Glass microballoon manufacturing device and preparation method thereof

A technology of glass beads and manufacturing devices, which is applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems of high production cost, easy formation of scars, and high platinum loss, so as to reduce power and energy consumption and ensure Product quality, the effect of improving the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

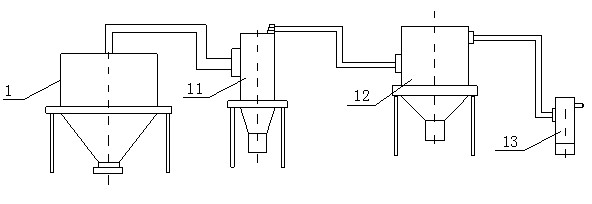

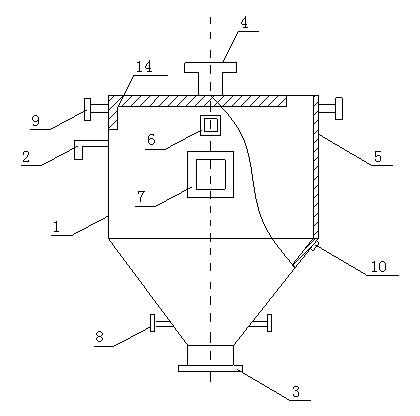

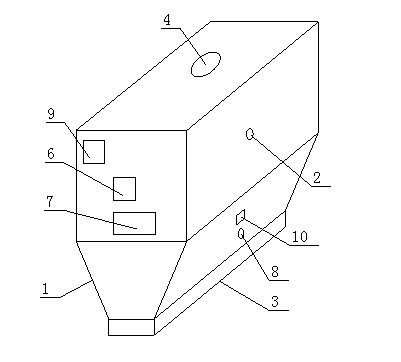

[0032] Such as figure 1 , figure 2 , image 3 Shown: a glass microsphere manufacturing device, which includes a furnace body 1 and a waste gas processor, the furnace body 1 is formed by gas-tight connection of one or more upper parts of the furnace body and one or more lower parts of the furnace body, and the waste gas treatment The device includes a cyclone separator 11, a dust collector 12 and a fan 13 which are connected in sequence through corresponding pipelines. The upper part of the furnace body is cube-shaped, and the top is provided with a waste gas discharge port 4. The waste gas discharge port 4 is connected with the cyclone separator 11. The furnace body One or more jet burners 2 are installed horizontally on the center line of the side of the upper part, and an observation window 6, a maintenance inlet 7 and a cooling water outlet 9 near the top are arranged on the adjacent surface of the side, and a preheating air is provided inside. Pipe 14, the lower part of...

Embodiment 2

[0042] Such as figure 1 , figure 2 , image 3 Shown: a glass microsphere manufacturing device, which includes a furnace body 1 and a waste gas processor, the furnace body 1 is formed by gas-tight connection of one or more upper parts of the furnace body and one or more lower parts of the furnace body, and the waste gas treatment The device includes a cyclone separator 11, a dust collector 12 and a fan 13 which are connected in sequence through corresponding pipelines. The upper part of the furnace body is cube-shaped, and the top is provided with a waste gas discharge port 4. The waste gas discharge port 4 is connected with the cyclone separator 11. The furnace body One or more jet burners 2 are installed horizontally on the center line of the side of the upper part, and an observation window 6, a maintenance inlet 7 and a cooling water outlet 9 near the top are arranged on the adjacent surface of the side, and a preheating air is provided inside. Pipe 14, the lower part of...

Embodiment 3

[0052] Such as figure 1 , figure 2 , image 3 Shown: a glass microsphere manufacturing device, which includes a furnace body 1 and a waste gas processor, the furnace body 1 is formed by gas-tight connection of one or more upper parts of the furnace body and one or more lower parts of the furnace body, and the waste gas treatment The device includes a cyclone separator 11, a dust collector 12 and a fan 13 which are connected in sequence through corresponding pipelines. The upper part of the furnace body is cube-shaped, and the top is provided with a waste gas discharge port 4. The waste gas discharge port 4 is connected with the cyclone separator 11. The furnace body One or more jet burners 2 are installed horizontally on the center line of the side of the upper part, and an observation window 6, a maintenance inlet 7 and a cooling water outlet 9 near the top are arranged on the adjacent surface of the side, and a preheating air is provided inside. Pipe 14, the lower part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com