Modified rigid cross-linked polyvinyl chloride foam and preparation method thereof

A technology of cross-linked polyvinyl chloride and polyvinyl chloride paste, which is applied in the field of polymer foam materials, can solve problems such as the thermal processing temperature of rigid cross-linked polyvinyl chloride foam, and achieve improved dimensional stability and thermal deformation temperature , solve the effect of low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

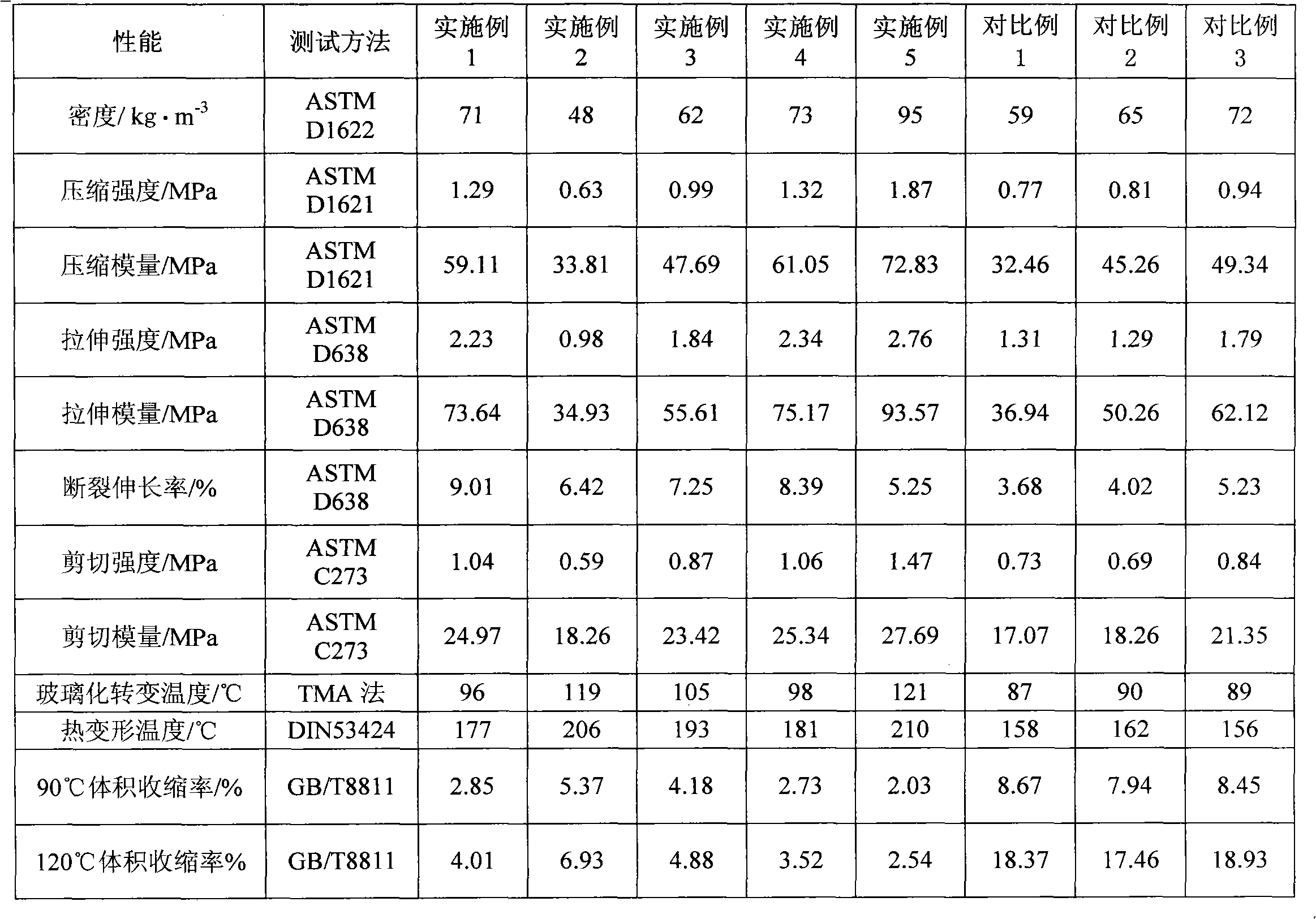

Examples

Embodiment 1

[0025] The formula components are composed of the following weight ratios: 90 parts of polyvinyl chloride paste resin with a K value of 70, 10 parts of chlorinated polyvinyl chloride resin with a chlorine content of 64%, 3 parts of triallyl isocyanurate, 30 parts of diphenylmethane diisocyanate modified by carbodiimide-urea ketimine, 9 parts of cis-cyclohexane-1,2-dicarboxylic anhydride, mixture of azodicarbonamide and azobisisobutyronitrile 4 parts, and the weight ratio of azodicarbonamide to azobisisobutyronitrile is 1:1, 2 parts of epoxy soybean oil, and 2 parts of hollow glass microspheres.

[0026] According to the formula ingredients, under the vacuum degree of 0.09MPa, mix the liquid raw materials in the components according to the stated weight, and then add the solid raw materials in the described components into the liquid according to the stated weight, and stir Get a uniform paste mixture in 20 minutes; fill the prepared paste into a 25mm thick steel mold, put the ...

Embodiment 2

[0028] The formula components are composed according to the following weight ratios: 99 parts of polyvinyl chloride paste resin with a K value of 80, 1 part of chlorinated polyvinyl chloride resin with a chlorine content of 68%, and 15 parts of trimethylolpropane trimethacrylate , 70 parts of polymethylene polyphenyl polyisocyanate (commercially available as a mixture), 24 parts of methyl hexahydrophthalic anhydride, 8 parts of a mixture of azodicarbonamide and azobisisobutyronitrile, and azobis The weight ratio of formamide to azobisisobutyronitrile is 1:5, epoxidized soybean oil is 15 parts, and titanium dioxide is 6 parts.

[0029] According to the formula ingredients, under the vacuum degree of 0.09MPa, mix the liquid raw materials in the components according to the stated weight, and then add the solid raw materials in the described components into the liquid according to the stated weight, and stir Get a uniform paste mixture in 20 minutes; fill the prepared paste into a...

Embodiment 3

[0031] The formula components are composed according to the following weight ratios: 95 parts of polyvinyl chloride paste resin with a K value of 75, 5 parts of chlorinated polyvinyl chloride resin with a chlorine content of 70%, and 8 parts of trimethylolpropane trimethacrylate , 25 parts of diphenylmethane diisocyanate modified by carbodiimide-urea ketimine and 25 parts of polymethylene polyphenyl polyisocyanate, 10 parts of methyl hexahydrophthalic anhydride, azodicarbonamide and azodiisocyanate 6 parts of a mixture of butyronitrile, and the weight ratio of azodicarbonamide to azobisisobutyronitrile is 1:3, 10 parts of epoxy soybean oil, 3 parts of titanium dioxide, and 5 parts of carbon nanotubes.

[0032] According to the formula ingredients, under the vacuum degree of 0.09MPa, mix the liquid raw materials in the components according to the stated weight, and then add the solid raw materials in the described components into the liquid according to the stated weight, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com