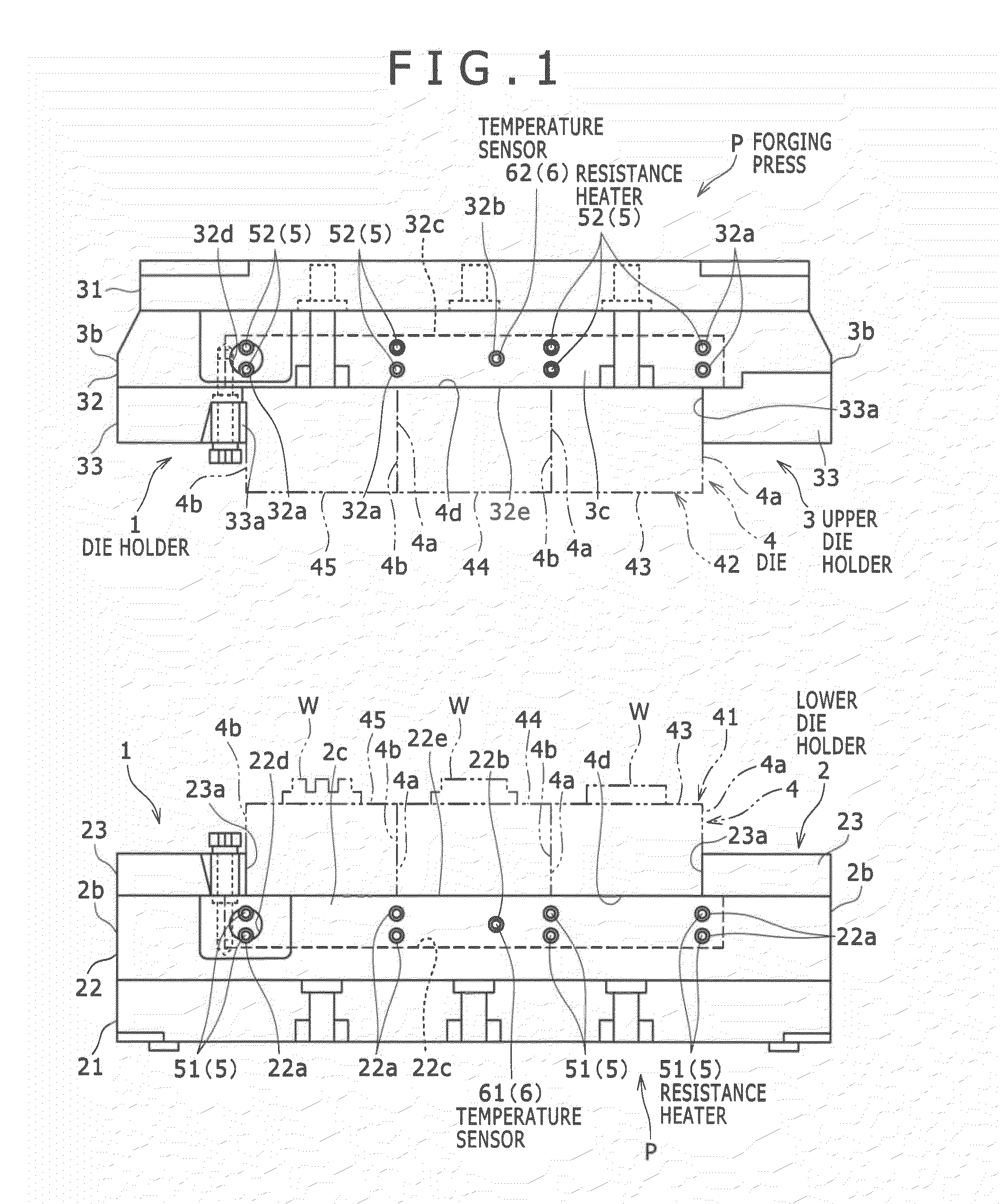

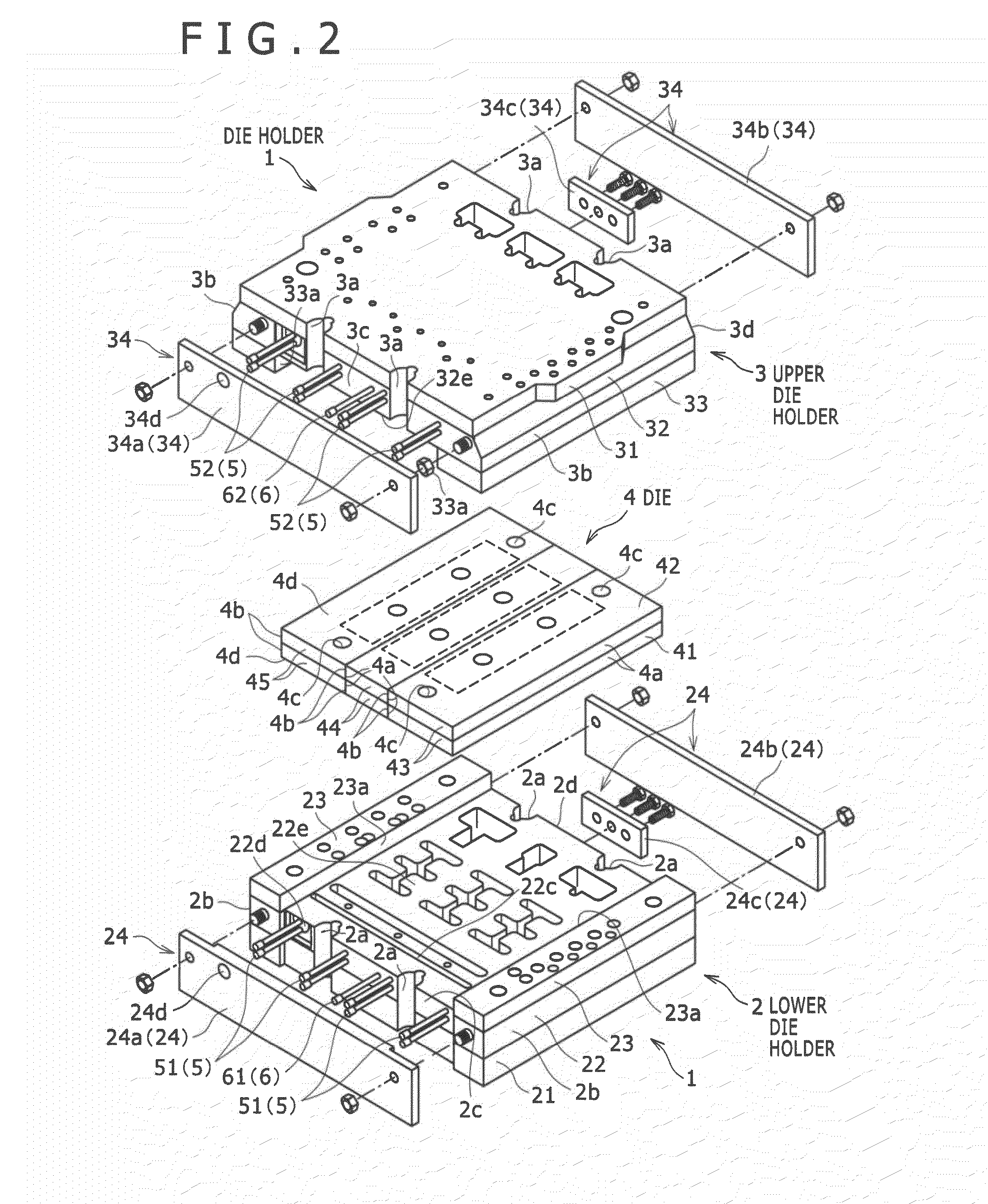

Forging die holder

ActiveUS20110259074A1Efficient heatingIncrease temperatureShaping toolsForging/hammering/pressing machinesEngineeringForging

There is provided a forging die holder including a resistance heater capable of efficiently heating a die via the die holder when warm forging or hot forging is performed. A die holder is for holding a die used in a forging press for performing warm forging or hot forging. The die holder has heater mounting holes into which resistance heaters are inserted, sensor mounting holes into which temperature sensors are inserted, and guide portions disposed on both end portions of holder surfaces of holders for supporting back surfaces of the foregoing die to support side surfaces of the foregoing die located therebetween on both sides thereof. The heater mounting holes are formed at positions opposing the holder surfaces in aligned relation with the side surfaces of the foregoing die.

Owner:KOBE STEEL LTD

Energy-saving drying device for papermaking equipment

The invention discloses an energy-saving drying device for papermaking equipment. The energy-saving drying device comprises a drying box; a preheating device and an infrared drying device are installed in the drying box and separated by a partition plate, a paper material spreading device is arranged above the infrared drying device, and a heat energy recovery device is arranged above the paper material spreading device; the heat energy recovery device comprises a condensation plate fixedly mounted on the inner wall of the drying box, a condensate water collecting tank is formed in the bottomof the condensation plate, and a steam trap valve is mounted on the condensate water collecting tank; the condensation plate is of a double-layer structure, the bottom surface of the condensation plate is in a wave shape, a cooling water inlet is formed in the top of the condensation plate, a hot water discharge port is formed in the bottom of the condensation plate, and a flow equalization boardis arranged on the top of a hollow layer of the condensation plate. According to the energy-saving drying device, not only can paper materials be quickly dried, but also heat generated in the drying process is effectively utilized, and the energy-saving drying device has the advantages of high efficiency and energy saving.

Owner:芜湖英特杰智能科技有限公司

Apparatus for Producing Trichlorosilane

ActiveUS20090269259A1Good heating efficiencyHigh ratioCatalytic gas-gas reactionChemical/physical/physico-chemical processesHydrogen chlorideChlorosilane

An apparatus for producing trichlorosilane, including: a reaction vessel in which a supply gas containing silicon tetrachloride and hydrogen is supplied to an internal reaction passageway to produce a reaction product gas containing trichlorosilane and hydrogen chloride; a heating mechanism that heats the interior of the reaction vessel; a gas supply section that supplies the supply gas in the reaction vessel; and a gas discharge section that discharges the reaction product gas from the reaction vessel to the outside, wherein the reaction passageway includes: a supply side passageway which is connected to the gas supply section at a central portion of the reaction vessel and flows the supply gas toward the outside while meandering in the reaction vessel; a return passageway which is connected to a downstream end of the supply side passageway and extends to the central portion of the reaction vessel; and a discharge side passageway that is disposed so as to be connected to a downstream end of the return passageway and to adjoin the supply side passageway of the central portion of the reaction vessel, the discharge side passageway being connected to the gas discharge section.

Owner:MITSUBISHI MATERIALS CORP

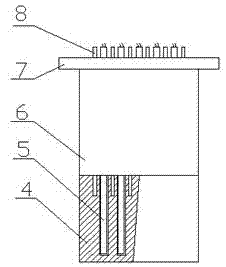

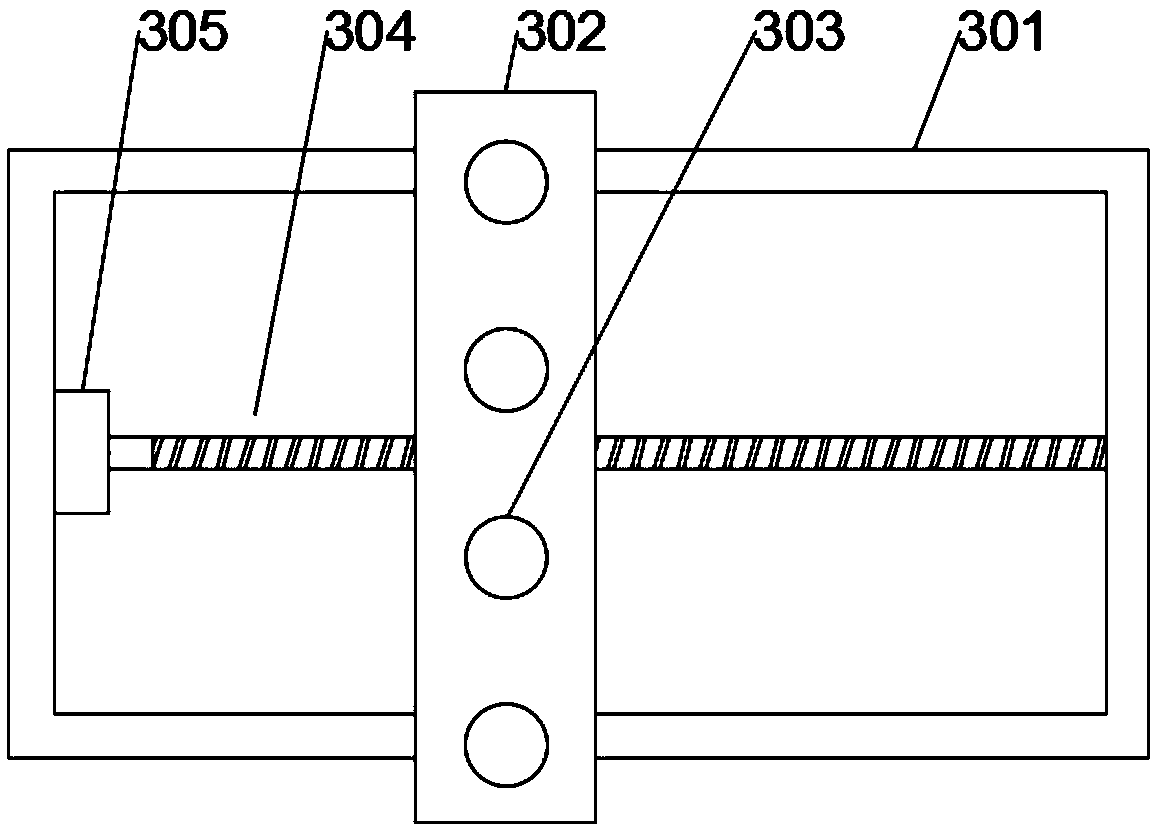

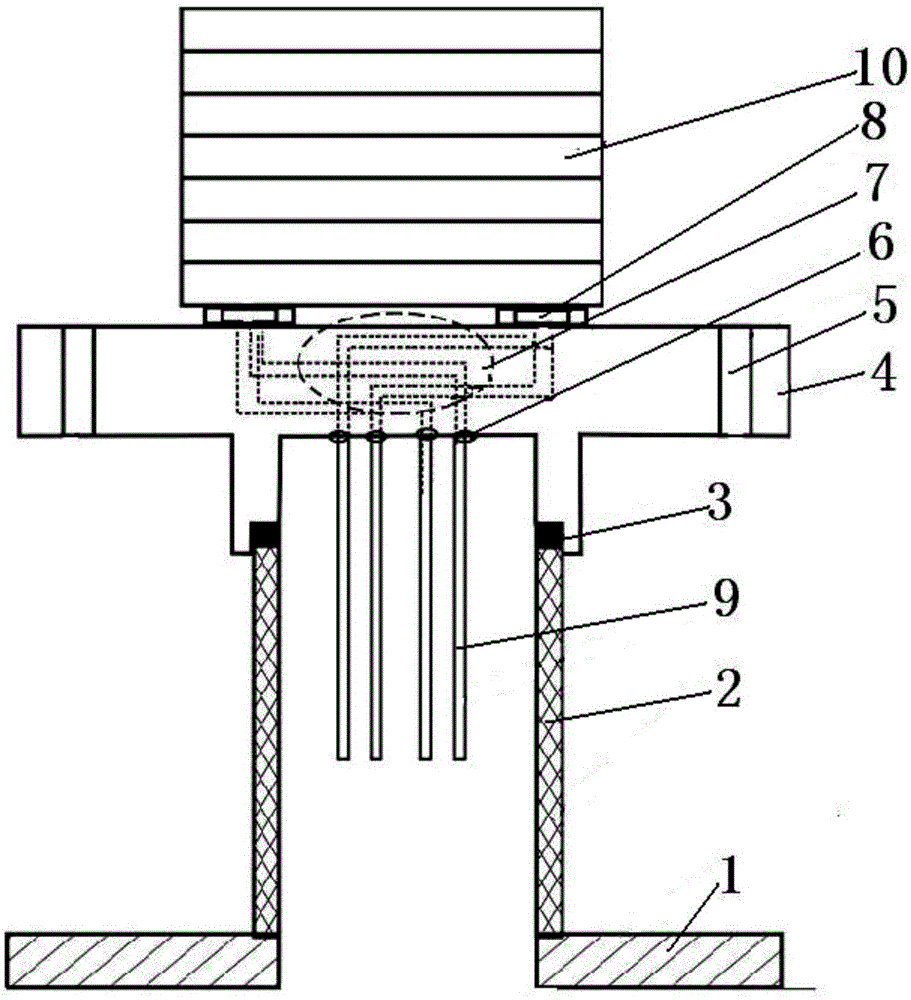

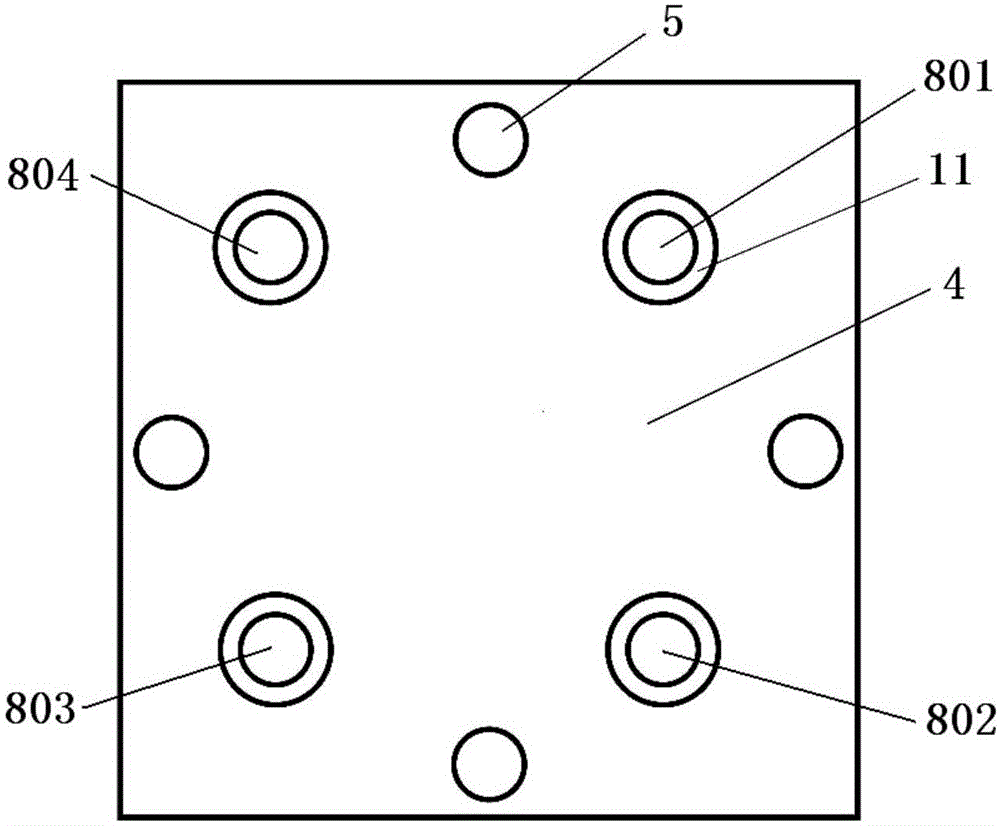

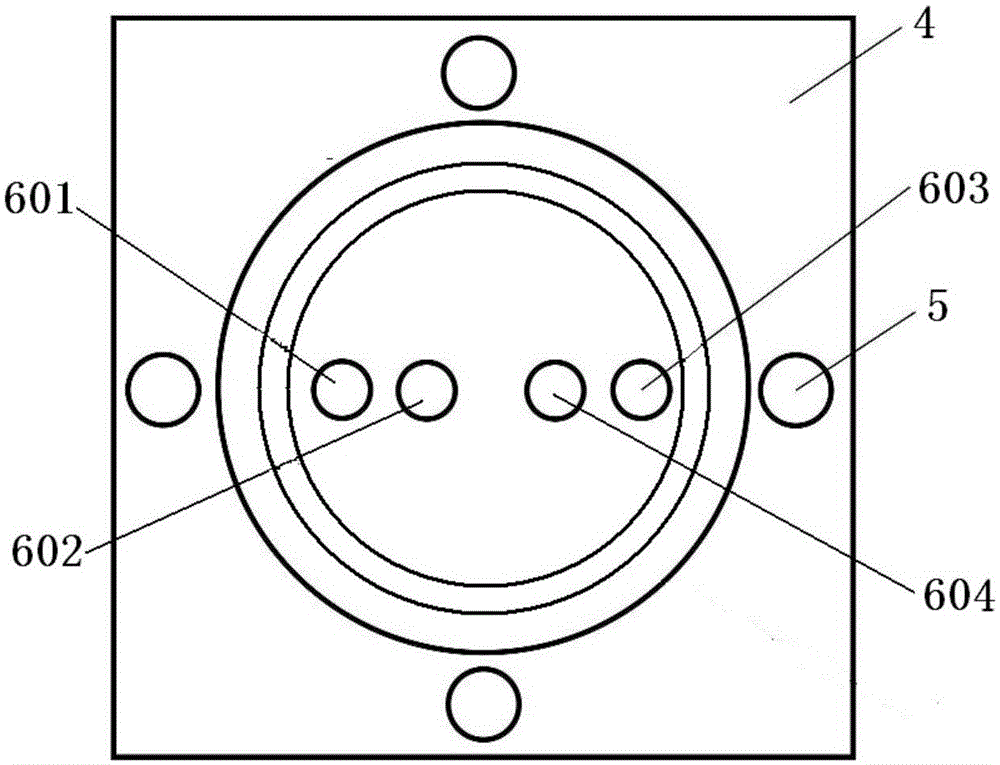

Bottom entering gas testing device for planar SOEC (solid oxide electrolyzer cell) stack

ActiveCN105161146ASolve the problem of air leakageTemperature resistantMeasurement devicesNuclear energy generationElectricityElectrolysis

The invention belongs to the technical field of high-temperature steam electrolysis for hydrogen production and relates to a bottom entering gas testing device for a planar SOEC (solid oxide electrolyzer cell) stack. The testing device comprises a support base plate, a ceramic support pipe, a buffer gasket, a testing base and four stainless steel gas path pipes, wherein 4 gas flow distribution hole channels are formed in a cuboid of the testing base and communicate four base bottom gas holes with four base top gas holes pairwise. The testing device is used as a testing platform for a high-temperature SOEC stack and has the characteristics of stable testing, practicality, convenience, easiness in assembly, simplicity in operation and the like; the testing device adopts a design mode for combining the ceramic material and the high-temperature-resistant stainless steel material and has the performance of temperature resistance, heat insulation and electric insulation; the gas flow distribution hole channels formed in the testing base adopt inside roundabout design, heat in a high-temperature furnace is used directly for preheating entering gas, and the problems of gas pipe cracking and gas leakage of pipe joints at a high temperature are solved. The testing device is applicable to stable operation and performance testing of the SOEC stack.

Owner:TSINGHUA UNIV

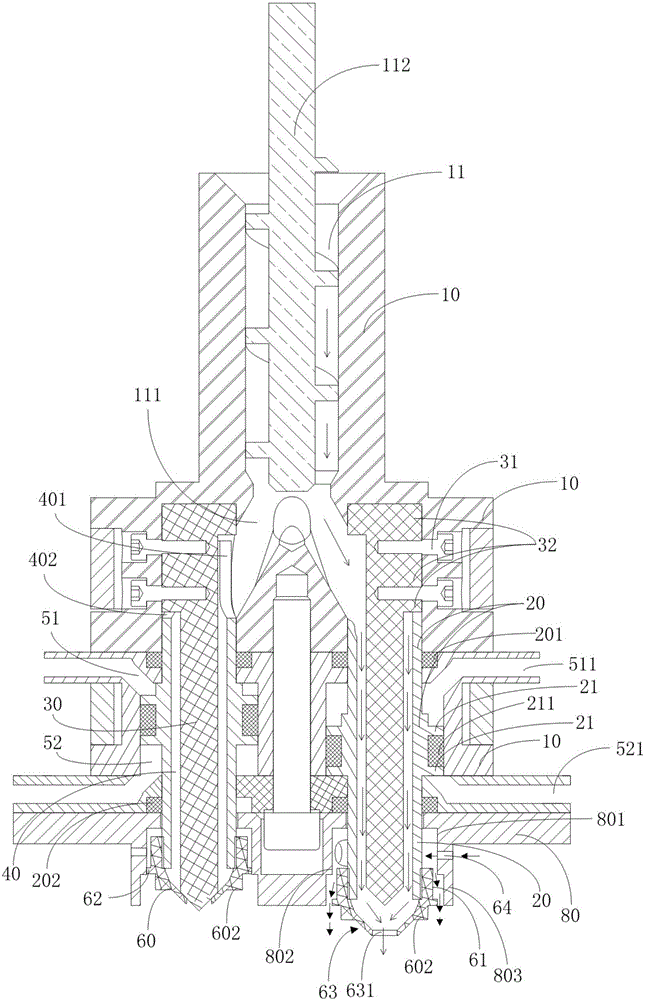

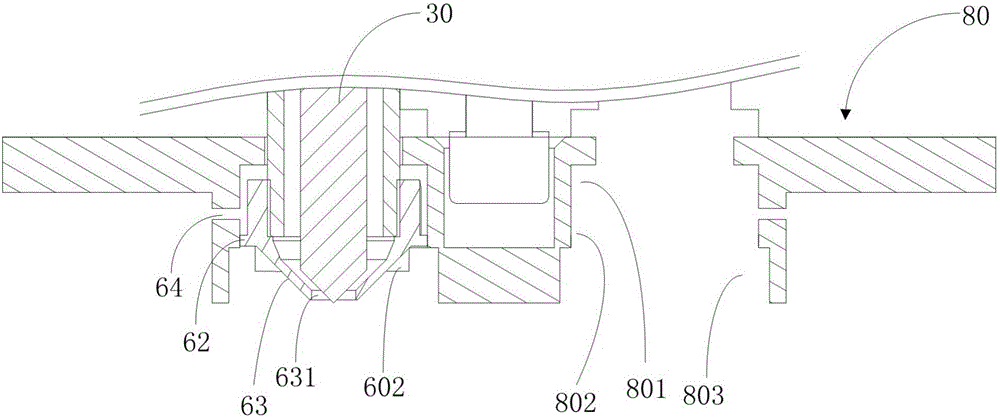

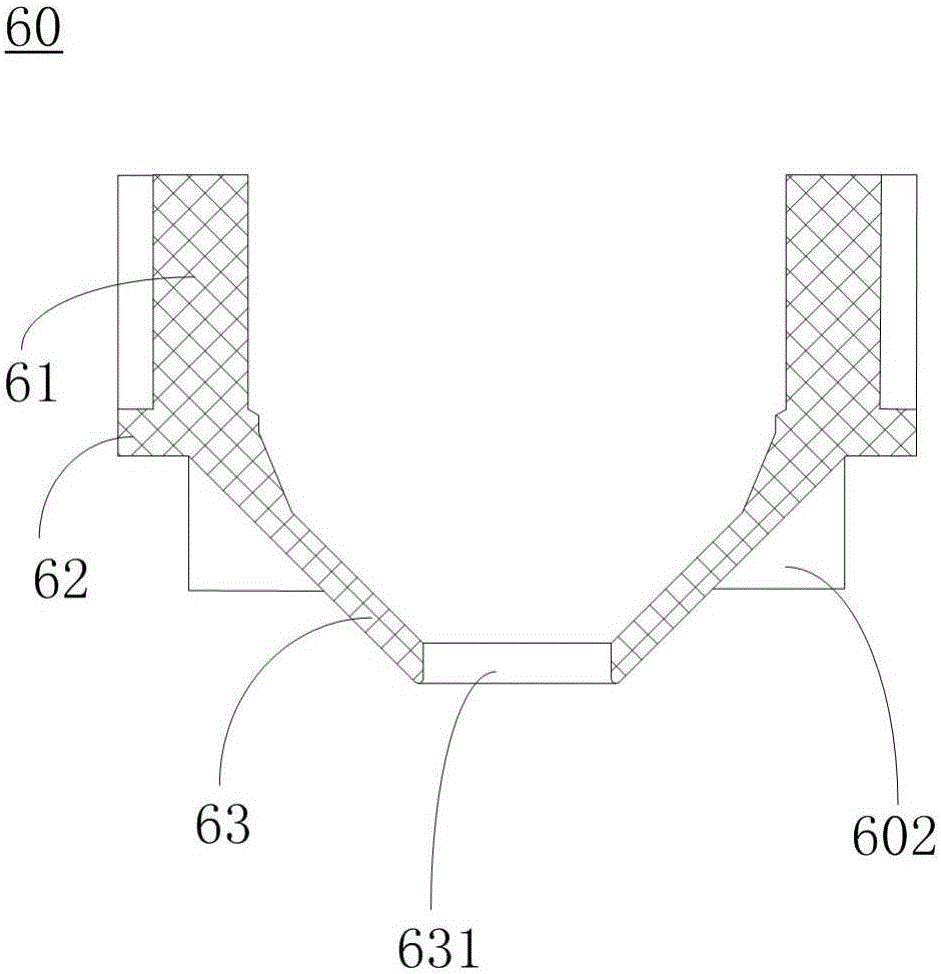

3D printing air nozzle and multi-channel telescopic nozzle valve provided with air nozzle

ActiveCN105922590AUniform cooling effectIncrease the windAdditive manufacturing apparatusMultiple way valvesEngineeringEnergy consumption

The invention discloses a 3D printing air nozzle. The air nozzle comprises a hollow air nozzle structure and a 3D printing nozzle, wherein the air nozzle structure comprises an air nozzle sealing section and an air outlet section, a nozzle hole is formed in the tail portion of the 3D printing nozzle, the 3D printing nozzle comprises a nozzle sealing section and a nozzle protruding section which are matched with the air nozzle sealing section, and the air nozzle structure installed around the outer side of the 3D printing nozzle. The invention further discloses a multi-channel telescopic nozzle valve provided with the air nozzle. The multi-channel telescopic nozzle valve comprises the 3D printing air nozzle and further comprises an installation base, cylinders and a valve needle, wherein the upper section of the installation base is provided with a feeding channel, the lower section of the installation base is provided with inner holes, and discharge ports are formed in the tops of the inner holes; the cylinders are installed in the inner holes and extend out from the open ends of the inner holes, and cylinder feed inlets are formed in the top ends of the cylinders; a hollow valve cavity is formed in each cylinder; the valve needle penetrates through the valve cavities and is installed on the installation base, and discharge channels are formed between the valve needle and the valve cavities. The 3D printing nozzle is arranged on the tail portions of the cylinders, and the air nozzle structure is arranged on the lower portion of the installation base. Air outflow is uniform, precision is high, energy consumption is low, noise is low, and environment protection and energy conservation are achieved.

Owner:浙江光镀智造科技有限公司

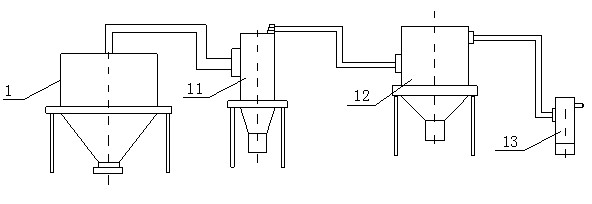

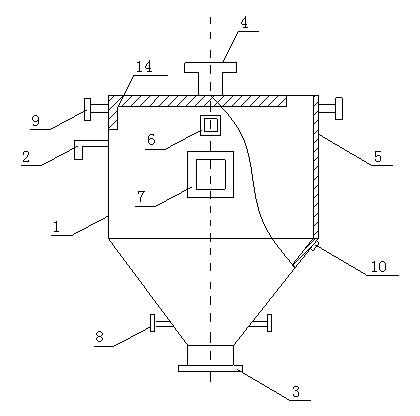

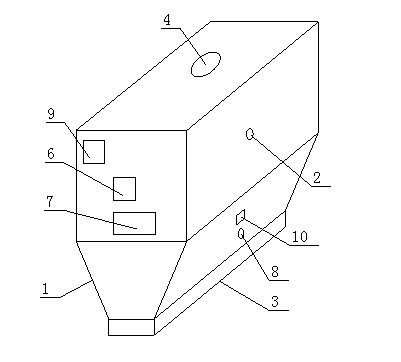

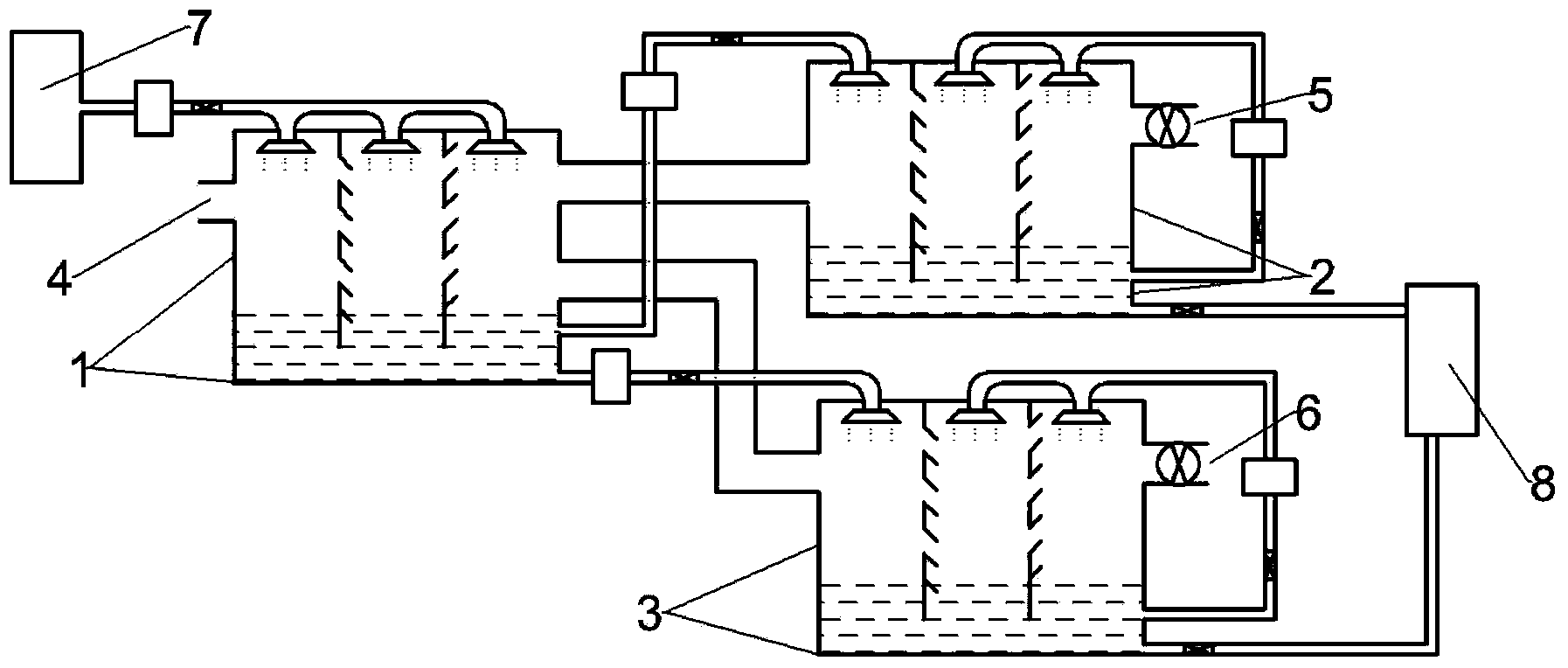

Wet dust removal and waste heat recovery device

ActiveCN104307279AEffective warm-upReduce the temperatureUsing liquid separation agentAlcoholFlue gas

The invention discloses a wet dust removal and waste heat recovery device. The device includes a first liquid storage pool, a first dust removal room, a second dust removal room, a third dust removal room and a second liquid storage pool, wherein the first liquid storage pool is used for accommodating a molasses alcohol fermentation liquor; two partition boards are vertically arranged inside each of the dust removal rooms, namely the first dust removal room, the second dust removal room, and the third dust removal room, and divide each dust removal room into three spaces; the lower parts of the three spaces in each dust removal room are communicated, and a first sprayer, a second sprayer and a third sprayer are respectively arranged at the upper parts of the three spaces in each dust removal room; a gas inlet is formed in one side of the first dust removal room, and the other side of the first dust removal room is respectively connected with one side of the second dust removal room and one side of the third dust removal room through a first vent pipe and a second vent pipe; a first gas outlet is formed in the other side of the second dust removal room, and a second gas outlet is formed in the other side of the third dust removal room. The device has the advantages that the thick molasses alcohol fermentation liquor is used for flue gas washing, so as to achieve good washing effect; the functions of recovering fertilizer particles and waste heat are achieved.

Owner:广西天源生物之本环保科技有限公司

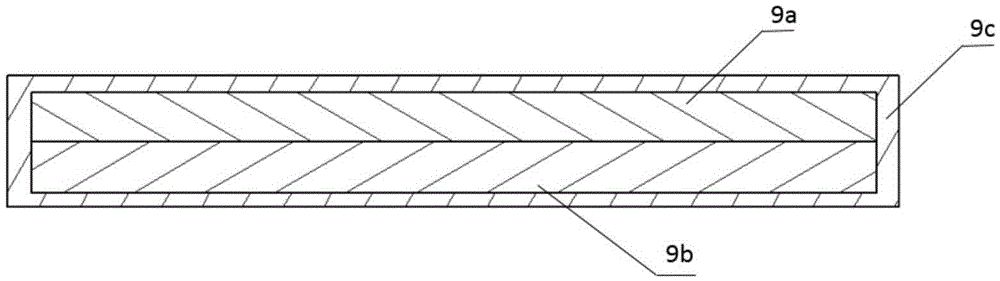

Electric heater for preheating and solidification prevention of high-temperature molten salt conveying pipe

PendingCN106131986AThe overall structure is simpleShort heating timeHeating element shapesElectric heatingResistance wire

The invention relates to an electric heater for preheating and solidification prevention of a high-temperature molten salt conveying pipe, and belongs to the technical field of electric heating in electrics. The electric heater comprises an electric heating pipe which is wound around the outer wall of the high-temperature molten salt conveying pipe or an electric heating pipe which is laid in parallel along the high-temperature molten salt conveying pipe and is close to the lower part of the high-temperature molten salt conveying pipe. The electric heating pipe is made of a high-temperature nichrome resistance wire which sequentially passes through a plurality of insulating fixed parts and is sleeved by a high-temperature fiber sleeve. The electric heater is simple in overall structure, is short in heating time, is high in work temperature, can reach the start temperature of a conveying pipe device in a shorter time, and achieves the effective preheating and solidification prevention of the high-temperature molten salt conveying pipe.

Owner:镇江市三维电加热器有限公司

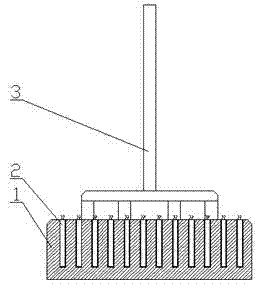

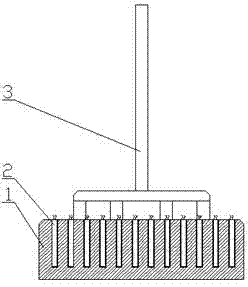

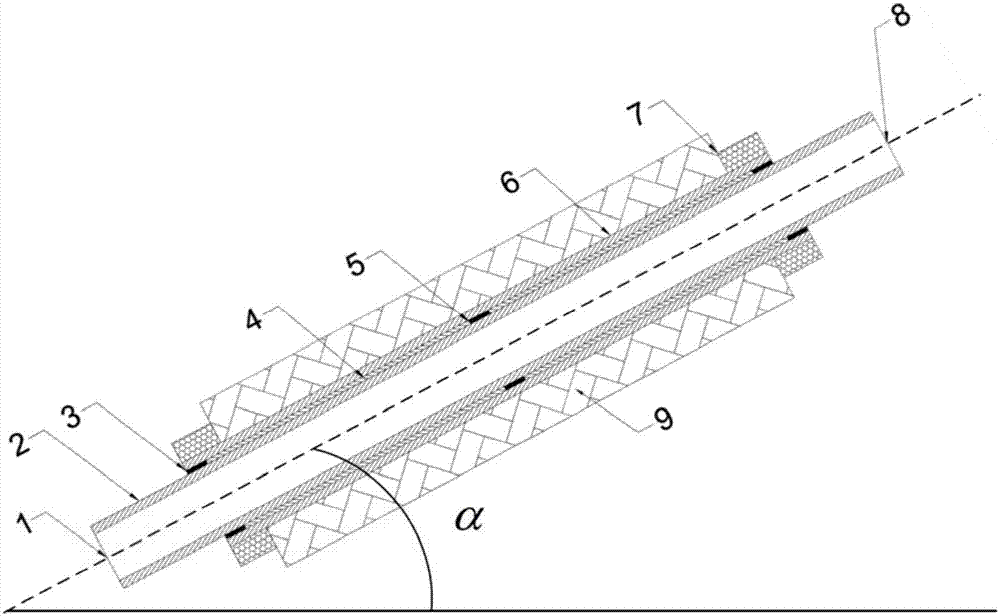

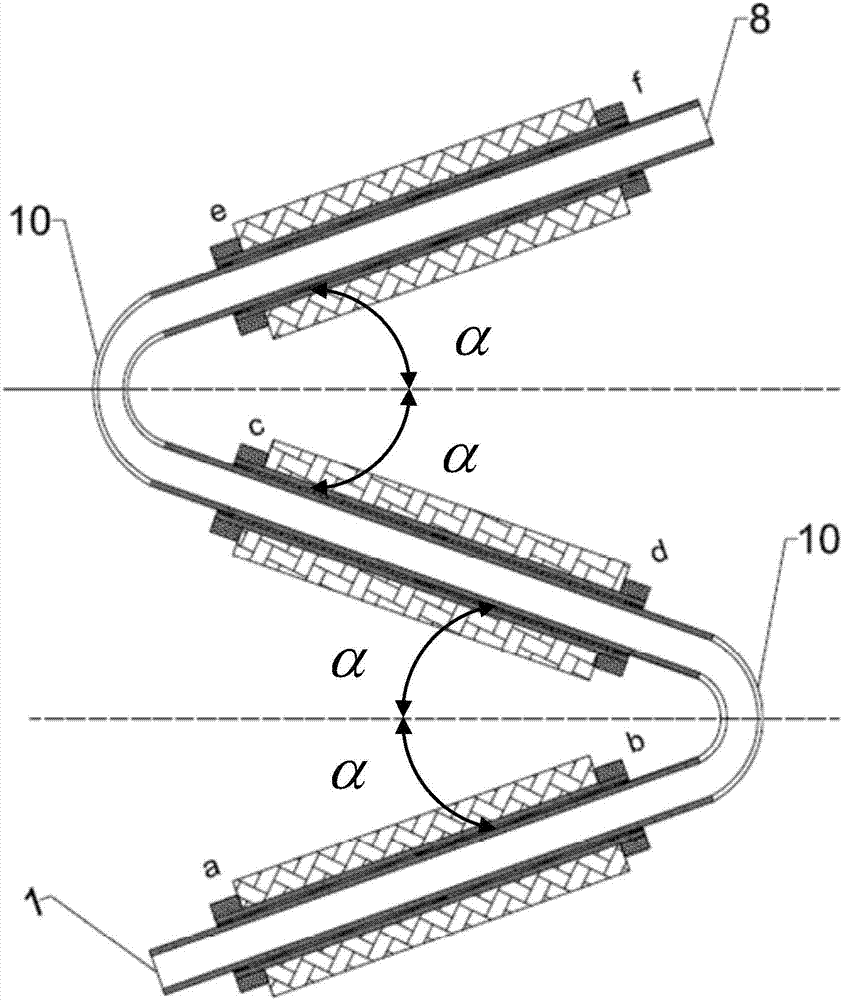

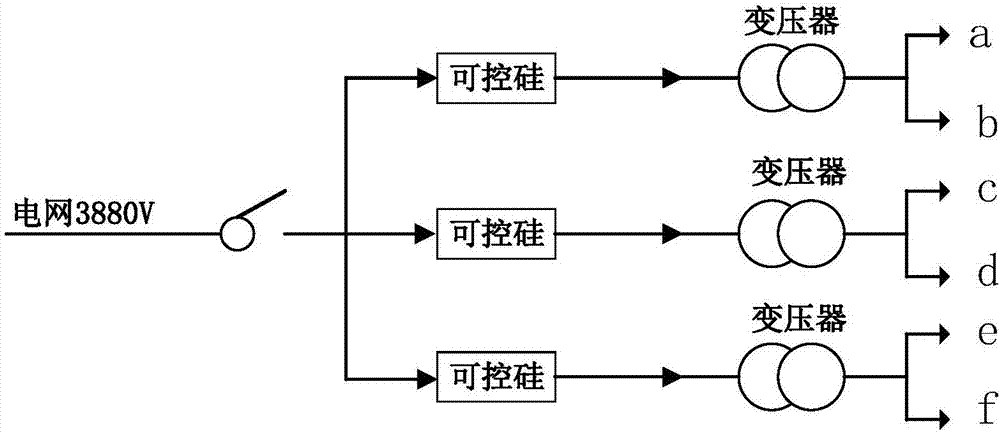

High-power preheater for liquid metal sodium experimental loop

The invention relates to a high-power preheater for a liquid metal sodium experimental loop. The high-power preheater mainly comprises inner pipes, an electric insulating layer, a positioning ring, two end sealing rings, outer pipes, two pairs of electrodes and a heat preservation layer. Connection between multiple stages of heating parts is achieved in the manner that bends the same as the inner pipes in radius are used for connecting outlets of the inner pipes of last stages with inlets of the inner pipes of the next stages; the power of the preheater is adjusted through controlled silicon; and the provided power of the preheater can reach hundred kilowatts or above, large-flow liquid metal sodium can be preheated in a large temperature rise manner, the temperature rise promoting level can reach 400 DEG C or above, any sealing measures are avoided, the structure is very simple, and use and operation are convenient.

Owner:XI AN JIAOTONG UNIV

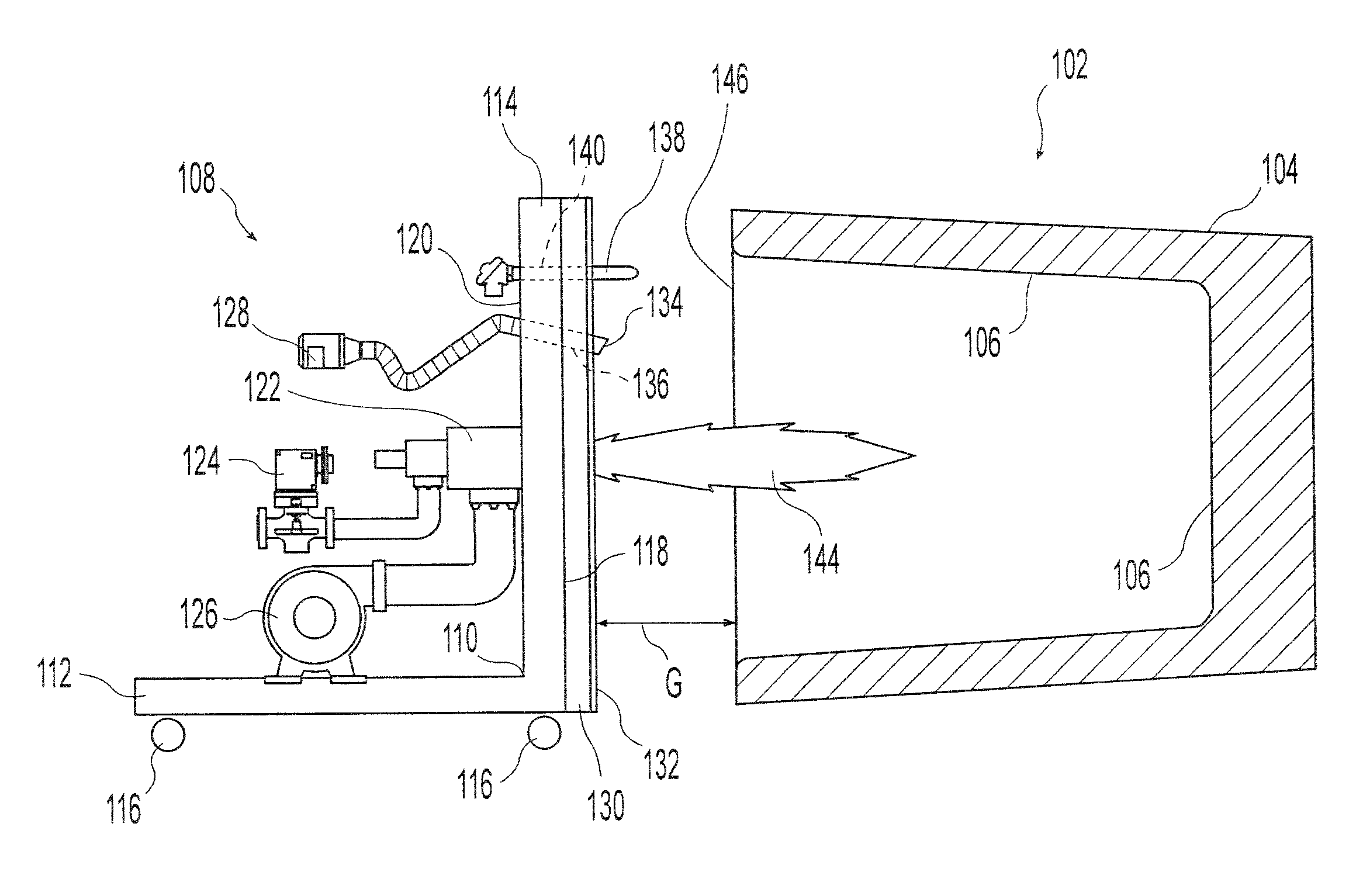

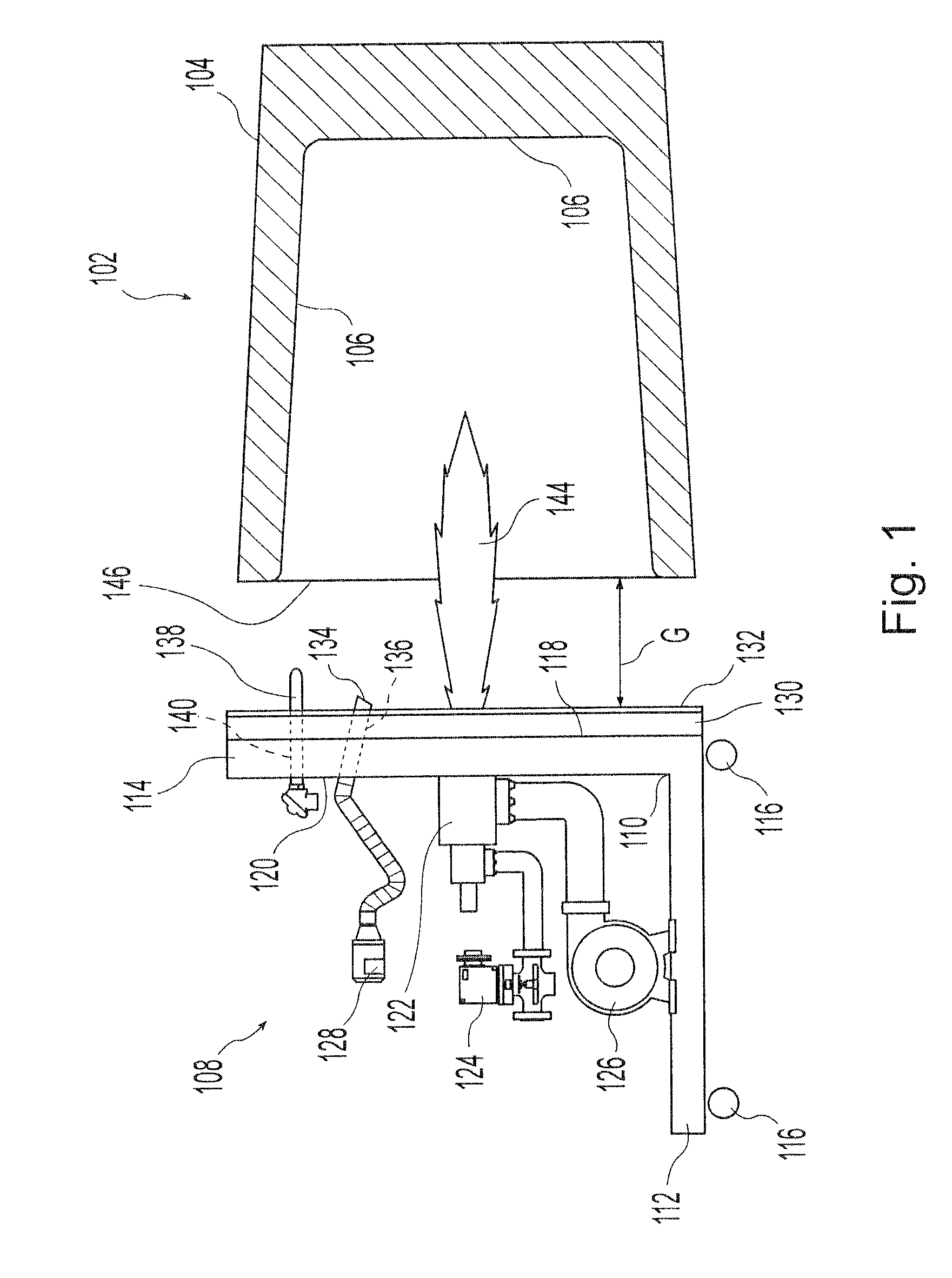

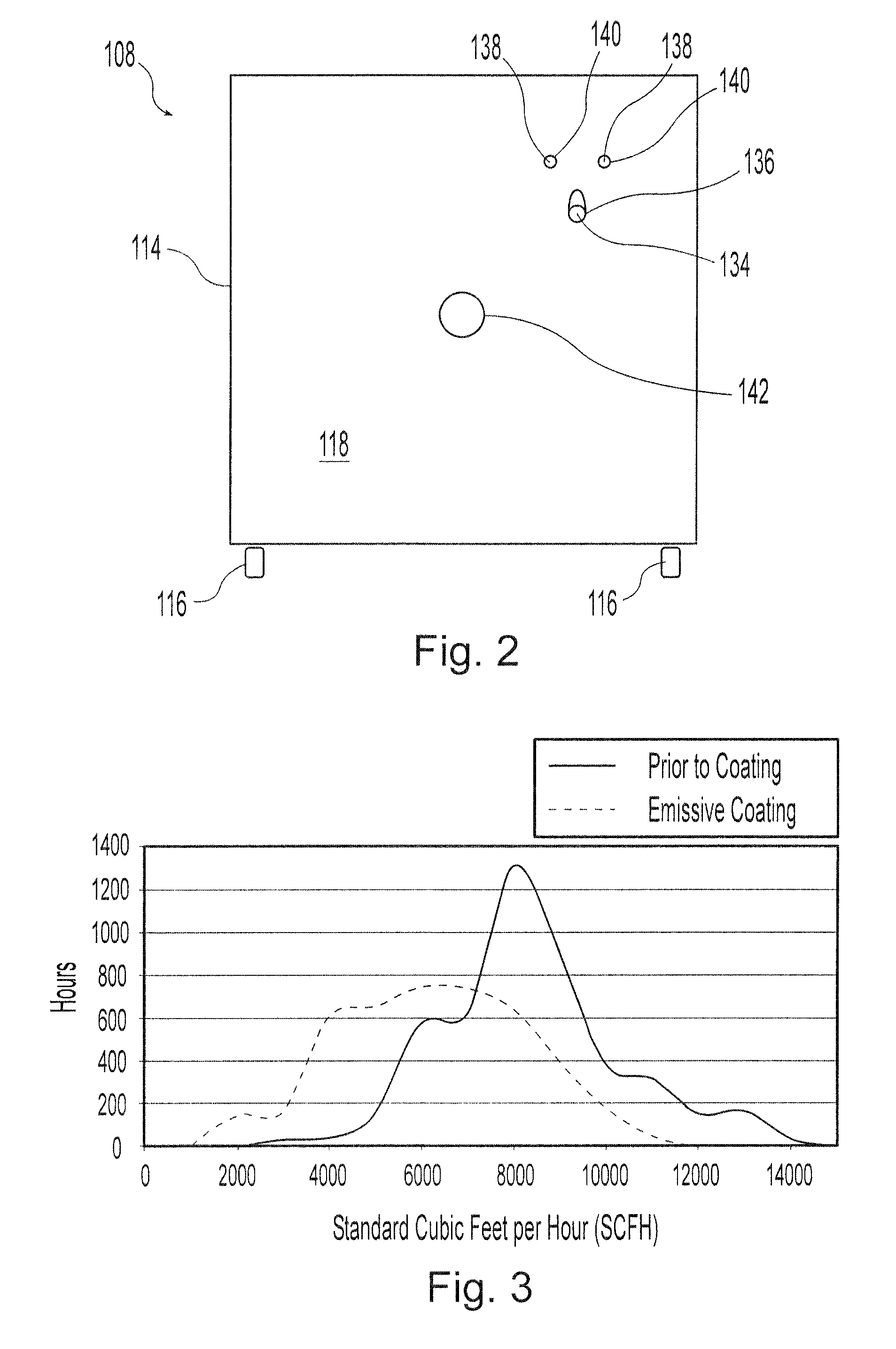

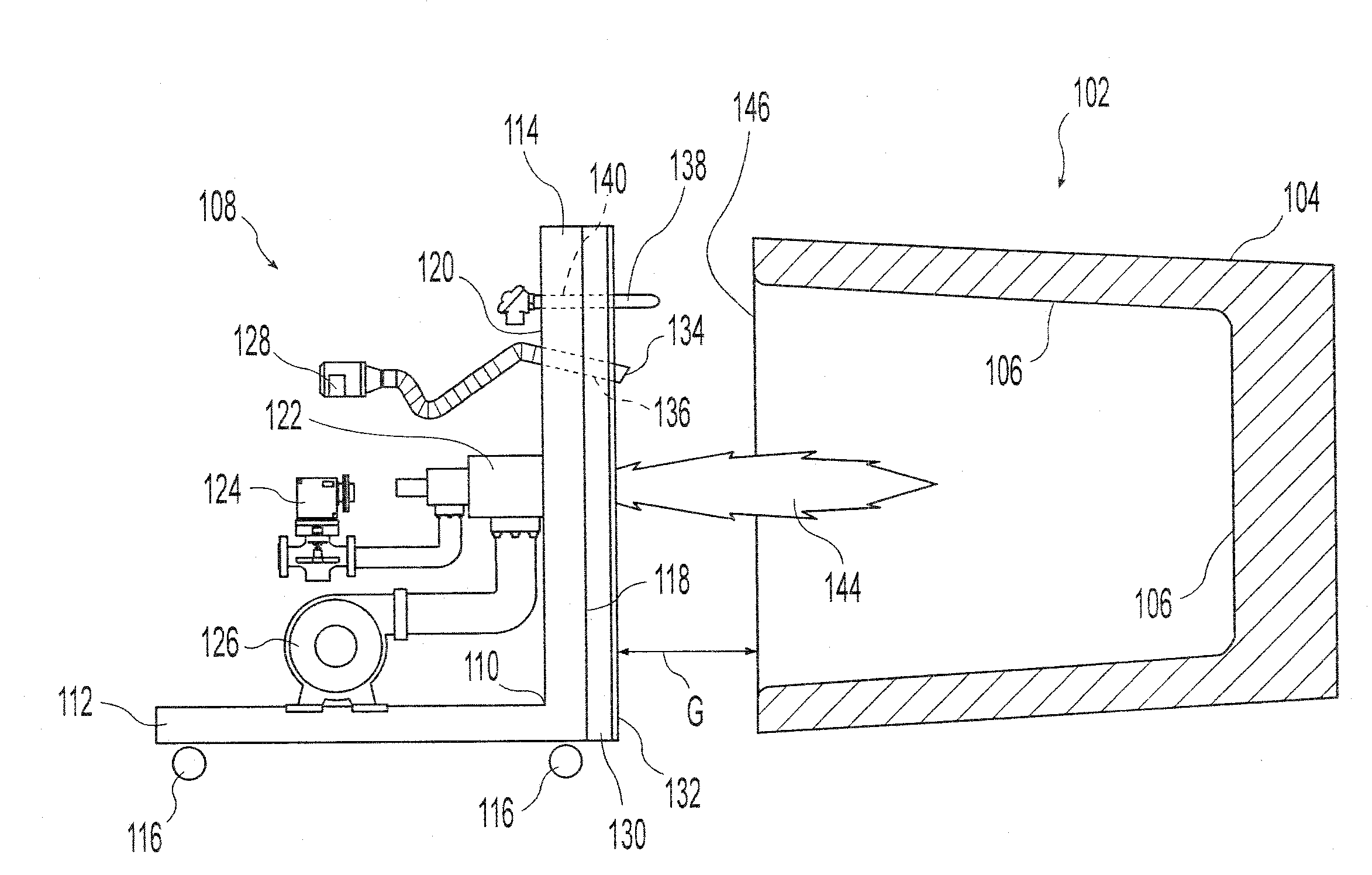

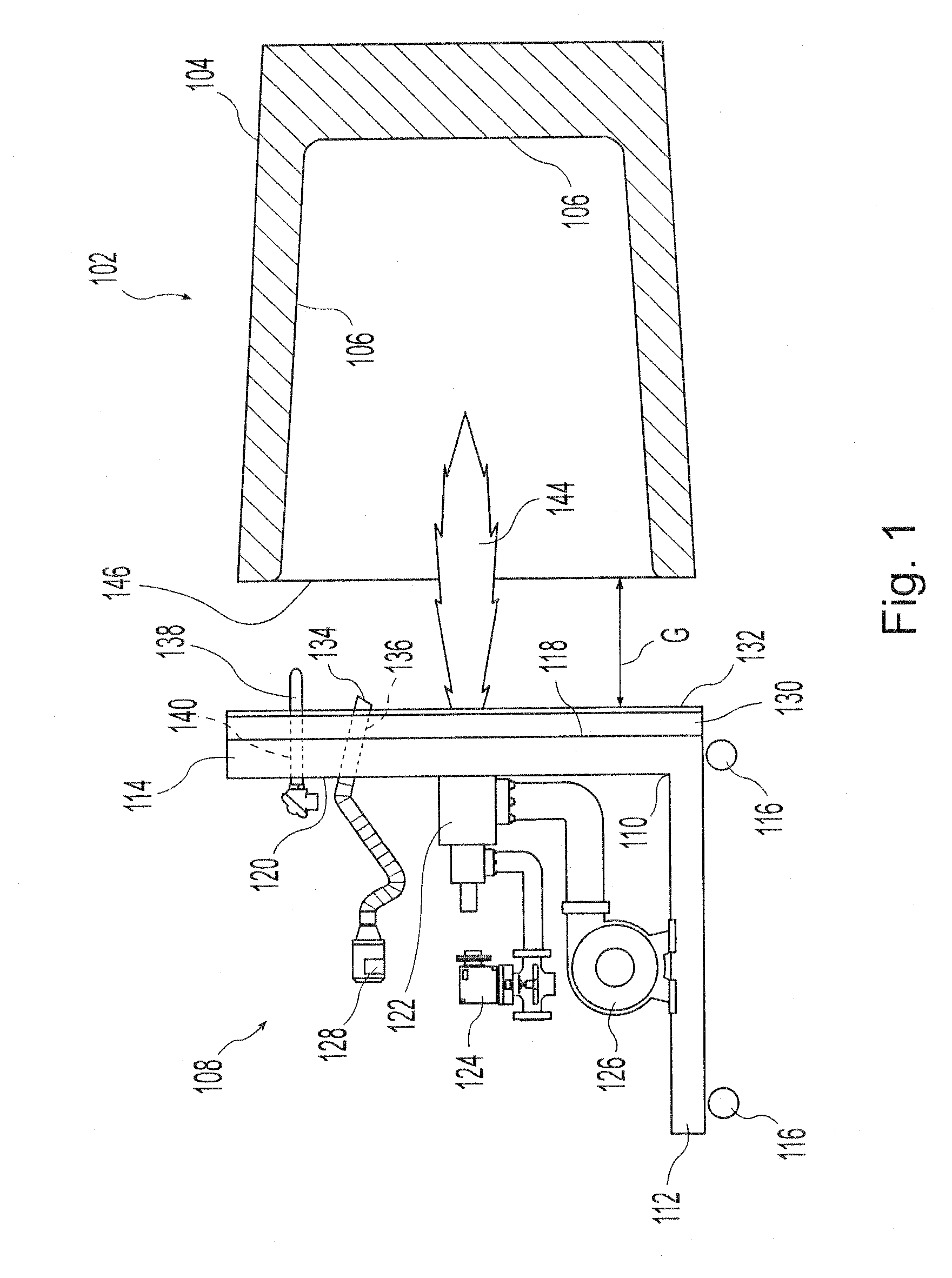

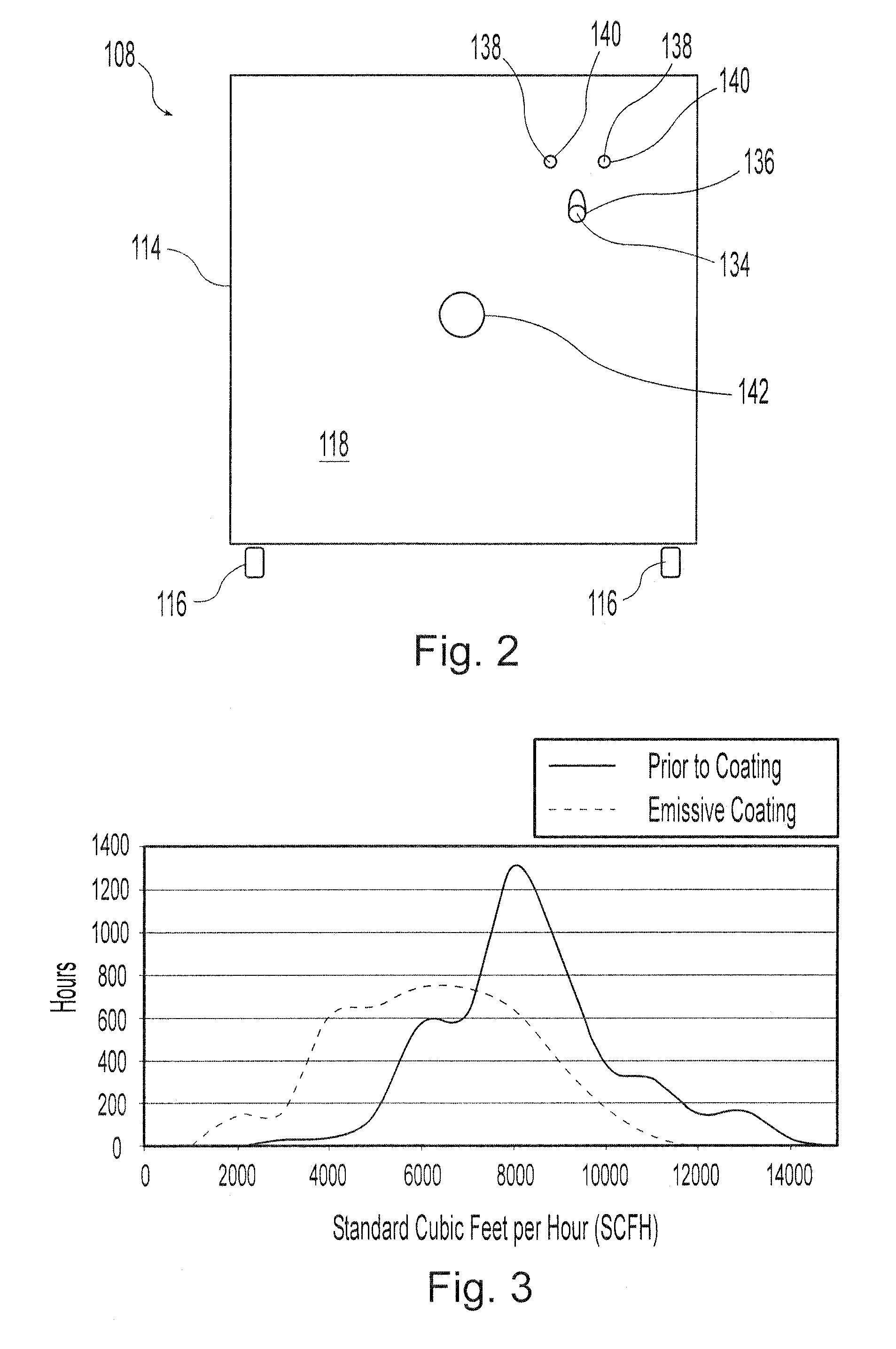

Method of preheating steelmaking ladles

ActiveUS8142541B2Reduce harmReduce thermal stressMelt-holding vesselsCharge manipulationSteelmakingCombustor

A method for when preheating a ladle for use in steelmaking where less fuel is consumed in heating the ladle efficiently accurately to a controlled temperature. A temperature of a preheating process is varied by controlling a burner of the heating unit based on measurements of refractories of the ladle taken by a pyrometer. The heating unit includes an emissive coating for reducing heat loss and efficient heating during the preheating process. The heating unit also includes valve mechanisms for accurately varying a flame size of the burner of the heating unit during an idle stage of the preheating process.

Owner:NUCOR CORP

Method of preheating steelmaking ladles

ActiveUS20080305446A1Reduce amountAvoid wear and damageMelt-holding vesselsCharge manipulationPyrometerCombustor

A method for when preheating a ladle for use in steelmaking where less fuel is consumed in heating the ladle efficiently accurately to a controlled temperature. A temperature of a preheating process is varied by controlling a burner of the heating unit based on measurements of refractories of the ladle taken by a pyrometer. The heating unit includes an emissive coating for reducing heat loss and efficient heating during the preheating process. The heating unit also includes valve mechanisms for accurately varying a flame size of the burner of the heating unit during an idle stage of the preheating process.

Owner:NUCOR CORP

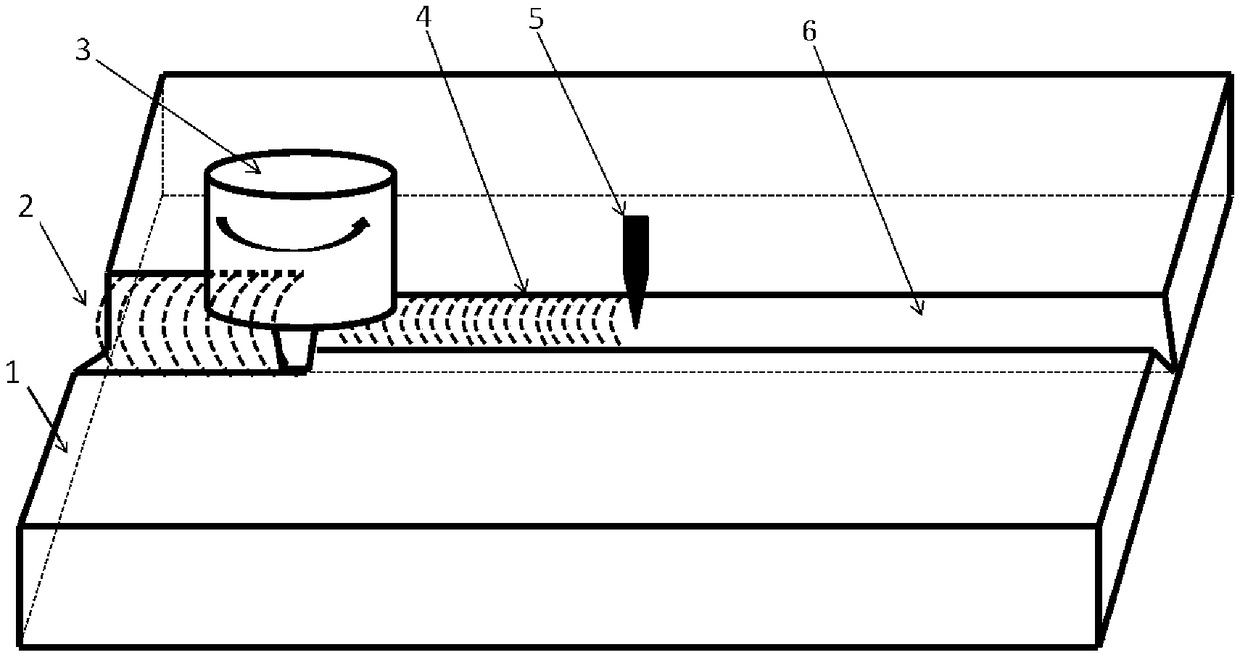

Fusion welding auxiliary heating friction-stir welding method under prefabricated groove situation

InactiveCN108857114AEffective warm-upImprove joint performanceWelding apparatusFriction weldingEngineering

The invention discloses a fusion welding auxiliary heating friction-stir welding method under a prefabricated groove situation. The method comprises the steps of firstly prefabricating grooves (6) with different shapes on a workpiece (1) to be welded, then utilizing fusion welding for accomplishing the welding of the workpiece (1) to be welded, and filling molten liquid metal in the grooves (6) for preheating welded joints, wherein during the welding process, friction-stir welding follows fusion welding, a stirring head (3) is located at the position which is 0 to 300mm away from a fusion welding gun (5), and the welding speed of the friction-stir welding and the welding speed of the fusion welding stay the same during the welding process, so that the distance between the stirring head (3)and the fusion welding gun (5) stays the same. The fusion welding energy is uniform, the workpiece to be welded is effectively preheated, the follow-up friction-stir welding plays a role in improvingthe connector performance, and through the combination of two welding modes, the weaknesses can be greatly avoided, and the welding operation is carried out simply, conveniently and flexibly.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Harmless disposal and comprehensive utilization method for high-salt chemical sludge

ActiveCN107388262ADoes not affect the effect of incinerationAffect lifeWater/sewage treatment by centrifugal separationTreatment involving filtrationSludgeCompound (substance)

The invention belongs to the technical field of solid waste disposal, and particularly relates to a harmless disposal and comprehensive utilization method for high-salt chemical sludge. According to the method, negative-pressure cyclic heat storage, incineration and recycling equipment is adopted, maintenance and replacement are easy, the use cost of the equipment is low, harmless disposal of the high-salt chemical sludge can be achieved, salt in the sludge is recycled, the technical problem that the high-salt chemical sludge is fused, forms rings, is caked and the like under the high-temperature condition to cause severe destruction to an incinerator can be solved, the incineration effect is improved, and energy conservation and environmental friendliness are achieved.

Owner:CHONGQING ANGRUIYUE SCI & TECH

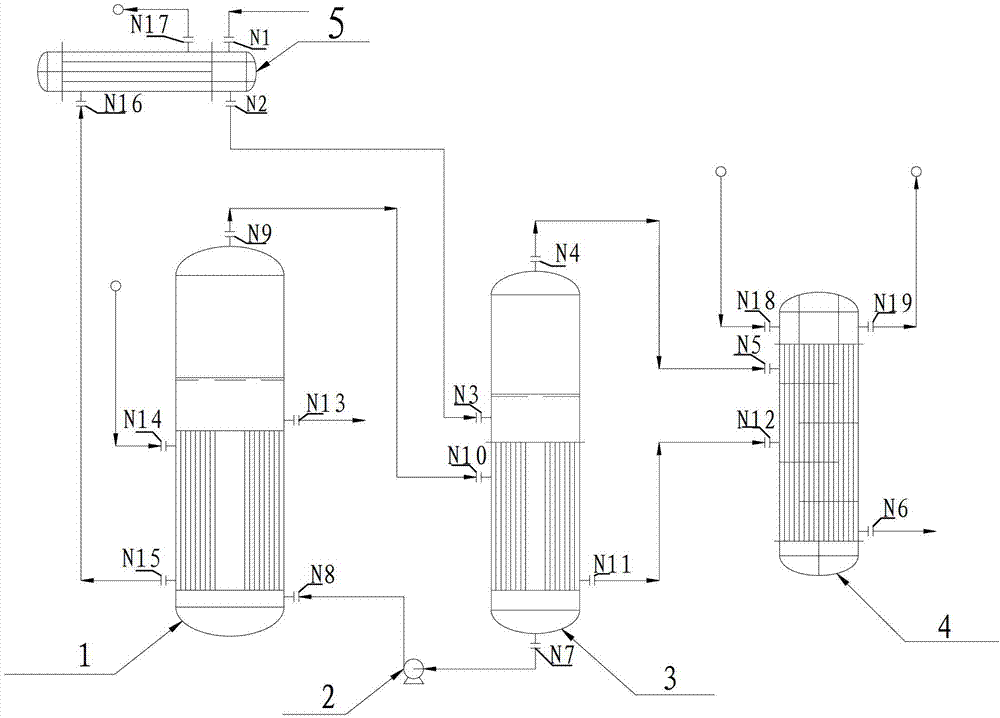

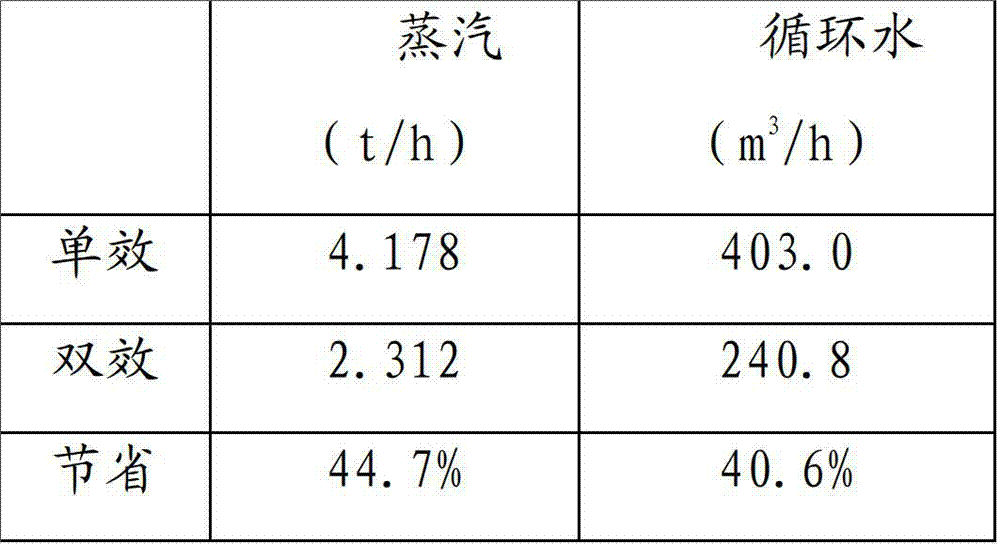

Double-effect evaporation method for crude toluene mixed solution and device using double-effect evaporation method

ActiveCN102886150ARealize ladder utilizationIncrease profitChemical industryHydrocarbon purification/separationEvaporationSingle effect

The invention relates to a double-effect evaporation method for a crude toluene mixed solution and a device using the double-effect evaporation method. Crude toluene enters a double-effect evaporator from a double-effect evaporator material inlet for evaporating; the double-effect toluene vapour overflows from the top part of the double-effect evaporator; a toluene concentrated solution flows out from the bottom of the double-effect evaporator and enters a single-effect evaporator from a concentrated toluene inlet on the lower part of the single-effect evaporator through a pump; the toluene concentrated solution inside the single-effect evaporator is distilled, so that single-effect toluene vapour overflows from the top part of the single-effect evaporator; toluene raffinate is discharged from an overflow port at the middle part of the single-effect evaporator; the single-effect toluene vapour enters a shell side of a heat exchange part of the double-effect evaporator from a single-effect toluene vapour pipeline, and performs heat exchange with the crude toluene in the double-effect evaporator, so that the crude toluene is heated and gasified, is overflown from the top part of the double-effect evaporator, and enters a condenser from a double-effect toluene vapour output tube, so as to be discharged after being condensed and cooled by circulating cooling water. The method uses double-effect evaporation, so an energy-saving effect is remarkable.

Owner:YANTAI DONGJIE ENVIRONMENTAL PROTECTION MACHINERYENG

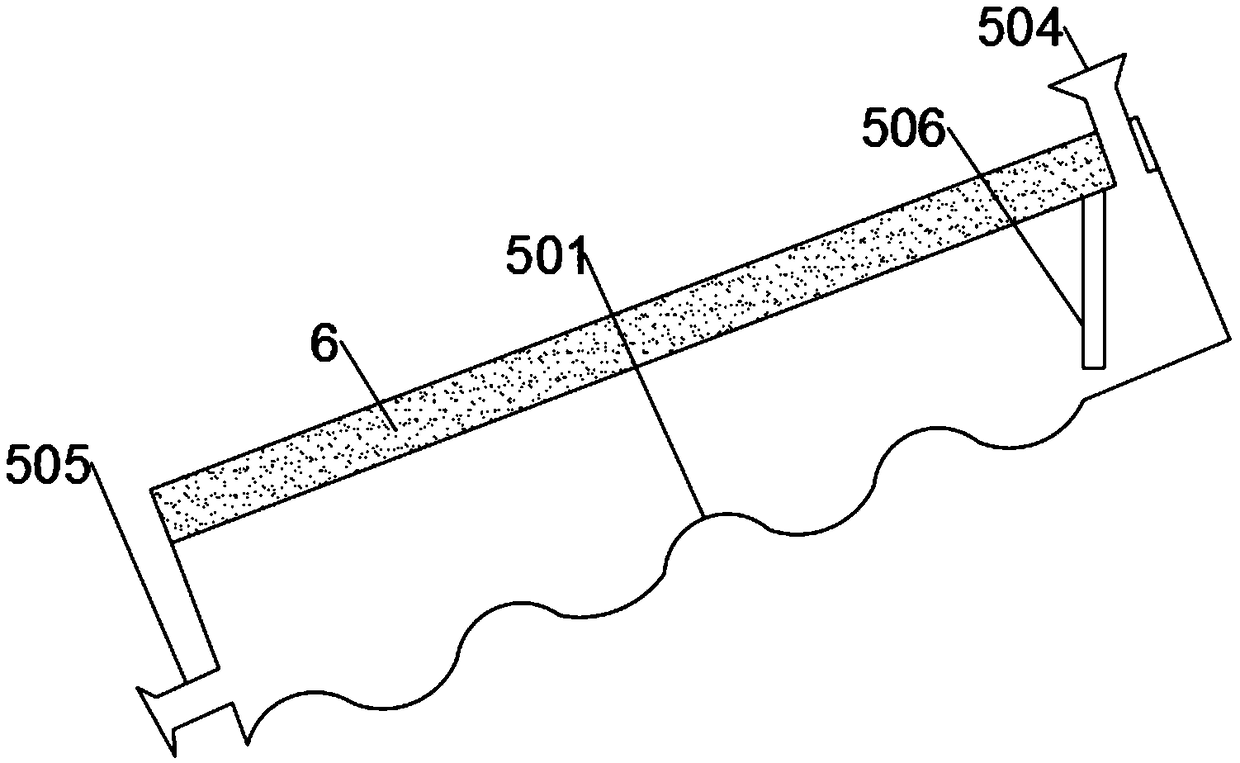

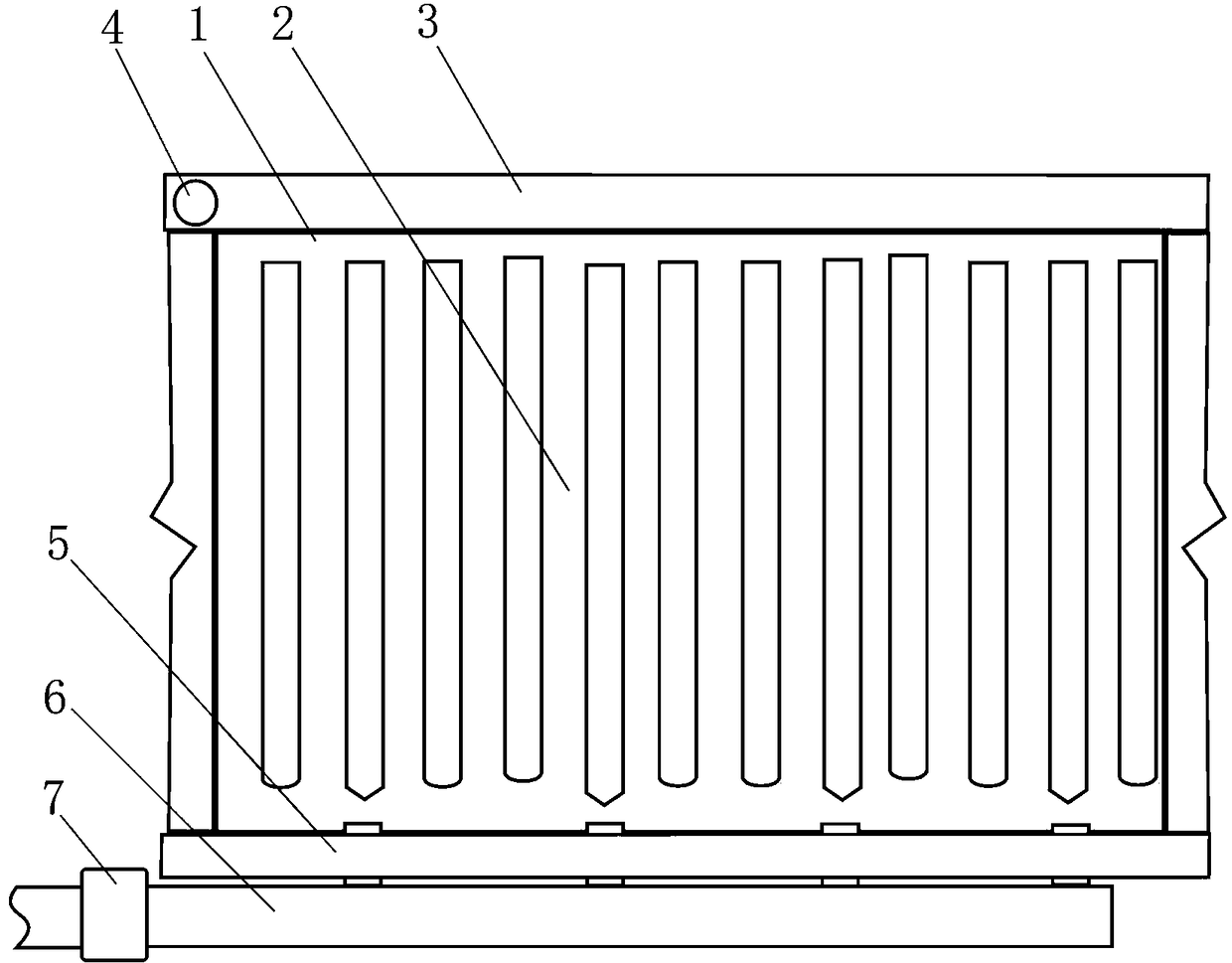

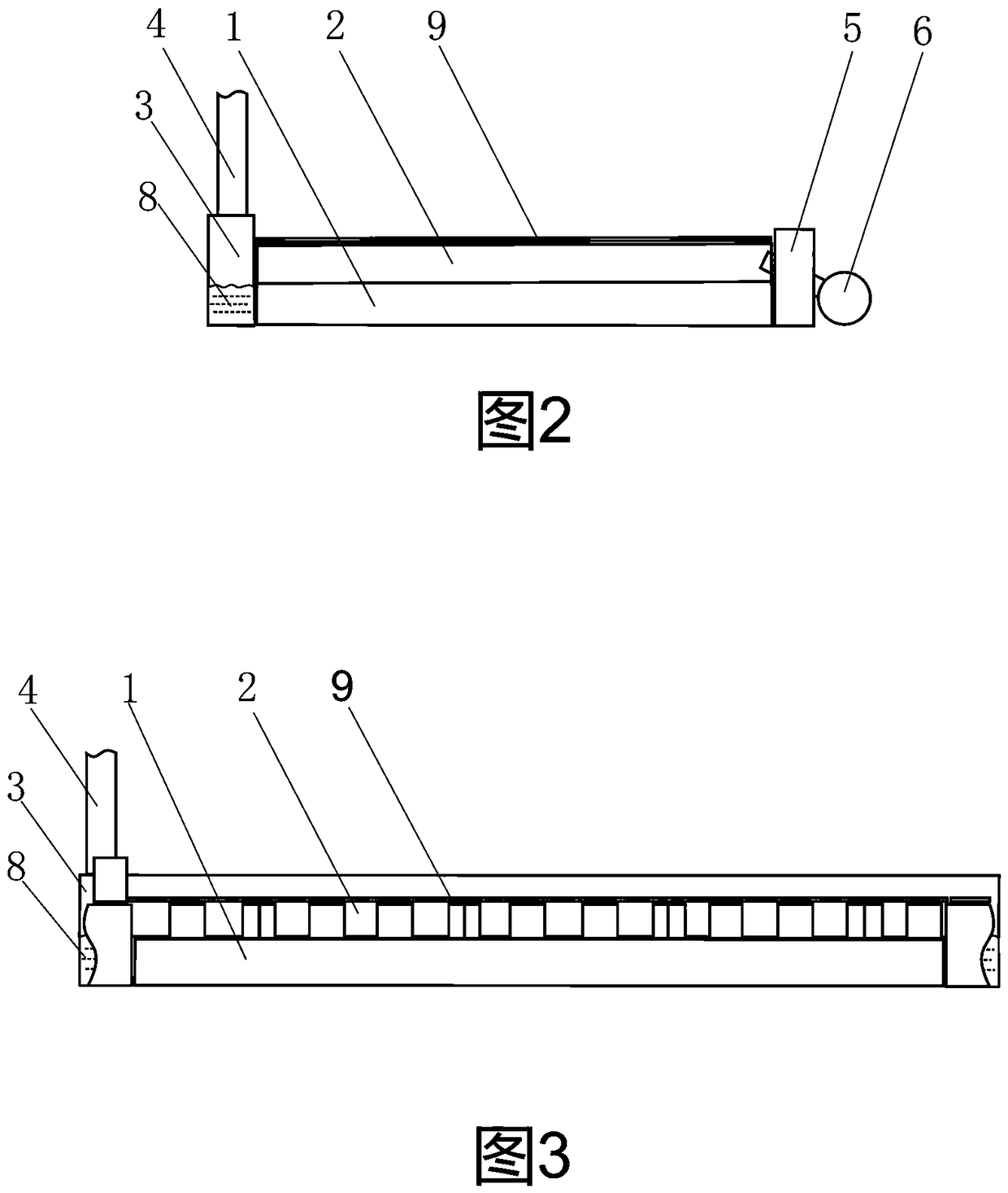

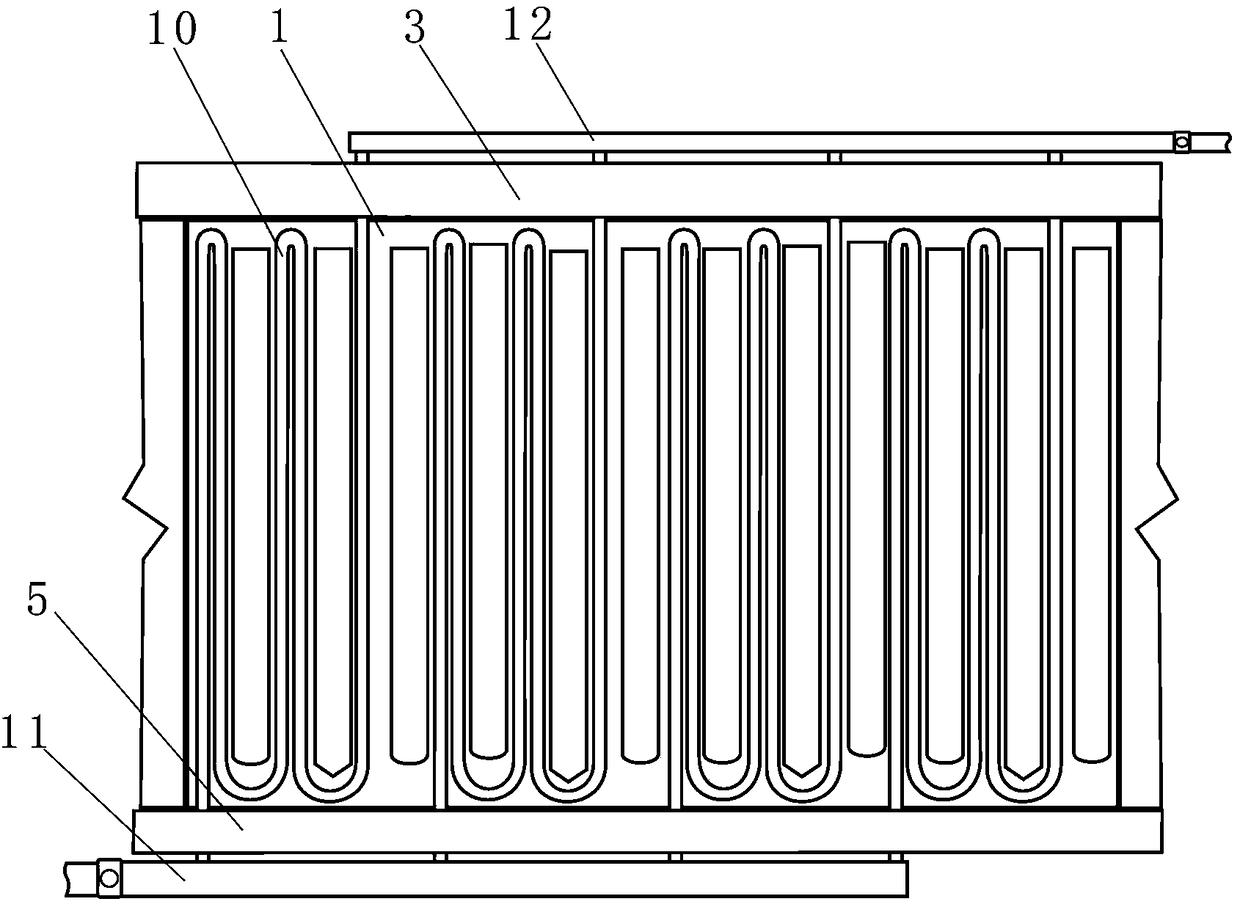

Heating bed for heating asphalt concrete raw materials by using waste heat of drying cylinder

InactiveCN108547199AEffective warm-upEfficient use ofRoads maintainenceThermal energyHeat conducting

A heating bed for heating asphalt concrete raw materials by using waste heat of a drying cylinder is characterized in that a heating bed base bed is arranged on the ground of a raw material stacking bin; a U-shaped groove is formed in the base bed; a heat transmission steel plate is arranged on the U-shaped groove; a rectangular heat conducting water coiled pipe is arranged in a position, at the lower end of the heat transmission steel plate, in the U-shaped groove; one end of the rectangular heat conducting water coiled pipe is linked to a hot water lead-in main pipe; the other end of the rectangular heat conducting water coiled pipe is linked to a cold water flow-out main pipe; a steam lead-in main pipe is arranged on the external side of a material isolation wall which is arranged at the front end of the heating bed; an induced draft fan is arranged at the front end of the steam lead-in main pipe; and the induced draft fan is linked with an induced pipe which is arranged on the induced draft fan used for exhausting tail gas (steam) in an asphalt mixing plant. By using a method of arranging the induced pipe on the induced draft fan for exhausting tail gas (steam) in a drying cylinder of the asphalt mixing plant and arranging a water jacket on the periphery of a flue of a chimney, the advantage that raw materials are preheated by using heat energy of high temperature tail gas(steam) and heat energy on the flue of the chimney is realized.

Owner:SICHUAN CHUANJIAO ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com