Nano-crystal Mn-Zn ferrite magnetic material with high initial permeability and high thermal-magnetic sensitivity and preparation method of nano-crystal Mn-Zn ferrite magnetic material

A technology of manganese-zinc ferrite and magnetic material, applied in the field of ferrite material and its preparation, manganese-zinc ferrite material, can solve the problem of low reactivity of component oxides, high price of high-purity reactants, microscopic Uneven structure and other problems, to achieve the effect of easy and precise control of composition, easy mass production, and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

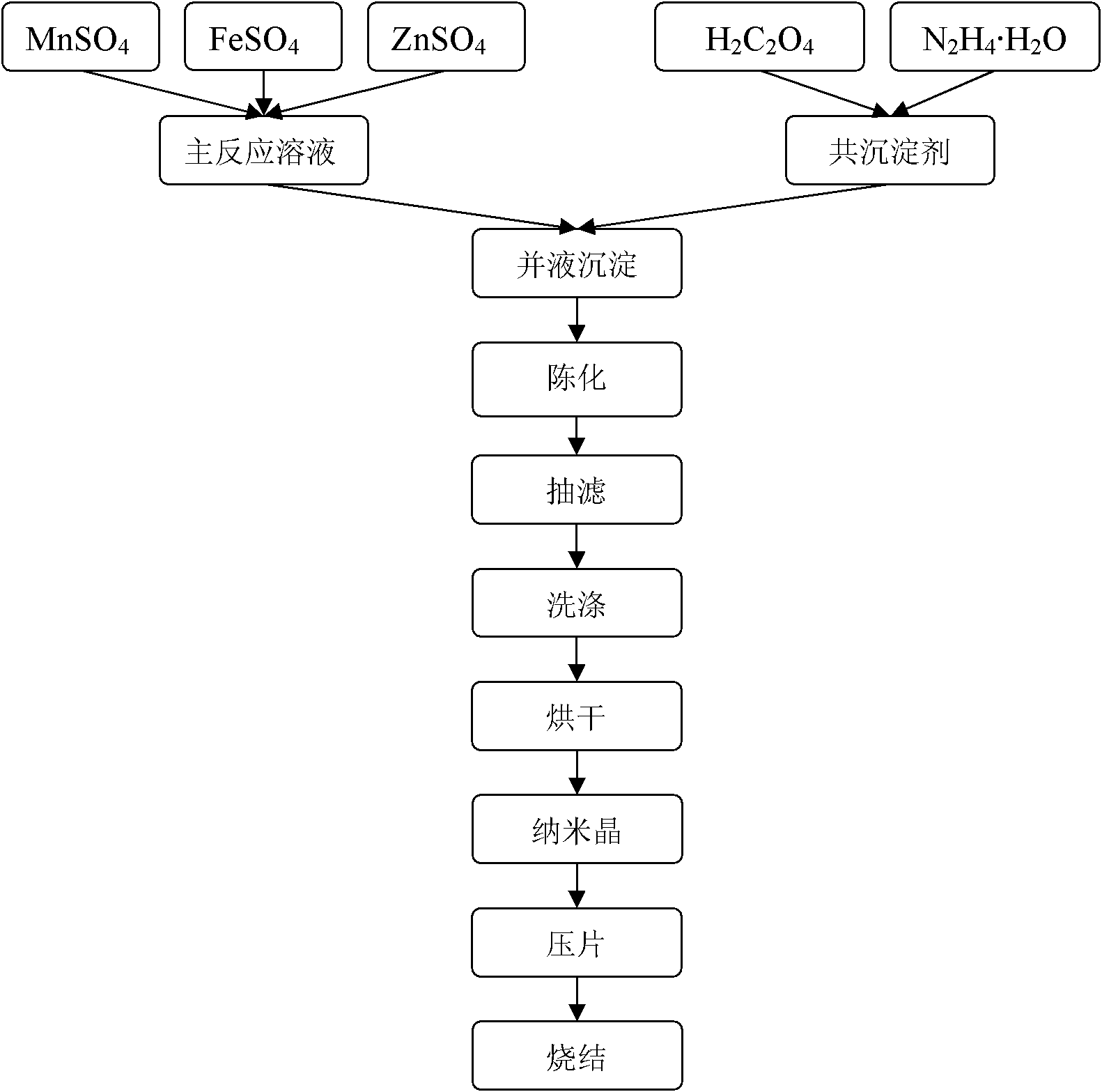

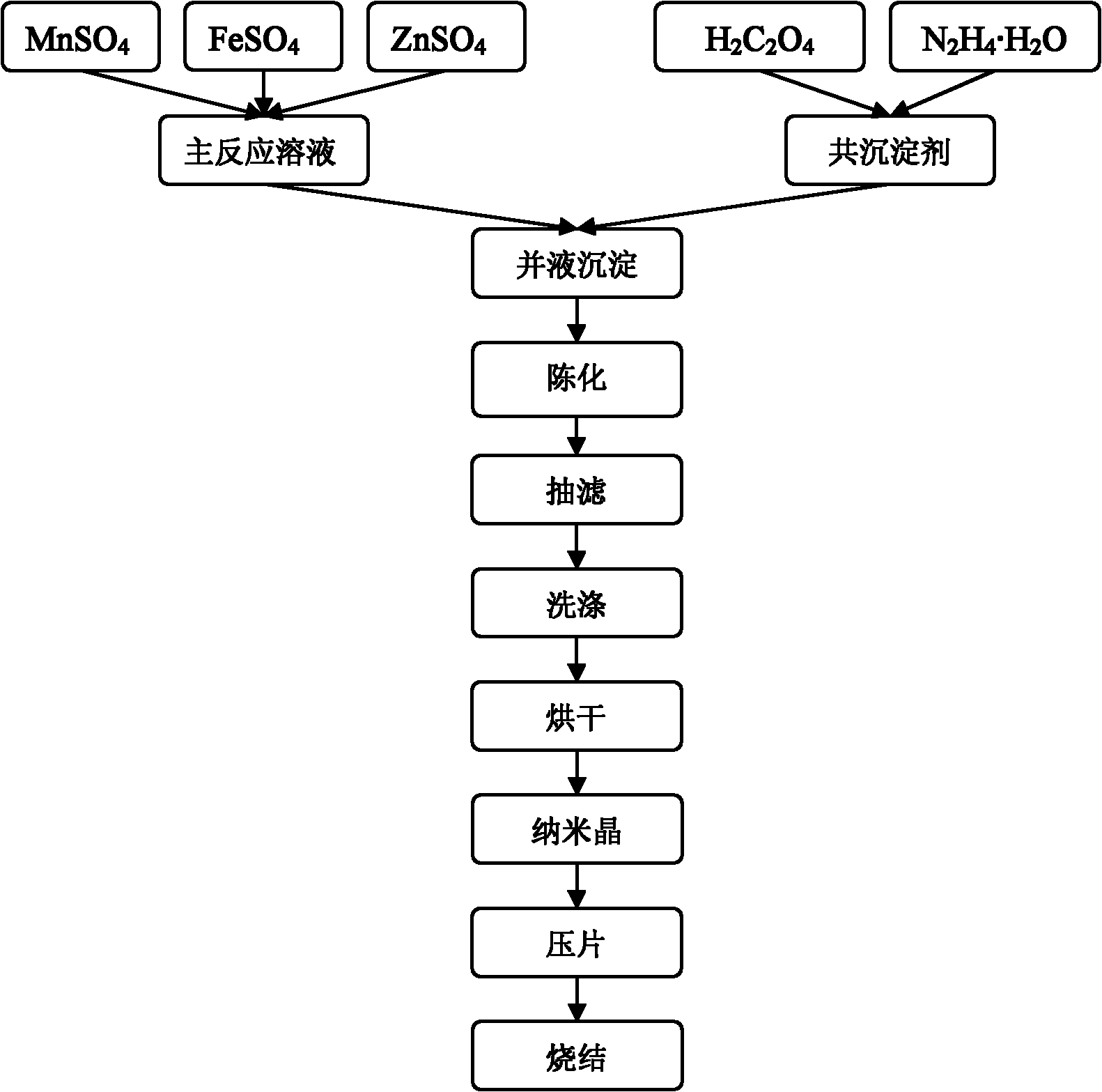

Method used

Image

Examples

Embodiment 1

[0035] (1) FeSO with a purity of 99% was weighed respectively 4 , ZnSO 4 , MnSO 4 , the mass ratio of the three is 68:15:17, and the solution is configured;

[0036] (2) Add oxalic acid crystals to hydrazine to configure hydrazine oxalate (H 2 C 2 o 4 N 2 h 4 ·H 2 O);

[0037] (3) The main reactant mixture configured in step (1) is preheated to 80°C, and then a precipitating agent (H 2 C 2 o 4 N 2 h 4 ·H 2 O) solution;

[0038] (4) Quickly add the solution of step (3) into the aqueous solution of TW-80 dispersant, adjust the pH to 3.8, and stir vigorously; (5) Stop stirring, age for 1 hour, and cool to room temperature;

[0039] (6) filtering, washing (cleaning with ethanol and deionized water to remove impurities), vacuum drying;

[0040] (7) After being ground into powder, use a desktop electric tablet press to press the powder into a blank of a specific shape and size;

[0041] (8) Sintering: Sintering is carried out in a resistance furnace. The specific ...

Embodiment 2

[0043] (1) FeSO with a purity of 99% was weighed respectively 4 , ZnSO 4 , MnSO 4 , the mass ratio of the three is 72:8:20, and the solution is configured;

[0044] (2) Add oxalic acid crystals to hydrazine to configure hydrazine oxalate (H 2 C 2 o 4 N 2 h 4 ·H 2 O);

[0045] (3) The main reactant mixture configured in step (1) is preheated to 70°C, and then a precipitating agent (H 2 C 2 o 4 N 2 h 4 ·H 2 O) solution;

[0046] (4) Quickly add the solution of step (3) into the aqueous solution of TW-80 dispersant, adjust the pH to 4.5, and stir vigorously;

[0047](5) Stop stirring, age for 2h, and cool to room temperature;

[0048] (6) filtering, washing (cleaning with ethanol and deionized water to remove impurities), vacuum drying;

[0049] (7) After being ground into powder, use a desktop electric tablet press to press the powder into a blank of a specific shape and size;

[0050] (8) Sintering: Sintering is carried out in a resistance furnace. The speci...

Embodiment 3

[0052] (1) FeSO with a purity of 99% was weighed respectively 4 , ZnSO 4 , MnSO 4 , the mass ratio of the three is 70:12:18, and the solution is configured;

[0053] (2) Add oxalic acid crystals to hydrazine to configure hydrazine oxalate (H 2 C 2 o 4 N 2 h 4 ·H 2 O);

[0054] (3) The main reactant mixture configured in step (1) is preheated to 90°C, and then a precipitating agent (H 2 C 2 o 4 N 2 h 4 ·H 2 O) solution;

[0055] (4) Quickly add solution (3) to the aqueous solution of TW-80 dispersant, adjust the pH to 4.0, and stir vigorously;

[0056] (5) Stop stirring, age for 2h, and cool to room temperature;

[0057] (6) filtering, washing (cleaning with ethanol and deionized water to remove impurities), vacuum drying;

[0058] (7) After being ground into powder, use a desktop electric tablet press to press the powder into a blank of a specific shape and size;

[0059] (8) Sintering: Sintering is carried out in a resistance furnace. The specific heat tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com