75 kg/m hypereutectoid steel rail and eutectoid steel rail air pressure welding method and welding part

A welding method and hypereutectoid technology, applied in the field of 75kg/m hypereutectoid rails and eutectoid rail weldments, can solve problems such as welding difficulties, achieve stable welding quality, improve welding productivity, and uniform temperature field distribution on the left and right sides of the weld Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

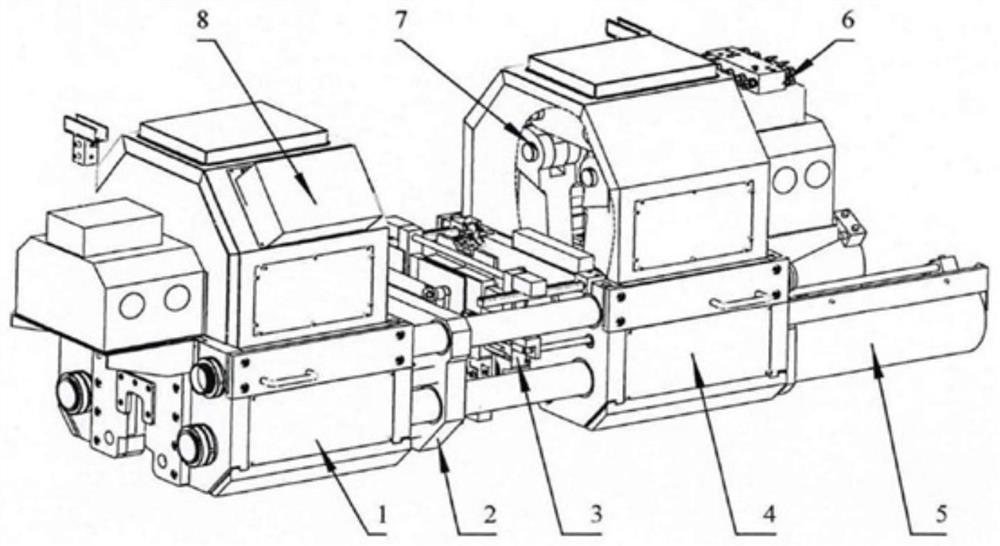

Image

Examples

Embodiment 1

[0046] In this embodiment, in order to ensure the quality of gas pressure welding, a special end milling machine is used to mill the rail before welding, and the rust and oxides near the welding joint are polished to 40 mm until the metallic luster is exposed. After the treatment, the slope deviation of the rail end surface is 0.1mm, and the gap after the joint is 0.15mm. After the end milling is completed, the burrs at the edge of the rail end are processed with a file, and the welded end surface is welded immediately after processing. To avoid secondary pollution such as oil stains after treatment, the rails are hoisted and clamped, and the end sections of the rails are cleaned with carbon tetrachloride before welding. After the end surface treatment is qualified, adopt "detonation ignition", and the ignition position is 40mm away from the weld to avoid contamination of the weld. After supplying gas for 3s, ignite the heater of the pressure welding device with an igniter.

...

Embodiment 2

[0052] In this embodiment, the same steps of welding front end milling and grinding as in embodiment 1 are performed.

[0053] "Detonation ignition" is adopted, and the ignition position is 40mm away from the weld to avoid contamination of the weld. After supplying gas for 4s, ignite the heater of the pressure welding device with an igniter.

[0054] Use an oxy-acetylene flame to heat the part of the rail to be welded, and perform the steps of first-stage heating, second-stage heating, upsetting welding, push-out and pressure-holding in sequence according to the following parameters. The following welding parameters were used for each step:

[0055]

[0056]

[0057] After the blast cooling is completed, the gas pressure welded joint is cooled to 440°C, the blast is stopped, and reheated for normalizing. After the rail is normalized, it is ground. The grinding surface is the rail head tread and the side of the rail. The grinding profile should keep the original rail he...

Embodiment 3

[0059] In this embodiment, the same steps of welding front end milling and grinding as in embodiment 1 are performed.

[0060] "Detonation ignition" is adopted, and the ignition position is 40mm away from the weld to avoid contamination of the weld. After supplying gas for 3s, ignite the heater of the pressure welding device with an igniter.

[0061] Use an oxy-acetylene flame to heat the part of the rail to be welded, and perform the steps of first-stage heating, second-stage heating, upsetting welding, push-out and pressure-holding in sequence according to the following parameters. The following welding parameters were used for each step:

[0062]

[0063] After the blast cooling is completed, the gas pressure welded joint is cooled to 445°C, the blast is stopped, and reheated for normalizing. After the rail is normalized, it is ground. The grinding surface is the rail head tread and the side of the rail. The grinding profile should keep the original rail head profile a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com