Preheating starting method for aluminium electrolysis cell

A technology for preheating and starting aluminum electrolytic cells, which is applied in the field of preheating and starting aluminum electrolytic cells. It can solve the problems of poor anti-disturbance performance of inert anodes and heating electrolyte, etc., and achieve the effects of reducing start-up costs, heating uniformly, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

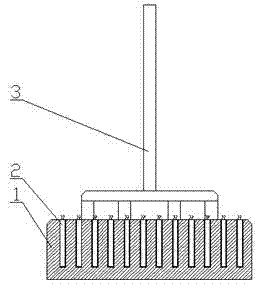

Embodiment 1

[0037]In traditional 300KA aluminum electrolytic cells, carbon anodes are used to make preheating electrodes. Drill a hole on the upper surface of the carbon anode (1) and put in the heating element (2). The anode does not need to be connected to the busbar with a soft connection. Fix the preheating electrode busbar (3) on the aluminum busbar with a clamp. The number of preheating electrodes is the same as The number of anodes is consistent during normal production. The furnace is filled with solid electrolyte, and cryolite and soda ash are added to the tank and anode to keep warm and prevent anodic oxidation. Turn on the heating element and start heating according to the temperature rise regime. When the furnace temperature is heated to 950°C, continue to add solid electrolyte until the electrolyte level is 25cm, add fluorine salt, adjust the electrolyte composition, adjust the heating component power to simulate the heat input in the electrolysis state, when the electrolyti...

Embodiment 2

[0039] The traditional 400KA aluminum electrolytic cell has a special-shaped cathode with a diversion structure. Drill a hole on the upper surface of the carbon anode (1) and put it into the heating assembly (2). The anode does not need to be connected to the busbar with a flexible connection. Fix the preheating electrode busbar (3) on the aluminum busbar with a clamp. The number of preheating electrodes is the same as The number of anodes is consistent during normal production. The furnace is filled with solid electrolyte, and the heating element is supplied with alternating current, and the heating starts according to the heating system. When the furnace temperature is heated to 960°C, add liquid electrolyte until the electrolyte level is 23cm, pour 10cm of aluminum water, add fluoride salt, adjust the electrolyte composition, adjust the heating component power to simulate the heat input in the electrolysis state, when the electrolytic cell reaches the expected heat balance ...

Embodiment 3

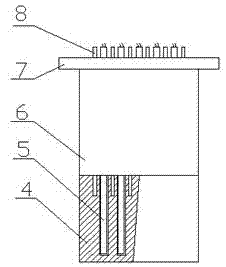

[0041] Vertical inert electrode aluminum electrolytic cell, "preheated anode" includes graphite electrode (4), heating component (5), corrosion-resistant material protective layer (6), plate busbar (7), guide rod (8). A hole is drilled on the upper surface of the graphite electrode (4), and the heating assembly (5) is put in; the heating assembly of the preheated electrode has a corrosion-resistant material protection layer (6) on the exposed graphite electrode part and the guide rod (4). The graphite electrode (4) is connected with the pole plate bus bar (7) through the guide rod (8). The "preheated cathode" is also made of graphite electrodes and has the same structure as the "preheated anode", but without drilling and without heating components. The preheated electrodes and preheated cathodes are fixed in the electrolytic cell in the form of "-yin-yang-yin-". There are 2 electrolytic cells in total, and each electrolytic cell contains 9 preheated anodes and 10 preheated cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com