Jet welding method and jet welding groove

A technology of jet welding and welding tank, applied in welding equipment, tin feeding devices, manufacturing tools, etc., can solve the problems of uneven flux coating and preheating, poor tin penetration, temperature drop, etc. The probability of copper exceeding the standard is reduced, the tin dross is easy to handle, and the effect of saving power resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

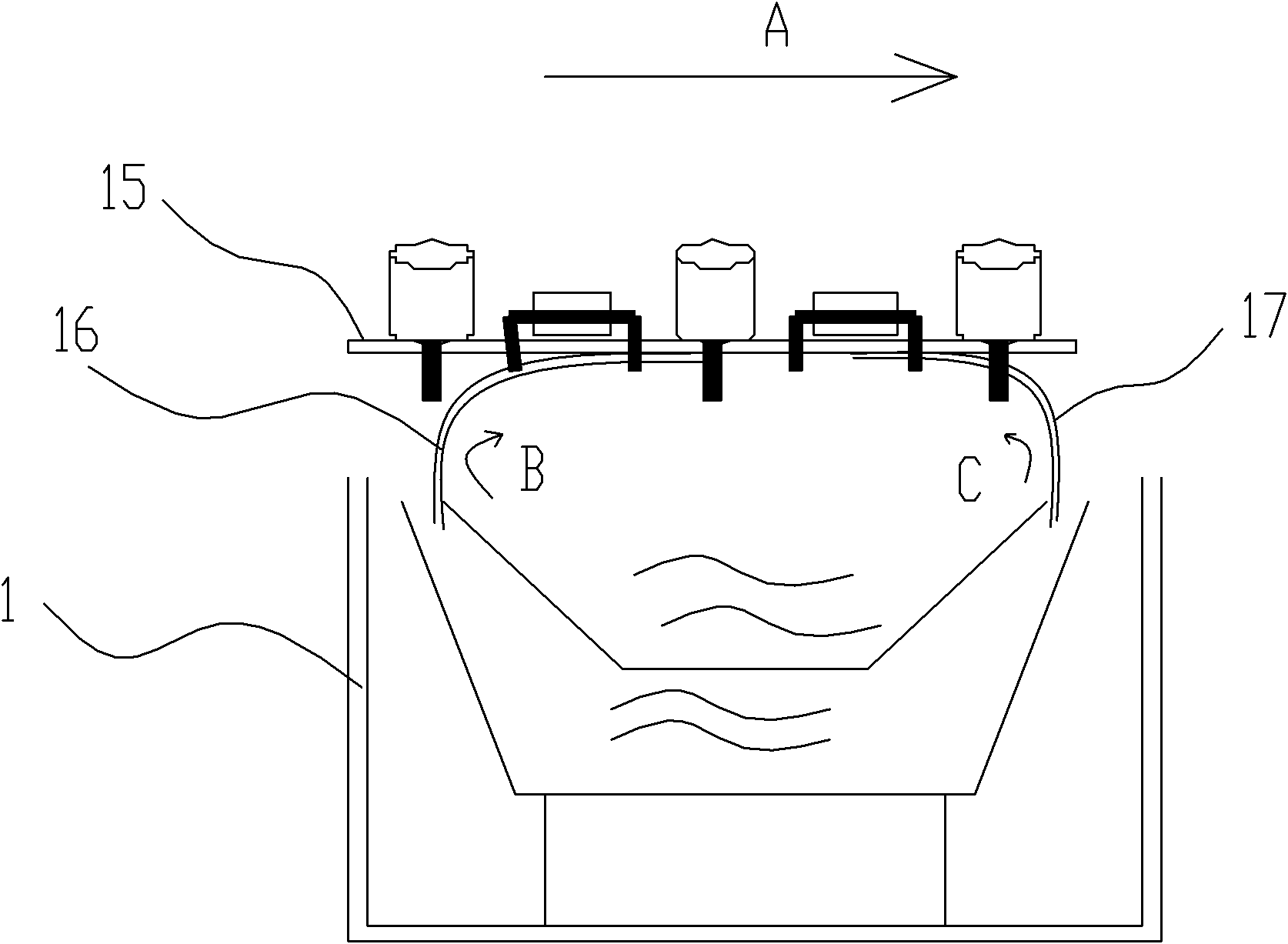

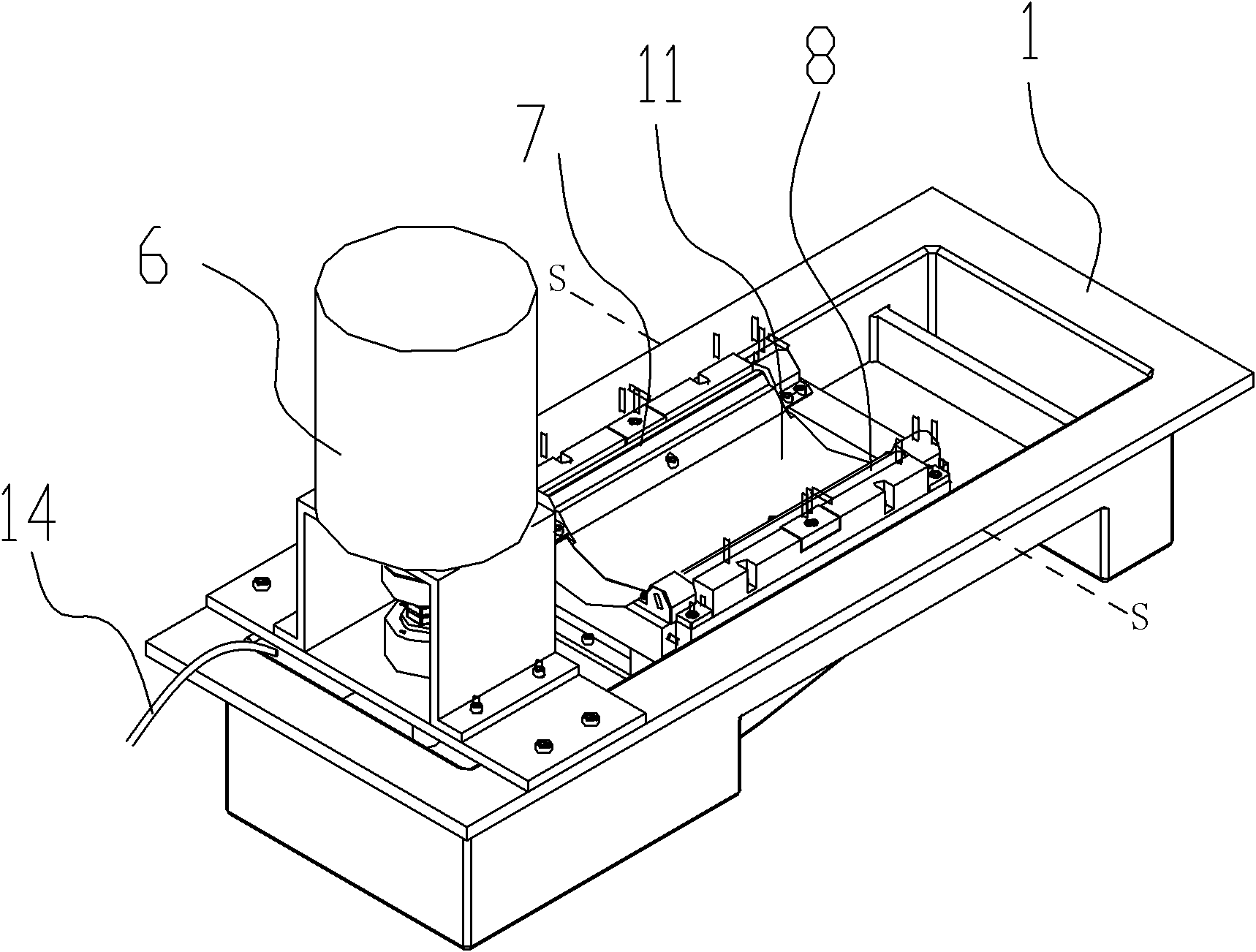

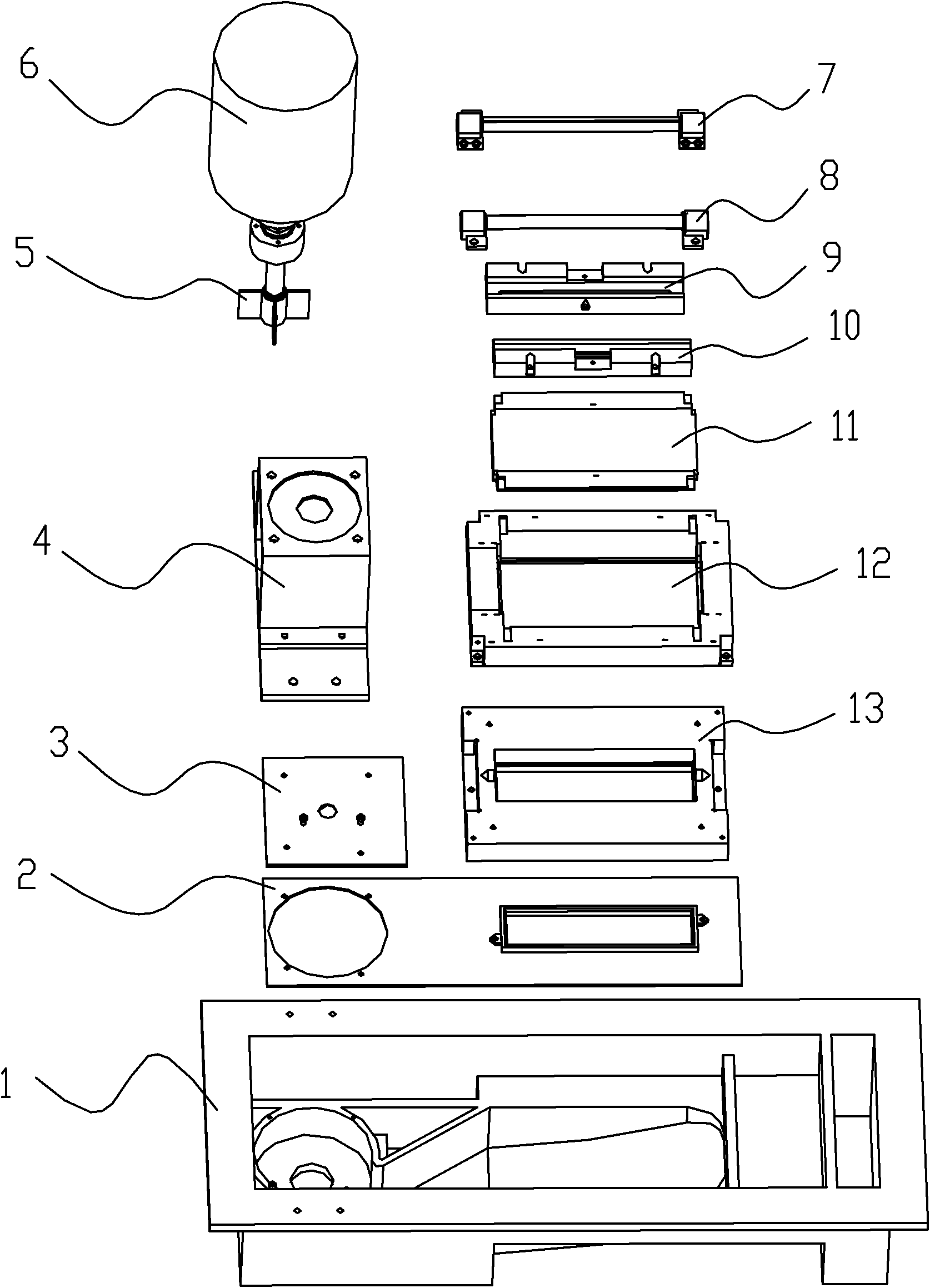

[0036] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a jet flow welding tank for realizing the above jet flow welding, comprising a welding tank 1, the welding tank 1 is divided into a welding chamber 103, a reducing agent addition chamber 105 and a high second medial partition 106 by a low first longitudinal partition 104 and a high second longitudinal partition 106. Waste recovery chamber 107, welding chamber 103 ends have a sunken circular solder chamber 101, and solder chamber 103 has a sunken strip-shaped solder passage 102 connected to the circular solder chamber 101 rising toward the first longitudinal partition plate 104 direction; welding chamber 103 There is a passage cover 2 on the upper cover, and the passage cover 2 is provided with a circular hole with a size similar to that of the circular solder chamber 101 above the circular solder chamber 101, and a hole smaller than the strip solder passage 102 is provided at the top of the strip sold...

Embodiment 2

[0038] Such as Figure 7 , another spray flow welding tank for realizing the above spray flow welding. The difference from Embodiment 1 is that a third longitudinal septum 110 is designed above the strip-shaped solder channel 102 close to the junction of the pressurized diverter fixing seat 12, A fifth longitudinal partition 108 is designed above the junction of the circular solder chamber 101 and the strip-shaped solder channel 102. The tops of the third longitudinal partition 110 and the fifth longitudinal partition 108 are level with the edge of the welding tank 1, and the bottom is flush with the edge of the soldering groove 1. The bottom of the tank 1 is separated; a fourth longitudinal septum 109 is designed in the middle of the third longitudinal septum 110 and the fifth longitudinal septum 108, the bottom of the fourth longitudinal septum 109 is in close contact with the upper surface of the strip-shaped solder channel 102, and the top is low at the edge of the weld gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com