Large-diameter steel stud composite welding method based on arcing-aluminothermy

A compound welding and large-diameter technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of internal air hole defects, lack of fusion, shallow fusion depth, etc., reduce internal hole defects, reduce the use of igniters, The effect of increased fluidity of the molten pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 1The flow chart of drawn arc-aluminothermic hybrid welding of large-diameter steel studs is shown, and the steps are as follows for welding large-diameter studs of 16mm: first prepare thermite flux, and weigh 65.5% iron oxide and 5.5% iron oxide by weight percentage Alloy iron powder, 7.0% auxiliary solvent and 22.0% aluminum powder are 100g in total, wherein iron oxide is 65.5g, alloy iron powder is 5.5g, auxiliary solvent is 7.0g, and aluminum powder is 22g. The quality purity of the aluminum powder is 98.0%; the weighed iron oxide powder, alloy iron powder, and auxiliary solvent are put into a ball mill jar together, with a ball-to-material ratio of 18:1 and a filler ratio of 40%, vacuumize and fill with argon After airing, ball mill for 6 hours at a speed ratio of 125r / min; the aluminum powder is ball milled separately under the above conditions, after the ball milling is completed, the ball mill balls are taken out, and the above powder is rolled in ...

Embodiment 2

[0041] In this embodiment, thermite flux is not used, and the 18mm large-diameter stud and the ceramic ring are grabbed by a robot. Close the welding power supply of the stud welding machine, set the welding current to 1300A, and the arc drawing time to 1200ms, start the arc drawing process of the stud welding, the stud welding machine performs welding, release the air claw after 13s, and complete the welding process.

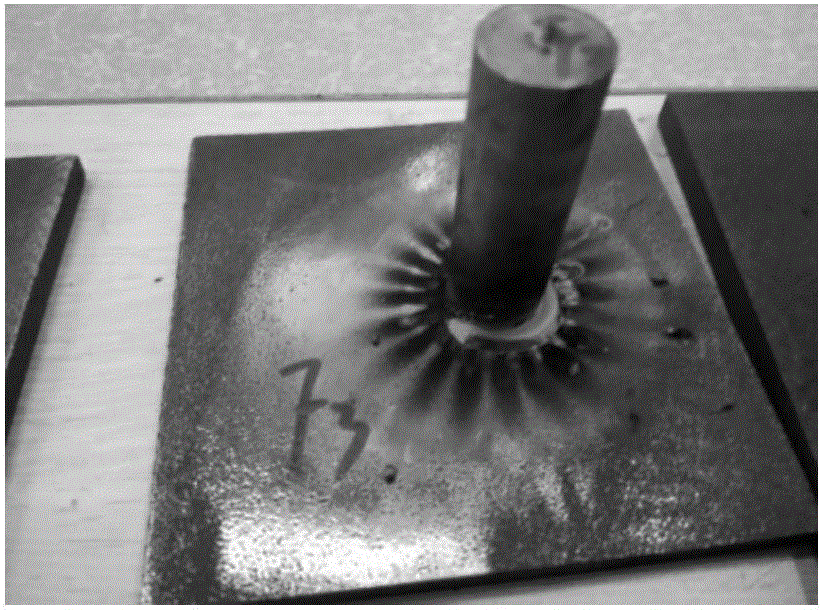

[0042] Such as figure 2 and Figure 11 As shown, the comparison found that under the condition of not using flux, the appearance of welding was poorly formed, and a perfect molten pool weld was formed. The stud welding seam can only be formed on one side, and the other side is difficult to be covered by the molten pool. The weld is not completely formed. The lack of weld pool leads to the entry of gas, which is easy to produce pores. The pores in the weld are obvious. Seriously affect the weld performance.

Embodiment 3

[0044] This embodiment adopts the technological conditions and process of Embodiment 1, wherein the diameter of the stud is 22mm, and the thermite flux uses 65.5% iron oxide, 5.5% alloy iron powder, 7.0% auxiliary solvent and 22.0% aluminum powder, thermite The filling amount of flux is 2.6g, the welding current is 2500A under the arc drawing condition, the arc drawing time is 1600ms, and the stud stabilization time is 15s.

[0045] Such as Figure 4 As shown, the use of flux increases the melting amount of the molten pool, the fluidity of the molten pool is enhanced, and it is helpful for the formation of the molten pool boss, the melting amount of the molten pool is increased, and the quality of the weld seam is optimized. 22mm stud The welds are well formed and form a good appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com