Modified phenolic resin material for 3D printing and preparation method thereof

A phenolic resin, 3D printing technology, applied in the field of 3D printing materials and their preparation, can solve the problems of single performance improvement, affecting the modification effect, unable to meet the 3D printing technology, etc., to achieve lower operating temperature, low production cost, and chain extension and the effect of simple and controllable cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

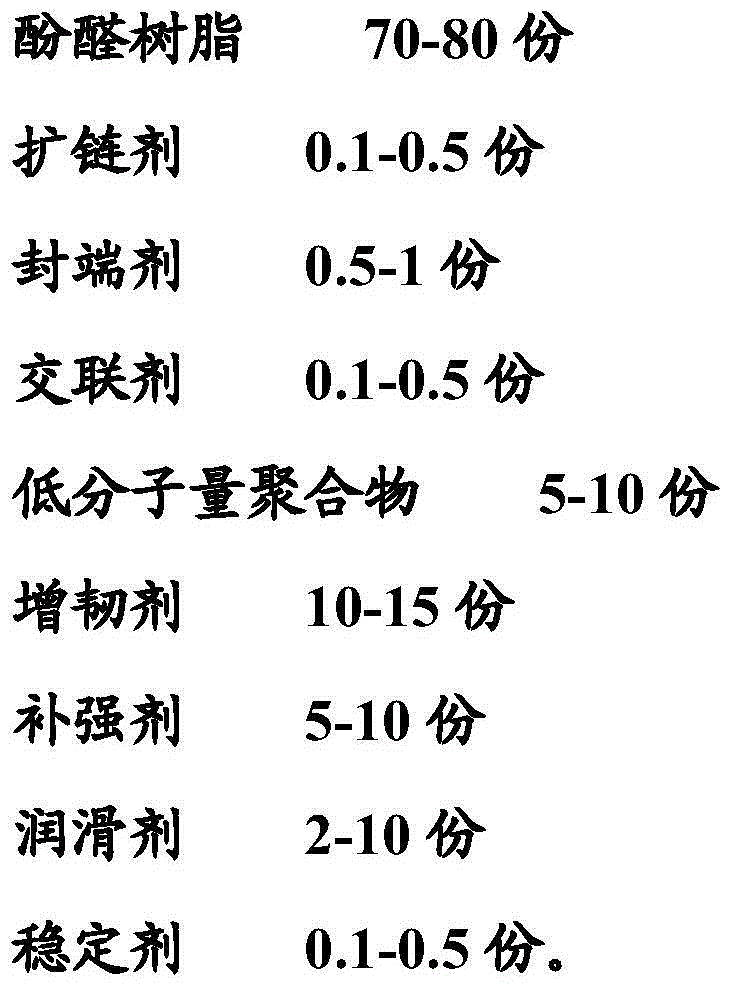

Method used

Image

Examples

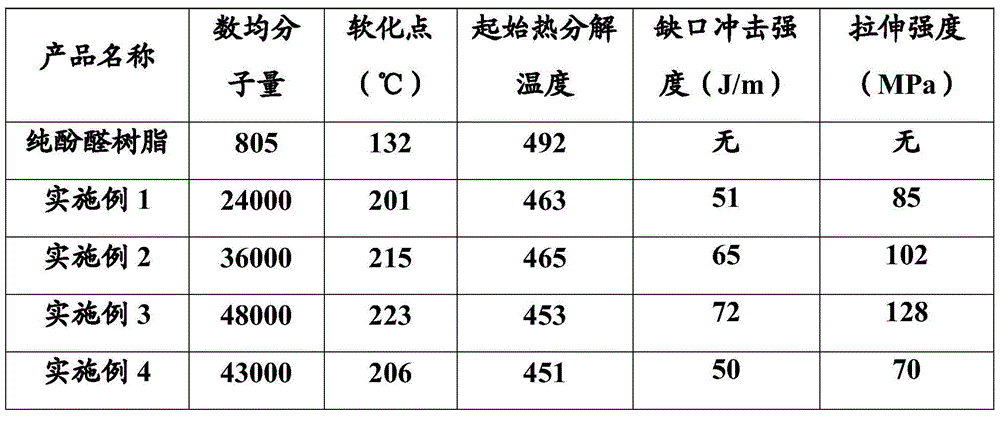

Embodiment 1

[0043] 1) Add 70 parts of thermoplastic phenolic resin (molecular weight 600) and 7 parts of polybutylmethacrylate oligomer with molecular weight 350 to the mixer, raise the temperature to 80°C, add 0.2 parts of chain extender, 0.4 parts of End-capping agent, react for half an hour, then add 0.2 parts of cross-linking agent and 7 parts of reinforcing agent, fully mix at 600r / min for 1 hour and then discharge;

[0044] 2) Mix and extrude the mixture obtained in step 1) with 12 parts of toughening agent, 3 parts of lubricant and 0.2 part of stabilizer with a twin-screw extruder to extrude and granulate the material in the extruder for no more than 3 parts. minute. The screw diameter of the twin-screw extruder is 71mm, the extruder temperature is set at 150-170°C, and the die head temperature is 170-180°C:

[0045] 3) Dry the particles made in step 2) with a drying oven at a temperature of 50° C. for 2-3 hours and then extrude them with a twin-screw extruder to process them into...

Embodiment 2

[0047] 1) Add 75 parts of thermoplastic phenolic resin (molecular weight 600) and 7 parts of polybutylmethacrylate oligomer with molecular weight 350 to the mixer, raise the temperature to 80°C, add 0.2 parts of chain extender and 0.6 parts of sealant in sequence Terminal agent, react for half an hour, then add 0.2 parts of cross-linking agent and 7 parts of reinforcing agent, fully mix at 600r / min for 1 hour and then discharge;

[0048] 2) Mix and extrude the mixture obtained in step 1) with 12 parts of toughening agent, 3 parts of lubricant and 0.2 part of stabilizer with a twin-screw extruder to extrude and granulate the material in the extruder for no more than 3 parts. minute. The screw diameter of the twin-screw extruder is 71mm, the extruder temperature is set at 150-170°C, and the die head temperature is 170-180°C:

[0049] 3) Dry the particles made in step 2) with a drying oven at a temperature of 50° C. for 2-3 hours and then extrude them with a twin-screw extruder ...

Embodiment 3

[0051] 1) Add 80 parts of thermoplastic phenolic resin (molecular weight 600) and 7 parts of polybutylmethacrylate oligomer with molecular weight 350 into the mixer, raise the temperature to 80°C, and add 0.2 parts of chain extender and 0.6 parts of sealing agent in turn. Terminal agent, react for half an hour, then add 0.2 parts of cross-linking agent and 7 parts of reinforcing agent, fully mix at 600r / min for 1 hour and then discharge;

[0052] 2) Mix and extrude the mixture obtained in step 1) with 12 parts of toughening agent, 3 parts of lubricant and 0.2 part of stabilizer with a twin-screw extruder to extrude and granulate the material in the extruder for no more than 3 parts. minute. The screw diameter of the twin-screw extruder is 71mm, the extruder temperature is set at 150-170°C, and the die head temperature is 170-180°C:

[0053] 3) Dry the particles made in step 2) with a drying oven at a temperature of 50° C. for 2-3 hours and then extrude them with a twin-screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com