Fusion welding auxiliary heating friction-stir welding method under prefabricated groove situation

A technology of friction stir and welding method, which is applied in the field of fusion welding auxiliary heat stir friction welding, which can solve the problems of joint welding defects, performance degradation, microstructure and mechanical properties difference, etc., and achieve the effect of improving joint performance and welding operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

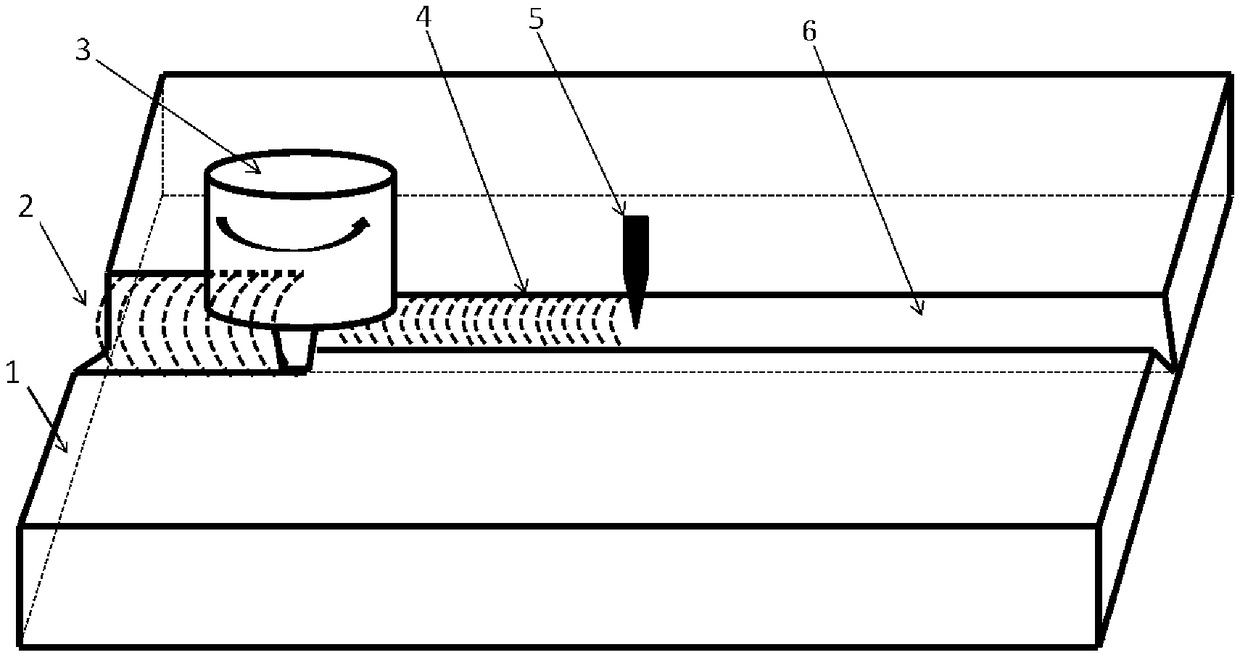

[0012] Such as figure 1 As shown, the workpiece 1 to be welded is low-carbon micro-alloy steel with a thickness of 7mm. Before welding, a V-shaped groove 6 is prefabricated on the workpiece 1 to be welded. The width and height of the V-shaped groove 6 are 6mm and 6mm respectively. The welding process Firstly, use mixed gas (65% Ar + 26.5% He + 8% CO 2 + 0.5% O2) shielded welding to weld the workpiece 1 to be welded, so that the molten welding wire fills the V-shaped groove 6, and the welding During the process, the voltage is 25V, the current is 200A, the welding speed is 75mm / min, and the diameter of the welding wire is 1.2mm. During the welding process, the friction stir welding follows the mixed gas shielded welding, the stirring head 3 is located 30mm behind the mixed gas shielded welding torch 5, and the friction stir welding travel speed is 75mm / min, which is consistent with the melting welding speed; the material of the stir head 3 It is W-Re alloy, the diameter of the...

Embodiment 2

[0014] The workpiece 1 to be welded is a 30mm thick 7050 aluminum alloy thick plate. Before welding, a V-shaped groove 6 is prefabricated on the workpiece 1 to be welded. The width and height of the V-shaped groove 6 are 20mm and 27mm respectively. MIG welding completes the welding of the workpiece, so that the molten welding wire fills the V-shaped groove 6. During the welding process, the voltage is 23V, the current is 240A, the welding speed is 50mm / min, and the diameter of the welding wire is 1.2mm. During the welding process, the friction stir welding follows the MIG, the stirring head 3 is located 45mm behind the fusion welding torch 5, and the friction stir welding travel speed is 50mm / min, which is consistent with the fusion welding travel speed. The material of the stirring head 3 is tool steel, the diameter of the shoulder of the stirring head 3 is 40mm, the stirring needle is tapered, the needle length is 28mm, and the rotational speed during the friction stir weldin...

Embodiment 3

[0016] The workpiece 1 to be welded is a 10mm thick red copper plate. Before welding, the unilateral V-shaped groove 6 is prefabricated on the workpiece 1 to be welded. The width and height of the unilateral V-shaped groove 6 are 5mm and 7mm respectively. During the welding process, first Use MIG welding to complete the welding of the workpiece, so that the molten welding wire fills the V-shaped groove 6. During the welding process, the voltage is 31V, the current is 240A, the welding speed is 50mm / min, and the diameter of the welding wire is 1.2mm. During the welding process, friction stir welding followed closely, the stirring head 3 was 30 mm behind the fusion welding torch 5, and the friction stir welding traveling speed was 50 mm / min, which was consistent with the fusion welding traveling speed. The material of the stirring head 3 is high-speed steel, the diameter of the shoulder of the stirring head 3 is 20mm, the stirring needle is tapered, the length of the needle is 9....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com