High-power preheater for liquid metal sodium experimental loop

A technology of liquid metal sodium and experimental circuits, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as poor economic benefits, preheater power that cannot reach 100 kilowatts, and sudden drop in heating power. Achieve the effect of saving space, simple structure and reducing running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

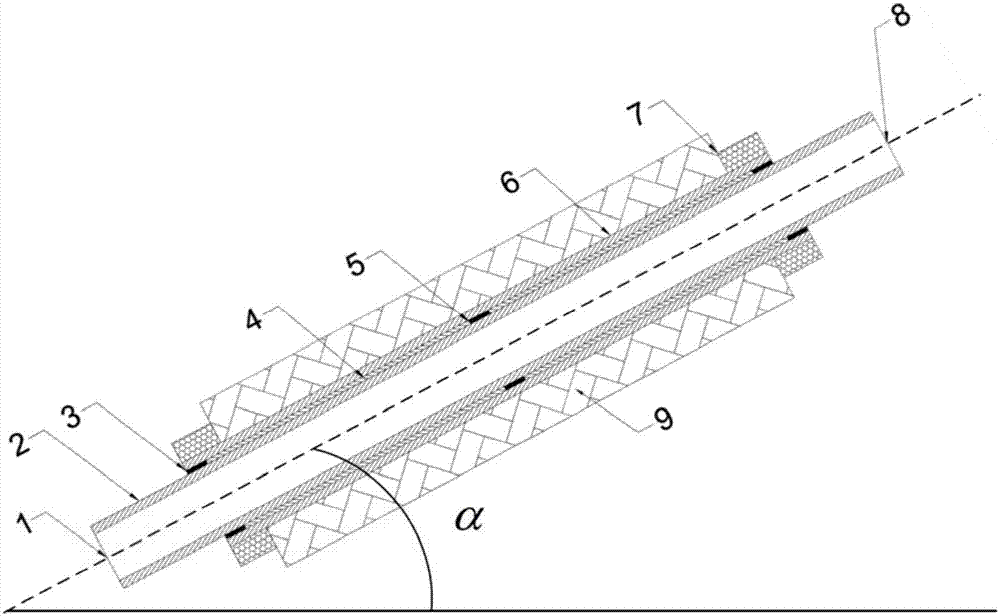

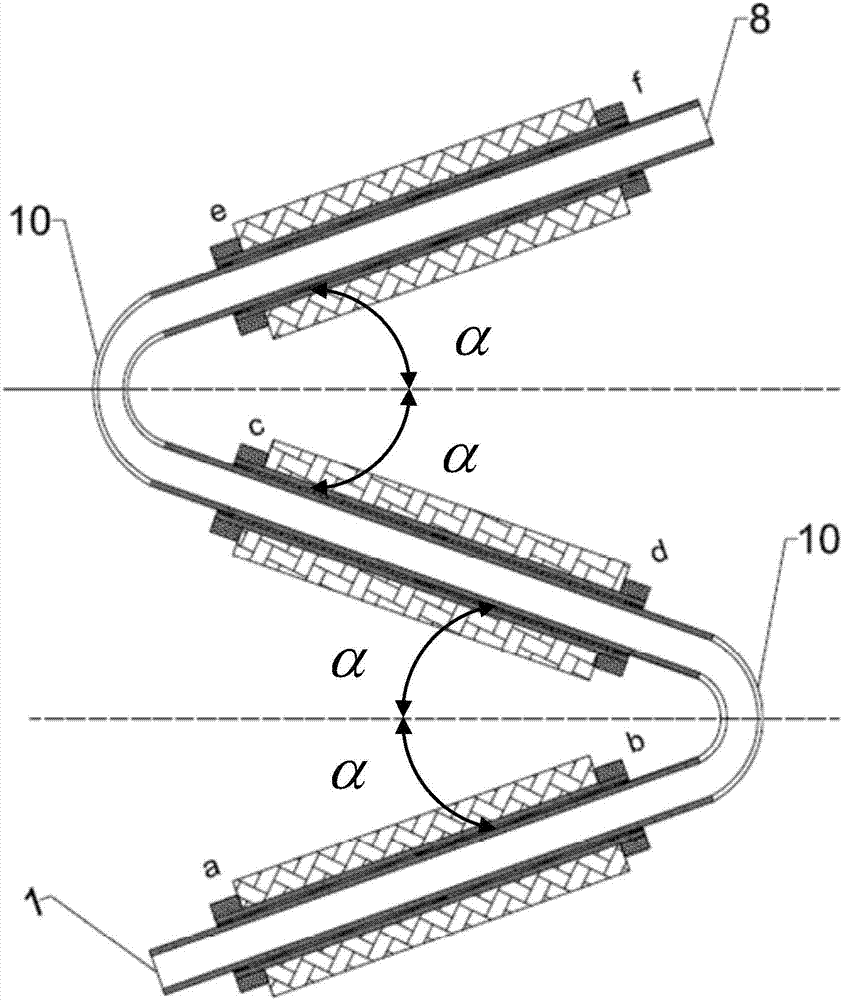

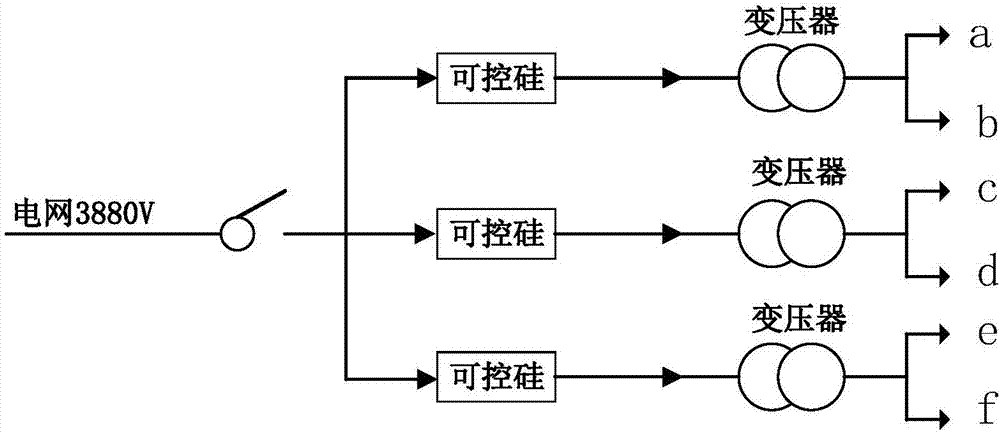

[0026] Such as figure 1 As shown, a high-power preheater for liquid metal sodium experimental circuit mainly includes: an inner tube 2, an electrical insulation layer 4, a positioning ring 5, two end sealing rings 3, an outer tube 6, two Counter electrode 7, insulation layer 9.

[0027] The inner tube 2 constitutes a liquid metal sodium flow channel and is installed obliquely to the horizontal plane, with the inlet 1 at the lower end and the outlet 8 at the upper end.

[0028] The outer tube 6 is used as an electric heating tube, and the heat generated is transferred to the inner tube through the electrical insulating layer, and the inner tube heats the liquid metal sodium.

[0029] There is an electrical insulating layer 4 between the inner tube 2 and the outer tube 6, the insulating layer 4 is composed of magnesium oxide or boron carbide, and is used for ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com