Fresh-keeping bag specially for white mushroom

A technology of fresh-keeping bags and white mushrooms, which is applied in the direction of protecting fruits/vegetables with a coating protective layer, can solve the problems of poor effect, inability to effectively inhibit the browning of white mushrooms, softening of the mushroom body, and deterioration of quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: (preparation of special fresh-keeping bag for white mushrooms 1)

[0050] Weigh LDPE 100kg, SiO 2 3kg, SBS10kg, EVA14kg, polyethylene glycol 0.7kg, glycerol monostearate 0.5kg, calcium phosphate 1.4kg, zeolite 2kg, paraffin 0.5kg, mix each component, double-roller kneading, pulverization, put into the speed 30r / min in the granulator, after 120°C, 145°C, 150°C and 160°C temperature in each zone, it becomes granular materials; then these granular materials are put into a plastic extruder with a speed of 40r / min, and passed through 150°C, 160°C ℃, 170℃ and 165℃ temperature zones, extrusion, blow molding, cooling, traction and winding process to make a finished film with a thickness of 0.03mm, and then make a special fresh-keeping bag for white mushrooms with a specification of 45cm×35cm×0.03mm.

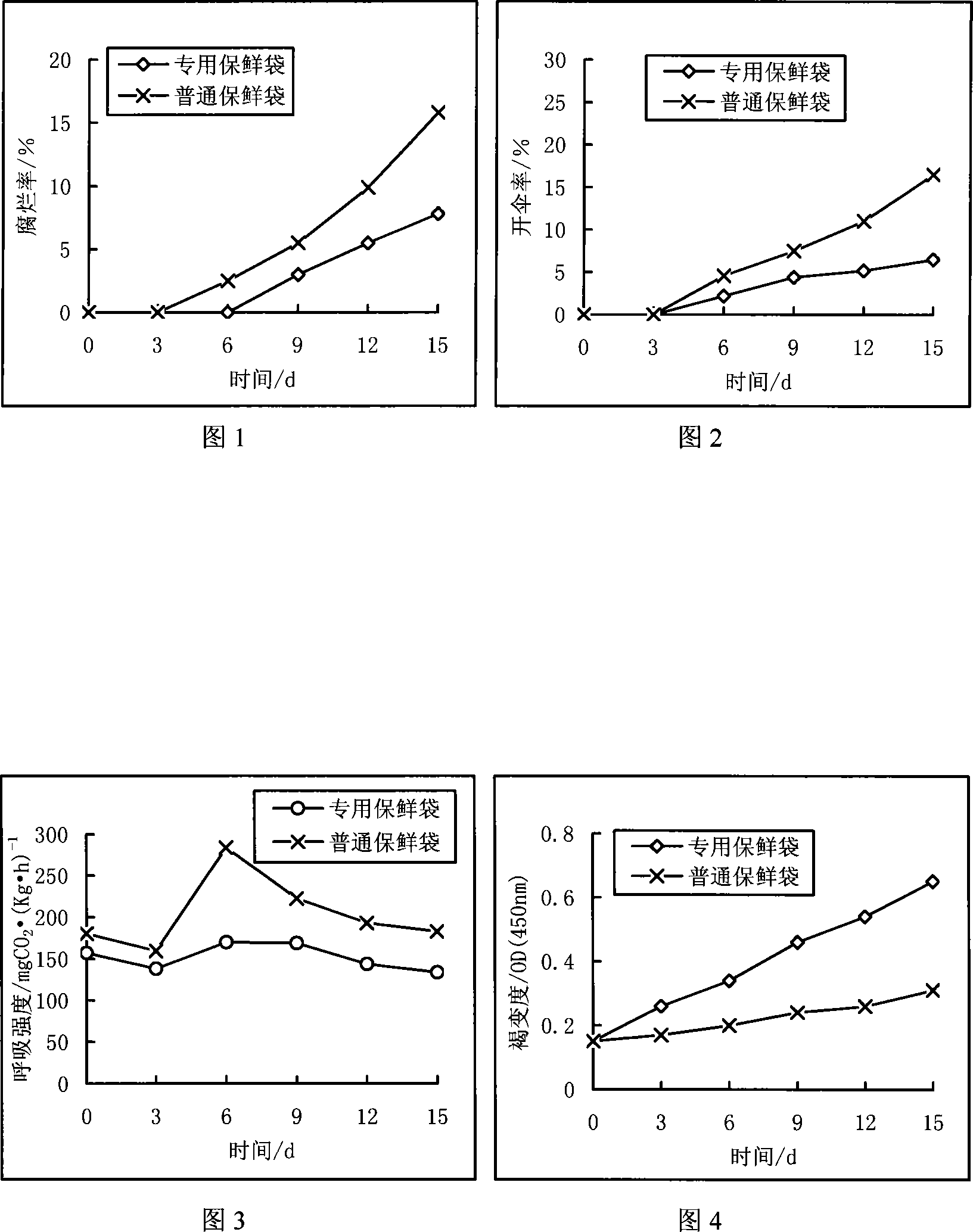

[0051] The white mushrooms are collected from Jiangshan City, Zhejiang Province. The damaged white mushrooms are removed, and the fresh-keeping bags are used to pac...

Embodiment 2

[0052] Embodiment 2: (preparation of special fresh-keeping bag for white mushroom 2)

[0053] In this example, each component weighs LDPE 100kg, SiO 2 2kg, SBS8.5kg, EVA13kg, polyethylene glycol 0.78kg, glycerol monostearate 0.64kg, calcium phosphate 1.25kg, zeolite 1.6kg, paraffin 0.4kg; film-making process and fresh-keeping process are the same as in Example 1, and stored for 15 days After that, the decay rate was 9.2%, and the umbrella opening rate was 8.3%.

Embodiment 3

[0054] Embodiment 3: (preparation 3 of white mushroom special fresh-keeping bag)

[0055] In this example, each component weighs LDPE 100kg, SiO 2 3.9kg, SBS11.5kg, EVA15kg, polyethylene glycol 0.61kg, glycerol monostearate 0.42kg, calcium phosphate 1.55kg, zeolite 2.45kg, paraffin 0.58kg; film-making process and fresh-keeping process are the same as embodiment 1, storage After 15 days, the decay rate was 8.7%, and the umbrella opening rate was 7.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com